无机材料学报 ›› 2023, Vol. 38 ›› Issue (6): 663-670.DOI: 10.15541/jim20220637 CSTR: 32189.14.10.15541/jim20220637

所属专题: 【能源环境】热电材料(202506)

汪波1( ), 余健1,2(

), 余健1,2( ), 李存成1,3, 聂晓蕾1, 朱婉婷1, 魏平1, 赵文俞1(

), 李存成1,3, 聂晓蕾1, 朱婉婷1, 魏平1, 赵文俞1( ), 张清杰1

), 张清杰1

收稿日期:2022-10-28

修回日期:2022-12-15

出版日期:2023-06-20

网络出版日期:2022-12-28

通讯作者:

余健, 讲师. E-mail: jianyujju@126.com;作者简介:汪波(1996-), 男, 硕士研究生. E-mail: bowang@whut.edu.cn

基金资助:

WANG Bo1( ), YU Jian1,2(

), YU Jian1,2( ), LI Cuncheng1,3, NIE Xiaolei1, ZHU Wanting1, WEI Ping1, ZHAO Wenyu1(

), LI Cuncheng1,3, NIE Xiaolei1, ZHU Wanting1, WEI Ping1, ZHAO Wenyu1( ), ZHANG Qingjie1

), ZHANG Qingjie1

Received:2022-10-28

Revised:2022-12-15

Published:2023-06-20

Online:2022-12-28

Contact:

YU Jian, lecturer. E-mail: jianyujju@126.com;About author:WANG Bo (1996-), male, Master candidate. E-mail: bowang@whut.edu.cn

Supported by:摘要:

将热电材料与磁卡材料复合, 发展基于热电制冷和磁制冷耦合增强的热电磁能源转换全固态制冷新技术, 有望实现从热电制冷向热电磁制冷的技术变革, 但目前热电磁复合材料在服役环境下的稳定性还有待研究。本研究采用放电等离子体烧结技术将Bi0.5Sb1.5Te3(BST)热电材料和Gd磁卡材料复合, 制备了一系列Gd/BST热电磁梯度复合材料, 系统研究了该复合材料在338 K、80%相对湿度(RH)的环境下老化12 d过程中的物相组成、显微结构、热电性能及制冷性能的演变特征。结果显示, Gd/BST热电磁梯度复合材料的物相组成和显微结构具有良好的服役稳定性, Gd/BST异质界面的Gd-Te扩散层化学成分和厚度(~4.5 µm)在老化过程中未发生明显变化。测试不同Gd浓度梯度方向热电性能和单臂器件制冷性能发现, 老化前后材料的ZT变化非常小, 单臂器件制冷温差在2.5 A阀值电流下稳定在6.5 K左右, 表明Gd/BST热电磁梯度复合材料具有良好的热电性能和制冷性能服役稳定性。

中图分类号:

汪波, 余健, 李存成, 聂晓蕾, 朱婉婷, 魏平, 赵文俞, 张清杰. Gd/Bi0.5Sb1.5Te3热电磁梯度复合材料的服役稳定性[J]. 无机材料学报, 2023, 38(6): 663-670.

WANG Bo, YU Jian, LI Cuncheng, NIE Xiaolei, ZHU Wanting, WEI Ping, ZHAO Wenyu, ZHANG Qingjie. Service Stability of Gd/Bi0.5Sb1.5Te3 Thermo-electro-magnetic Gradient Composites[J]. Journal of Inorganic Materials, 2023, 38(6): 663-670.

