Journal of Inorganic Materials ›› 2019, Vol. 34 ›› Issue (1): 49-59.DOI: 10.15541/jim20180243

Special Issue: MAX相和MXene材料; 光伏材料

• REVIEW • Previous Articles Next Articles

WANG Xiao, WANG Ran-Ran, SHI Liang-Jing, SUN Jing

Received:2018-05-25

Revised:2018-07-24

Published:2019-01-21

Online:2018-12-17

About author:WANG Xiao. E-mail: wangxiao@mail.sic.ac.cn

CLC Number:

WANG Xiao, WANG Ran-Ran, SHI Liang-Jing, SUN Jing. Synthesis, Optimization of Cu Nanowires and Application of Its Transparent Electrodes[J]. Journal of Inorganic Materials, 2019, 34(1): 49-59.

| Solvent | Reducing agent | Capping agent | Cu precursor | Average diameter/nm | Average length | Ref. |

|---|---|---|---|---|---|---|

| DI water | H3PO3 | Sodium dodecyl benzene sulfonate (SDBS) | CuSO4·5H2O, | ~85 | Tens of micrometers | [17] |

| DI water | Hydrazine hydrate | Ethylenediamine | Cu(NO3)2 | 35-70 | 20-80 μm | [11-13, 18] |

| DI water | Ascorbic Acid | PVP | Cu(NO3)2 | ~50 | >10 μm | [19] |

| DI water | Glucose | HDA | CuCl2·2H2O | 24±4 | Tens to hundreds micrometers | [20] |

| DI water | Glucose | Oleic acid, Oleylamine | CuCl2 | ~45 | 60-90 μm | [9] |

| 1-hexadecylamine (HDA) | 1-Hexadecylamine (HDA) | Hexadecyl trimethyl ammonium bromide (CTAB) | Cu(acac)2 | ~78 | Tens to hundreds micrometers | [14] |

| Oleylamine | Oleylamine | Oleylamine | CuCl | ~63 | 10-30 μm | [10] |

| Oleylamine | Oleylamine | Oleylamine | CuBr2/CuCl2 | 16.2-90.0 | 20-40 μm | [15-16] |

| Oleylamine | Tris(trimethylsilyl) silane | Oleylamine | CuCl2 | ~16.1 | ~17 μm | [21] |

Table 1 Summary of representitive synthetic methods of Cu nanowires

| Solvent | Reducing agent | Capping agent | Cu precursor | Average diameter/nm | Average length | Ref. |

|---|---|---|---|---|---|---|

| DI water | H3PO3 | Sodium dodecyl benzene sulfonate (SDBS) | CuSO4·5H2O, | ~85 | Tens of micrometers | [17] |

| DI water | Hydrazine hydrate | Ethylenediamine | Cu(NO3)2 | 35-70 | 20-80 μm | [11-13, 18] |

| DI water | Ascorbic Acid | PVP | Cu(NO3)2 | ~50 | >10 μm | [19] |

| DI water | Glucose | HDA | CuCl2·2H2O | 24±4 | Tens to hundreds micrometers | [20] |

| DI water | Glucose | Oleic acid, Oleylamine | CuCl2 | ~45 | 60-90 μm | [9] |

| 1-hexadecylamine (HDA) | 1-Hexadecylamine (HDA) | Hexadecyl trimethyl ammonium bromide (CTAB) | Cu(acac)2 | ~78 | Tens to hundreds micrometers | [14] |

| Oleylamine | Oleylamine | Oleylamine | CuCl | ~63 | 10-30 μm | [10] |

| Oleylamine | Oleylamine | Oleylamine | CuBr2/CuCl2 | 16.2-90.0 | 20-40 μm | [15-16] |

| Oleylamine | Tris(trimethylsilyl) silane | Oleylamine | CuCl2 | ~16.1 | ~17 μm | [21] |

