无机材料学报 ›› 2021, Vol. 36 ›› Issue (9): 999-1005.DOI: 10.15541/jim20200576 CSTR: 32189.14.10.15541/jim20200576

王影1( ), 张文龙1, 邢彦锋1(

), 张文龙1, 邢彦锋1( ), 曹苏群2, 戴新义3, 李晶泽4(

), 曹苏群2, 戴新义3, 李晶泽4( )

)

收稿日期:2020-09-30

修回日期:2021-01-07

出版日期:2021-09-20

网络出版日期:2021-01-25

通讯作者:

邢彦锋, 教授. E-mail: smsmsues@163.com; 李晶泽, 教授. E-mail: lijingze@uestc.edu.cn

作者简介:王 影(1978-), 女, 讲师. E-mail: wangyingcae@sues.edu.cn

WANG Ying1( ), ZHANG Wenlong1, XING Yanfeng1(

), ZHANG Wenlong1, XING Yanfeng1( ), CAO suqun2, DAI Xinyi3, LI Jingze4(

), CAO suqun2, DAI Xinyi3, LI Jingze4( )

)

Received:2020-09-30

Revised:2021-01-07

Published:2021-09-20

Online:2021-01-25

Contact:

XING Yanfeng, professor. E-mail: smsmsues@163.com; LI Jingze, professor. E-mail: lijingze@uestc.edu.cn

About author:WANG Ying (1978-), female, lecturer. E-mail: wangyingcae@sues.edu.cn

Supported by:摘要:

长期以来, 表面包覆一直是改善锂离子电池电极材料电化学性能的有效手段。本研究采用磁控溅射法将非晶态磷酸锂包覆在Li4Ti5O12电极片表面, 修饰后电极表面光滑, 形成了均匀的非晶态磷酸锂包覆层。在0.01-3.00 V电压范围的充放电测试结果显示, 该包覆层可显著改善电极的倍率性能和循环性能。当充放电电流密度分别为35和1750 mA∙g-1时, 电池容量可以达到265和151 mAh∙g-1, 远高于未包覆电池的240和22 mAh∙g-1, 并以88 mA∙g-1的电流密度进一步充放电200个循环后, 仍保留了238 mAh∙g-1的高可逆容量。这是由于非晶态磷酸锂包覆层可稳定电解质界面, 保持粒子间电子通道的完整性, 并在电极表面形成交联离子导电网络, 使得改性电极的倍率性能和循环稳定性显著提高。

中图分类号:

王影, 张文龙, 邢彦锋, 曹苏群, 戴新义, 李晶泽. 非晶态磷酸锂包覆钛酸锂电极在0.01~3.00 V电压范围的性能研究[J]. 无机材料学报, 2021, 36(9): 999-1005.

WANG Ying, ZHANG Wenlong, XING Yanfeng, CAO suqun, DAI Xinyi, LI Jingze. Performance of Amorphous Lithium Phosphate Coated Lithium Titanate Electrodes in Extended Working Range of 0.01-3.00 V[J]. Journal of Inorganic Materials, 2021, 36(9): 999-1005.

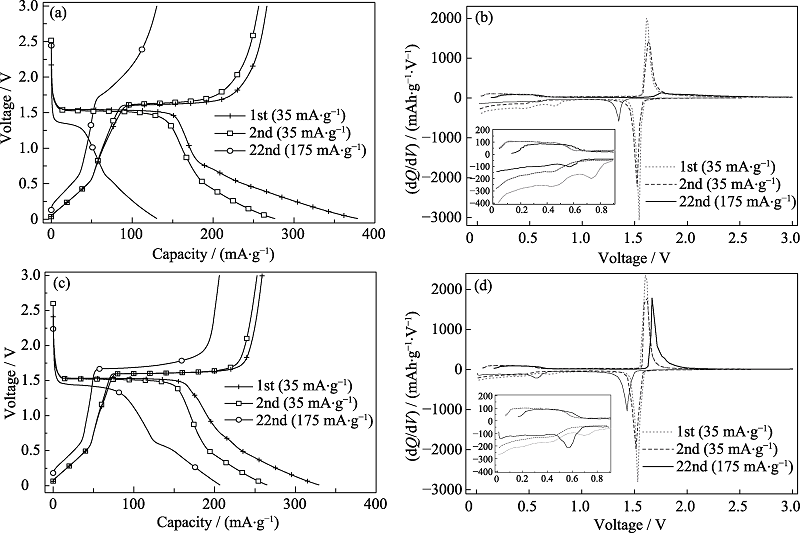

Fig. 3 (a, c) First two discharge-charge curves at 35 mA∙g-1, 22nd discharge-charge curve at 175 mA∙g-1 and (b, d) the corresponding differential capacity plots of (a, b) pristine electrode LTOLPO00 and (c, d) coated electrode LTOLPO20

