无机材料学报 ›› 2022, Vol. 37 ›› Issue (9): 1009-1015.DOI: 10.15541/jim20220050 CSTR: 32189.14.10.15541/jim20220050

冯锟1,2( ), 朱勇1, 张凯强1, 陈长1, 刘宇2(

), 朱勇1, 张凯强1, 陈长1, 刘宇2( ), 高彦峰1(

), 高彦峰1( )

)

收稿日期:2022-01-27

修回日期:2022-03-22

出版日期:2022-09-20

网络出版日期:2022-04-07

通讯作者:

高彦峰, 教授. E-mail: yfgao@shu.edu.cn;作者简介:冯 锟(1998-), 男, 硕士研究生. E-mail: fengkun@shu.edu.cn

基金资助:

FENG Kun1,2( ), ZHU Yong1, ZHANG Kaiqiang1, CHEN Zhang1, LIU Yu2(

), ZHU Yong1, ZHANG Kaiqiang1, CHEN Zhang1, LIU Yu2( ), GAO Yanfeng1(

), GAO Yanfeng1( )

)

Received:2022-01-27

Revised:2022-03-22

Published:2022-09-20

Online:2022-04-07

Contact:

GAO Yanfeng, professor. E-mail: yfgao@shu.edu.cn;>About author:FENG Kun, male, Master candidate. E-mail: fengkun@shu.edu.cn

Supported by:摘要:

采用勃姆石涂覆改性聚烯烃隔膜可以提升锂离子电池的隔膜热稳定性和电解液润湿性。本工作通过简单的水热法合成了平均粒径约为150 nm的勃姆石纳米片, 并采用刮涂法涂覆在聚乙烯(Polyethylene, PE)隔膜表面。该涂覆隔膜的孔隙率达到46.6%、吸液率为138.9%、离子电导率为0.47 mS/cm和锂离子迁移数为0.42, 使得该隔膜组装的锂离子电池具有较好的循环稳定性, 在1C(1C=150 mA/g)的电流密度下循环100次后仍能保留93.7%的放电比容量。同时, 勃姆石纳米片涂覆的隔膜的孔结构分布均匀, 优化了锂离子传输通量, 抑制了锂枝晶。

中图分类号:

冯锟, 朱勇, 张凯强, 陈长, 刘宇, 高彦峰. 勃姆石纳米片增强锂离子电池隔膜性能研究[J]. 无机材料学报, 2022, 37(9): 1009-1015.

FENG Kun, ZHU Yong, ZHANG Kaiqiang, CHEN Zhang, LIU Yu, GAO Yanfeng. Boehmite Nanosheets-coated Separator with Enhanced Performance for Lithium-ion Batteries[J]. Journal of Inorganic Materials, 2022, 37(9): 1009-1015.

