无机材料学报 ›› 2021, Vol. 36 ›› Issue (9): 929-935.DOI: 10.15541/jim20200525 CSTR: 32189.14.10.15541/jim20200525

李昆儒1( ), 胡省辉1, 张正富1, 郭玉忠1(

), 胡省辉1, 张正富1, 郭玉忠1( ), 黄瑞安2(

), 黄瑞安2( )

)

收稿日期:2020-09-08

修回日期:2020-11-08

出版日期:2021-09-20

网络出版日期:2020-12-10

通讯作者:

郭玉忠, 教授. E-mail: yzguocn62@sina.com; 黄瑞安, 副教授. E-mail: hruian@siom.ac.cn

作者简介:李昆儒(1996-), 男, 硕士研究生. E-mail: likunru@stu.kust.edu.cn

基金资助:

LI Kunru1( ), HU Xinghui1, ZHANG Zhengfu1, GUO Yuzhong1(

), HU Xinghui1, ZHANG Zhengfu1, GUO Yuzhong1( ), HUANG Ruian2(

), HUANG Ruian2( )

)

Received:2020-09-08

Revised:2020-11-08

Published:2021-09-20

Online:2020-12-10

Contact:

GUO Yuzhong, professor. E-mail: yzguocn62@sina.com; HUANG Ruian, associate professor. E-mail: hruian@siom.ac.cn

About author:LI Kunru(1996-), male, Master candidate. E-mail: likunru@stu.kust.edu.cn

Supported by:摘要:

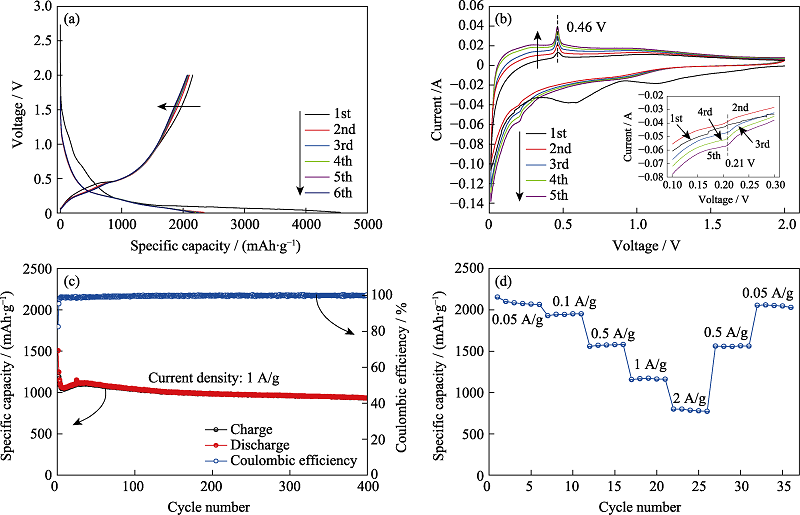

锂离子电池硅基负极材料的理论比容量比传统石墨材料高10倍, 是最有前途的锂离子电池负极材料之一。然而硅基纳米材料的制备工艺复杂、成本高昂, 严重限制了锂离子电池硅负极的商业应用。本工作采用溪木贼为原料, 通过深度还原、浅度氧化和碳包覆工艺制备了三维多孔生物质硅/碳复合材料(多孔3D-bio-Si/C)。三维多孔结构不仅有利于Li+的快速传输, 而且提供足够的空隙缓解在脱-嵌锂过程中发生的体积变化。得益于三维结构中大量的孔隙和高强度的外部碳层, 多孔3D-bio-Si/C制备的电极表现出优异的电化学性能。当电流密度为1 A/g时, 多孔3D-bio-Si/C的可逆容量为1243.2 mAh/g, 循环400次后仍可保持933.4 mAh/g, 容量保持率高达89%。利用溪木贼作为生物质硅源制备高性能硅基负极材料, 实现了低成本、可规模化、绿色和可持续的合成路线, 有望为Si基锂离子电池负极材料的商业应用打下基础。

中图分类号:

李昆儒, 胡省辉, 张正富, 郭玉忠, 黄瑞安. 源于溪木贼的高性能锂离子电池三维多孔生物质硅/碳复合负极材料[J]. 无机材料学报, 2021, 36(9): 929-935.