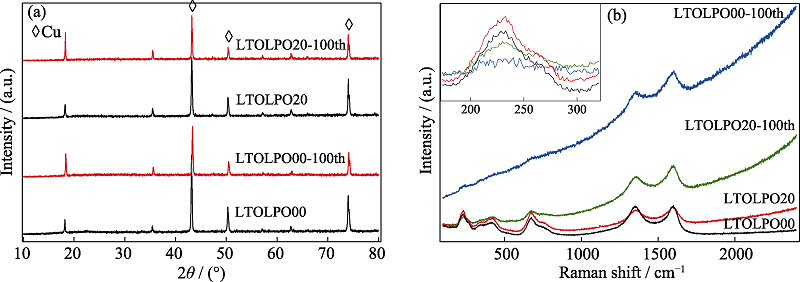

Fig. 5 XRD patterns and (b) Raman spectra of LTOLPO00 and LTOLPO20 before and after discharge-charge tests with inset in (b) showing magnification of Raman shift at 233 cm-1

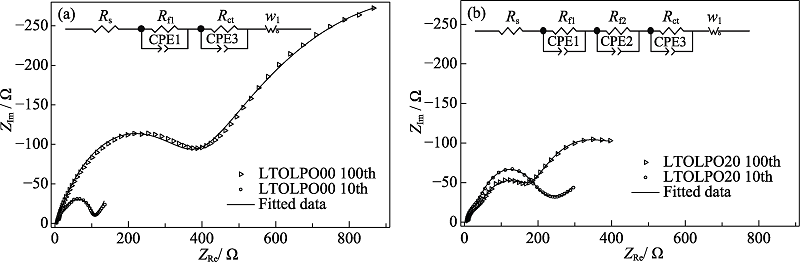

Fig. 6 EIS plots and the fitted data of (a) LTOLPO00 and (b) LTOLPO20 after discharge-charged for 10 and 100 cycles with insets showing the corresponding equivalent circuits

| Sample | Cycle No. | Rs/Ω | Rf1/Ω | Rf2/Ω | Rct/Ω |

|---|---|---|---|---|---|

| LTOLPO00 | 10 | 5 | 15 | - | 86 |

| LTOLPO20 | 10 | 5 | 21 | 180 | 54 |

| LTOLPO00 | 100 | 5 | 364 | - | 1019 |

| LTOLPO20 | 100 | 7 | 25 | 146 | 216 |

Table 1 Fitted data for EIS plots of LTOLPO00 and LTOLPO20 at given cycles

| Sample | Cycle No. | Rs/Ω | Rf1/Ω | Rf2/Ω | Rct/Ω |

|---|---|---|---|---|---|

| LTOLPO00 | 10 | 5 | 15 | - | 86 |

| LTOLPO20 | 10 | 5 | 21 | 180 | 54 |

| LTOLPO00 | 100 | 5 | 364 | - | 1019 |

| LTOLPO20 | 100 | 7 | 25 | 146 | 216 |

| [1] |

ZAGHIB K, SIMONEAU M, ARMAND M, et al. Electrochemical study of Li4Ti5O12 as negative electrode for Li-ion polymer rechargeable batteries. Journal of Power Sources, 1999, 81-82:300-305.

DOI URL |

| [2] |

CHOI S H, KWON T, COSKUN A, et al. Highly elastic binders integrating polyrotaxanes for silicon microparticle anodes in lithium ion batteries. Science, 2017, 357(6348):279-283.

DOI URL |

| [3] |

ZHONG Z Y, OUYANG C, SHI S Q, et al. Ab initio studies on Li4+xTi5O12 compounds as anode materials for lithium-ion batteries. ChemPhysChem, 2008, 9(14):2104-2108.

DOI URL |

| [4] |

STENINA I A, SOBOLEV A N, YAROSLAVTSEV S, et al. Influence of iron doping on structure and electrochemical properties of Li4Ti5O12. Electrochimica Acta, 2016, 219:524-530.

DOI URL |

| [5] |

BHATTI H S, ANJUM D H, ULLAH S, et al. Electrochemical characteristics and Li+ ion intercalation kinetics of dual-phase Li4Ti5O12/Li2TiO3 composite in the voltage range 0-3 V. The Journal of Physical Chemistry C, 2016, 120(18):9553-9561.