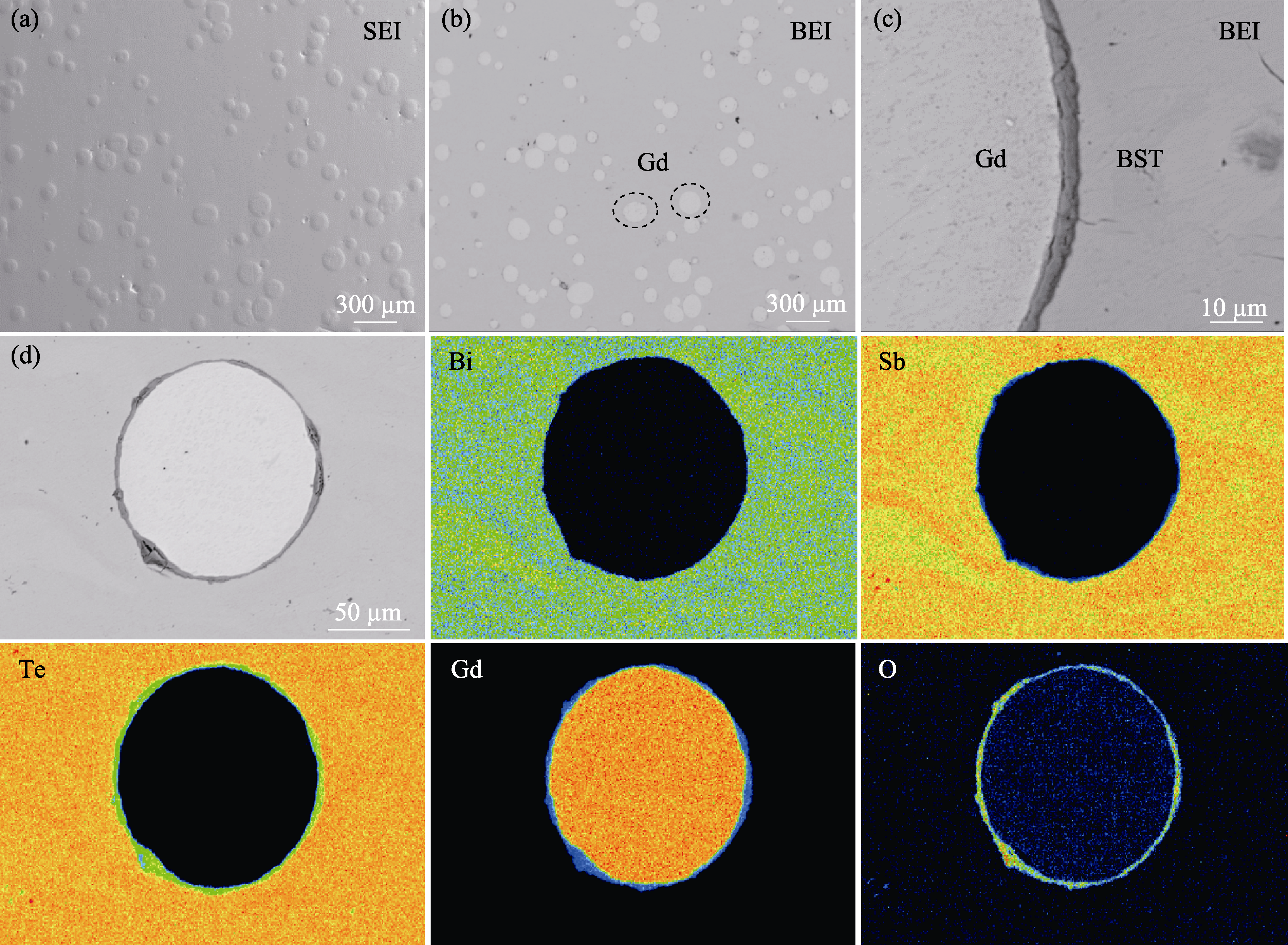

图4 老化处理12d后样品的(a)二次电子像、(b, c) 背散射电子像及(d)元素EPMA面扫图

Fig. 4 (a) Secondary electron image (SEI), (b, c) backscattered electron images (BEI) and (d) EPMA elemental mapping images of the samples after aging for 12 d