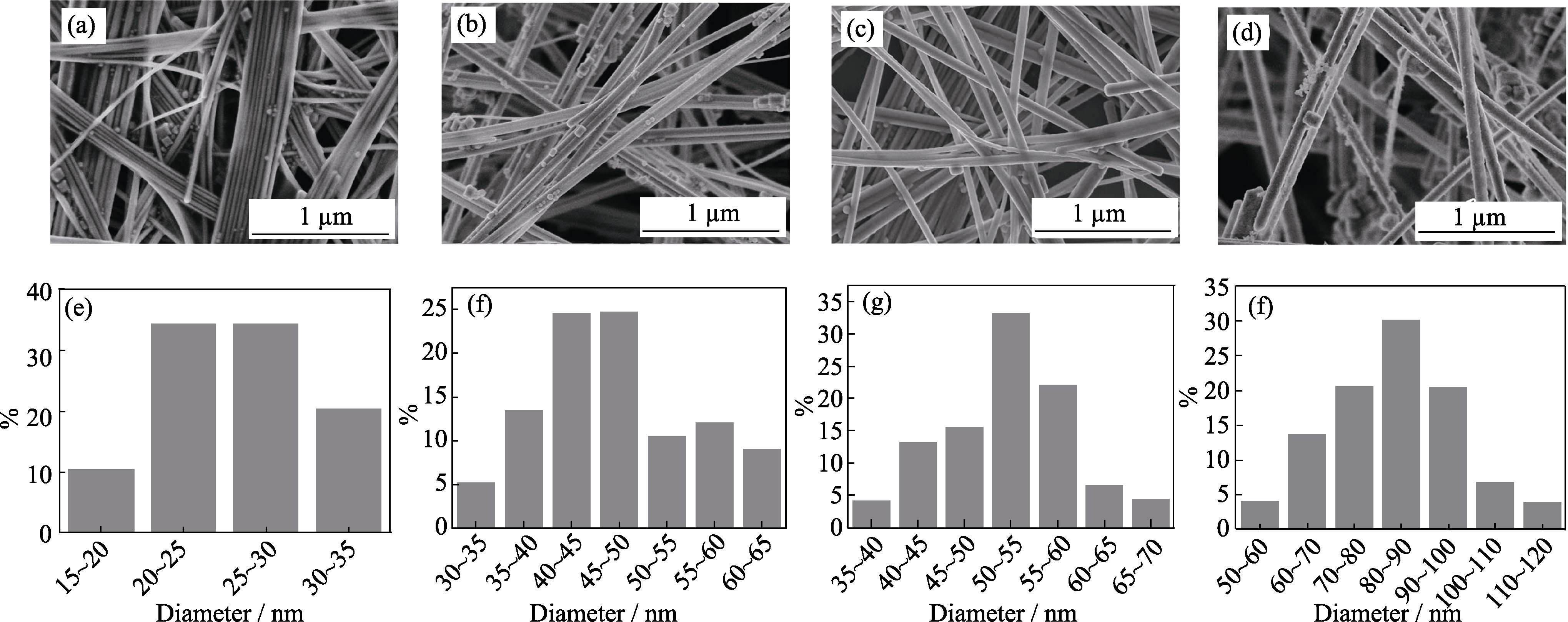

Fig. 2 SEM images and diameter distribution of Cu nanowires synthesized by using different halide ions[16] (a, e) 2.6 mmol Cl-; (b,f) 2.0 mmol Cl-; (c,g) 1.6 mmol Cl-; (d,h) 1.6 mmol Br-

Fig. 3 (A) SEM image of Cu-Ni NWs with inset showing high resolution SEM image of Cu-Ni NWs; (B) Dark field optical microscopy images of Cu-Ni NWs; (C-H) The distribution of Cu and Ni elements of Cu-Ni NWs with different contents of nickel[23]

