Journal of Inorganic Materials ›› 2024, Vol. 39 ›› Issue (10): 1182-1188.DOI: 10.15541/jim20240091

Special Issue: 【结构材料】高导热陶瓷(202506); 【结构材料】陶瓷基复合材料(202506)

• RESEARCH LETTER • Previous Articles

WANG Bo1,2( ), CAI Delong1(

), CAI Delong1( ), ZHU Qishuai2,3, LI Daxin2, YANG Zhihua2, DUAN Xiaoming2, LI Yanan4, WANG Xuan5, JIA Dechang2(

), ZHU Qishuai2,3, LI Daxin2, YANG Zhihua2, DUAN Xiaoming2, LI Yanan4, WANG Xuan5, JIA Dechang2( ), ZHOU Yu2,6

), ZHOU Yu2,6

Received:2024-03-03

Revised:2024-05-09

Published:2024-10-20

Online:2024-05-16

Contact:

CAI Delong, associate professor. E-mail: dlcai@hit.edu.cn;About author:WANG Bo (1996-), male, PhD candidate. E-mail: bowang6600@126.com

Supported by:CLC Number:

WANG Bo, CAI Delong, ZHU Qishuai, LI Daxin, YANG Zhihua, DUAN Xiaoming, LI Yanan, WANG Xuan, JIA Dechang, ZHOU Yu. Mechanical Properties and Thermal Shock Resistance of SrAl2Si2O8 Reinforced BN Ceramic Composites[J]. Journal of Inorganic Materials, 2024, 39(10): 1182-1188.

| Sintering pressure/ MPa | Density/ (g·cm-3) | Bending strength/ MPa | Fracture toughness/ (MPa·m1/2) |

|---|---|---|---|

| 10 | 1.90 | 87±5 | 1.33±0.04 |

| 20 | 2.25 | 138±4 | 1.84±0.05 |

| 30 | 2.33 | 136±11 | 1.50±0.24 |

Table 1 Density, bending strength and fracture toughness of BN-SAS ceramic composites

| Sintering pressure/ MPa | Density/ (g·cm-3) | Bending strength/ MPa | Fracture toughness/ (MPa·m1/2) |

|---|---|---|---|

| 10 | 1.90 | 87±5 | 1.33±0.04 |

| 20 | 2.25 | 138±4 | 1.84±0.05 |

| 30 | 2.33 | 136±11 | 1.50±0.24 |

Fig. 3 HRTEM and TEM characterization of BN-SAS ceramic composites sintered at 10 MPa (a) HRTEM image; (b) Inverse FFT image of area A in figure (a); (c) SAED pattern of h-BN; (d) TEM image of BN-SAS ceramic composites; (e-j) Elemental analysis of the figure (d); (e) B; (f) N; (g) O; (h) Sr; (i) Al; (j) Si

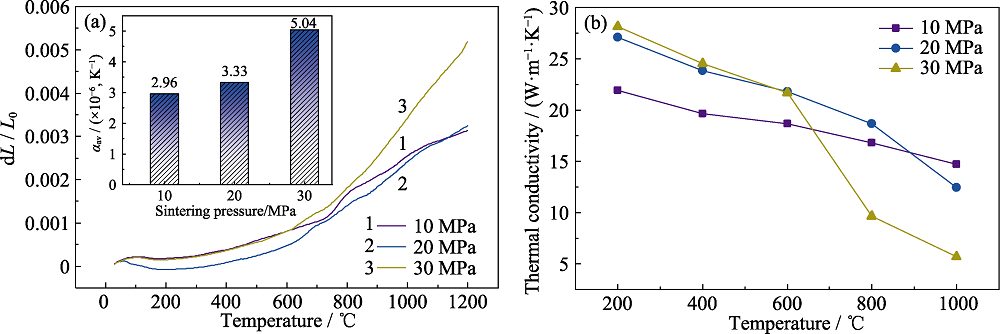

Fig. 5 Thermal properties of BN-SAS ceramic composites sintered at different pressures (a) Thermal expansion rate with inset showing the average CTE (α); (b) Thermal conductivity

| Sintering pressure/MPa | Bending strength/MPa | Fracture toughness/ (MPa·m1/2) | Young's modulus/GPa | Average CTE/ (×10−6, K−1) | λ/( W·m-1·K-1, 1000 ℃) | R/℃ | RⅣ/μm |