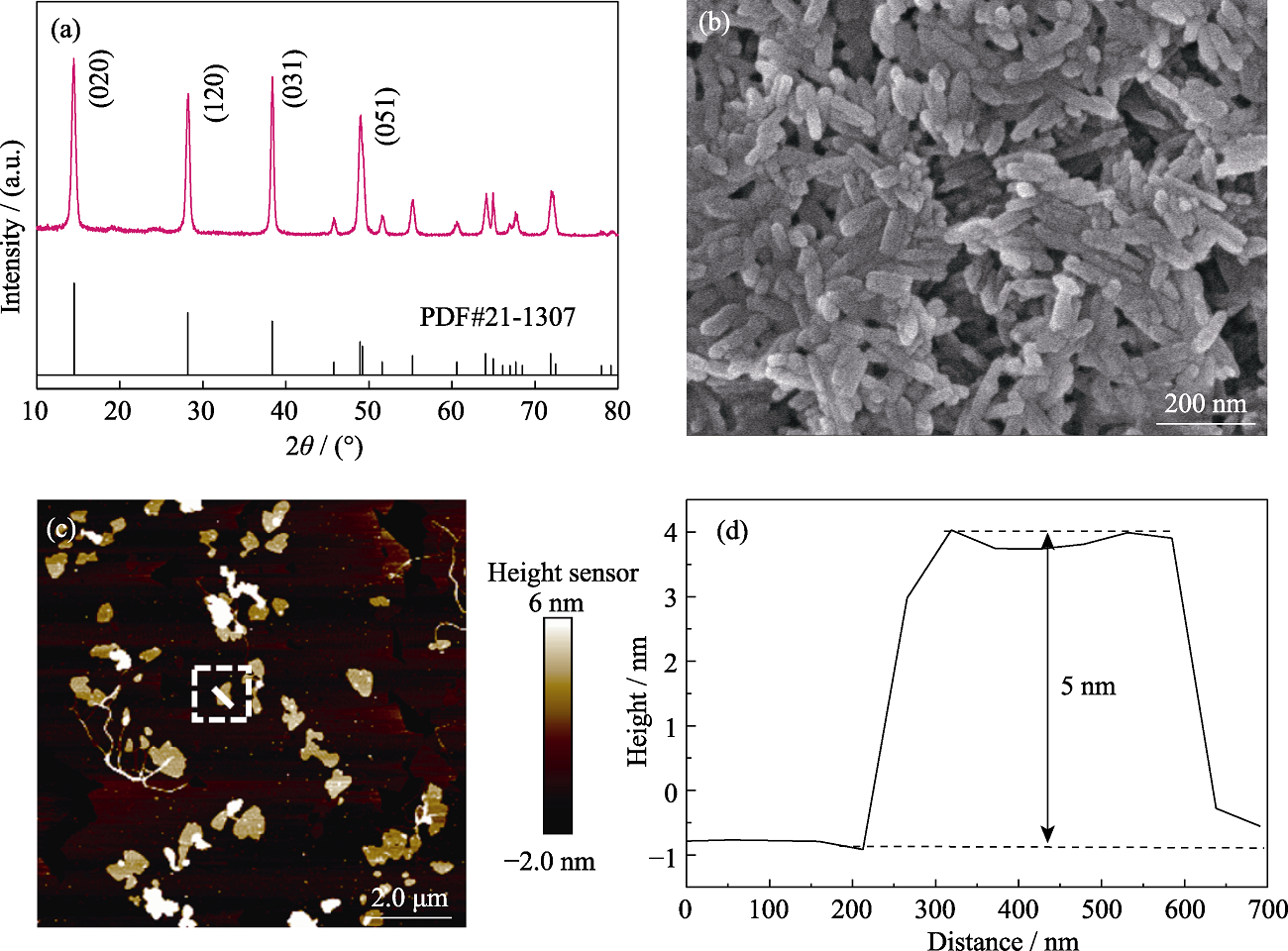

图1 勃姆石纳米片的(a)XRD图谱、(b) SEM照片、(c)AFM照片和(d)高度剖面图

Fig. 1 (a) XRD pattern, (b)SEM image, (c)AFM image, and (d) cross-sectional height profile of boehmite nanosheets

