无机材料学报 ›› 2022, Vol. 37 ›› Issue (9): 1016-1022.DOI: 10.15541/jim20210739 CSTR: 32189.14.10.15541/jim20210739

所属专题: 【能源环境】金属有机框架材料(202309)

宿拿拿1( ), 韩静茹1, 郭印毫1, 王晨宇1, 石文华1, 吴亮1, 胡执一1,2, 刘婧1, 李昱1,2(

), 韩静茹1, 郭印毫1, 王晨宇1, 石文华1, 吴亮1, 胡执一1,2, 刘婧1, 李昱1,2( ), 苏宝连1,3

), 苏宝连1,3

收稿日期:2021-12-03

修回日期:2022-02-08

出版日期:2022-09-20

网络出版日期:2022-02-21

通讯作者:

李 昱, 教授. E-mail: yu.li@whut.edu.cn作者简介:宿拿拿(1997-), 女, 硕士研究生. E-mail: nana.su@whut.edu.cn

基金资助:

SU Nana1( ), HAN Jingru1, GUO Yinhao1, WANG Chenyu1, SHI Wenhua1, WU Liang1, HU Zhiyi1,2, LIU Jing1, LI Yu1,2(

), HAN Jingru1, GUO Yinhao1, WANG Chenyu1, SHI Wenhua1, WU Liang1, HU Zhiyi1,2, LIU Jing1, LI Yu1,2( ), SU Baolian1,3

), SU Baolian1,3

Received:2021-12-03

Revised:2022-02-08

Published:2022-09-20

Online:2022-02-21

Contact:

LI Yu, professor. E-mail: yu.li@whut.edu.cnAbout author:SU Nana (1997-), female, Master candidate. E-mail: nana.su@whut.edu.cn

Supported by:摘要:

锂离子电池已广泛应用于各种便携式电子设备及新能源汽车等领域, 但随着电子设备的不断更新换代及电动汽车的快速发展, 理论比容量较低的传统石墨负极(372 mAh/g)已无法满足社会的需求。基于此, 本工作设计并制备了一种Zn基金属有机物框架(ZIF-8)衍生的三维网络状硅碳(Si@NC)复合材料用于锂离子电池性能研究。首先对纳米硅表面进行化学改性,然后在改性的硅表面原位生长ZIF-8小颗粒(Si@ZIF-8), 最后对Si@ZIF-8碳化得到Si@NC复合材料。研究表明, Si@NC复合材料的三维网络状多孔结构既可以很好地限制硅的体积膨胀, 又能极大地提升材料的电导率, 展现出稳定的循环性能和良好的倍率性能, 在5 A/g的大电流下能保持760 mAh/g的放电比容量。与商业三元正极材料组装的全电池也表现出较好的性能, 在0.4C (1C =160 mA/g)下循环50圈依然可以保持60.4%的比容量。这些研究结果说明该Si@NC复合材料具有较好的应用前景。

中图分类号:

宿拿拿, 韩静茹, 郭印毫, 王晨宇, 石文华, 吴亮, 胡执一, 刘婧, 李昱, 苏宝连. 基于ZIF-8的三维网络硅碳复合材料锂离子电池性能研究[J]. 无机材料学报, 2022, 37(9): 1016-1022.

SU Nana, HAN Jingru, GUO Yinhao, WANG Chenyu, SHI Wenhua, WU Liang, HU Zhiyi, LIU Jing, LI Yu, SU Baolian. ZIF-8-derived Three-dimensional Silicon-carbon Network Composite for High-performance Lithium-ion Batteries[J]. Journal of Inorganic Materials, 2022, 37(9): 1016-1022.

图3 Si@NC样品的(a)TEM, (b)HRTEM, (c) HAADF-STEM, (d) SAED照片和(e~f) EDX元素分布图

Fig. 3 (a) TEM, (b) HRTEM, (c) HAADF-STEM images, (d) SAED pattern (rectangular area in (c)), and (e-f) corresponding EDX elemental maps of Si@NC (d) Rectangular area in (c); (e-f) Corresponding area in (c), Si (green), C (yellow), N (blue), O (cyan) and Zn (red)