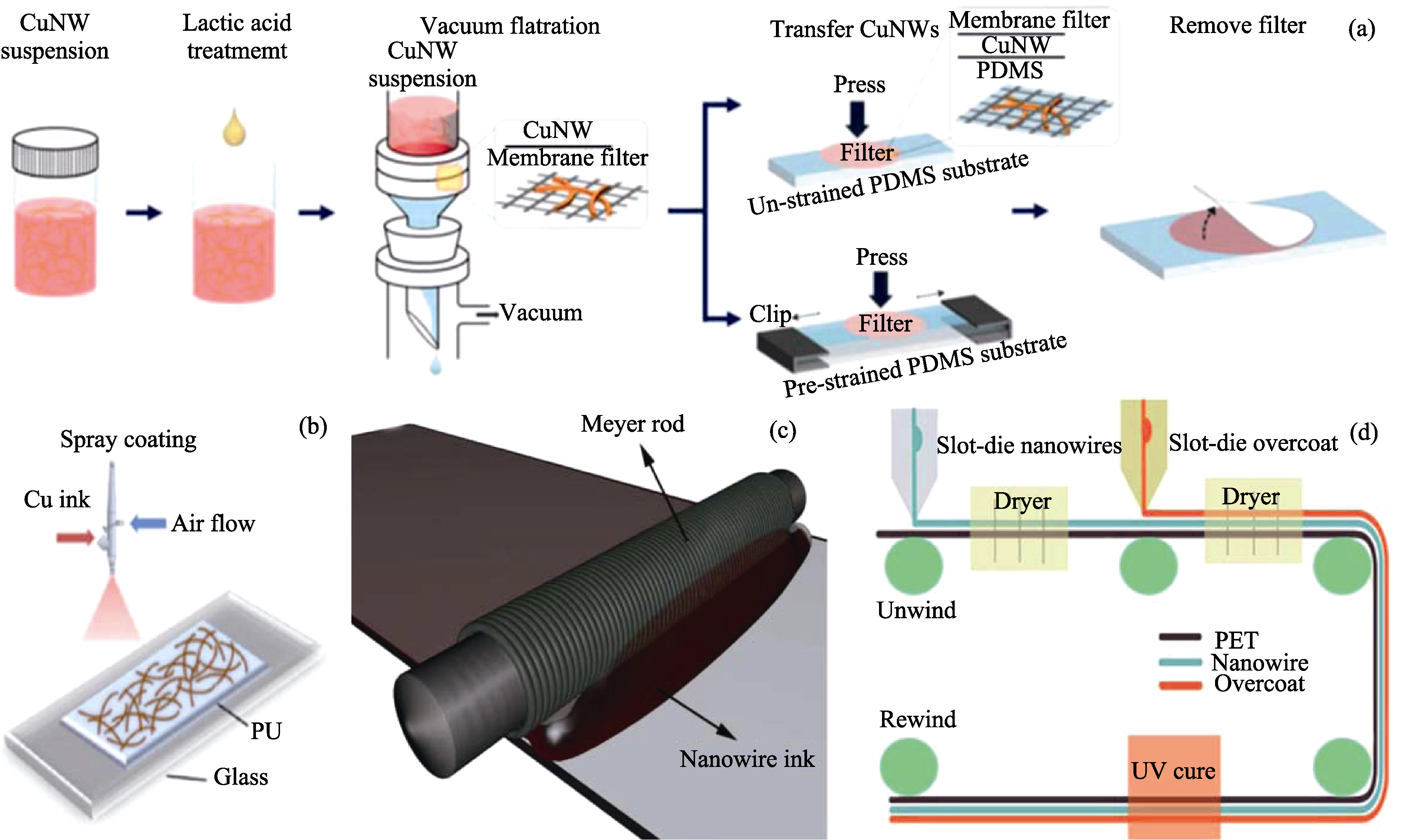

Fig. 4 Schematic diagram of the vaccum transfer method (a)[35], the spray-coating method (b)[36], the meyer rod coating method (c)[37], and the roll-to-roll coating method (d)[37]

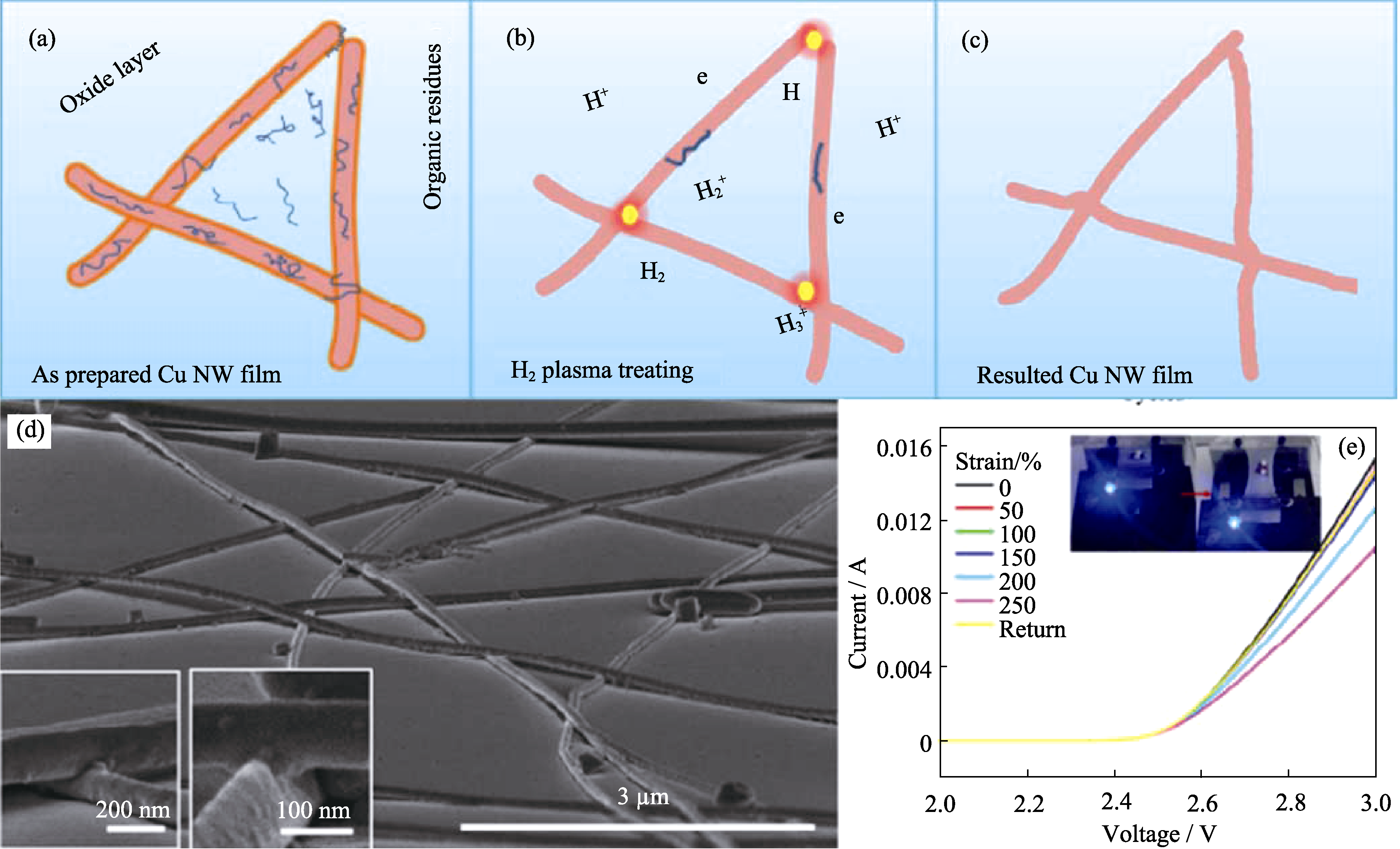

Fig. 5 (a-c) Schematic diagram of the experimental setup of a typical plasma treatment process; (d) SEM image of the nanowire junction after plasma treatment; (e) Current-voltage measurement of LED lamps connected by stretchable Cu NW conductors at various strains. Insets are digital photos of the whole setup at 0 and 250% strain[48]