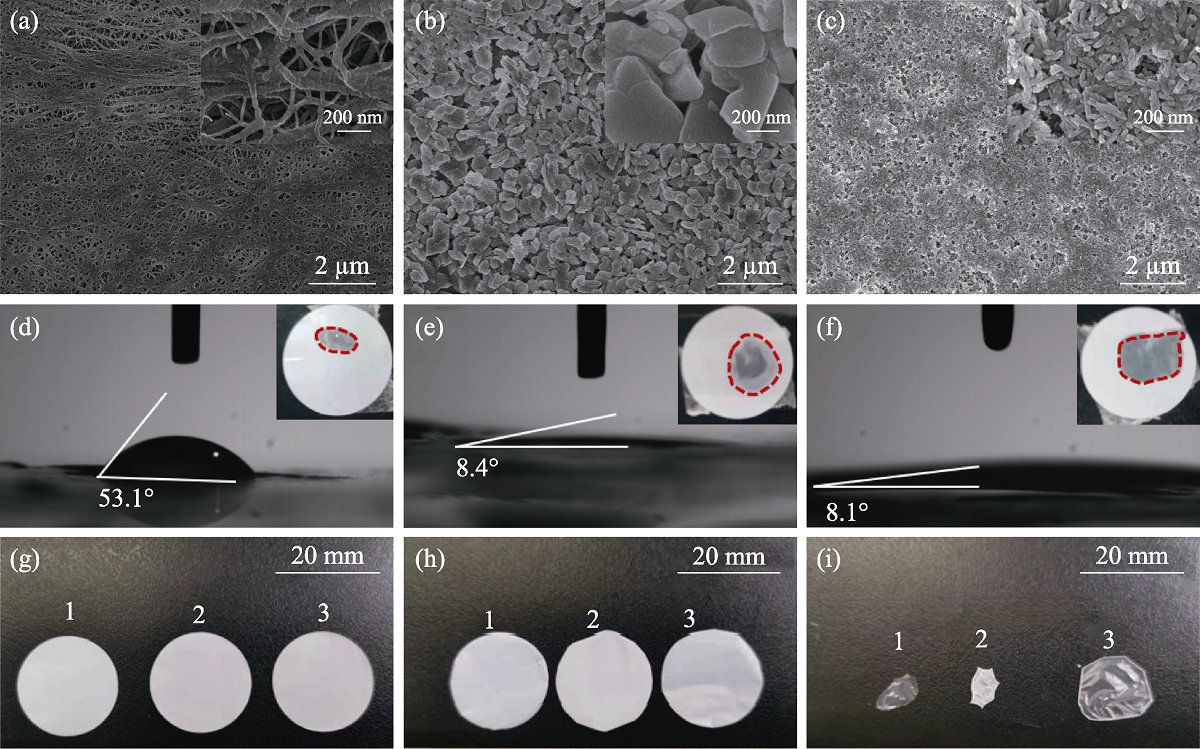

图2 PE、PE-AlOOHNP和PE-AlOOHNS的物理性质

Fig. 2 Physical properties of PE, PE-AlOOHNP and PE-AlOOHNS Surface SEM images of (a) PE, (b) PE-AlOOHNP and (c) PE-AlOOHNS; Electrolyte contact angles of (d) PE, (e) PE-AlOOHNP and (f) PE-AlOOHNS with insets showing pictures of the electrolyte-wetted separators; (g) Initial photo of the separators at 25 ℃; Photos of the separators after heat treatment at (h) 130 ℃ and (i) 150 ℃ for 30 min (1: PE, 2: PE-AlOOHNP, 3: PE-AlOOHNS)