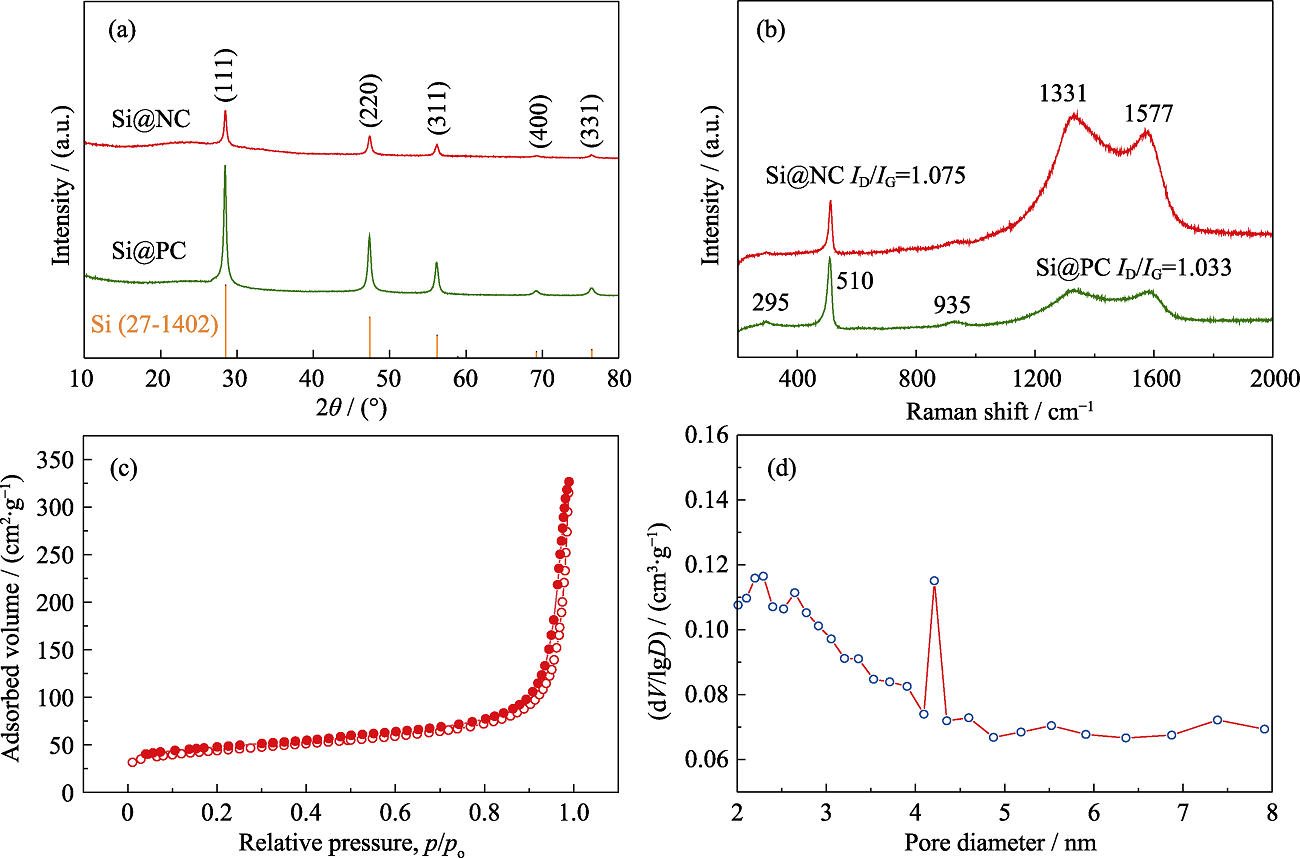

图4 Si@NC和Si@PC样品的(a)XRD图谱和(b)拉曼光谱图, Si@NC的(c)氮气吸/脱附等温线和(d)孔径分布图

Fig. 4 (a) XRD patterns and (b) Raman spectra of Si@NC and Si@PC, (c) nitrogen adsorption-desorption isotherm and (d) pore size distribution of Si@NC

图5 Si@NC的(a) CV曲线和(b)在0.2 A/g电流密度下前三圈的充放电曲线, Si@NC和Si@PC的(c)倍率性能和(d)在0.5 A/g电流密度下的循环性能, (e) Si@NC、NC和Si@PC在1 A/g电流密度下的长循环性能(黑色圆圈表示Si@NC的库仑效率)