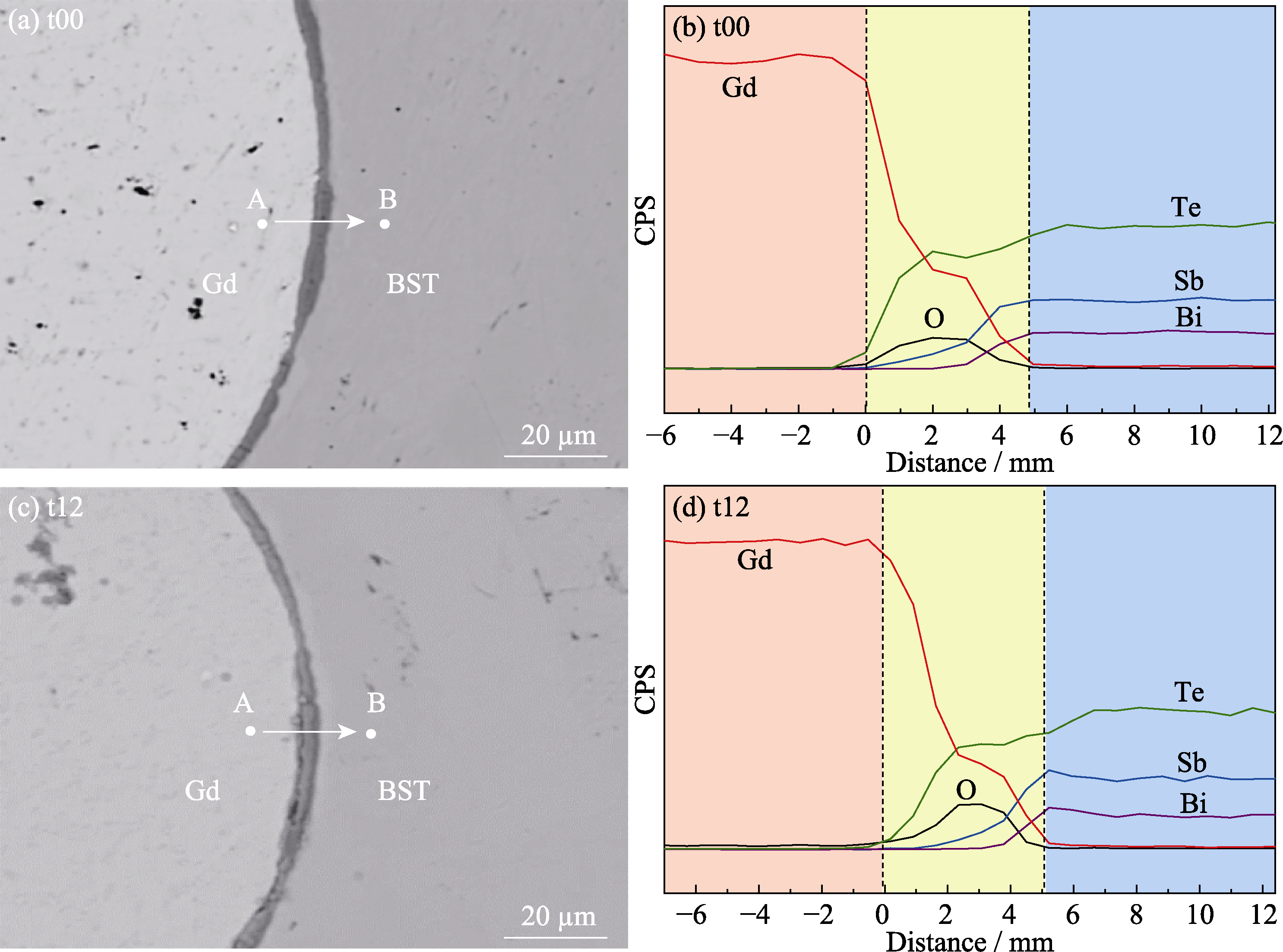

图6 (a, b)未老化和(c, d)老化12 d后样品中从Gd球到BST基体方向各元素的EPMA波谱线扫结果

Fig. 6 EPMA element line analysis from Gd ball to BST matrix for (a, b) as-prepared sample and (c, d) sample after aging for 12 d