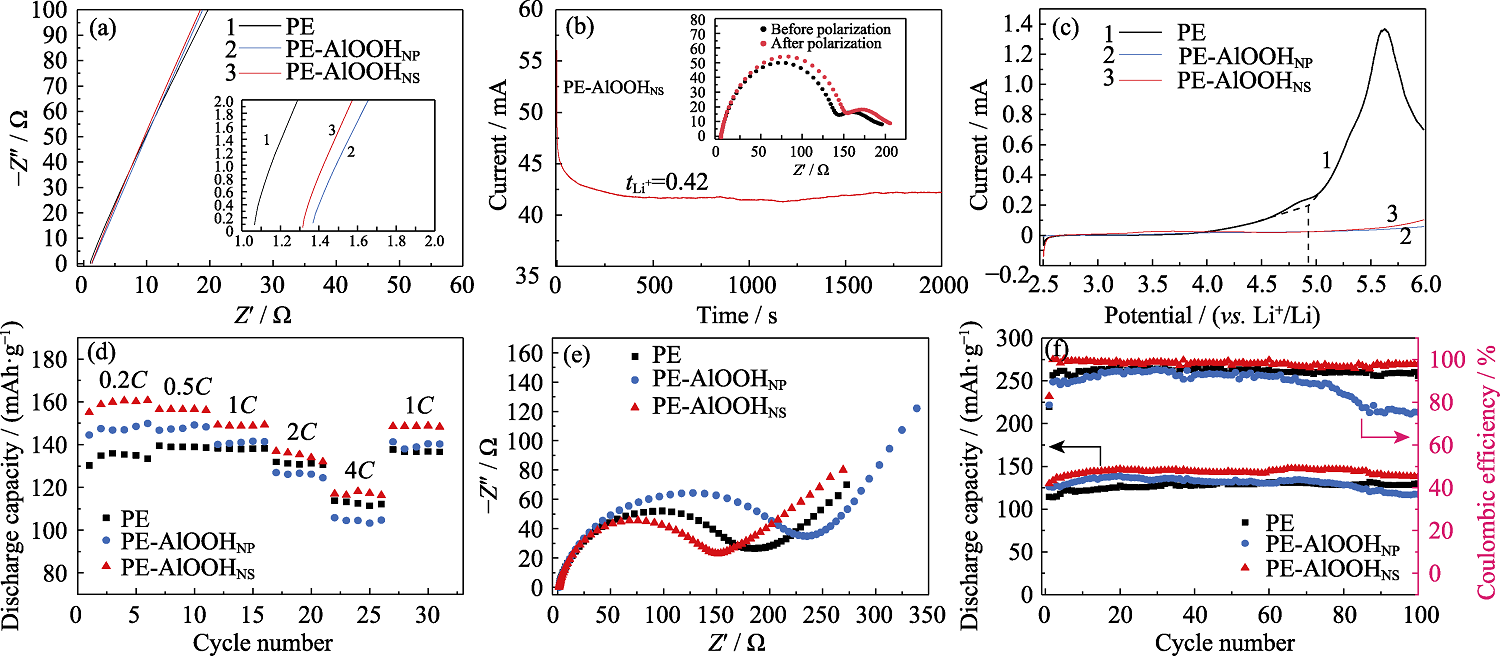

图3 (a)不同隔膜组装的 SS/SS电池的Nyquist图谱; (b)Li/PE-AlOOHNS/Li电池的计时电流曲线, 插图为极化前后的阻抗图; (c) 含有不同隔膜的SS/Li电池的LSV曲线; 不同隔膜组装的LFP/Li电池的(d)倍率性能, (e) EIS图谱和(f)循环性能曲线

Fig. 3 (a)Nyquist plots of SS/SS cells assembled with different separators; (b) Chronoamperometry profile of Li/PE-AlOOHNS/Li cell with inset showing EIS plots before and after polarization; (c) LSV curves of SS/Li cells assembled with different separators; (d) Rate capabilities, (e) EIS spectra and (f) cycle performances of LFP/Li cells with different separators Colorful figures are available on website

