无机材料学报 ›› 2025, Vol. 40 ›› Issue (7): 781-789.DOI: 10.15541/jim20240531 CSTR: 32189.14.jim20240531

杨光( ), 张楠, 陈舒锦, 王义(

), 张楠, 陈舒锦, 王义( ), 谢安, 严育杰(

), 谢安, 严育杰( )

)

收稿日期:2024-12-23

修回日期:2025-01-23

出版日期:2025-07-20

网络出版日期:2025-03-19

通讯作者:

严育杰, 副教授. E-mail: yujieyan@xmut.edu.cn;作者简介:杨光(2000-), 男, 硕士研究生. E-mail: yangguang@stu.xmut.edu.cn

基金资助:

YANG Guang( ), ZHANG Nan, CHEN Shujin, WANG Yi(

), ZHANG Nan, CHEN Shujin, WANG Yi( ), XIE An, YAN Yujie(

), XIE An, YAN Yujie( )

)

Received:2024-12-23

Revised:2025-01-23

Published:2025-07-20

Online:2025-03-19

Contact:

YAN Yujie, associate professor. E-mail: yujieyan@xmut.edu.cn;About author:YANG Guang (2000-), male, Master candidate. E-mail: yangguang@stu.xmut.edu.cn

Supported by:摘要:

电致变色智能窗可通过调制电致变色材料的光学透过率来调控室外入射光进而实现节能建筑。由于磁控溅射技术具有大面积和均匀沉积的优势, 利用其所制备的非晶三氧化钨(Tungsten Oxide, WO3)最有实现商业化的潜力。然而, 磁控溅射制备的WO3薄膜本征致密原子结构导致较低的离子传输效率, 因此其电致变色性能远低于溶液法。本研究提出了基于埋层多孔电极制备微结构磁控溅射基WO3薄膜的方法, 从而提高材料的光学调制幅度和响应时间。实验结果表明, 与致密WO3薄膜相比, 通过该方法制备的多孔WO3薄膜展现出显著提升的电致变色性能。当多孔WO3薄膜厚度增加到300 nm时, 获得了高达79.08%的光学调制幅度, 2.6 s的着色时间和2.0 s的褪色时间, 以及高达52.5 cm2/C的着色效率。性能提升主要归因于多孔氧化铟锡(Indium Tin Oxide, ITO)电极和多孔WO3薄膜的协同作用。多孔ITO电极可增加与WO3组分的接触面积, 使更多电荷注入WO3薄膜中, 进而促进氧化还原反应过程。此外, 多孔WO3薄膜也增加了与电解液的接触面积, 随之增加了反应活性位点以及缩短了离子扩散路径, 进而加速了离子扩散和迁移过程, 实现了高效的氧化还原反应和快速的离子传输。本工作为制备高性能微纳结构磁控溅射电致变色薄膜提供了一种有效的方法。

中图分类号:

杨光, 张楠, 陈舒锦, 王义, 谢安, 严育杰. 基于多孔ITO电极的WO3薄膜的制备及其电致变色性能[J]. 无机材料学报, 2025, 40(7): 781-789.

YANG Guang, ZHANG Nan, CHEN Shujin, WANG Yi, XIE An, YAN Yujie. WO3 Films Based on Porous ITO Electrodes: Preparation and Electrochromic Property[J]. Journal of Inorganic Materials, 2025, 40(7): 781-789.

图2 多孔ITO薄膜与多孔和致密WO3薄膜的SEM照片

Fig. 2 SEM images of the porous ITO film and porous and dense WO3 film (a) SEM image of porous ITO film; (b, c) SEM-EDS images of In and Sn elements in ITO film; (d) SEM image of porous WO3 film; (e, f) SEM-EDS images of W and O elements in WO3 film; (g) SEM image of porous WO3 film; (h) Cross-sectional SEM image of FTO/ITO/WO3; (i) SEM image of dense WO3 film