DOI URL |

| [6] |

WANG Y, REN Y, DAI X Y, et al. Electrochemical performance of ZnO-coated Li4Ti5O12 composite electrodes for lithium-ion batteries with the voltage ranging from 3 to 0.01 V. Royal Society Open Science, 2018, 5(10):180762.

DOI URL |

| [7] |

JIANG S, ZHAO B, CHEN Y, et al. Li4Ti5O12 electrodes operated under hurdle conditions and SiO2 incorporation effect. Journal of Power Sources, 2013, 238:356-365.

DOI URL |

| [8] |

JUNG Y S, CAVANAGH A S, RILEY L A, et al. Ultrathin direct atomic layer deposition on composite electrodes for highly durable and safe Li-ion batteries. Advanced Materials, 2010, 22(19):2172-2176.

DOI URL |

| [9] |

LI N W, YIN Y X, YANG C P, et al. An artificial solid electrolyte interphase layer for stable lithium metal anodes. Advanced Materials, 2016, 28(9):1853-1858.

DOI URL |

| [10] |

WANG Y, ZHOU A J, DAI X Y, et al. Solid-state synthesis of submicron-sized Li4Ti5O12/Li2TiO3 composites with rich grain boundaries for lithium ion batteries. Journal of Power Sources, 2014, 266:114-120.

DOI URL |

| [11] |

LU X, ZHAO L, HE X Q, et al. Lithium storage in Li4Ti5O12 spinel: the full static picture from electron microscopy. Advanced Materials, 2012, 24(24):3233-3238.

DOI URL |

| [12] |

TAN G Q, WU F, LI L, et al. Coralline glassy lithium phosphate- coated LiFePO4 cathodes with improved power capability for lithium ion batteries. Journal of Physical Chemistry C, 2013, 117(12):6013-6021.

DOI URL |

| [13] |

LEE S W, KIM M S, JEONG J H, et al. Li3PO4 surface coating on Ni-rich LiNi0.6Co0.2Mn0.2O2 by a citric acid assisted Sol-Gel method: improved thermal stability and high-voltage performance. Journal of Power Sources, 2017, 360:206-214.

DOI URL |

| [14] |

HIRAYAMA M, KIM K, TOUJIGAMORI T, et al. Epitaxial growth and electrochemical properties of Li4Ti5O12 thin-film lithium battery anodes. Dalton Transactions, 2011, 40(12):2882-2887.

DOI URL |

| [15] |

ZHAO L, HU Y S, LI H, et al. Porous Li4Ti5O12 coated with N-doped carbon from ionic liquids for Li-ion batteries. Advanced Materials, 2011, 23(11):1385-1388.

DOI URL |

| [16] | HALL D S, GAUTHIER R, ELDESOKY A, et al. New chemical insights into the beneficial role of Al2O3 cathode coatings in lithium-ion cells. ACS Applied Materials & Interfaces, 2019, 11(15):14095-14100. |

| [17] |

BORGHOLS W J H, WAGEMAKER M, LAFONT U, et al. Size effects in the Li4+xTi5O12 spinel. Journal of the American Chemical Society, 2009, 131(49):17786-17792.

DOI URL |

| [18] |

GANAPATHY S, WAGEMAKER M J A N. Nanosize storage properties in spinel Li4Ti5O12 explained by anisotropic surface lithium insertion. ACS Nano, 2012, 6(10):8702-8712.

DOI URL |

| [19] |

WAGEMAKER M, SIMON D R, KELDER E M, et al. A kinetic two-phase and equilibrium solid solution in spinel Li4+xTi5O12. Advanced Materials, 2010, 18(23):3169-3173.

DOI URL |

| [20] |

JUNG Y S, LU P, CAVANAGH A S, et al. Unexpected improved performance of ALD coated LiCoO2/graphite Li-ion batteries. Advanced Energy Materials, 2013, 3(2):213-219.

DOI URL |

| [21] |

MOGUSMILANKOVIC A, SANTIC A, KARABULUT M, et al. Study of electrical properties of MoO3-Fe2O3-P2O5 and SrO-Fe2O3-P2O5 glasses by impedance spectroscopy. II. Journal of Non-Crystalline Solids, 2003, 330(1/2/3):128-141.

DOI URL |

| [22] |

AHN D, XIAO X J E C. Extended lithium titanate cycling potential window with near zero capacity loss. Electrochemistry Communications, 2011, 13(8):796-799.

