Journal of Inorganic Materials ›› 2025, Vol. 40 ›› Issue (7): 799-807.DOI: 10.15541/jim20240536

• RESEARCH ARTICLE • Previous Articles Next Articles

WANG Lujie1( ), ZHANG Yuxin2, LI Tongyang1, YU Yuan1, REN Pengwei1, WANG Jianzhang1, TANG Huaguo1, YAO Xiumin3, HUANG Yihua3, LIU Xuejian3, QIAO Zhuhui1,2,4(

), ZHANG Yuxin2, LI Tongyang1, YU Yuan1, REN Pengwei1, WANG Jianzhang1, TANG Huaguo1, YAO Xiumin3, HUANG Yihua3, LIU Xuejian3, QIAO Zhuhui1,2,4( )

)

Received:2024-12-25

Revised:2025-02-20

Published:2025-07-20

Online:2025-03-06

Contact:

QIAO Zhuhui, professor. E-mail: zhqiao@licp.cas.cnAbout author:WANG Lujie (1990-), male, associate professor. E-mail: ljwang@licp.cas.cn

Supported by:CLC Number:

WANG Lujie, ZHANG Yuxin, LI Tongyang, YU Yuan, REN Pengwei, WANG Jianzhang, TANG Huaguo, YAO Xiumin, HUANG Yihua, LIU Xuejian, QIAO Zhuhui. Corrosion and Wear Behavior of Silicon Carbide Ceramic in Deep-sea Service Environment[J]. Journal of Inorganic Materials, 2025, 40(7): 799-807.