|---|---|---|---|---|---|---|---|

| 10 | 87±5 | 1.33±0.04 | 48.47 | 2.96 | 14.70 | ||

| 20 | 138±4 | 1.84±0.05 | 67.83 | 3.33 | 12.42 | ||

| 30 | 136±11 | 1.50±0.24 | 66.94 | 5.04 | 5.72 |

Table 2 Properties of the BN-SAS ceramic composites

| Sintering pressure/MPa | Bending strength/MPa | Fracture toughness/ (MPa·m1/2) | Young's modulus/GPa | Average CTE/ (×10−6, K−1) | λ/( W·m-1·K-1, 1000 ℃) | R/℃ | RⅣ/μm |

|---|---|---|---|---|---|---|---|

| 10 | 87±5 | 1.33±0.04 | 48.47 | 2.96 | 14.70 | ||

| 20 | 138±4 | 1.84±0.05 | 67.83 | 3.33 | 12.42 | ||

| 30 | 136±11 | 1.50±0.24 | 66.94 | 5.04 | 5.72 |

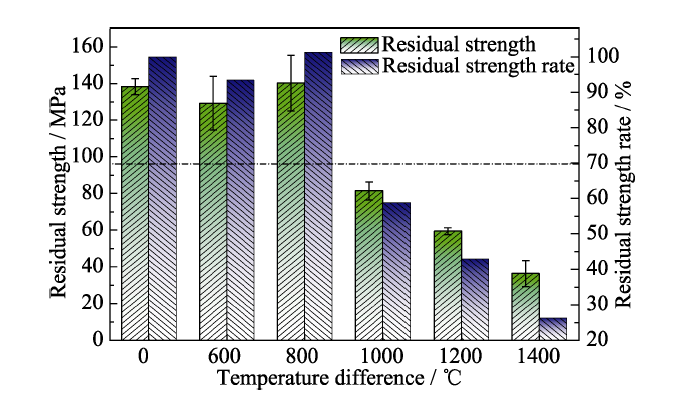

Fig. 6 Residual bending strength and residual strength rate of BN-SAS composites sintered at 20 MPa as a function of thermal shock temperature difference

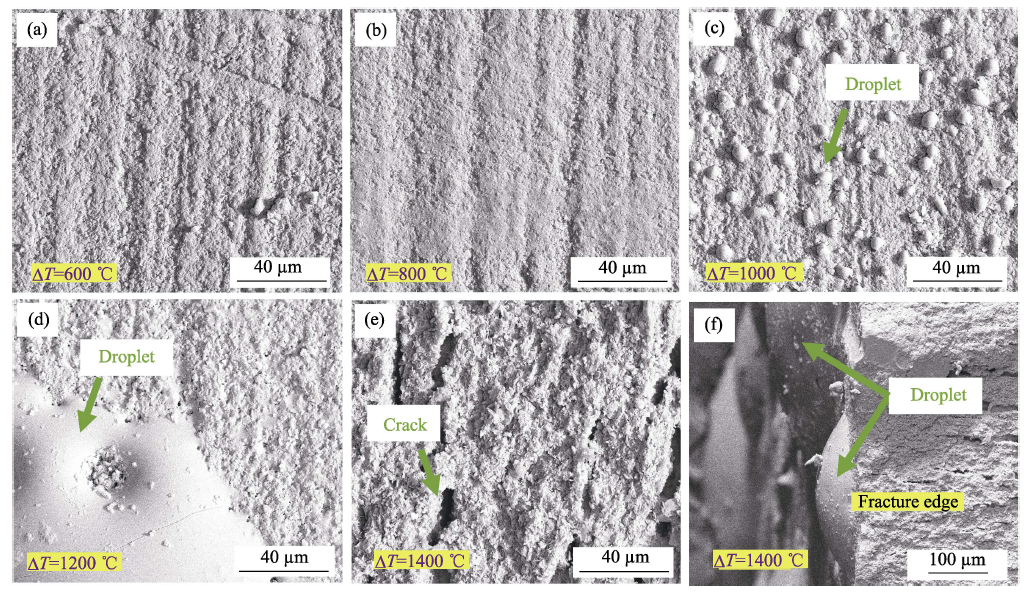

Fig. 7 Micrographs of surfaces and fracture edges of BN-SAS ceramic composites sintered at 20 MPa after thermal shock with different temperature differences (a) 600 ℃; (b) 800 ℃; (c) 1000 ℃; (d) 1200 ℃; (e) 1400 ℃; (f) Fracture edge morphology under thermal shock temperature difference of 1400 ℃