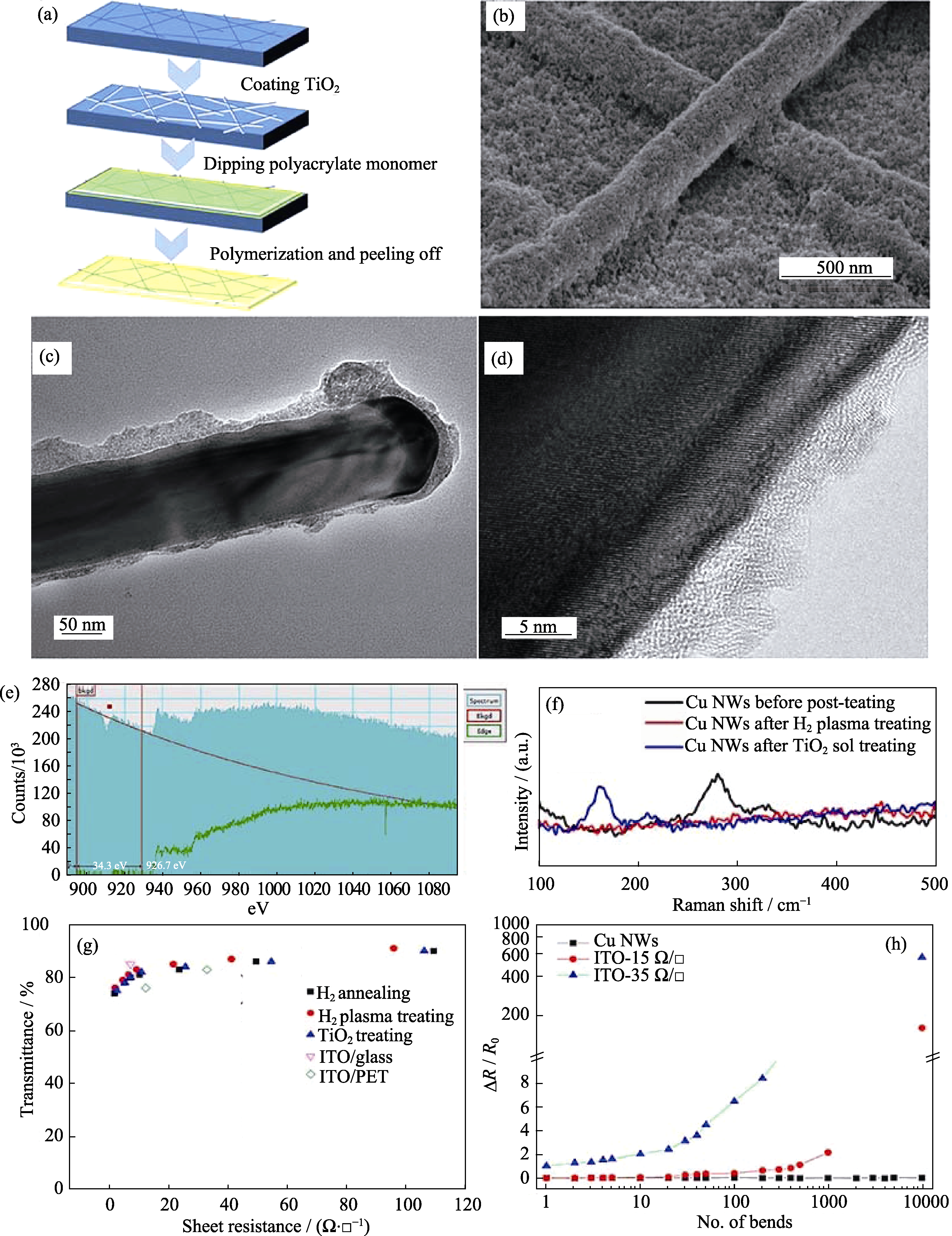

Fig. 6 Schematic diagram (a) of the preparation procedure of Cu NWs/PA electrode. SEM (b), TEM (c), HRTEM (d) and EELS spetra (e) of the Cu NWs film after TiO2 nanopartical sol treatment. Raman spectra (f) of Cu NWs before post-treating, after H2 plasma treatment and TiO2 nanopartical sol treatment. Plot of the transmittance (at a wavelength of 550 nm) with respect to the sheet resistance (g) for films of Cu NWs with H2 annealing, H2 plasma treatment and TiO2 nanopartical sol treatment. Sheet resistance variation (h) of the commercial ITO/PET and Cu NWs/PA electrodes during the bending test of 104 cycles[53]