LI Kunru, HU Xinghui, ZHANG Zhengfu, GUO Yuzhong, HUANG Ruian. Three-dimensional Porous Biogenic Si/C Composite for High Performance Lithium-ion Battery Anode Derived from Equisetum Fluviatile[J]. Journal of Inorganic Materials, 2021, 36(9): 929-935.

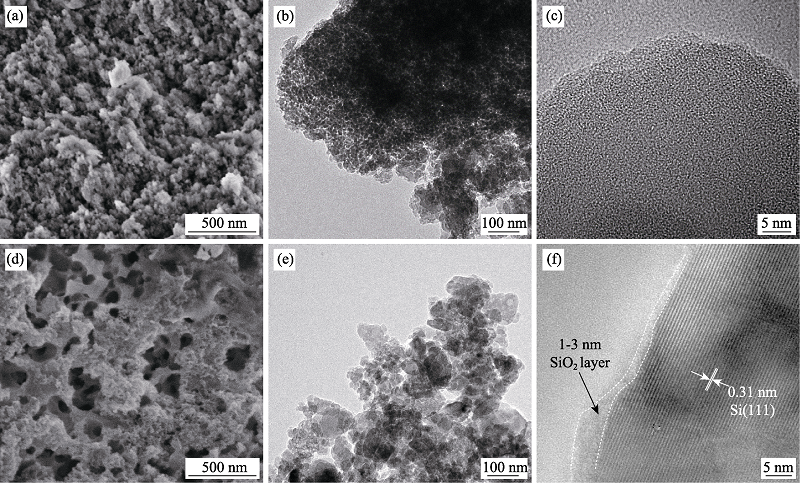

图5 (a~c)多孔3D-bio-SiO2和(d~f)多孔3D-bio-Si的(a, d)扫描电镜照片、(b, e)透射电镜照片和(c, f)高分辨透射电镜照片

Fig. 5 (a, d) SEM, (b, e) TEM and (c, f) HRTEM images of (a-c) 3D-bio-SiO2 and (d-f) 3D-bio-Si

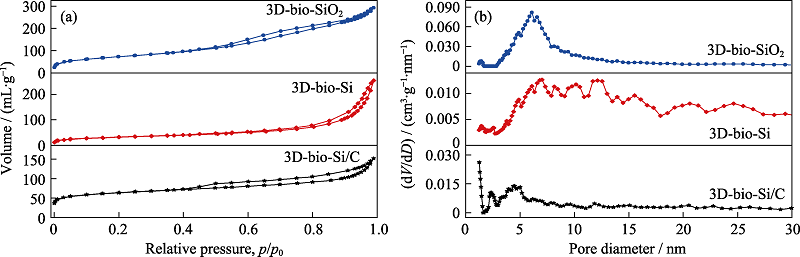

图7 多孔3D-bio-SiO2、多孔3D-bio-Si和多孔3D-bio-Si/C的(a)N2吸附-脱附等温线和(b)孔径分布曲线

Fig. 7 (a) Nitrogen adsorption-desorption isotherms and (b) pore size distribution curves for 3D-bio-SiO2, 3D-bio-Si and 3D-bio-Si/C

图8 多孔3D-bio-Si/C (a)在0.05 A/g电流密度下的第1~6圈的充放电曲线, (b)循环伏安(CV)曲线, (c)循环性能曲线(1 A/g)和(d)倍率性能曲线

Fig. 8 (a) Charge and discharge curves for initial 6 cycles at 0.05 A/g, (b) CV curves at a scanning rate of 0.5 mV/s, (c) cycling performance (1 A/g), and (d) rate capability at different rates of 3D-bio-Si/C

| Sample | Si source | Structure | Current density/(A∙g-1) | Capacity/(mAh∙g-1) (Cycle number) | Ref. |

|---|---|---|---|---|---|

| Si/N-doped C | Rice husk | Spheres | 0.5 | 1031 (100th) | [ |

| Si/C | Rice husk | Spheres | 0.1 | 560 (180th) | [ |

| Si/N-doped C | Bamboo charcoal | Porous | 0.2 | 603 (120th) | [ |

| Si@C/RGO | Bamboo leaf | Nanoparticles | 0.84 | 1900 (100th) | [ |

| Si/N-doped C | Horsetail | Nanoparticles | 1 | 750 (760th) | [ |

| Si/C | Reed plants | Porous | 0.5 | 1050 (200th) | [ |

| Si/C | Rice husk | Bulks | 0.1 | 537 (100th) | [ |

| 3D-bio-Si/C | Equisetum fluviatile | Porous | 1 | 933 (400th) | This work |

表1 不同生物质硅作为锂离子电池负极材料的电化学性能比较

Table 1 Comparison of electrochemical properties for various biomass-derived Si as LIBs anodes