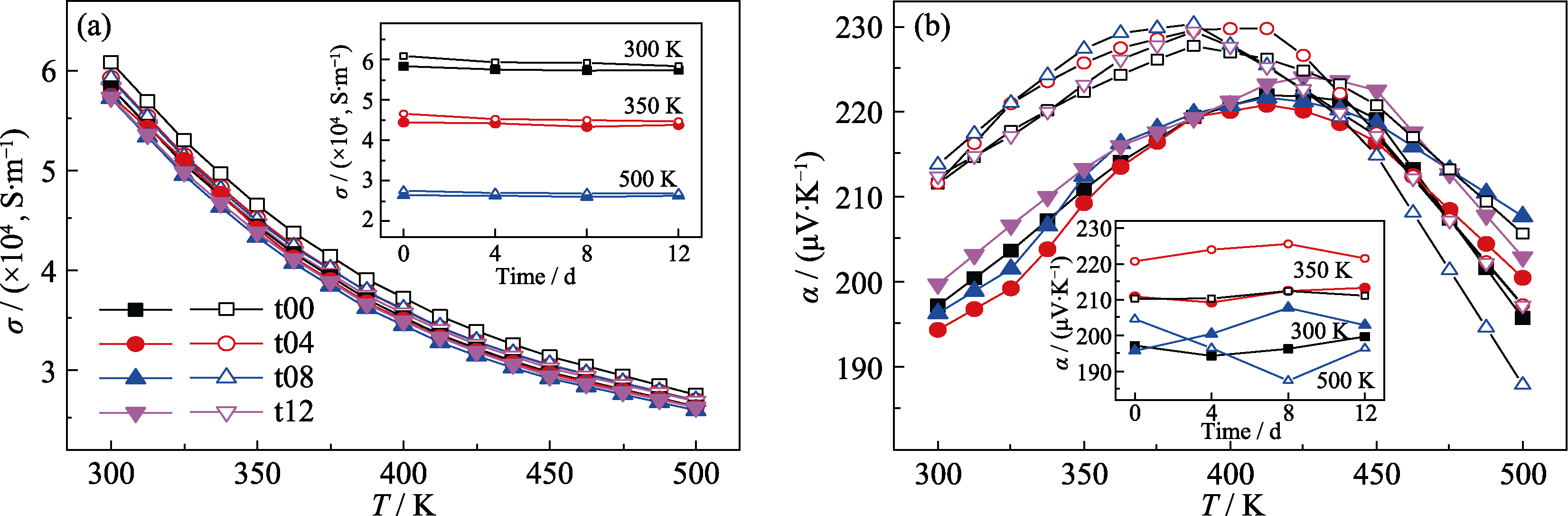

图7 Gd/BST梯度复合材料老化不同时间后正向(实心图标)和反向(空心图标)测试的(a)电导率和(b)Seebeck系数与温度的关系曲线, 插图为300、350和500 K条件下的电导率和Seebeck系数与老化时间之间的关系曲线

Fig. 7 Temperature dependence of (a) electrical conductivity and (b) Seebeck coefficient for forward (solid icon) and reverse (hollow icon) testing of Gd/BST gradient composites for different aging time with insets showing change of electrical conductivity and Seebeck coefficient with aging time at 300, 350 and 500 K