| Composition | Mass concentration/(g·L-1) |

|---|---|

| NaCl | 24.53 |

| MgCl2 | 5.20 |

| Na2SO4 | 4.09 |

| CaCl2 | 1.16 |

| KCl | 0.695 |

| NaHCO3 | 0.201 |

| KBr | 0.101 |

| H3BO3 | 0.027 |

| SrCl2 | 0.025 |

| NaF | 0.003 |

Table 1 Artificial seawater composition

| Composition | Mass concentration/(g·L-1) |

|---|---|

| NaCl | 24.53 |

| MgCl2 | 5.20 |

| Na2SO4 | 4.09 |

| CaCl2 | 1.16 |

| KCl | 0.695 |

| NaHCO3 | 0.201 |

| KBr | 0.101 |

| H3BO3 | 0.027 |

| SrCl2 | 0.025 |

| NaF | 0.003 |

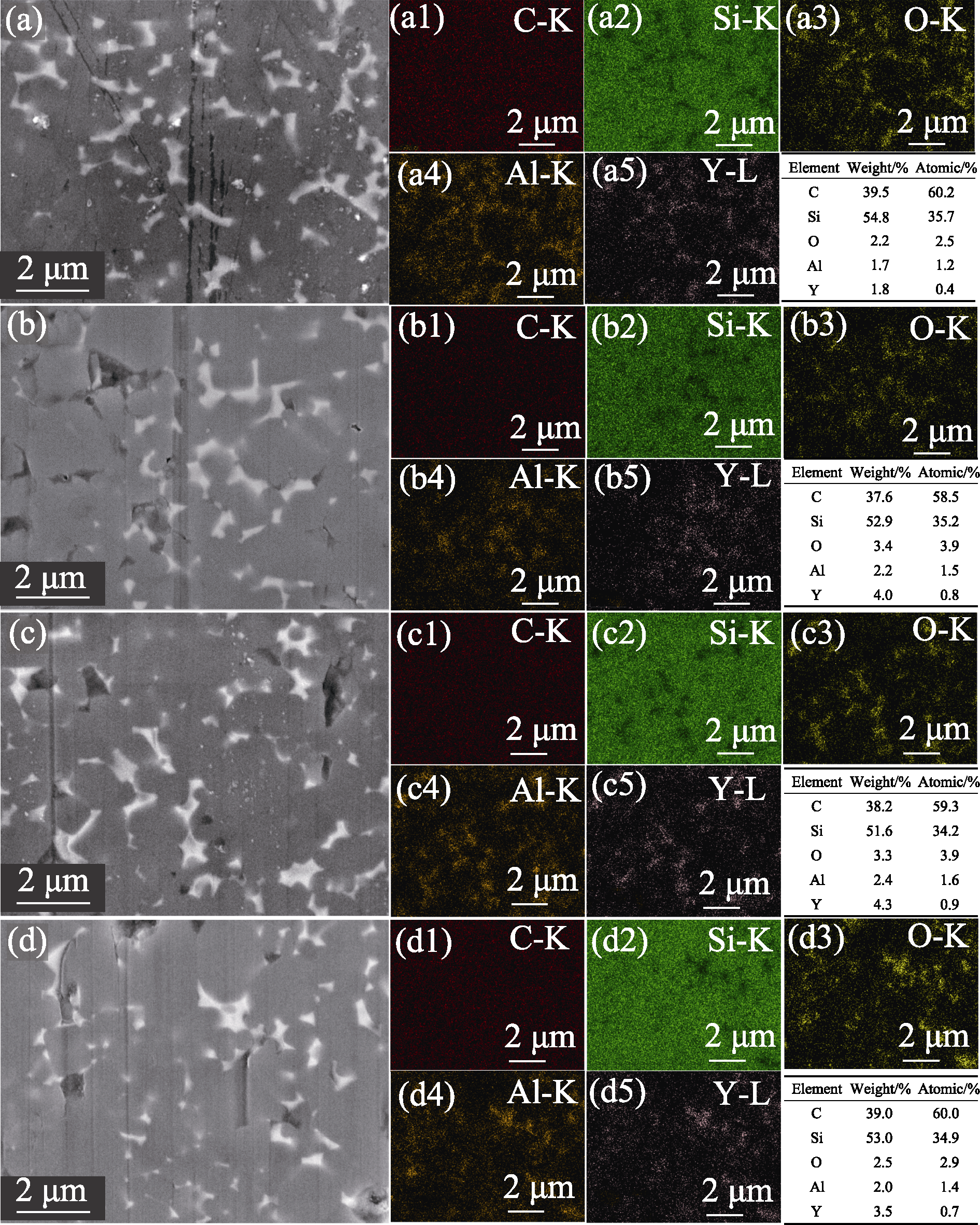

Fig. 3 SEM images (a-f) and EDS analyses (a1-f5) of the surface of SiC ceramic before and after corrosion in seawater at different depths (a, a1-a5) Before corrosion; (b, b1-b5) 0 km; (c, c1-c5) 1 km; (d, d1- d5) 2 km; (e, e1-e5) 3 km; (f, f1-f5) 5 km

Fig. 5 Weight (a), Vickers hardness (b), flexural strength (c), and fracture toughness (d) of SiC ceramics before and after corrosion in seawater at different depths

Fig. 6 Wear morphologies (a-d) and corresponding EDS analyses (a1-d5) of SiC ceramics in different deep-sea environments (a, a1-a5) 0 km; (b, b1-b5) 1 km; (c, c1-c5) 2 km; (d, d1-d5) 3 km

Fig. 7 3D wear morphologies of SiC ceramic surface in different deep-sea environments (a) 0 km; (b) 1 km; (c) 2 km; (d) 3 km. Colorful figures are available on website