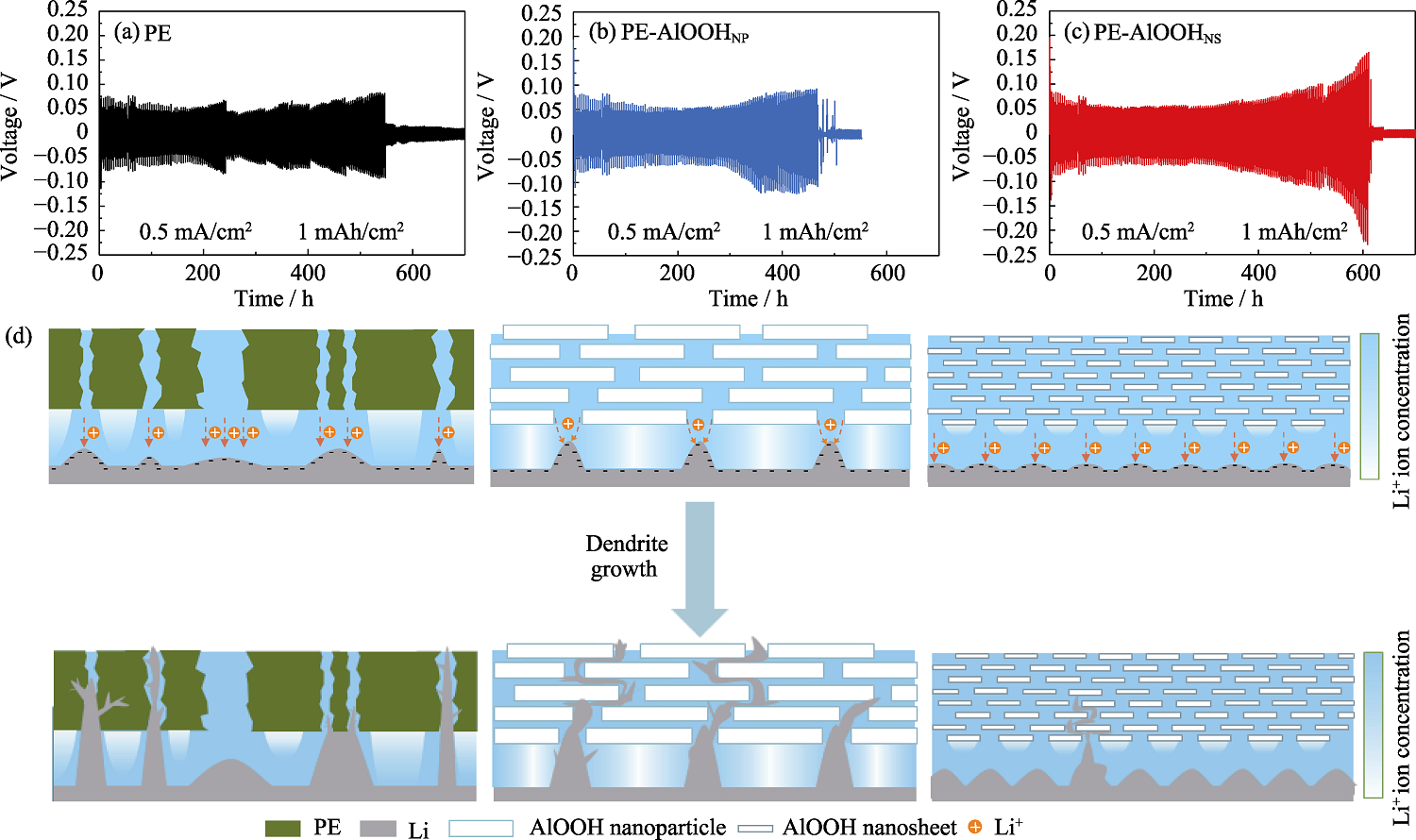

图4 (a) PE, (b) PE-AlOOHNP, (c) PE-AlOOHNS组装的Li/Li对称电池的电压曲线;(d)抑制锂枝晶机理示意图

Fig. 4 Voltage profiles of Li/Li symmetric cells assembled with (a) PE, (b) PE-AlOOHNP and (c) PE-AlOOHNS, and (d) schematic illustration of suppressing lithium dendrite formation

| Thickness/μm | Porosity/% | Electrolyte uptake /% | Bulk resistance /Ω | Ionic conductivity /(mS·cm-1) | Lithium-ion transference number | |

|---|---|---|---|---|---|---|

| PE | 9 | 39.6 | 84.6 | 1.06 | 0.43 | 0.15 |

| PE-AlOOHNP | 12 | 42.4 | 112.5 | 1.37 | 0.45 | 0.39 |

| PE-AlOOHNS | 12 | 46.6 | 138.9 | 1.31 | 0.47 | 0.42 |

表S1 不同隔膜的物理参数

Table S1 Physical parameters of different separators

| Thickness/μm | Porosity/% | Electrolyte uptake /% | Bulk resistance /Ω | Ionic conductivity /(mS·cm-1) | Lithium-ion transference number | |