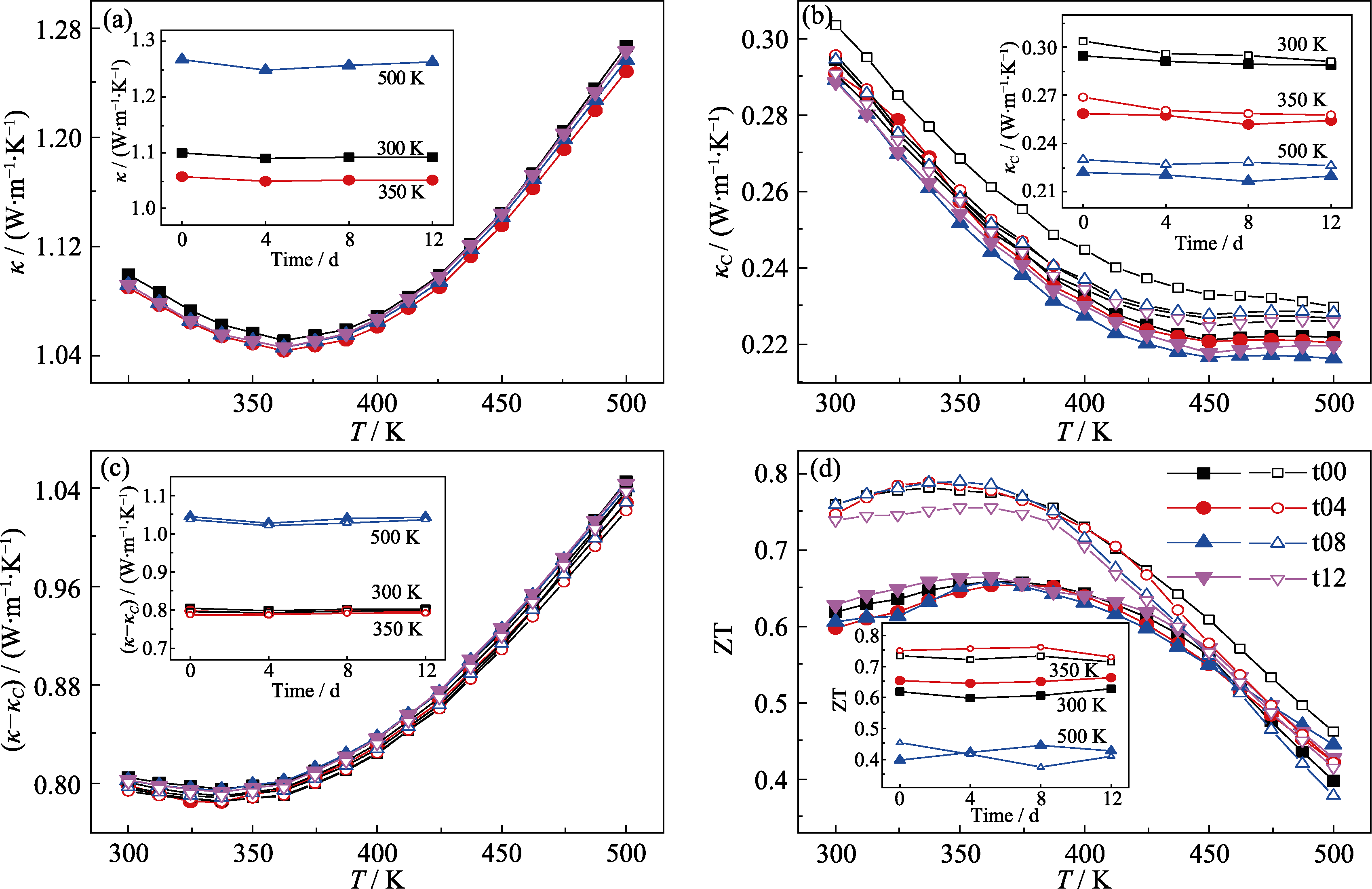

图8 Gd/BST梯度复合材料老化不同时间后正向(实心图标)和反向(空心图标)测试的(a)热导率、(b)载流子热导率、(c)晶格热导率和(d)ZT与与温度的关系曲线, 图中的插图为300、350和500 K时的热导率、载流子热导率、晶格热导率和ZT与老化时间之间的关系曲线

Fig. 8 Temperature dependence of (a) thermal conductivity, (b) carrier thermal conductivity, (c) lattice thermal conductivity, and (d) ZT for forward (solid icon) and reverse (hollow icon) testing of Gd/BST gradient composites with different aging time with insets showing changes of thermal conductivity, carrier thermal conductivity, lattice thermal conductivity, and ZT with aging time at 300, 350 and 500 K