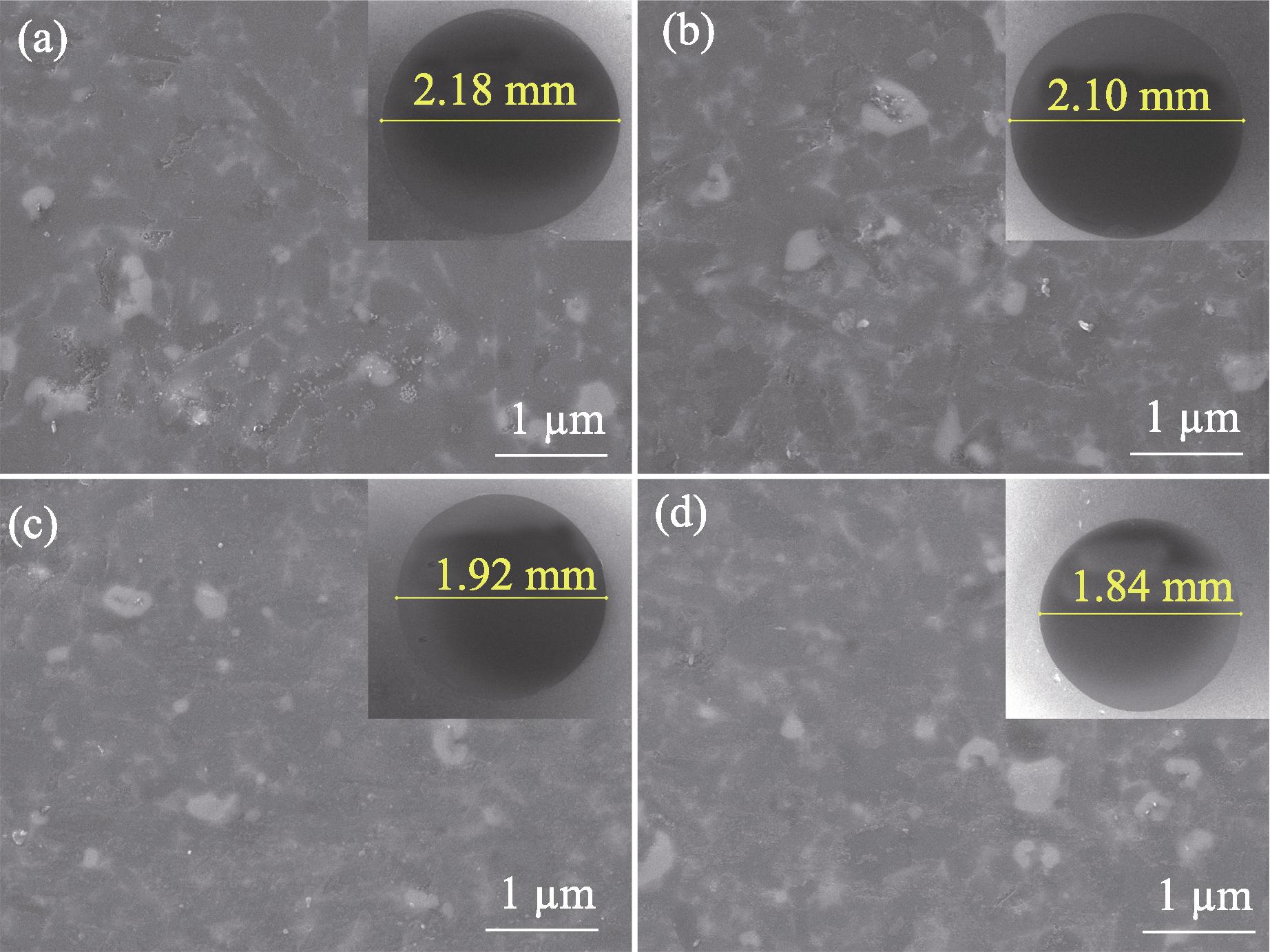

Fig. 8 Friction morphologies of Si3N4 friction pairs in different deep-sea environments (a) 0 km; (b) 1 km; (c) 2 km; (d) 3 km; Insets: diameters of wear traces of Si3N4 friction pairs

| [1] |

BORCHERS A, PIELER T. Programming pluripotent precursor cells derived from Xenopus embryos to generate specific tissues and organs. Genes, 2010, 1(3): 413.

DOI PMID |

| [2] | SHEN C, KHONSARI M M, SPADAFORA M, et al. Tribological performance of polyamide-imide seal ring under seawater lubrication. Tribology Letters, 2016, 62(3): 39. |

| [3] | SHANKAR S, KRISHNA KUMAR P. Frictional characteristics of diamond like carbon and tungsten carbide/carbon coated high carbon high chromium steel against carbon in dry sliding conformal contact for mechanical seals. Mechanics & Industry, 2017, 18(1): 115. |

| [4] | PEREIRA P, VILHENA L M, SACRAMENTO J, et al. Tribological behaviour of different formulations of WC composites. Wear, 2022, 506: 204415. |

| [5] | YAO X M, WANG X J, LIU X J, et al. Friction-wear properties and mechanism of hard facing pairs of SiC and WC. Journal of Inorganic Materials, 2019, 34(6): 673. |

| [6] |

CHEN Q, BAI S X, YE Y C. Highly thermal conductive silicon carbide ceramics matrix composites for thermal management: a review. Journal of Inorganic Materials, 2023, 38(6): 634.

DOI |

| [7] | RAMASUBRAMANIAN K, NIKHIL C, RAO S, et al. Tribological behavior of diamond coated reaction-bonded silicon carbide under dry and seawater environment. Surface and Coatings Technology, 2024, 476: 130204. |

| [8] | GUO X Z, WANG R, ZHENG P, et al. Pressureless sintering of multilayer graphene reinforced silicon carbide ceramics for mechanical seals. Advances in Applied Ceramics, 2019, 118(7): 409. |

| [9] | CAI N N, GUO D D, WU G P, et al. Decreasing resistivity of silicon carbide ceramics by incorporation of graphene. Materials, 2020, 13(16): 3586. |

| [10] | DIAO Q W, ZOU H B, REN X Y, et al. A focused review on the tribological behavior of C/SiC composites: present status and future prospects. Journal of the European Ceramic Society, 2023, 43(9): 3875. |