|---|---|---|---|---|---|---|

| PE | 9 | 39.6 | 84.6 | 1.06 | 0.43 | 0.15 |

| PE-AlOOHNP | 12 | 42.4 | 112.5 | 1.37 | 0.45 | 0.39 |

| PE-AlOOHNS | 12 | 46.6 | 138.9 | 1.31 | 0.47 | 0.42 |

图S4 Li/PE-AlOOHNP/Li电池的计时电流曲线, 插图为极化前后的阻抗图谱

Fig. S4 Chronoamperometry profile of Li/PE-AlOOHNP/Li cell with inset showing the EIS plots before and after polarization

| [1] |

PENG L, WANG X, DAI J, et al. A reinforced ceramic-coated separator by overall-covered modification of electron-insulated polypyrrole for the safe performance of lithium-ion batteries. Materials Chemistry Frontiers, 2021, 5(4): 1884-1894.

DOI URL |

| [2] | LEE J, LEE C L, PARK K, et al. Synthesis of an Al2O3-coated polyimide nanofiber mat and its electrochemical characteristics as a separator for lithium ion batteries. Journal of Power Sources, 2014, 248: 1211-1217. |

| [3] |

YUAN B, WEN K, CHEN D, et al. Composite separators for robust high rate lithium ion batteries. Advanced Functional Materials, 2021, 31(32): 2101420.

DOI URL |

| [4] |

HASSOUN J, PANERO S, REALE P, et al. A new, safe, high-rate and high-energy polymer lithium-ion battery. Advanced Materials, 2009, 21(47): 4807-4810.

DOI URL |

| [5] |

DING Y, CANO Z P, YU A, et al. Automotive Li-ion batteries: current status and future perspectives. Electrochemical Energy Reviews, 2019, 2(1): 1-28.

DOI URL |

| [6] | HUANG X, HE R, LI M, et al. Functionalized separator for next-generation batteries. Materials Today, 2020, 41: 143-155. |

| [7] |

FRANCIS C F J, KYRATZIS I L, BEST A S. Lithium-ion battery separators for ionic-liquid electrolytes: a review. Advanced Materials, 2020, 32(18): 1904205.

DOI URL |

| [8] | ZHANG X, SUN Q, ZHEN C, et al. Recent progress in flame-retardant separators for safe lithium-ion batteries. Energy Storage Materials, 2021, 37: 628-647. |

| [9] |

ZHANG S S. A review on the separators of liquid electrolyte Li-ion batteries. Journal of Power Sources, 2007, 164(1): 351-364.

DOI URL |

| [10] |

ZHANG H, SHENG L, BAI Y, et al. Amino-functionalized Al2O3 particles coating separator with excellent lithium-ion transport properties for high-power density lithium-ion batteries. Advanced Engineering Materials, 2020, 22(11): 1901545.

DOI URL |

| [11] |

JIANG H, LIN X, WEI C, et al. Scalable synthesis of nano-sized Bi for separator modifying in 5V-class lithium metal batteries and potassium ion batteries anodes. Small, 2021, 18(4): 2104264.

DOI URL |

| [12] |

XIANG H, CHEN J, LI Z, et al. An inorganic membrane as a separator for lithium-ion battery. Journal of Power Sources, 2011, 196(20): 8651-8655.

DOI URL |

| [13] | GAO H. The low-crystallinity PVDF/PMMA/PEG/TiO2 type polymer diaphragm prepared by phase inversion method. International Journal of Electrochemical Science, 2018, 13: 10751-10765. |

| [14] | CHEN H, LIN Q, XU Q, et al. Plasma activation and atomic layer deposition of TiO2 on polypropylene membranes for improved performances of lithium-ion batteries. Journal of Membrane Science, 2014, 458: 217-224. |

| [15] |

LIANG J, CHEN Q, LIAO X, et al. A nano-shield design for separators to resist dendrite formation in lithium-metal batteries. Angewandte Chemie International Edition, 2020, 59(16): 6561-6566.

DOI URL |

| [16] |

JEONG H S, LEE S Y. Closely packed SiO2 nanoparticles/poly (vinylidene fluoride-hexafluoropropylene) layers-coated polyethylene separators for lithium-ion batteries. Journal of Power Sources, 2011, 196(16): 6716-6722.