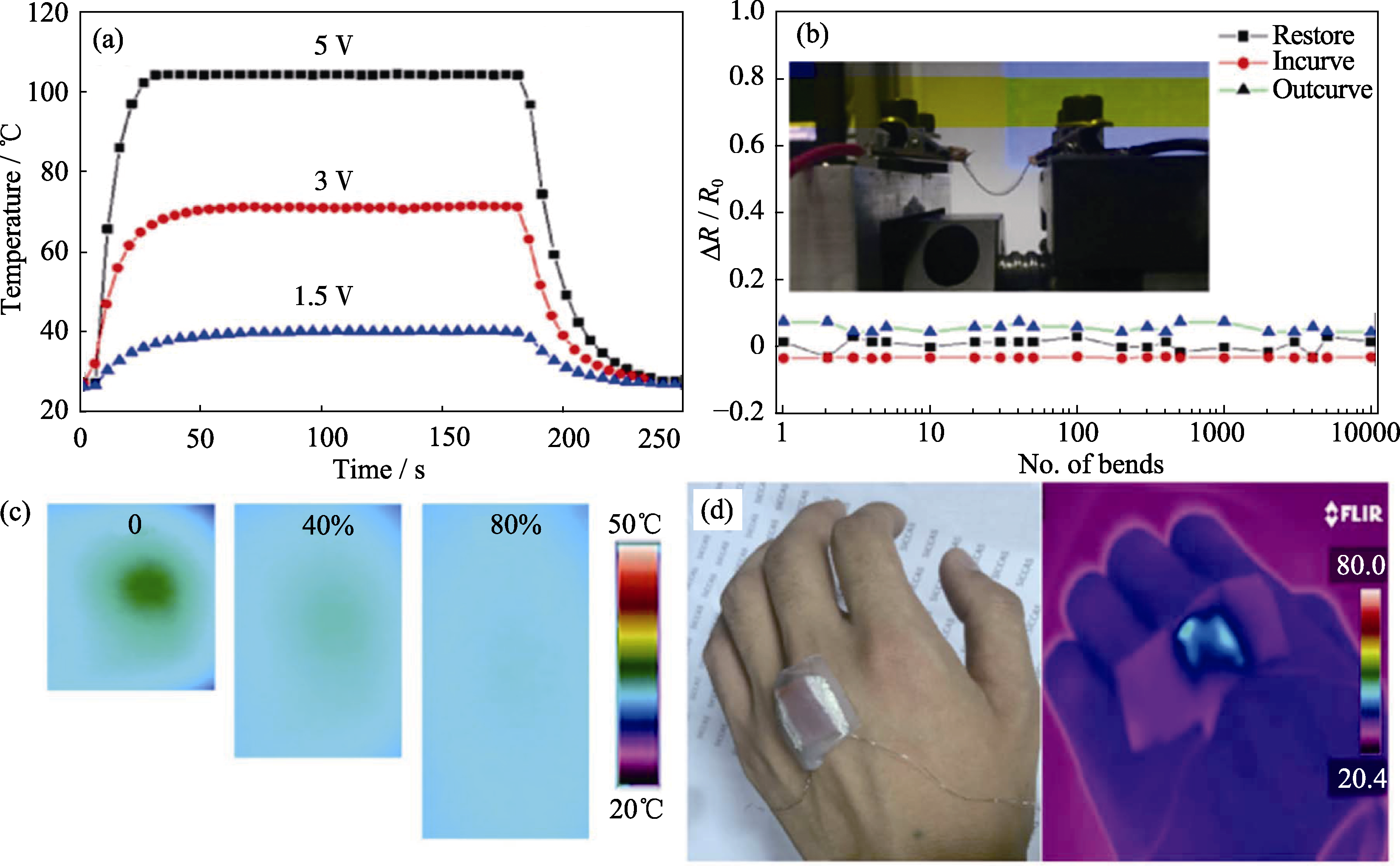

Fig. 7 (a) Time-dependent temperature curves of Cu NW-1000 on PET films at input voltages of 1.5-5 V under ambient conditions; (b) PET/ITO transparent heaters during 104 cycles of bending tests; (c) Infrared photograph and (d) application examples of Cu NW-based stretchable heater[61]

| [1] | CHENG H Y, LUO J, HUANG L Q, et al.Preparation of flexible dye-sensitized solar cells based on hierarchical structure ZnO nanosheets. Journal of Inorganic Materials, 2018, 33(5): 507-514. |

| [2] | ZHANG J, YANG X, DENG H, et al. Low-dimensional halide perovskites and their advanced optoelectronic applications. Nano-Micro Letters, 2017, 9(3): 36-1-26. |

| [3] | GUERRERO A, GARCIA-BELMONTE G. Recent advances to understand morphology stability of organic photovoltaics. Nano- Micro Letters, 2016, 9(1): 10-1-16. |

| [4] | CHEN D, LÜ J G, HUANG J Y, et al.Performances of GaN-based LEDs with AZO films as transparent electrodes. Journal of Inorganic Materials, 2013, 28(6): 649-652. |

| [5] | HAN S S, LIU L Y, SHAN Y K, et al.Research of graphene/ antireflection nanostructure composite transparent conducting films. Journal of Inorganic Materials, 2017, 32(2): 197-202. |

| [6] | HUANG W, ZHU J Y, LI H, et al.Preparation and characterization of graphene/carbon nanotube hybrid thin films by drop-coating. Journal of Inorganic Materials, 2017, 32(2): 203-209. |

| [7] | LEE J, LEE P, LEE H, et al.Very long Ag nanowire synthesis and its application in a highly transparent, conductive and flexible metal electrode touch panel. Nanoscale, 2012, 4(20): 6408-6414. |

| [8] | HU L B, WU H, CUI Y.Metal nanogrids, nanowires, and nanofibers for transparent electrodes. MRS Bulletin, 2011, 36(10): 760-765. |

| [9] | LI S, CHEN Y, HUANG L, et al.Large-scale synthesis of well-dispersed copper nanowires in an electric pressure cooker and their application in transparent and conductive networks. Inorganic Chemistry, 2014, 53(9): 4440-4444. |

| [10] | YANG H J, HE S Y, TUAN H Y.Self-seeded growth of five-fold twinned copper nanowires: mechanistic study, characterization, and SERS applications. Langmuir, 2014, 30(2): 602-610. |