Fig. 5 (a) CV curves at a scanning rate of 0.2 mV/s and (b) charge-discharge curves for initial 3 cycles at 0.2 A/g of Si@NC, (c) rate performances and (d) cycling performances at 0.5 A/g of Si@NC and Si@PC, and (e) long cycling performances of Si@NC, NC and Si@PC at 1 A/g (black circles showing Coulombic efficiencies of Si@NC)

图6 Si@NC//NCM622全电池(a)在1~4.5 V范围的充放电曲线和(b)0.4C下的循环性能

Fig. 6 (a) Charge-discharge profiles in the range of 1~4.5 V, and (b) cycle performance at 0.4C of Si@NC//NCM622 full-cell

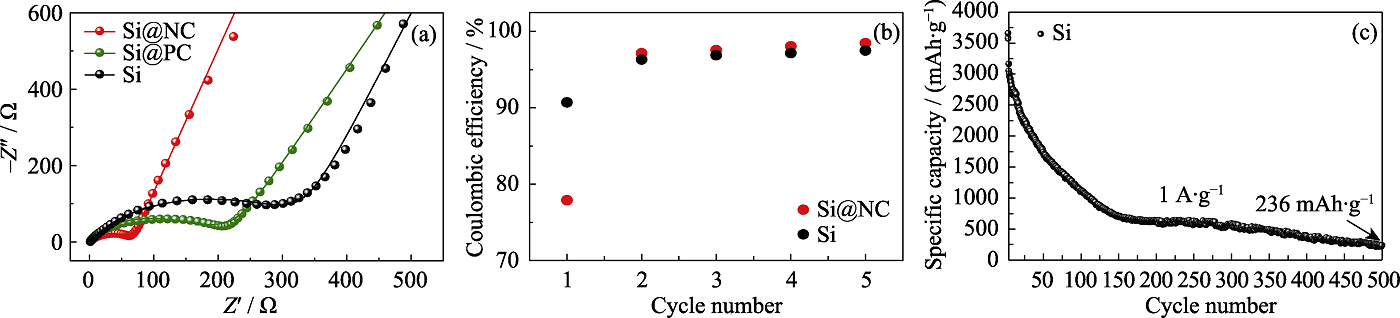

图S3 (a)纯Si、Si@NC和Si@PC的电化学阻抗谱图, (b) Si@NC和纯Si前5圈的库仑效率, (c)纯Si在1 A/g下的长循环性能

Fig. S3 EIS plots of pure Si, Si@NC and Si@PC, (b) Coulombic efficiencies of Si@NC and pure Si for the first 5 cycles, (c) cycle performance of pure Si at 1 A/g

图S4 半电池中Si@NC电极(a)循环前、循环(b)50和(c)200圈后的截面及表面SEM照片

Fig. S4 Cross section and surface SEM images of Si@NC electrodes for half-cell (a) before the cycle, after (b)50 and (c) 200 cycles

| Anode material | Cycle performance/(mAh·g-1) (Cycle number) | Current density/ (A·g-1) | Rate capability/(mAh·g-1) (Current density/(A·g-1)) | Ref. |

|---|---|---|---|---|

| Three-dimensional Network Si/C | 666 (500th) | 1 | 760 (5) | This work |

| MHR-Si/rGO | 530 (400th) | 1 | 513 (5) | [1] |

| Si@C/Co/CNTs | 700 (500th) | 1 | 480 (5) | [2] |

| Pseudographite/Si/Ni | 800 (500th) | 1 | 271 (5) | [3] |

| Si@void@C/C-2 | 450 (500th) | 1 | 410 (3.2) | [4] |

| Yolk-shell structured Si-based anode | 657 (200th) | 1 | 350 (5) | [5] |

| Si@C-ZIF@carbon Nanofibers | 760 (500th) | 1 | 523.9 (5) | [6] |

表S1 Si/C复合材料电化学性能比较

Table S1 Comparison of electrochemical performance for Si/C composite materials

| Anode material | Cycle performance/(mAh·g-1) (Cycle number) | Current density/ (A·g-1) | Rate capability/(mAh·g-1) (Current density/(A·g-1)) | Ref. |