DOI URL |

| [17] | KIM P S, LE MONG A, KIM D. Thermal, mechanical, and electrochemical stability enhancement of Al2O3 coated polypropylene/ polyethylene/polypropylene separator via poly(vinylidene fluoride)-poly(ethoxylated pentaerythritol tetraacrylate) semi-interpenetrating network binder. Journal of Membrane Science, 2020, 612: 118481. |

| [18] | ZHANG Z, LAI Y, ZHANG Z, et al. Al2O3-coated porous separator for enhanced electrochemical performance of lithium sulfur batteries. Electrochimica Acta, 2014, 129: 55-61. |

| [19] |

XIAO W, SONG J, HUANG L, et al. PVA-ZrO2 multilayer composite separator with enhanced electrolyte property and mechanical strength for lithium-ion batteries. Ceramics International, 2020, 46(18): 29212-29221.

DOI URL |

| [20] |

WANG Y, WANG Q, WEI X, et al. A novel three-dimensional boehmite nanowhiskers network-coated polyethylene separator for lithium-ion batteries. Ceramics International, 2021, 47(7): 10153-10162.

DOI URL |

| [21] | WANG Y, WANG Q, LAN Y, et al. Aqueous aluminide ceramic coating polyethylene separators for lithium-ion batteries. Solid State Ionics, 2020, 345: 115188. |

| [22] |

CHOI E S, LEE S Y. Particle size-dependent, tunable porous structure of a SiO2/poly (vinylidene fluoride-hexafluoropropylene)- coated poly (ethylene terephthalate) nonwoven composite separator for a lithium-ion battery. Journal of Materials Chemistry, 2011, 21(38): 14747-14754.

DOI URL |

| [23] | QI X, ZHANG Z, TU C, et al. Covalent grafting interface engineering to prepare highly efficient and stable polypropylene/ mesoporous SiO2 separator for Li-ion batteries. Applied Surface Science, 2021, 541: 148405. |

| [24] | ZHANG X, CHEN Y, YU B, et al. Lithiophilic 3D VN@N-rGO as a multifunctional interlayer for dendrite-free and ultrastable lithium-metal batteries. ACS Applied Materials & Interfaces, 2021, 13(17): 20125-20136. |

| [25] |

ZHANG S S, FAN X, WANG C. Preventing lithium dendrite- related electrical shorting in rechargeable batteries by coating separator with a Li-killing additive. Journal of Materials Chemistry A, 2018, 6(23): 10755-10760.

DOI URL |

| [26] |

WANG J, LIU Y, CAI Q, et al. Hierarchically porous silica membrane as separator for high-performance lithium-ion batteries. Advanced Materials, 2022, 34(3): 2107957.

DOI URL |

| [27] | ZHANG Y, QIU Z, WANG Z, et al. Functional polyethylene separator with impurity entrapment and faster Li+ ions transfer for superior lithium-ion batteries. Journal of Colloid and Interface Science, 2022, 607: 742-751. |

| [28] |

ZHANG X, HUI Z, KING S, et al. Tunable porous electrode architectures for enhanced Li-ion storage kinetics in thick electrodes. Nano Letters, 2021, 21(13): 5896-5904.

DOI URL |

| [29] | CHEN X, ZHANG R, ZHAO R, et al. A “dendrite-eating” separator for high-areal-capacity lithium-metal batteries. Energy Storage Materials, 2020, 31: 181-186. |

| [30] | QIU Z, YUAN S, WANG Z, et al. Construction of silica- oxygen-borate hybrid networks on Al2O3-coated polyethylene separators realizing multifunction for high-performance lithium ion batteries. Journal of Power Sources, 2020, 472: 228445. |

| [31] | YANG Y, ZHANG J. Layered nanocomposite separators enabling dendrite-free lithium metal anodes at ultrahigh current density and cycling capacity. Energy Storage Materials, 2021, 37: 135-142. |