| [1] | KENION T, YANG N, XU C. Dielectric and mechanical properties of hypersonic radome materials and metamaterial design: a review. Journal of the European Ceramic Society, 2022, 42(1): 1. |

| [2] | KUMAR S, GUPTA P. A review on ceramic and polymer materials for radome applications. IEEE Indian Conference on Antennas and Propogation (InCAP), Ahmedabad, 2019. |

| [3] | ADLER W. Development of design data for rain impact damage in infrared-transmitting windows and radomes. Optical Engineering, 1987, 26(2): 262143. |

| [4] | KHATAVKAR N. Composite materials for supersonic aircraft radomes with ameliorated radio frequency transmission--a review. RSC Advances, 2016, 6(8): 679. |

| [5] | KOZAKOFF D. Analysis of radome-enclosed antennas. Boston: Artech House, 1997. |

| [6] | CI L J, SONG L, JIN C H, et al. Atomic layers of hybridized boron nitride and graphene domains. Nature Materials, 2010, 9(5): 430. |

| [7] | STEINBORN C, HERRMANN M, KEITEL U, et al. Correlation between microstructure and electrical resistivity of hexagonal boron nitride ceramics. Journal of the European Ceramic Society, 2013, 33(6): 1225. |

| [8] | WANG Z G, GE M, YU S Q, et al. Microstructural evolution of polymer-derived hexagonal boron nitride fibres under high-temperature stretching. Journal of Advanced Ceramics. 2023, 12(10): 1973. |

| [9] | EICHLER J, LESNIAK C. Boron nitride (BN) and BN composites for high-temperature applications. Journal of the European Ceramic Society, 2008, 28(5): 1105. |

| [10] | DING C, LIU G L. Preparation and mechanical properties of diamond/hexagonal boron nitride composite with spark plasma sintering. Journal of Ceramics, 2023, 44(3): 517. |

| [11] | WEI D, MENG Q C, JIA D C. Microstructure of hot-pressed h-BN/Si3N4 ceramic composites with Y2O3-Al2O3 sintering additive. Ceramics International, 2007, 33(2): 221. |

| [12] | WEN G, WU G L, LEI T Q, et al. Co-enhanced SiO2-BN ceramics for high-temperature dielectric applications. Journal of the European Ceramic Society, 2000, 20(12): 1923. |

| [13] | CAI D L, YANG Z H, DUAN X M, et al. A novel BN-MAS system composite ceramics with greatly improved mechanical properties prepared by low temperature hot-pressing. Materials Science and Engineering: A, 2015, 633: 194. |

| [14] | NIU B, CAI D L, YANG Z H, et al. Anisotropies in structure and properties of hot-press sintered h-BN-MAS composite ceramics: effects of raw h-BN particle size. Journal of the European Ceramic Society, 2019, 39(2/3): 539. |

| [15] | ZHANG X, CHEN J X, LI X C, et al. Microstructure and mechanical properties of h-BN/Y2SiO5 composites. Ceramics International, 2015, 41(1): 1279. |

| [16] | QIU B F, DUAN X M, ZHANG Z, et al. Microstructural evolution and mechanical properties of h-BN composite ceramics with Y2O3-AlN addition by liquid-phase sintering. Rare Metals, 2020, 39(5): 555. |

| [17] | QIU B F, DUAN X M, ZHANG Z, et al. Microstructural evolution of h-BN matrix composite ceramics with La-Al-Si-O glass phase during hot-pressed sintering. Journal of Advanced Ceramics, 2021, 10(3): 493. |

| [18] | ZHANG Z, DUAN X M, TIAN Z, et al. Texture and anisotropy of hot-pressed h-BN matrix composite ceramics with in situ formed YAG. Journal of Advanced Ceramics, 2022, 11(4): 532. |

| [19] | LIU Z T, ZHAO S Q, YANG T, et al. Improvement in mechanical properties in AlN-h-BN composites with high thermal conductivity. Journal of Advanced Ceramics, 2021, 10(6): 1317. |

| [20] | MIAO Y M, LIU L G. Effects of pressure and the content of SiC on densification and mechanical properties of hot press sintered h-BN ceramics. Journal of Ceramics, 2022, 43(4): 637. |