DOI URL |

| [23] |

GE H, LI N, LI D Y, et al. Study on the theoretical capacity of spinel lithium titanate induced by low-potential intercalation. Journal of Physical Chemistry C, 2009, 113(16):6324-6326.

DOI URL |

| [24] |

LEVI M D, SALITRA G, MARKOVSKY B, et al. Solid-state electrochemical kinetics of Li-ion intercalation into Li1-xCoO2: simultaneous application of electroanalytical techniques SSCV, PITT, and EIS. Journal of The Electrochemical Society, 1999, 146(4):1279-1289.

DOI URL |

| [1] | 谭博文, 耿双龙, 张锴, 郑百林. 硅电极组分梯度设计抑制力-化学耦合劣化[J]. 无机材料学报, 2025, 40(7): 772-780. |

| [2] | 杨光, 张楠, 陈舒锦, 王义, 谢安, 严育杰. 基于多孔ITO电极的WO3薄膜的制备及其电致变色性能[J]. 无机材料学报, 2025, 40(7): 781-789. |

| [3] | 渠吉发, 王旭, 张维轩, 张康喆, 熊永恒, 谭文轶. 掺杂改性NaYTiO4增强固体氧化物燃料电池阳极抗硫中毒性能[J]. 无机材料学报, 2025, 40(5): 489-496. |

| [4] | 刘鹏东, 王桢, 刘永锋, 温广武. 硅泥在锂离子电池中的应用研究进展[J]. 无机材料学报, 2024, 39(9): 992-1004. |

| [5] | 潘建隆, 马官军, 宋乐美, 郇宇, 魏涛. 燃料还原法原位制备高稳定性/催化活性SOFC钴基钙钛矿阳极[J]. 无机材料学报, 2024, 39(8): 911-919. |

| [6] | 程节, 周月, 罗薪涛, 高美婷, 骆思妃, 蔡丹敏, 吴雪垠, 朱立才, 袁中直. 蛋黄壳结构FeF3·0.33H2O@N掺杂碳纳米笼正极材料的构筑及其电化学性能[J]. 无机材料学报, 2024, 39(3): 299-305. |

| [7] | 肖文艳, 付艳, 杨书镔, 朱洁, 程照阳, 温小煦, 唐嘉繁, 于亮, 张骞. 自支撑非晶Ce-FeHPi/NF电极的电解海水性能研究[J]. 无机材料学报, 2024, 39(12): 1348-1356. |

| [8] | 胡梦菲, 黄丽萍, 李贺, 张国军, 吴厚政. 锂/钠离子电池硬碳负极材料的研究进展[J]. 无机材料学报, 2024, 39(1): 32-44. |

| [9] | 苏楠, 邱介山, 王治宇. 高容量氟掺杂碳包覆纳米硅负极材料: 气相氟化法制备及其储锂性能[J]. 无机材料学报, 2023, 38(8): 947-953. |

| [10] | 杨卓, 卢勇, 赵庆, 陈军. X射线衍射Rietveld精修及其在锂离子电池正极材料中的应用[J]. 无机材料学报, 2023, 38(6): 589-605. |

| [11] | 宿拿拿, 韩静茹, 郭印毫, 王晨宇, 石文华, 吴亮, 胡执一, 刘婧, 李昱, 苏宝连. 基于ZIF-8的三维网络硅碳复合材料锂离子电池性能研究[J]. 无机材料学报, 2022, 37(9): 1016-1022. |

| [12] | 王洋, 范广新, 刘培, 尹金佩, 刘宝忠, 朱林剑, 罗成果. 钾离子掺杂提高锂离子电池正极锰酸锂性能的微观机制[J]. 无机材料学报, 2022, 37(9): 1023-1029. |

| [13] | 朱河圳, 王选朋, 韩康, 杨晨, 万睿哲, 吴黎明, 麦立强. 超高镍LiNi0.91Co0.06Al0.03O2@Ca3(PO4)2正极材料的储锂稳定性的提升机制[J]. 无机材料学报, 2022, 37(9): 1030-1036. |

| [14] | 冯锟, 朱勇, 张凯强, 陈长, 刘宇, 高彦峰. 勃姆石纳米片增强锂离子电池隔膜性能研究[J]. 无机材料学报, 2022, 37(9): 1009-1015. |

| [15] | 陈莹, 栾伟玲, 陈浩峰, 朱轩辰. 基于应力场的锂离子电池正极多尺度失效研究[J]. 无机材料学报, 2022, 37(8): 918-924. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||