| [11] | CHANG Y, LYE M L, ZENG H C.Large-scale synthesis of high-quality ultralong copper nanowires. Langmuir, 2005, 21(9): 3746-3748. |

| [12] | YE S, RATHMELL A R, HA Y C, et al.The role of cuprous oxide seeds in the one-pot and seeded syntheses of copper nanowires. Small, 2014, 10(9): 1771-1778. |

| [13] | RATHMELL A R, WILEY B J.The synthesis and coating of long, thin copper nanowires to make flexible, transparent conducting films on plastic substrates. Advanced Materials, 2011, 23(41): 4798-4803. |

| [14] | ZHANG D, WANG R, WEN M, et al.Synthesis of ultralong copper nanowires for high-performance transparent electrodes. Journal of the American Chemical Society, 2012, 134(35): 14283-14286. |

| [15] | GUO H, LIN N, CHEN Y, et al. Copper nanowires as fully transparent conductive electrodes. Scientific Reports, 2013, 3: 2323-1-8. |

| [16] | WANG X, WANG R, SHI L, et al.Kinetically controlled synthesis of Cu nanowires with tunable diameters and their applications in transparent electrodes. Journal of Materials Chemistry C, 2018, 6(5): 1048-1056. |

| [17] | LIU Z, YANG Y, LIANG J, et al.Synthesis of copper nanowires via a complex-surfactant-assisted hydrothermal reduction process. The Journal of Physical Chemistry B, 2003, 107(46): 12658-12661. |

| [18] | YE S, RATHMELL A R, STEWART I E, et al.A rapid synthesis of high aspect ratio copper nanowires for high-performance transparent conducting films. Chemical Communications, 2014, 50(20): 2562-2564. |

| [19] | ZHANG X, ZHANG D, NI X, et al.One-step preparation of copper nanorods with rectangular cross sections. Solid State Communications, 2006, 139(8): 412-414. |

| [20] | JIN M, HE G, ZHANG H, et al.Shape-controlled synthesis of copper nanocrystals in an aqueous solution with glucose as a reducing agent and hexadecylamine as a capping agent. Angewandte Chemie, 2011, 50(45): 10560-10564. |

| [21] | CUI F, YU Y, DOU L, et al.Synthesis of ultrathin copper nanowires using tris(trimethylsilyl)silane for high-performance and low-haze transparent conductors. Nano Letters, 2015, 15(11): 7610-7615. |

| [22] | RATHMELL A R, NGUYEN M, CHI M, et al.Synthesis of oxidation- resistant cupronickel nanowires for transparent conducting nanowire networks. Nano Letters, 2012, 12(6): 3193-3199. |

| [23] | WANG X, WANG R, SHI L, et al.Synthesis of metal/bimetal nanowires and their applications as flexible transparent electrodes. Small, 2015, 11(36): 4737-4744. |

| [24] | SOREL S, LYONS P E, DE S, et al. The dependence of the optoelectrical properties of silver nanowire networks on nanowire length and diameter. Nanotechnology, 2012, 23(18): 185201-1-10. |

| [25] | LAGRANGE M, LANGLEY D P, GIUSTI G, et al.Optimization of silver nanowire-based transparent electrodes: effects of density, size and thermal annealing. Nanoscale, 2015, 7(41): 17410-17423. |

| [26] | KIM A, WON Y, WOO K, et al.All-solution-processed indium- free transparent composite electrodes based on Ag nanowire and metal oxide for thin-film solar cells. Advanced Functional Materials, 2014, 24(17): 2462-2471. |

| [27] | FINN D J, LOTYA M, COLEMAN J N.Inkjet printing of silver nanowire networks. ACS Applied Materials & Interfaces, 2015, 7(17): 9254-9261. |

| [28] | LU H, LIN J, WU N, et al. Inkjet printed silver nanowire network as top electrode for semi-transparent organic photovoltaic devices. Applied Physics Letters, 2015, 106(9): 093302-1-4. |

| [29] | BELLEW A T, BELL A P, MCCARTHY E K, et al.Programmability of nanowire networks. Nanoscale, 2014, 6(16): 9632-9639. |

| [30] | SCARDACI V, COULL R, LYONS P E, et al.Spray deposition of highly transparent, low-resistance networks of silver nanowires over large areas. Small, 2011, 7(18): 2621-2628. |

| [31] | HAUGER T C, AL-RAFIA S M, BURIAK J M. Rolling silver nanowire electrodes: simultaneously addressing adhesion, roughness, and conductivity. ACS Applied Materials & Interfaces, 2013, 5(23): 12663-12671. |

| [32] | BORCHERT J W, STEWART I E, YE S, et al.Effects of length dispersity and film fabrication on the sheet resistance of copper nanowire transparent conductors. Nanoscale, 2015, 7(34): 14496-14504. |

| [33] | KOGA H, NOGI M, KOMODA N, et al. Uniformly connected conductive networks on cellulose nanofiber paper for transparent paper electronics. npg Asia Mater., 2014, 6(3): e93-1-8. |

| [34] | DENG B, HSU P C, CHEN G, et al.Roll-to-roll encapsulation of metal nanowires between graphene and plastic substrate for high-performance flexible transparent electrodes. Nano Letters, 2015, 15(6): 4206-4213. |