图9 老化不同时间后Gd/BST梯度复合材料单臂器件在不同正向电流下的制冷端和散热端的温度变化

Fig. 9 Cooling performance of the Gd/BST gradient composite device with different aging time under different forward currents ΔT: Difference of working temperatures; ΔTC: Difference of cooling temperatures Colorful figures are available on website

| Sample | I = 1.5 A | I=2.0 A | I=2.5 A | I=3.0 A | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Iforward | Ireverse | Iforward | Ireverse | Iforward | Ireverse | Iforward | Ireverse | |||||||||

| ΔT | ΔTC | ΔT | ΔTC | ΔT | ΔTC | ΔT | ΔTC | ΔT | ΔTC | ΔT | ΔTC | ΔT | ΔTC | ΔT | ΔTC | |

| t00 | 14.6 | 5.4 | 15.8 | 5.5 | 18.7 | 6.1 | 21.1 | 6.3 | 24.1 | 6.6 | 27.3 | 7.0 | 28.4 | 6.1 | 33.3 | 7.0 |

| t04 | 15.6 | 5.4 | 16.6 | 5.7 | 20.1 | 6.3 | 22.2 | 6.2 | 24.6 | 6.8 | 28.3 | 6.7 | 28.8 | 6.7 | 34.9 | 6.5 |

| t08 | 14.4 | 5.2 | 15.5 | 5.4 | 19.3 | 6.1 | 21.0 | 6.3 | 24.1 | 6.4 | 27.0 | 6.9 | 29.2 | 6.2 | 33.2 | 7.0 |

| t12 | 15.3 | 5.4 | 15.9 | 5.6 | 19.1 | 6.2 | 21.2 | 6.2 | 23.2 | 6.5 | 26.5 | 6.5 | 27.0 | 6.3 | 31.6 | 6.6 |

表1 Gd/BST梯度复合材料单臂器件老化不同时间后的制冷性能/K

Table 1 Cooling performance of Gd/BST gradient composite device with different ageing time/K

| Sample | I = 1.5 A | I=2.0 A | I=2.5 A | I=3.0 A | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Iforward | Ireverse | Iforward | Ireverse | Iforward | Ireverse | Iforward | Ireverse | |||||||||

| ΔT | ΔTC | ΔT | ΔTC | ΔT | ΔTC | ΔT | ΔTC | ΔT | ΔTC | ΔT | ΔTC | ΔT | ΔTC | ΔT | ΔTC | |

| t00 | 14.6 | 5.4 | 15.8 | 5.5 | 18.7 | 6.1 | 21.1 | 6.3 | 24.1 | 6.6 | 27.3 | 7.0 | 28.4 | 6.1 | 33.3 | 7.0 |

| t04 | 15.6 | 5.4 | 16.6 | 5.7 | 20.1 | 6.3 | 22.2 | 6.2 | 24.6 | 6.8 | 28.3 | 6.7 | 28.8 | 6.7 | 34.9 | 6.5 |

| t08 | 14.4 | 5.2 | 15.5 | 5.4 | 19.3 | 6.1 | 21.0 | 6.3 | 24.1 | 6.4 | 27.0 | 6.9 | 29.2 | 6.2 | 33.2 | 7.0 |

| t12 | 15.3 | 5.4 | 15.9 | 5.6 | 19.1 | 6.2 | 21.2 | 6.2 | 23.2 | 6.5 | 26.5 | 6.5 | 27.0 | 6.3 | 31.6 | 6.6 |

| [1] |

HE W, ZHANG G, ZHANG X, et al. Recent development and application of thermoelectric generator and cooler. Applied Energy, 2015, 143: 1.

DOI URL |

| [2] |

LYUBINA J. Magnetocaloric materials for energy efficient cooling. Journal of Physics D: Applied Physics, 2017, 50(5):053002.

DOI URL |

| [3] |

PECHARSKY V K, GSCHNEIDNER K A. Advanced magnetocaloric materials: what does the future hold? International Journal of Refrigeration, 2006, 29(8):1239.

DOI URL |

| [4] |

RAM N R, PRAKASH M, NARESH U, et al. Review on magnetocaloric effect and materials. Journal of Superconductivity and Novel Magnetism, 2018, 31(7): 1971.

DOI |

| [5] |

YU J, Ma S, Xie X, et al. Unique surface structure resulting in the excellent long-term thermal stability of Fe4Sb12-based filled skutterudites. Journal of the European Ceramic Society, 2022, 42(3):1007.