|---|---|---|---|---|

| Three-dimensional Network Si/C | 666 (500th) | 1 | 760 (5) | This work |

| MHR-Si/rGO | 530 (400th) | 1 | 513 (5) | [1] |

| Si@C/Co/CNTs | 700 (500th) | 1 | 480 (5) | [2] |

| Pseudographite/Si/Ni | 800 (500th) | 1 | 271 (5) | [3] |

| Si@void@C/C-2 | 450 (500th) | 1 | 410 (3.2) | [4] |

| Yolk-shell structured Si-based anode | 657 (200th) | 1 | 350 (5) | [5] |

| Si@C-ZIF@carbon Nanofibers | 760 (500th) | 1 | 523.9 (5) | [6] |

| [1] | CAI Y, WANG H E, ZHAO X, et al. Walnut-like porous core/shell TiO2 with hybridized phases enabling fast and stable lithium storage. ACS Applied Materials & Interfaces, 2017, 9(12): 10652-10663. |

| [2] |

ZHANG L, SHAO Q, ZHANG J. An overview of non-noble metal electrocatalysts and their associated air cathodes for Mg-air batteries. Materials Reports: Energy, 2021, 1(1): 100002.

DOI URL |

| [3] | LU Y, RONG X, HU Y S, et al. Research and development of advanced battery materials in China. Energy Storage Materials, 2019, 23: 144-153. |

| [4] |

GANNETT C N, MELECIO-ZAMBRANO L, THEIBAULT M, et al. Organic electrode materials for fast-rate, high-power battery applications. Materials Reports: Energy, 2021, 1(1): 100008.

DOI URL |

| [5] |

WU F, MAIER J, YU Y. Guidelines and trends for next-generation rechargeable lithium and lithium-ion batteries. Chemical Society Reviews, 2020, 49(5): 1569-1614.

DOI URL |

| [6] |

LI G, WANG Y, GUO H, et al. Direct plasma phosphorization of Cu foam for Li ion batteries. Journal of Materials Chemistry A, 2020, 8(33): 16920-16925.

DOI URL |

| [7] |

LIU J, ZHANG Q, ZHANG T, et al. A robust ion-conductive biopolymer as a binder for Si anodes of lithium-ion batteries. Advanced Functional Materials, 2015, 25(23): 3599-3605.

DOI URL |

| [8] | SUN Z, WANG G, CAI T, et al. Sandwich-structured graphite- metallic silicon@C nanocomposites for Li-ion batteries. Electrochimica Acta, 2016, 191: 299-306. |

| [9] |

YANG Y, YUAN W, KANG W, et al. Silicon-nanoparticle-based composites for advanced lithium-ion battery anodes. Nanoscale, 2020, 12(14): 7461-7484.

DOI URL |

| [10] |

AN W, GAO B, MEI S, et al. Scalable synthesis of ant-nest-like bulk porous silicon for high-performance lithium-ion battery anodes. Nature Communications, 2019, 10(1): 1-11.

DOI URL |

| [11] |

AN Y, FEI H, ZENG G, et al. Green, scalable, and controllable fabrication of nanoporous silicon from commercial alloy precursors for high-energy lithium-ion batteries. ACS Nano, 2018, 12(5): 4993-5002.

DOI URL |

| [12] | LIU N, HUO K, MCDOWELL M T, et al. Rice husks as a sustainable source of nanostructured silicon for high performance Li-ion battery anodes. Scientific Reports, 2013, 3(1): 1-7. |

| [13] |

PARK S, SUNG J, CHAE S, et al. Scalable synthesis of hollow β-SiC/Si anodes via selective thermal oxidation for lithium-ion batteries. ACS Nano, 2020, 14(9): 11548-11557.

DOI URL |

| [14] | WU H, CHAN G, CHOI J W, et al. Stable cycling of double-walled silicon nanotube battery anodes through solid-electrolyte interphase control. Nature Nanotechnolagy, 2012, 7(5): 310-315. |

| [15] | ZHANG Z, LI H. Sequential-template synthesis of hollowed carbon polyhedron@SiC@Si for lithium-ion battery with high capacity and electrochemical stability. Applied Surface Science, 2020, 514:145920. |

| [16] |

WANG J, HUANG W, KIM Y S, et al. Scalable synthesis of nanoporous silicon microparticles for highly cyclable lithium-ion batteries. Nano Research, 2020, 13(6): 1558-1563.