| Sample | Si source | Structure | Current density/(A∙g-1) | Capacity/(mAh∙g-1) (Cycle number) | Ref. |

|---|---|---|---|---|---|

| Si/N-doped C | Rice husk | Spheres | 0.5 | 1031 (100th) | [ |

| Si/C | Rice husk | Spheres | 0.1 | 560 (180th) | [ |

| Si/N-doped C | Bamboo charcoal | Porous | 0.2 | 603 (120th) | [ |

| Si@C/RGO | Bamboo leaf | Nanoparticles | 0.84 | 1900 (100th) | [ |

| Si/N-doped C | Horsetail | Nanoparticles | 1 | 750 (760th) | [ |

| Si/C | Reed plants | Porous | 0.5 | 1050 (200th) | [ |

| Si/C | Rice husk | Bulks | 0.1 | 537 (100th) | [ |

| 3D-bio-Si/C | Equisetum fluviatile | Porous | 1 | 933 (400th) | This work |

| [1] |

FU X W, ZHONG W H. Biomaterials for high-energy lithium-based batteries: strategies, challenges, and perspectives. Advanced Energy Materials, 2019, 9(40):1901774.

DOI URL |

| [2] | REHMAN W U, WANG H F, MANJ R Z A, et al. When silicon materials meet natural sources: opportunities and challenges for low-cost lithium storage. Small, 2019: 1904508. |

| [3] |

GOODENOUGH J B, KIM Y. Challenges for rechargeable Li batteries. Chemistry of Materials, 2010, 22:587-603.

DOI URL |

| [4] |

LIU Z H, YU Q, ZHAO Y L, et al. Silicon oxides: a promising family of anode materials for lithium-ion batteries. Chemical Society Reviews, 2019, 48:285-309.

DOI URL |

| [5] |

PIPER D M, TRAVIS J J, YOUNG M, et al. Reversible high-capacity Si nanocomposite anodes for lithium-ion batteries enabled by molecular layer deposition. Advanced Materials, 2014, 26(10):1596-1601.

DOI URL |

| [6] |

BAO Z H, WEATHERSPOON M R, SHIAN S, et al. Chemical reduction of three-dimensional silica micro-assemblies into microporous silicon replicas. Nature, 2007, 446:172-175.

DOI URL |

| [7] |

DU F D, WANG K X, CHEN J S. Strategies to succeed in improving the lithium-ion storage properties of silicon nanomaterials. Journal of Materials Chemistry A, 2016, 4(1):32-50.

DOI URL |

| [8] |

MCDOWELL M T, LEE S W, NIX W D, et al. 25th Anniversary article: understanding the lithiation of silicon and other alloying anodes for lithium-ion batteries. Advanced Materials, 2013, 25(36):4966-4985.

DOI URL |

| [9] |

DU N, ZHANG H, FAN X, et al. Large-scale synthesis of silicon arrays of nanowire on titanium substrate as high-performance anode of Li-ion batteries. Journal of Alloys and Compounds, 2012, 526:53-58.

DOI URL |

| [10] |

ZHANG Y C, YOU Y, XIN S, et al. Rice husk-derived hierarchical silicon/nitrogen doped carbon/carbon nanotube spheres as low cost and high-capacity anodes for lithium-ion batteries. Nano Energy, 2016, 25:120-127.

DOI URL |

| [11] |

GAO P B, HUANG X, ZHAO Y T, et al. Formation of Si hollow structures as promising anode materials through reduction of silica in AlCl3-NaCl molten salt. ACS Nano, 2018, 12(11):11481-11490.

DOI URL |

| [12] |

LUO X, ZHANG H J, PAN W, et al. SiOx nanodandelion by laser ablation for anode of lithium-ion battery. Small, 2015, 11(45):6009-6012.