DOI URL |

| [6] | TRITT T M. Overview of various strategies and promising new bulk materials for potential thermoelectric applications. MRS Online Proceedings Library, 2002, 691(1):11. |

| [7] |

ZHANG X, ZHAO L D. Thermoelectric materials: energy conversion between heat and electricity. Journal of Materiomics, 2015, 1(2):92.

DOI URL |

| [8] |

TWAHA S, ZHU J, YAN Y, et al. A comprehensive review of thermoelectric technology: materials, applications, modelling and performance improvement. Renewable and Sustainable Energy Reviews, 2016, 65: 698.

DOI URL |

| [9] |

SAJID M, HASSAN I, RAHMAN A. An overview of cooling of thermoelectric devices. Renewable and Sustainable Energy Reviews, 2017, 78: 15.

DOI URL |

| [10] |

KIM S I, LEE K H, MUN H, et al. Dense dislocation arrays embedded in grain boundaries for high-performance bulk thermoelectrics. Science, 2015, 348: 109.

DOI URL |

| [11] |

SILVA D J, BORDALO B D, PEREIRA A M, et al. Solid state magnetic refrigerator. Applied Energy, 2012, 93: 570.

DOI URL |

| [12] |

ROMERO GÓMEZ J, FERREIRO GARCIA R, DE MIGUEL CATOIRA A, et al. Magnetocaloric effect: a review of the thermodynamic cycles in magnetic refrigeration. Renewable and Sustainable Energy Reviews, 2013, 17: 74.

DOI URL |

| [13] |

GUTFLEISCH O, WILLARD M A, BRÜCK E, et al. Magnetic materials and devices for the 21st century: stronger, lighter, and more energy efficient. Advanced Materials, 2011, 23(7):821.

DOI URL |

| [14] |

DE VRIES W, VAN DER MEER T H. Application of Peltier thermal diodes in a magnetocaloric heat pump. Applied Thermal Engineering, 2017, 111: 377.

DOI URL |

| [15] |

TOMC U, TUŠEK J, KITANOVSKI A, et al. A new magnetocaloric refrigeration principle with solid-state thermoelectric thermal diodes. Applied Thermal Engineering, 2013, 58(1):1.

DOI URL |

| [16] |

MONFARED B. Simulation of solid-state magnetocaloric refrigeration systems with Peltier elements as thermal diodes. International Journal of Refrigeration, 2017, 74: 324.

DOI URL |

| [17] |

ZHAO W, LIU Z, SUN Z, et al. Superparamagnetic enhancement of thermoelectric performance. Nature, 2017, 549(7671):247.

DOI URL |

| [18] |

ZHAO W, LIU Z, WEI P, et al. Magnetoelectric interaction and transport behaviours in magnetic nanocomposite thermoelectric materials. Nature Nanotechnology, 2017, 12(1):55.

DOI PMID |

| [19] |

LAZARO F J, LOPEZ A, LARREA A, et al. Paramagnetic-superparamagnetic transition in molecular-sieve-supported antiferromagnetic particles. IEEE Transactions on Magnetics, 1998, 34(4):1030.

DOI URL |

| [20] |

HE D, MU X, ZHOU H, et al. Effects of Fe3O4 magnetic nanoparticles on the thermoelectric properties of heavy-fermion YbAl3 materials. Journal of Electronic Materials, 2018, 47(6):3338.

DOI URL |

| [21] | SUTJAHJA I M, AKBAR T, NUGROHO A. Lanthanide contraction effect in magnetic thermoelectric materials of rare earth-doped Bi1.5Pb0.5Ca2Co2O8. AIP Conference Proceedings, 2010: 71. |

| [22] |

WEI P, KE B, XING L, et al. Atomic-resolution interfacial structures and diffusion kinetics in Gd/Bi0.5Sb1.5Te3 magnetocaloric/thermoelectric composites. Materials Characterization, 2020, 163: 110240.