| [1] | 谭博文, 耿双龙, 张锴, 郑百林. 硅电极组分梯度设计抑制力-化学耦合劣化[J]. 无机材料学报, 2025, 40(7): 772-780. |

| [2] | 刘鹏东, 王桢, 刘永锋, 温广武. 硅泥在锂离子电池中的应用研究进展[J]. 无机材料学报, 2024, 39(9): 992-1004. |

| [3] | 程节, 周月, 罗薪涛, 高美婷, 骆思妃, 蔡丹敏, 吴雪垠, 朱立才, 袁中直. 蛋黄壳结构FeF3·0.33H2O@N掺杂碳纳米笼正极材料的构筑及其电化学性能[J]. 无机材料学报, 2024, 39(3): 299-305. |

| [4] | 文志朋, 韦毅, 侯向华, 郭佳文, 黎渠, 朱满庆, 张家浩, 潘凯, 吴炼. 膨润土基功能材料在电化学储能中的研究进展[J]. 无机材料学报, 2024, 39(12): 1301-1315. |

| [5] | 胡梦菲, 黄丽萍, 李贺, 张国军, 吴厚政. 锂/钠离子电池硬碳负极材料的研究进展[J]. 无机材料学报, 2024, 39(1): 32-44. |

| [6] | 苏楠, 邱介山, 王治宇. 高容量氟掺杂碳包覆纳米硅负极材料: 气相氟化法制备及其储锂性能[J]. 无机材料学报, 2023, 38(8): 947-953. |

| [7] | 杨卓, 卢勇, 赵庆, 陈军. X射线衍射Rietveld精修及其在锂离子电池正极材料中的应用[J]. 无机材料学报, 2023, 38(6): 589-605. |

| [8] | 宿拿拿, 韩静茹, 郭印毫, 王晨宇, 石文华, 吴亮, 胡执一, 刘婧, 李昱, 苏宝连. 基于ZIF-8的三维网络硅碳复合材料锂离子电池性能研究[J]. 无机材料学报, 2022, 37(9): 1016-1022. |

| [9] | 王洋, 范广新, 刘培, 尹金佩, 刘宝忠, 朱林剑, 罗成果. 钾离子掺杂提高锂离子电池正极锰酸锂性能的微观机制[J]. 无机材料学报, 2022, 37(9): 1023-1029. |

| [10] | 朱河圳, 王选朋, 韩康, 杨晨, 万睿哲, 吴黎明, 麦立强. 超高镍LiNi0.91Co0.06Al0.03O2@Ca3(PO4)2正极材料的储锂稳定性的提升机制[J]. 无机材料学报, 2022, 37(9): 1030-1036. |

| [11] | 陈莹, 栾伟玲, 陈浩峰, 朱轩辰. 基于应力场的锂离子电池正极多尺度失效研究[J]. 无机材料学报, 2022, 37(8): 918-924. |

| [12] | 江依义, 沈旻, 宋半夏, 李南, 丁祥欢, 郭乐毅, 马国强. 双功能电解液添加剂对锂离子电池高温高电压性能的影响[J]. 无机材料学报, 2022, 37(7): 710-716. |

| [13] | 苏东良, 崔锦, 翟朋博, 郭向欣. 石榴石型Li6.4La3Zr1.4Ta0.6O12对Si/C负极表面固体电解质中间相的调控机制研究[J]. 无机材料学报, 2022, 37(7): 802-808. |

| [14] | 肖美霞, 李苗苗, 宋二红, 宋海洋, 李钊, 毕佳颖. 表面端基卤化Ti3C2 MXene应用于锂离子电池高容量电极材料的研究[J]. 无机材料学报, 2022, 37(6): 660-668. |

| [15] | 王禹桐, 张非凡, 许乃才, 王春霞, 崔立山, 黄国勇. 水系锂离子电池负极材料LiTi2(PO4)3的研究进展[J]. 无机材料学报, 2022, 37(5): 481-492. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||