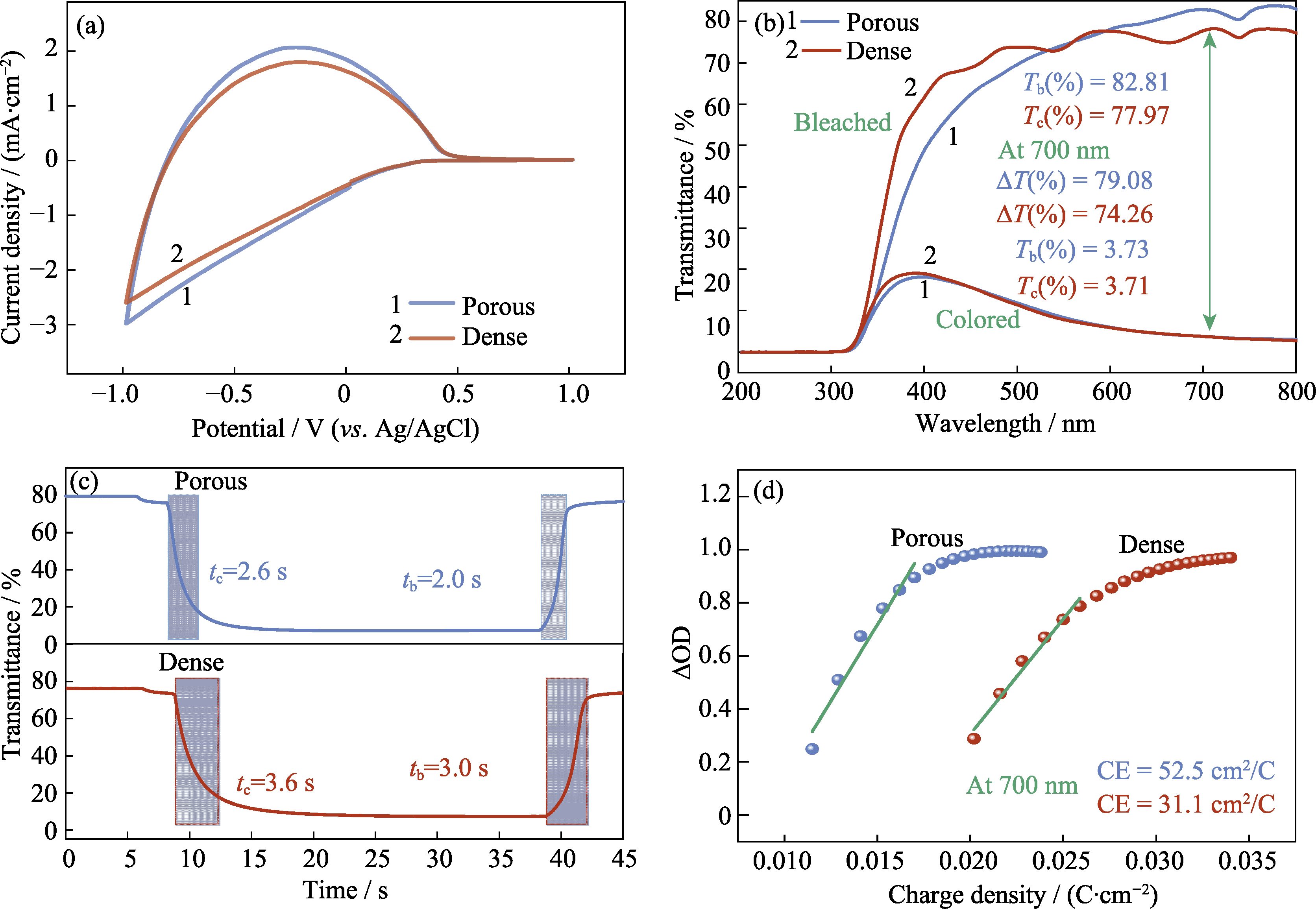

图3 多孔与致密WO3薄膜的电化学和电致变色性能

Fig. 3 Electrochemical and electrochromic properties of the porous and dense WO3 films (a) CV curves at 50 mV/s; (b) Transmittance spectra at the colored and bleached states; (c) In-situ transmittance spectra at 700 nm; (d) Optical density (ΔOD) variations with respect to the charge density at 700 nm