DOI URL |

| [17] | BAI Y, ZENG M, WU X, et al. Three-dimensional cage-like Si@ZIF-67 core-shell composites for high-performance lithium storage. Applied Surface Science, 2020, 510: 145477. |

| [18] |

XU Y, ZHU Y, WANG C. Mesoporous carbon/silicon composite anodes with enhanced performance for lithium-ion batteries. Journal of Materials Chemistry A, 2014, 2(25): 9751-9757.

DOI URL |

| [19] |

HERTZBERG B, ALEXEEV A, YUSHIN G. Deformations in Si-Li anodes upon electrochemical alloying in nano-confined space. Journal of the American Chemical Society, 2010, 132(25): 8548-8549.

DOI URL |

| [20] |

PARK M H, KIM M G, JOO J, et al. Silicon nanotube battery anodes. Nano Letters, 2009, 9(11): 3844-3847.

DOI URL |

| [21] |

JIA H, LI X, SONG J, et al. Hierarchical porous silicon structures with extraordinary mechanical strength as high-performance lithium- ion battery anodes. Nature Communications, 2020, 11(1): 1-9.

DOI URL |

| [22] |

LIU B, SOARES P, CHECKLES C, et al. Three-dimensional hierarchical ternary nanostructures for high-performance Li-ion battery anodes. Nano Letters, 2013, 13(7): 3414-3419.

DOI URL |

| [23] |

WU L, LI Y, FU Z Y, et al. Hierarchically structured porous materials: synthesis strategies and applications in energy storage. National Science Review, 2020, 7(11): 1667-1701.

DOI URL |

| [24] |

ZHOU N, DONG W D, ZHANG Y J, et al. Embedding tin disulfide nanoparticles in two-dimensional porous carbon nanosheet interlayers for fast-charging lithium-sulfur batteries. Science China Materials, 2021, 64(11): 2697-2709.

DOI URL |

| [25] |

XIE C, XU Q, SARI H M K, et al. Elastic buffer structured Si/C microsphere anodes via polymerization-induced colloid aggregation. Chemical Communications, 2020, 56(50): 6770-6773.

DOI URL |

| [26] |

HONG Y, DONG H, LI J, et al. Enhanced lithium storage performance of porous Si/C composite anodes using a recrystallized NaCl template. Dalton Transactions, 2021, 50(8): 2815-2823.

DOI URL |

| [27] | LI C, WANG Y Y, LI H Y, et al. Weaving 3D highly conductive hierarchically interconnected nanoporous web by threading MOF crystals onto multi walled carbon nanotubes for high performance Li-Se battery. Journal of Energy Chemistry, 2021, 59: 396-404. |

| [28] | SONG J P, WU L, DONG W D, et al. MOF-derived nitrogen- doped core-shell hierarchical porous carbon confining selenium for advanced lithium-selenium battery. Nanoscale, 2019, 11: 6970-6981 |

| [29] |

WANG X, MA X, WANG H, et al. A zinc(II) benzenetricarboxylate metal organic framework with unusual adsorption properties, and its application to the preconcentration of pesticides. Microchimica Acta, 2017, 184(10): 3681-3687.

DOI URL |

| [30] |

BAI X J, LIU C, HOU M, et al. Silicon/CNTs/graphene free- standing anode material for lithium-ion battery. Journal of Inorganic Materials, 2017, 32(7): 705-712.

DOI URL |

| [31] |

CHAE S, XU Y, YI R, et al. A micrometer-sized silicon/carbon composite anode synthesized by impregnation of petroleum pitch in nanoporous silicon. Advanced Materials, 2021, 33(40): 2103095.

DOI URL |

| [32] | HOU Z, LIU H, CHEN P, et al. Nanocaging silicon nanoparticles into a porous carbon framework toward enhanced lithium-ion storage. Particle & Particle Systems Characterization, 2021: 38(9): 2100107. |

| [33] | ZHANG Y, CHENG Y, SONG J, et al. Functionalization-assistant ball milling towards Si/graphene anodes in high performance Li-ion batteries. Carbon, 2021, 181: 300-309. |

| [34] | WANG L, WANG Z, XIE L, et al. ZIF-67-derived N-doped Co/C nanocubes as high-performance anode materials for lithium-ion batteries. ACS Applied Materials & Interfaces, 2019, 11(18): 16619-16628. |