DOI URL |

| [23] | 柯波.p型碲化铋基热电/磁卡复合制冷材料异质界面与性能研究. 武汉: 武汉理工大学硕士学位论文, 2020. |

| [24] | DENG R, SU X, HAO S, et al. High thermoelectric performance in Bi0.46Sb1.54Te3 nanostructured with ZnTe. Energy & Environmental Science, 2018, 11(6):1520. |

| [25] |

KIM H S, GIBBS Z M, TANG Y, et al. Characterization of Lorenz number with Seebeck coefficient measurement. APL Materials, 2015, 3(4):041506.

DOI URL |

| [1] | 贺丹琪, 魏明旭, 刘蕤之, 汤志鑫, 翟鹏程, 赵文俞. 一步法制备重费米子YbAl3热电材料及其性能提升[J]. 无机材料学报, 2023, 38(5): 577-582. |

| [2] | 林思琪, 李艾燃, 付晨光, 李荣斌, 金敏. Zintl相Mg3X2(X=Sb, Bi)基晶体生长及热电性能研究进展[J]. 无机材料学报, 2023, 38(3): 270-279. |

| [3] | 鲁志强, 刘可可, 李强, 胡芹, 冯利萍, 张清杰, 吴劲松, 苏贤礼, 唐新峰. p型多晶Bi0.5Sb1.5Te3合金类施主效应与热电性能[J]. 无机材料学报, 2023, 38(11): 1331-1337. |

| [4] | 江润璐, 吴鑫, 郭昊骋, 郑琦, 王连军, 江莞. UiO-67基导电复合材料的制备及其热电性能研究[J]. 无机材料学报, 2023, 38(11): 1338-1344. |

| [5] | 程成, 李建波, 田震, 王鹏将, 康慧君, 王同敏. In2O3/InNbO4复合材料的热电性能研究[J]. 无机材料学报, 2022, 37(7): 724-730. |

| [6] | 刘丹, 赵亚欣, 郭锐, 刘艳涛, 张志东, 张增星, 薛晨阳. 退火条件对磁控溅射MgO-Ag3Sb-Sb2O4柔性薄膜热电性能的影响[J]. 无机材料学报, 2022, 37(12): 1302-1310. |

| [7] | 任培安, 汪聪, 訾鹏, 陶奇睿, 苏贤礼, 唐新峰. Te与In共掺杂对Cu2SnSe3热电性能的影响[J]. 无机材料学报, 2022, 37(10): 1079-1086. |

| [8] | 逯旭, 侯绩翀, 张强, 樊建锋, 陈少平, 王晓敏. Mg含量对Mg3(1+z)Sb2化合物热电传输性能的影响[J]. 无机材料学报, 2021, 36(8): 835-840. |

| [9] | 杨枭, 苏贤礼, 鄢永高, 唐新峰. (GeTe)nBi2Te3的结构与热电性能研究[J]. 无机材料学报, 2021, 36(1): 75-80. |

| [10] | 李周, 肖翀. 异层等价离子双掺杂策略优化BiCuSeO的热电性能[J]. 无机材料学报, 2019, 34(3): 294-300. |

| [11] | 胡慧珊, 杨君友, 辛集武, 李思慧, 姜庆辉. SnO的歧化反应对SnTe热电性能的优化[J]. 无机材料学报, 2019, 34(3): 315-320. |

| [12] | 黄志成, 姚瑶, 裴俊, 董金峰, 张波萍, 李敬锋, 尚鹏鹏. n型SnS热电材料的制备与性能研究[J]. 无机材料学报, 2019, 34(3): 321-327. |

| [13] | 檀小芳, 端思晨, 王泓翔, 吴庆松, 李苗苗, 刘国强, 徐静涛, 谈小建, 邵和助, 蒋俊. 多掺杂协同调控碲化锡热导率和功率因子提升热电性能[J]. 无机材料学报, 2019, 34(3): 335-340. |

| [14] | 刘虹霞, 李文, 张馨月, 李娟, 裴艳中. (Ag2Se)1-x(Bi2Se3)x的热电性能研究[J]. 无机材料学报, 2019, 34(3): 341-348. |

| [15] | 李松浩, 张 忻, 刘洪亮, 郑 亮, 张久兴. Ag掺杂SnSe化合物的制备及热电性能[J]. 无机材料学报, 2016, 31(7): 751-755. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||