图4 不同厚度多孔WO3薄膜的电化学和电致变色性能

Fig. 4 Electrochemical and electrochromic properties of the porous WO3 films with different thicknesses (a) CV curves at 50 mV/s; (b) Transmittance spectra at the colored and bleached states; (c) In-situ transmittance spectra at 700 nm; (d) ΔOD variations with respect to the charge density at 700 nm; (e) Digital photos of the coloring and bleaching states. Colorful figures are available on website

图5 不同直径PS微球制备的多孔WO3薄膜的电化学和电致变色性能

Fig. 5 Electrochemical and electrochromic properties of the porous WO3 films prepared from PS microspheres with different diameters (a) CV curves at 50 mV/s; (b) Transmittance spectra at the colored and bleached states; (c) In-situ transmittance spectra at 700 nm; (d) ΔOD variations with respect to the charge density at 700 nm. Colorful figures are available on website

图6 多孔与致密WO3薄膜的离子与电荷传输示意图以及EIS曲线

Fig. 6 Schematic diagrams of ion and charge transport in dense bulk and porous WO3 films and related EIS curves (a) Dense bulk WO3 film; (b) Porous WO3 film; (c) EIS curves of dense bulk and porous WO3 films. Colorful figures are available on website

| [1] | LI Y, SUN P Y, CHEN J, et al. Colorful electrochromic displays with high visual quality based on porous metamaterials. Advanced Materials, 2023, 35(23): 2300116. |

| [2] | BERA M K, MOHANTY S, KASHYAP S S, et al. Electrochromic coordination nanosheets: achievements and future perspective. Coordination Chemistry Reviews, 2022, 454: 214353. |

| [3] | AMATE R U, MORANKAR P J, TELI A M, et al. Versatile electrochromic energy storage smart window utilizing surfactant- assisted niobium oxide thin films. Chemical Engineering Journal, 2024, 484: 149556. |

| [4] | LIU H H, ZHANG Y M, LEI P Y, et al. Selective electrochromic regulation for near-infrared and visible light via porous tungsten oxide films with core/shell architecture. ACS Applied Materials & Interfaces, 2023, 15(19): 23412. |

| [5] |

MENG Q C, CAO S, GUO J Q, et al. Sol-Gel-based porous Ti-doped tungsten oxide films for high-performance dual-band electrochromic smart windows. Journal of Energy Chemistry, 2023, 77: 137.

DOI |

| [6] | ZHANG S L, PENG Y T, ZHAO J, et al. Amorphous and porous tungsten oxide films for fast-switching dual-band electrochromic smart windows. Advanced Optical Materials, 2023, 11(1): 2202115. |

| [7] | ZHOU Z, CHEN Z, MA D, et al. Porous WO3·2H2O film with large optical modulation and high coloration efficiency for electrochromic smart window. Solar Energy Materials and Solar Cells, 2023, 253: 112226. |

| [8] |

MIAO H Y, CHEN L, XING F F, et al. Viologen-based solution-processable ionic porous polymers for electrochromic applications. Chemical Science, 2024, 15(20): 7576.

DOI PMID |

| [9] | ZHAO Y M, ZHANG X, CHEN X, et al. Preparation of WO3 films with controllable crystallinity for improved near-infrared electrochromic performances. ACS Sustainable Chemistry & Engineering, 2020, 8(31): 11658. |

| [10] | WANG Y X, ZENG J M, ZHOU Z H, et al. Growth of a high-performance WO3 nanofilm directly on a polydopamine- modified ITO electrode for electrochromism and power storage applications. Applied Surface Science, 2022, 573: 151603. |

| [11] | LOULOUDAKIS D, MOURATIS K, KOUDOUMAS E, et al. Electrochromic response and porous structure of WO3 cathode layers. Electrochimica Acta, 2021, 376: 138049. |

| [12] | ZHOU K L, WANG H, ZHANG Q Q, et al. Dynamic process of ions transport and cyclic stability of WO3 electrochromic film. Journal of Inorganic Materials, 2021, 36(2): 152. |

| [13] | HAN Z, TONG M, ZHANG C, et al. Unlocking dual-band electrochromism with stacked structure of amorphous tungsten oxide and Prussian blue. Solar Energy Materials and Solar Cells, 2024, 273: 112939. |

| [14] | NIU H B, HUANG J H, LI Q W, et al. Directly hydrothermal growth and electrochromic properties of porous NiMoO4 nanosheet films. Journal of Inorganic Materials, 2023, 38(12): 1427. |