| [35] | TU Z, YANG G, SONG H, et al. Amorphous ZnO quantum dot/mesoporous carbon bubble composites for a high-performance lithium-ion battery anode. ACS Applied Materials & Interfaces, 2017, 9(1): 439-446. |

| [36] | CUI J, CUI Y, LI S, et al. Microsized porous SiOx@C composites synthesized through aluminothermic reduction from rice husks and used as anode for lithium-ion batteries. ACS Applied Materials & Interfaces, 2016, 8(44): 30239-30247. |

| [1] | 谭博文, 耿双龙, 张锴, 郑百林. 硅电极组分梯度设计抑制力-化学耦合劣化[J]. 无机材料学报, 2025, 40(7): 772-780. |

| [2] | 刘鹏东, 王桢, 刘永锋, 温广武. 硅泥在锂离子电池中的应用研究进展[J]. 无机材料学报, 2024, 39(9): 992-1004. |

| [3] | 程节, 周月, 罗薪涛, 高美婷, 骆思妃, 蔡丹敏, 吴雪垠, 朱立才, 袁中直. 蛋黄壳结构FeF3·0.33H2O@N掺杂碳纳米笼正极材料的构筑及其电化学性能[J]. 无机材料学报, 2024, 39(3): 299-305. |

| [4] | 胡梦菲, 黄丽萍, 李贺, 张国军, 吴厚政. 锂/钠离子电池硬碳负极材料的研究进展[J]. 无机材料学报, 2024, 39(1): 32-44. |

| [5] | 苏楠, 邱介山, 王治宇. 高容量氟掺杂碳包覆纳米硅负极材料: 气相氟化法制备及其储锂性能[J]. 无机材料学报, 2023, 38(8): 947-953. |

| [6] | 杨卓, 卢勇, 赵庆, 陈军. X射线衍射Rietveld精修及其在锂离子电池正极材料中的应用[J]. 无机材料学报, 2023, 38(6): 589-605. |

| [7] | 王洋, 范广新, 刘培, 尹金佩, 刘宝忠, 朱林剑, 罗成果. 钾离子掺杂提高锂离子电池正极锰酸锂性能的微观机制[J]. 无机材料学报, 2022, 37(9): 1023-1029. |

| [8] | 朱河圳, 王选朋, 韩康, 杨晨, 万睿哲, 吴黎明, 麦立强. 超高镍LiNi0.91Co0.06Al0.03O2@Ca3(PO4)2正极材料的储锂稳定性的提升机制[J]. 无机材料学报, 2022, 37(9): 1030-1036. |

| [9] | 冯锟, 朱勇, 张凯强, 陈长, 刘宇, 高彦峰. 勃姆石纳米片增强锂离子电池隔膜性能研究[J]. 无机材料学报, 2022, 37(9): 1009-1015. |

| [10] | 陈莹, 栾伟玲, 陈浩峰, 朱轩辰. 基于应力场的锂离子电池正极多尺度失效研究[J]. 无机材料学报, 2022, 37(8): 918-924. |

| [11] | 江依义, 沈旻, 宋半夏, 李南, 丁祥欢, 郭乐毅, 马国强. 双功能电解液添加剂对锂离子电池高温高电压性能的影响[J]. 无机材料学报, 2022, 37(7): 710-716. |

| [12] | 苏东良, 崔锦, 翟朋博, 郭向欣. 石榴石型Li6.4La3Zr1.4Ta0.6O12对Si/C负极表面固体电解质中间相的调控机制研究[J]. 无机材料学报, 2022, 37(7): 802-808. |

| [13] | 肖美霞, 李苗苗, 宋二红, 宋海洋, 李钊, 毕佳颖. 表面端基卤化Ti3C2 MXene应用于锂离子电池高容量电极材料的研究[J]. 无机材料学报, 2022, 37(6): 660-668. |

| [14] | 王禹桐, 张非凡, 许乃才, 王春霞, 崔立山, 黄国勇. 水系锂离子电池负极材料LiTi2(PO4)3的研究进展[J]. 无机材料学报, 2022, 37(5): 481-492. |

| [15] | 王晶, 徐守冬, 卢中华, 赵壮壮, 陈良, 张鼎, 郭春丽. 钠离子电池中空结构CoSe2/C负极材料的制备及储钠性能研究[J]. 无机材料学报, 2022, 37(12): 1344-1350. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||