| [11] | ZHANG W, YAMASHITA S, KITA H. Progress in tribological research of SiC ceramics in unlubricated sliding-a review. Materials & Design, 2020, 190: 108528. |

| [12] | ZHANG W. Tribology of SiC ceramics under lubrication: features, developments, and perspectives. Current Opinion in Solid State and Materials Science, 2022, 26(4): 101000. |

| [13] | YAMAMOTO Y, URA A. Influence of interposed wear particles on the wear and friction of silicon carbide in different dry atmospheres. Wear, 1992, 154(1): 141. |

| [14] | PRESSER V, KRUMMHAUER O, NICKEL K G, et al. Tribological and hydrothermal behaviour of silicon carbide under water lubrication. Wear, 2009, 266(7/8): 771. |

| [15] | MATSUDA M, KATO K, HASHIMOTO A. Friction and wear properties of silicon carbide in water from different sources. Tribology Letters, 2011, 43(1): 33. |

| [16] | REN P W, MENG H M, XIA Q J, et al. Tribocorrosion of 316L stainless steel by in situ electrochemical methods under deep-sea high hydrostatic pressure environment. Corrosion Science, 2022, 202: 110315. |

| [17] | REN P W, MENG H M, XIA Q J, et al. Influence of seawater depth and electrode potential on the tribocorrosion of Ti6Al4V alloy under the simulated deep-sea environment by in situ electrochemical technique. Corrosion Science, 2021, 180: 109185. |

| [18] | REN P W, MENG H M, XIA Q J, et al. Study on the tribocorrosion behavior of Cu-Ni-Zn alloy in deep-sea environment by in situ electrochemical method. Wear, 2023, 514: 204594. |

| [19] | VERICHEV S N, MISHAKIN V V, NUZHDIN D A, et al. Experimental study of abrasive wear of structural materials under the high hydrostatic pressure. Ocean Engineering, 2015, 99: 9. |

| [20] | MISHAKIN V V, VERICHEV S N, RAZOV E N. Investigation of the influence of high hydrostatic pressure on the abrasive wear of hard-alloy materials. Journal of Friction and Wear, 2017, 38(4): 286. |

| [21] | WANG J Z, CHEN J, CHEN B B, et al. Wear behaviors and wear mechanisms of several alloys under simulated deep-sea environment covering seawater hydrostatic pressure. Tribology International, 2012, 56: 38. |

| [22] | WANG L J, QIAO Z H, QI Q, et al. Improving abrasive wear resistance of Si3N4 ceramics with self-matching through tungsten induced tribochemical wear. Wear, 2022, 494: 204254. |

| [23] | FENG D, QIN Z B, REN Q X, et al. Occurrence forms of major impurity elements in silicon carbide. Ceramics International, 2022, 48(1): 205. |

| [24] | XIANG D D, HE Q C, LAN D, et al. Regulating the phase composition and microstructure of Fe3Si/SiC nanofiber composites to enhance electromagnetic wave absorption. Chemical Engineering Journal, 2024, 498: 155406. |

| [25] | KIM W, LIM S H, HONG H, et al. Optimum boundaries for maximum load-carrying capacity in water-lubricated composite journal bearings incorporating turbulences and inertial effects based on elastohydrodynamic analysis. Journal of Computational Design and Engineering, 2022, 9(6): 2506. |

| [26] | ZHANG X L, YIN Z W, JIANG D, et al. The design of hydrodynamic water-lubricated step thrust bearings using CFD method. Mechanics & Industry, 2014, 15(3): 197. |

| [27] | WANG X L, ADACHI K, OTSUKA K, et al. Optimization of the surface texture for silicon carbide sliding in water. Applied Surface Science, 2006, 253(3): 1282. |

| [1] | ZHONG Weimin, ZHAO Ke, WANG Kewei, LIU Dianguang, LIU Jinling, AN Linan. Effect of Oscillatory Pressure Amplitude on Microstructures and Wear Resistance of Tungsten Carbide [J]. Journal of Inorganic Materials, 2025, 40(9): 964-970. |

| [2] | LIANG Ruihui, ZHONG Xin, HONG Du, HUANG Liping, NIU Yaran, ZHENG Xuebin. High-temperature Water Vapor Corrosion Behaviors of Environmental Barrier Coatings with Yb2O3-modified Silicon Bond Layer [J]. Journal of Inorganic Materials, 2025, 40(4): 425-432. |