| [15] | LIU H Y, WANG M Y, DIAO X G, et al. In situ synthesis and structural morphology analysis of 3D porous hierarchical V2O5 films for transmissive-to-black all-solid-state electrochromic devices. Chemical Engineering Journal, 2024, 500: 156657. |

| [16] | SUN X H, WU W, LIU N N, et al. Controlled assembly and synthesis of oxygen-deficient W18O49 films based on solvent molecular strategy for electrochromic energy storage smart windows. Chemical Engineering Journal, 2024, 499: 156109. |

| [17] | SAHU D R, HUANG C Y, WANG S C, et al. Effects of a polystyrene intermediate layer for improved electrochromic properties of nano porous WO3 electrochromic films. Advanced Materials, 2022, 3(14): 6000. |

| [18] | JEONG S J, KIM K H, BAI S, et al. Porous fluorine-doped tin oxide-anchored vanadium oxide films for multi-functional highly capacitive electrochromic layers. Journal of Alloys and Compounds, 2022, 923: 166329. |

| [19] | TONG X R, WANG J H, ZHANG P, et al. Insight into the structure-activity relationship in electrochromism of WO3 with rational internal cavities for broadband tunable smart windows. Chemical Engineering Journal, 2023, 470: 144130. |

| [20] | KHAN A, FACEIRA B, BARDET L, et al. Silver nanowire-based transparent electrodes for V2O5 thin films with electrochromic properties. ACS Applied Mater & Interfaces, 2024, 16(8): 10439. |

| [21] | LI J, LIU W, WEI Y, et al. SiO2 : a novel electrolyte for high-performance all-solid-state electrochromic devices. ACS Sustainable Chemistry & Engineering, 2023, 11(2): 824. |

| [22] | XIE H L, WANG Y X, LIU H T, et al. Electrochromic electrode with high optical contrast and long cyclic life using nest-like porous doped-Sm WO3 films. Ceramics International, 2023, 49(5): 8223. |

| [23] | WANG L K, LIU Y, HAN G R, et al. Dual-band electrochromic film based on mesoporous h-WO3/o-WO3·H2O/r-TiO2 for high performance smart windows. Solar Energy Materials and Solar Cells, 2023, 250: 112053. |

| [24] | DAI B H, WU C Z, XIE Y, et al. Boosting the electrochromic performance of TiO2 nanowire film via successively evolving surface structure. Science China Chemical, 2021, 64(5): 745. |

| [25] | SONG Y L, ZHANG Q Y, YAO A H. Template-free electrodeposition and electrochromic performance of porous WO3·2H2O thin film. Chinese Journal of Inorganic Chemistry, 2023, 39(1): 127. |

| [26] | SHI Y D, SUN M J, ZHANG Y, et al. Rational design of oxygen deficiency-controlled tungsten oxide electrochromic films with an exceptional memory effect. ACS Applied Materials & Interfaces, 2020, 12(29): 32658. |

| [27] | BIAN C C, WANG J H, LIU H H, et al. Complementary multicolor electrochromic devices with excellent stability based on porous tin oxide nanosheet scaffold. Nano Research, 2024, 17(4): 3035. |

| [28] | CHANG C M, CHIANG Y C, CHENG M H, et al. Fabrication of WO3 electrochromic devices using electro-exploding wire techniques and spray coating. Solar Energy Materials and Solar Cells, 2021, 223: 110960. |

| [29] | DADKHAH M, NINE M J, PURASINHALA K, et al. Nanostructure-dependent colouration efficiency of electrochromic coatings using 0D, 1D, and 2D WO3 for smart windows. (2024-10-05). https://doi.org/10.1016/j.nanoms.2024.09.003. |

| [30] | LI Z J, WANG M H, WEI L Y, et al. Preparation of porous WO3 film and its electrochromic properties. Journal of Functional Materials, 2023, 54(9): 9172. |

| [31] | SHI Y D, MA K, FAN M X, et al. Designed growth of hollow WO3/PEDOT bilayer hybrid nanosphere arrays film with superior electrochromic and capacitive performance. Acta Materiae Compositae Sinica, 2024, 41(6): 3060. |