DOI URL |

| [13] |

CHEN Y, LIU L F, XIONG J, et al. Porous Si nanowires from cheap metallurgical silicon stabilized by a surface oxide layer for lithium ion batteries. Advanced Functional Materials, 2015, 25:6701-6709.

DOI URL |

| [14] |

GREGOIRE C, REMUS-BOREL W, VIVANCOS J, et al. Discovery of a multigene family of aquaporin silicon transporters in the primitive plant Equisetum arvense. Plant Journal, 2012, 72(2):320-330.

DOI URL |

| [15] |

SAPEI L, NÖSKE R, STRAUCH P, et al. Isolation of mesoporous biogenic silica from the perennial plant Equisetum hyemale. Chemistry of Materials, 2008, 20:2020-2025.

DOI URL |

| [16] |

YU K F, ZHANG H X, QI H, et al. Rice husk as the source of silicon/carbon anode material and stable electrochemical performance. ChemistrySelect, 2018, 3(19):5439-5444.

DOI URL |

| [17] | HUANG R A, HU X H, GUO Y Z, et al. Highly Hierarchical fibrillar biogenic silica with mesoporous structure derived from the perennial plant Equisetum fluviatile. ACS Applied Materials & Interfaces, 2020, 12(31):35259-35265. |

| [18] |

XIE A T, CUI J Y, YANG J, et al. Photo-Fenton self-cleaning PVDF/NH2-MIL-88B(Fe) membranes towards highly-efficient oil/water emulsion separation. Journal of Membrane Science, 2020, 595:117499.

DOI URL |

| [19] |

HASSAN F M, CHABOT V, ELSAYED A R, et al. Engineered Si electrode nanoarchitecture: a scalable postfabrication treatment for the production of next-generation Li-ion batteries. Nano Letters, 2014, 14(1):277-283.

DOI URL |

| [20] |

HUANG R A, GUO Y Z, CHEN Z N, et al. An easy and scalable approach to synthesize three-dimensional sandwich-like Si/polyaniline/ graphene nanoarchitecture anode for lithium ion batteries. Ceramics International, 2018, 44(4):4282-4286.

DOI URL |

| [21] |

LIANG J W, LI X N, HOU Z G, et al. A deep reduction and partial oxidation strategy for fabrication of mesoporous Si anode for lithium ion batteries. ACS Nano, 2016, 10(2):2295-2304.

DOI URL |

| [22] |

WON C W, NERSISYAN H H, WON H I. Solar-grade silicon powder prepared by combining combustion synthesis with hydrometallurgy. Solar Energy Materials and Solar Cells, 2011, 95(2):745-750.

DOI URL |

| [23] | ZHAN J, XU C F, LONG Y Y, et al. Bi2Mn4O10: preparation by polyacrylamide gel method and electrochemical performance. Journal of Inorganic Materials, 2020, 35(7):827-833. |

| [24] |

SHELKE M V, GULLAPALLI H, KALAGA K, et al. Facile synthesis of 3D anode assembly with Si nanoparticles sealed in highly pure few layer graphene deposited on porous current collector for long life Li-ion battery. Advanced Materials Interfaces, 2017, 4(10):1601043.

DOI URL |

| [25] | 许笑目, 张兴帅, 郭玉忠, 等. 无序介孔硅复合纳米结构的制备与慢活化行为. 高等学校化学学报, 2017, 38(5):713-721. |

| [26] |

CHU H Y, WU Q Z, HUANG J G. Rice husk derived silicon/carbon and silica/carbon nanocomposites as anodic materials for lithium-ion batteries. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2018, 558:495-503.

DOI URL |

| [27] | ZHANG C C, CAI X, CHEN W Y, et al. 3D porous silicon/N-doped carbon composite derived from bamboo charcoal as high-performance anode material for lithium ion batteries. ACS Sustainable Chemistry & Engineering, 2018, 6:9930-9939. |

| [28] |

WANG L, GAO B, PENG C J, et al. Bamboo leaf derived ultrafine Si nanoparticles and Si/C nanocomposites for high-performance Li-ion battery anodes. Nanoscale, 2015, 7:13840-13847.

DOI URL |

| [29] |

HE Y Y, XU G, WANG C S, et al. Horsetail-derived Si@N-doped carbon as low-cost and long cycle life anode for Li-ion half/full cells. Electrochimica Acta, 2018, 264:173-182.