| [35] | WON Y, KIM A, YANG W, et al.A highly stretchable, helical copper nanowire conductor exhibiting a stretchability of 700%. npg Asia Mater., 2014, 6(9): e132-e132. |

| [36] | DING S, JIU J, GAO Y, et al.One-step fabrication of stretchable copper nanowire conductors by a fast photonic sintering technique and its application in wearable devices. ACS Applied Materials & Interfaces, 2016, 8(9): 6190-6199. |

| [37] | YE S, RATHMELL A R, CHEN Z, et al.Metal nanowire networks: the next generation of transparent conductors. Advanced Materials, 2014, 26(39): 6670-6687. |

| [38] | WON Y, KIM A, LEE D, et al. Annealing-free fabrication of highly oxidation-resistive copper nanowire composite conductors for photovoltaics. npg Asia Materials, 2014, 6: e105-1-9. |

| [39] | TAO A, KIM F, HESS C, et al.Langmuir-Blodgett silver nanowire monolayers for molecular sensing using surface-enhanced Raman spectroscopy. Nano Letters, 2003, 3(9): 1229-1233. |

| [40] | LIU J W, WANG J L, WANG Z H, et al.Manipulating nanowire assembly for flexible transparent electrodes. Angewandte Chemie, 2014, 53(49): 13477-13482. |

| [41] | KANG S, KIM T, CHO S, et al.Capillary printing of highly aligned silver nanowire transparent electrodes for high-performance optoelectronic devices. Nano Letters, 2015, 15(12): 7933-7942. |

| [42] | JASON N N, SHEN W, CHENG W.Copper nanowires as conductive ink for low-cost draw-on electronics. ACS Applied Materials & Interfaces, 2015, 7(30): 16760-16766. |

| [43] | GARNETT E C, CAI W, CHA J J, et al.Self-limited plasmonic welding of silver nanowire junctions. Nature Materials, 2012, 11(3): 241-249. |

| [44] | BELL A P, FAIRFIELD J A, MCCARTHY E K, et al.Quantitative study of the photothermal properties of metallic nanowire networks. ACS Nano, 2015, 9(5): 5551-5558. |

| [45] | HAN S, HONG S, HAM J, et al.Fast plasmonic laser nanowelding for a Cu-nanowire percolation network for flexible transparent conductors and stretchable electronics. Advanced Materials, 2014, 26(33): 5808-5814. |

| [46] | SONG T B, CHEN Y, CHUNG C H, et al.Nanoscale Joule heating and electromigration enhanced ripening of silver nanowire contacts. ACS Nano, 2014, 8(3): 2804-2811. |

| [47] | MAIZE K, DAS S R, SADEQUE S, et al. Super-Joule heating in graphene and silver nanowire network. Applied Physics Letters, 2015, 106(14): 143104-1-6. |

| [48] | WANG R, ZHAI H, WANG T, et al.Plasma-induced nanowelding of a copper nanowire network and its application in transparent electrodes and stretchable conductors. Nano Research, 2016, 9(7): 2138-2148. |

| [49] | LU H, ZHANG D, REN X, et al.Selective growth and integration of silver nanoparticles on silver nanowires at room conditions for transparent nano-network electrode. ACS Nano, 2014, 8(10): 10980-10987. |

| [50] | LU H F, ZHANG D, CHENG J Q, et al.Locally welded silver nano-network transparent electrodes with high operational stability by a simple alcohol-based chemical approach. Advanced Functional Materials, 2015, 25(27): 4211-4218. |

| [51] | XIONG W, LIU H, CHEN Y, et al.Highly conductive, air-stable silver nanowire@iongel composite films toward flexible transparent electrodes. Advanced Materials, 2016, 28(33): 7167-7172. |

| [52] | WANG X, WANG R, ZHAI H, et al.Room-temperature surface modification of Cu nanowires and their applications in transparent electrodes, SERS-based sensors, and organic solar cells. ACS Applied Materials & Interfaces, 2016, 8(42): 28831-28837. |

| [53] | ZHAI H, LI Y, CHEN L, et al.Copper nanowire-TiO2-polyacrylate composite electrodes with high conductivity and smoothness for flexible polymer solar cells. Nano Research, 2018, 11(4): 1895-1904. |

| [54] | ZHAI H, LI Y, CHEN L, et al.Semi-transparent polymer solar cells with all-copper nanowire electrodes. Nano Research, 2018, 11(4): 1956-1966. |

| [55] | ZHAI H, WANG R, WANG W, et al.Novel fabrication of copper nanowire/cuprous oxidebased semiconductor-liquid junction solar cells. Nano Research, 2015, 8(10): 3205-3215. |

| [56] | HSU P C, LIU X, LIU C, et al.Personal thermal management by metallic nanowire-coated textile. Nano Letters, 2015, 15(1): 365-371. |

| [57] | GUPTA R, RAO K D, KIRUTHIKA S, et al.Visibly transparent heaters. ACS Applied Materials & Interfaces, 2016, 8(20): 12559-12575. |

| [58] | KANG J, KIM H, KIM K S, et al.High-performance graphene- based transparent flexible heaters. Nano Letters, 2011, 11(12): 5154-5158. |

| [59] | JANAS D, KOZIOL K K.A review of production methods of carbon nanotube and graphene thin films for electrothermal applications. Nanoscale, 2014, 6(6): 3037-3045. |