| [32] | WANG X R, ZHENG Y, CHEN L R, et al. Multicolor V2O5/TiO2 electrochromic films with fast switching and long lifespan for camouflage and information display. Science China Mater, 2024, 67(9): 2807. |

| [33] | GANESHA M K, MONDAL I, SINGH A K, et al. Fabrication of large-area, affordable dual-function electrochromic smart windows by using a hybrid electrode coated with an oxygen-deficient tungsten oxide ultrathin porous film. ACS Applied Materials & Interfaces, 2023, 15(15): 19111. |

| [1] | 葛泽生, 刘苗, 汤哲, 周岩, 万舜, 宗鹏安. 柔性Cu0.005Bi0.5Sb1.495Te3薄膜的磁控溅射制备与热电性能研究[J]. 无机材料学报, 2025, 40(11): 1237-1244. |

| [2] | 宛心怡, 王文奇, 李加诚, 赵俊亮, 马董云, 王金敏. 基于WO3·xH2O与可逆金属电沉积的无色/黑色转换电致变色器件[J]. 无机材料学报, 2025, 40(10): 1163-1174. |

| [3] | 甄明硕, 刘晓然, 范向前, 张文平, 严东东, 刘磊, 李晨. 电致变色型智能可视化湿度系统[J]. 无机材料学报, 2024, 39(4): 432-440. |

| [4] | 冯星哲, 马董云, 王金敏. 多孔NiMn-LDH纳米片薄膜的溶剂热生长及其电致变色性能[J]. 无机材料学报, 2024, 39(12): 1391-1396. |

| [5] | 牛海滨, 黄佳慧, 李倩文, 马董云, 王金敏. 多孔NiMoO4纳米片薄膜的直接水热生长及其电致变色性能[J]. 无机材料学报, 2023, 38(12): 1427-1433. |

| [6] | 孙佳伟, 宛心怡, 杨婷, 马董云, 王金敏. Ti2Nb10O29薄膜的制备及其电致变色性能[J]. 无机材料学报, 2023, 38(12): 1434-1440. |

| [7] | 陈长, 赵若伊, 韩少杰, 王焕燃, 杨群, 高彦峰. 纳米晶液相镀膜制备WO3电致变色薄膜研究和性能优化[J]. 无机材料学报, 2023, 38(11): 1355-1363. |

| [8] | 张家强, 邹馨蕾, 王能泽, 贾春阳. 两步电沉积法制备Zn-Fe PBA薄膜及其在电致变色器件中的性能研究[J]. 无机材料学报, 2022, 37(9): 961-968. |

| [9] | 张笑宇, 刘永盛, 李然, 李耀刚, 张青红, 侯成义, 李克睿, 王宏志. 基于Cu3(HHTP)2薄膜的离子液体电致变色电极[J]. 无机材料学报, 2022, 37(8): 883-890. |

| [10] | 黄郅航, 滕官宏伟, 铁鹏, 范德松. 钙钛矿陶瓷薄膜的电致变色特性[J]. 无机材料学报, 2022, 37(6): 611-616. |

| [11] | 王影, 张文龙, 邢彦锋, 曹苏群, 戴新义, 李晶泽. 非晶态磷酸锂包覆钛酸锂电极在0.01~3.00 V电压范围的性能研究[J]. 无机材料学报, 2021, 36(9): 999-1005. |

| [12] | 王金敏, 后丽君, 马董云. 氧化钼电致变色材料与器件[J]. 无机材料学报, 2021, 36(5): 461-470. |

| [13] | 张翔, 李文杰, 王乐滨, 陈曦, 赵九蓬, 李垚. 无机电致变色材料反射特性研究进展[J]. 无机材料学报, 2021, 36(5): 451-460. |

| [14] | 武琦, 丛杉, 赵志刚. 多彩氧化钨薄膜的红外电致变色性能研究[J]. 无机材料学报, 2021, 36(5): 485-491. |

| [15] | 王天悦, 王梦颖, 黄庆姣, 杨佳明, 王顺花, 刁训刚. 溶胶-凝胶旋涂法制备电致变色智能窗用钛酸锂薄膜[J]. 无机材料学报, 2021, 36(5): 471-478. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||