| [3] | LI Ziwei, GONG Weilu, CUI Haifeng, YE Li, HAN Weijian, ZHAO Tong. (Zr, Hf, Nb, Ta, W)C-SiC Composite Ceramics: Preparation via Precursor Route and Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 271-280. |

| [4] | FAN Wenkai, YANG Xiao, LI Honghua, LI Yong, LI Jiangtao. Pressureless Sintering of (Y0.2Gd0.2Er0.2Yb0.2Lu0.2)2Zr2O7 High-entropy Ceramic and Its High Temperature CMAS Corrosion Resistance [J]. Journal of Inorganic Materials, 2025, 40(2): 159-167. |

| [5] | AI Yizhaotong, REN Jiulong, QIANG Linya, ZHANG Xiaozhen, YANG Kai, GAO Yanfeng. Friction and Wear Properties of Al2O3-GdAlO3 (GAP) Amorphous Ceramic Coatings under High Load Capacity [J]. Journal of Inorganic Materials, 2025, 40(10): 1111-1118. |

| [6] | WANG Hao, LIU Xuechao, ZHENG Zhong, PAN Xiuhong, XU Jintao, ZHU Xinfeng, CHEN Kun, DENG Weijie, TANG Meibo, GUO Hui, GAO Pan. Performance of Lateral 4H-SiC Photoconductive Semiconductor Switches by Extrinsic Backside Trigger [J]. Journal of Inorganic Materials, 2024, 39(9): 1070-1076. |

| [7] | FAN Wugang, CAO Xiong, ZHOU Xiang, LI Ling, ZHAO Guannan, ZHANG Zhaoquan. Anticorrosion Performance of 8YSZ Ceramics in Simulated Aqueous Environment of Pressurized Water Reactor [J]. Journal of Inorganic Materials, 2024, 39(7): 803-809. |

| [8] | LI Liuyuan, HUANG Kaiming, ZHAO Xiuyi, LIU Huichao, WANG Chao. Influence of RE-Si-Al-O Glass Phase on Microstructure and CMAS Corrosion Resistance of High Entropy Rare Earth Disilicates [J]. Journal of Inorganic Materials, 2024, 39(7): 793-802. |

| [9] | LI Jie, LUO Zhixin, CUI Yang, ZHANG Guangheng, SUN Luchao, WANG Jingyang. CMAS Corrosion Resistance of Y3Al5O12/Al2O3 Ceramic Coating Deposited by Atmospheric Plasma Spraying [J]. Journal of Inorganic Materials, 2024, 39(6): 671-680. |

| [10] | ZHANG Rui, ZHANG Kan, YUAN Mengya, GU Xinlei, ZHENG Weitao. Nitrogen Vacancy Regulated Lattice Distortion on Improvement of (NbMoTaW)Nx Thin Films: Mechanical Properties and Wear Resistance [J]. Journal of Inorganic Materials, 2024, 39(6): 715-725. |

| [11] | SUN Chuan, HE Pengfei, HU Zhenfeng, WANG Rong, XING Yue, ZHANG Zhibin, LI Jinglong, WAN Chunlei, LIANG Xiubing. SiC-based Ceramic Materials Incorporating GNPs Array: Preparation and Mechanical Characterization [J]. Journal of Inorganic Materials, 2024, 39(3): 267-273. |

| [12] | XU Hao, QIAN Wei, HUA Yinqun, YE Yunxia, DAI Fengze, CAI Jie. Effects of Micro Texture Processed by Picosecond Laser on Hydrophobicity of Silicon Carbide [J]. Journal of Inorganic Materials, 2023, 38(8): 923-930. |

| [13] | MAO Aiqin, LU Wenyu, JIA Yanggang, WANG Ranran, SUN Jing. Flexible Piezoelectric Devices and Their Wearable Applications [J]. Journal of Inorganic Materials, 2023, 38(7): 717-730. |

| [14] | CHEN Qiang, BAI Shuxin, YE Yicong. Highly Thermal Conductive Silicon Carbide Ceramics Matrix Composites for Thermal Management: a Review [J]. Journal of Inorganic Materials, 2023, 38(6): 634-646. |

| [15] | FAN Dong, ZHONG Xin, WANG Yawen, ZHANG Zhenzhong, NIU Yaran, LI Qilian, ZHANG Le, ZHENG Xuebin. Corrosion Behavior and Mechanism of Aluminum-rich CMAS on Rare-earth Silicate Environmental Barrier Coatings: [J]. Journal of Inorganic Materials, 2023, 38(5): 544-552. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||