| [60] | CELLE C, MAYOUSSE C, MOREAU E, et al.Highly flexible transparent film heaters based on random networks of silver nanowires. Nano Research, 2012, 5(6): 427-433. |

| [61] | ZHAI H, WANG R, WANG X, et al.Transparent heaters based on highly stable Cu nanowire films. Nano Research, 2016, 9(12): 3924-3936. |

| [62] | IM H G, JUNG S H, JIN J, et al.Flexible transparent conducting hybrid film using a surface-embedded copper nanowire network: a highly oxidation-resistant copper nanowire electrode for flexible optoelectronics. ACS Nano, 2014, 8(10): 10973-10979. |

| [63] | CHENG Y, WANG S, WANG R, et al.Copper nanowire based transparent conductive films with high stability and superior stretchability. Journal of Materials Chemistry C, 2014, 2(27): 5309-5316. |

| [64] | WANG T, WANG R, CHENG Y, et al.Quasi in situ polymerization to fabricate copper nanowire-based stretchable conductor and its applications. ACS Applied Materials & Interfaces, 2016, 8(14): 9297-9304. |

| [65] | CHEN Z, RATHMELL A R, YE S, et al.Optically transparent water oxidation catalysts based on copper nanowires. Angewandte Chemie International Edition, 2013, 52(51): 13708-13711. |

| [66] | XIAO S, LIU P, ZHU W, et al.Copper nanowires: a substitute for noble metals to enhance photocatalytic H2 generation. Nano Letters, 2015, 15(8): 4853-4858. |

| [67] | PARK S G, MUN C, LEE M, et al.3D hybrid plasmonic nanomaterials for highly efficient optical absorbers and sensors. Advanced Materials, 2015, 27(29): 4290-4295. |

| [1] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [2] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [3] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [4] | ZHANG Bihui, LIU Xiaoqiang, CHEN Xiangming. Recent Progress of Hybrid Improper Ferroelectrics with Ruddlesden-Popper Structure [J]. Journal of Inorganic Materials, 2025, 40(6): 587-608. |

| [5] | WU Jie, YANG Shuai, WANG Mingwen, LI Jinglei, LI Chunchun, LI Fei. Textured PT-based Piezoelectric Ceramics: Development, Status and Challenge [J]. Journal of Inorganic Materials, 2025, 40(6): 575-586. |

| [6] | JIANG Kun, LI Letian, ZHENG Mupeng, HU Yongming, PAN Qinxue, WU Chaofeng, WANG Ke. Research Progress on Low-temperature Sintering of PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 627-638. |

| [7] | TIAN Ruizhi, LAN Zhengyi, YIN Jie, HAO Nanjing, CHEN Hangrong, MA Ming. Microfluidic Technology Based Synthesis of Inorganic Nano-biomaterials: Principles and Progress [J]. Journal of Inorganic Materials, 2025, 40(4): 337-347. |

| [8] | ZHANG Jiguo, WU Tian, ZHAO Xu, YANG Fan, XIA Tian, SUN Shien. Improvement of Cycling Stability of Cathode Materials and Industrialization Process for Sodium-ion Batteries [J]. Journal of Inorganic Materials, 2025, 40(4): 348-362. |

| [9] | YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 245-255. |

| [10] | CHEN Guangchang, DUAN Xiaoming, ZHU Jinrong, GONG Qing, CAI Delong, LI Yuhang, YANG Donglei, CHEN Biao, LI Xinmin, DENG Xudong, YU Jin, LIU Boya, HE Peigang, JIA Dechang, ZHOU Yu. Advanced Ceramic Materials in Helicopter Special Structures: Research Progress and Application Prospect [J]. Journal of Inorganic Materials, 2025, 40(3): 225-244. |

| [11] | FAN Xiaobo, ZU Mei, YANG Xiangfei, SONG Ce, CHEN Chen, WANG Zi, LUO Wenhua, CHENG Haifeng. Research Progress on Proton-regulated Electrochemical Ionic Synapses [J]. Journal of Inorganic Materials, 2025, 40(3): 256-270. |

| [12] | HAIREGU Tuxun, GUO Le, DING Jiayi, ZHOU Jiaqi, ZHANG Xueliang, NUERNISHA Alifu. Research Progress of Optical Bioimaging Technology Assisted by Upconversion Fluorescence Probes in Tumor Imaging [J]. Journal of Inorganic Materials, 2025, 40(2): 145-158. |

| [13] | SUN Shujuan, ZHENG Nannan, PAN Haokun, MA Meng, CHEN Jun, HUANG Xiubing. Research Progress on Preparation Methods of Single-atom Catalysts [J]. Journal of Inorganic Materials, 2025, 40(2): 113-127. |

| [14] | TAO Guilong, ZHI Guowei, LUO Tianyou, OUYANG Peidong, YI Xinyan, LI Guoqiang. Progress on Key Technologies of Cavity-structured Thin Film Bulk Acoustic Wave Filter [J]. Journal of Inorganic Materials, 2025, 40(2): 128-144. |

| [15] | ZHOU Fan, TIAN Zhilin, LI Bin. Research Progress on Carbide Ultra-high Temperature Ceramic Anti-ablation Coatings for Thermal Protection System [J]. Journal of Inorganic Materials, 2025, 40(1): 1-16. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||