DOI URL |

| [30] |

LIU J, KOPOLD P, PETER A V A, et al. Energy storage materials from nature through nanotechnology: a sustainable route from reed plants to a silicon anode for lithium-ion batteries. Angewandte Chemie International Edition, 2015, 54(33):9632-9636.

DOI URL |

| [1] | 谭博文, 耿双龙, 张锴, 郑百林. 硅电极组分梯度设计抑制力-化学耦合劣化[J]. 无机材料学报, 2025, 40(7): 772-780. |

| [2] | 刘鹏东, 王桢, 刘永锋, 温广武. 硅泥在锂离子电池中的应用研究进展[J]. 无机材料学报, 2024, 39(9): 992-1004. |

| [3] | 程节, 周月, 罗薪涛, 高美婷, 骆思妃, 蔡丹敏, 吴雪垠, 朱立才, 袁中直. 蛋黄壳结构FeF3·0.33H2O@N掺杂碳纳米笼正极材料的构筑及其电化学性能[J]. 无机材料学报, 2024, 39(3): 299-305. |

| [4] | 胡梦菲, 黄丽萍, 李贺, 张国军, 吴厚政. 锂/钠离子电池硬碳负极材料的研究进展[J]. 无机材料学报, 2024, 39(1): 32-44. |

| [5] | 苏楠, 邱介山, 王治宇. 高容量氟掺杂碳包覆纳米硅负极材料: 气相氟化法制备及其储锂性能[J]. 无机材料学报, 2023, 38(8): 947-953. |

| [6] | 杨卓, 卢勇, 赵庆, 陈军. X射线衍射Rietveld精修及其在锂离子电池正极材料中的应用[J]. 无机材料学报, 2023, 38(6): 589-605. |

| [7] | 宿拿拿, 韩静茹, 郭印毫, 王晨宇, 石文华, 吴亮, 胡执一, 刘婧, 李昱, 苏宝连. 基于ZIF-8的三维网络硅碳复合材料锂离子电池性能研究[J]. 无机材料学报, 2022, 37(9): 1016-1022. |

| [8] | 王洋, 范广新, 刘培, 尹金佩, 刘宝忠, 朱林剑, 罗成果. 钾离子掺杂提高锂离子电池正极锰酸锂性能的微观机制[J]. 无机材料学报, 2022, 37(9): 1023-1029. |

| [9] | 朱河圳, 王选朋, 韩康, 杨晨, 万睿哲, 吴黎明, 麦立强. 超高镍LiNi0.91Co0.06Al0.03O2@Ca3(PO4)2正极材料的储锂稳定性的提升机制[J]. 无机材料学报, 2022, 37(9): 1030-1036. |

| [10] | 冯锟, 朱勇, 张凯强, 陈长, 刘宇, 高彦峰. 勃姆石纳米片增强锂离子电池隔膜性能研究[J]. 无机材料学报, 2022, 37(9): 1009-1015. |

| [11] | 陈莹, 栾伟玲, 陈浩峰, 朱轩辰. 基于应力场的锂离子电池正极多尺度失效研究[J]. 无机材料学报, 2022, 37(8): 918-924. |

| [12] | 江依义, 沈旻, 宋半夏, 李南, 丁祥欢, 郭乐毅, 马国强. 双功能电解液添加剂对锂离子电池高温高电压性能的影响[J]. 无机材料学报, 2022, 37(7): 710-716. |

| [13] | 苏东良, 崔锦, 翟朋博, 郭向欣. 石榴石型Li6.4La3Zr1.4Ta0.6O12对Si/C负极表面固体电解质中间相的调控机制研究[J]. 无机材料学报, 2022, 37(7): 802-808. |

| [14] | 肖美霞, 李苗苗, 宋二红, 宋海洋, 李钊, 毕佳颖. 表面端基卤化Ti3C2 MXene应用于锂离子电池高容量电极材料的研究[J]. 无机材料学报, 2022, 37(6): 660-668. |

| [15] | 王禹桐, 张非凡, 许乃才, 王春霞, 崔立山, 黄国勇. 水系锂离子电池负极材料LiTi2(PO4)3的研究进展[J]. 无机材料学报, 2022, 37(5): 481-492. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||