| [21] | CHINN R, HAUN M, KIM C, et al. Microstructures and properties of three composites of alumina, mullite, and monoclinic SrAl2Si2O8. Journal of the American Ceramic Society, 2000, 83(11): 2668. |

| [22] | CHINN R, HAUN M, KIM C, et al. Low-temperature transient glass-phase processing of monoclinic SrAl2Si2O8. Journal of the American Ceramic Society, 1998, 81(9): 2285. |

| [23] | YANG Z H, JIA D C, ZHOU Y, et al. Thermal shock resistance of in situ formed SiC-BN composites. Materials Chemistry and Physics, 2008, 107(2/3): 476. |

| [24] | HASSELMAN D. Thermal stress resistance parameters for brittle refractory ceramics: a compendium. Ceramic Bulletin, 1970, 49: 1033. |

| [1] | SUN Yuxuan, WANG Zheng, SHI Xue, SHI Ying, DU Wentong, MAN Zhenyong, ZHENG Liaoying, LI Guorong. Defect Dipole Thermal-stability to the Electro-mechanical Properties of Fe Doped PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 545-551. |

| [2] | CHEN Yi, QIU Haipeng, CHEN Mingwei, XU Hao, CUI Heng. SiC/SiC Composite: Matrix Boron Modification and Mechanical Properties [J]. Journal of Inorganic Materials, 2025, 40(5): 504-510. |

| [3] | CUI Ning, ZHANG Yuxin, WANG Lujie, LI Tongyang, YU Yuan, TANG Huaguo, QIAO Zhuhui. Single-phase Formation Process and Carbon Vacancy Regulation of (TiVNbMoW)Cx High-entropy Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 511-520. |

| [4] | LI Ziwei, GONG Weilu, CUI Haifeng, YE Li, HAN Weijian, ZHAO Tong. (Zr, Hf, Nb, Ta, W)C-SiC Composite Ceramics: Preparation via Precursor Route and Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 271-280. |

| [5] | GAO Chenguang, SUN Xiaoliang, CHEN Jun, LI Daxin, CHEN Qingqing, JIA Dechang, ZHOU Yu. SiBCN-rGO Ceramic Fibers Based on Wet Spinning Technology: Microstructure, Mechanical and Microwave-absorbing Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 290-296. |

| [6] | MU Haojie, ZHANG Yuanjiang, YU Bin, FU Xiumei, ZHOU Shibin, LI Xiaodong. Preparation and Properties of ZrO2 Doped Y2O3-MgO Nanocomposite Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 281-289. |

| [7] | WANG Yueyue, HUANG Jiahui, KONG Hongxing, LI Huaizhu, YAO Xiaohong. Silver Loaded Radial Mesoporous Silica: Preparation and Application in Dental Resins [J]. Journal of Inorganic Materials, 2025, 40(1): 77-83. |

| [8] | FAN Wugang, CAO Xiong, ZHOU Xiang, LI Ling, ZHAO Guannan, ZHANG Zhaoquan. Anticorrosion Performance of 8YSZ Ceramics in Simulated Aqueous Environment of Pressurized Water Reactor [J]. Journal of Inorganic Materials, 2024, 39(7): 803-809. |

| [9] | WU Yuhao, PENG Renci, CHENG Chunyu, YANG Li, ZHOU Yichun. First-principles Study on Mechanical Properties and Melting Curve of HfxTa1-xC System [J]. Journal of Inorganic Materials, 2024, 39(7): 761-768. |

| [10] | WANG Weiming, WANG Weide, SU Yi, MA Qingsong, YAO Dongxu, ZENG Yuping. Research Progress of High Thermal Conductivity Silicon Nitride Ceramics Prepared by Non-oxide Sintering Additives [J]. Journal of Inorganic Materials, 2024, 39(6): 634-646. |

| [11] | SUN Haiyang, JI Wei, WANG Weimin, FU Zhengyi. Design, Fabrication and Properties of Periodic Ordered Structural Composites with TiB-Ti Units [J]. Journal of Inorganic Materials, 2024, 39(6): 662-670. |

| [12] | CAI Feiyan, NI Dewei, DONG Shaoming. Research Progress of High-entropy Carbide Ultra-high Temperature Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 591-608. |

| [13] | LIU Guoang, WANG Hailong, FANG Cheng, HUANG Feilong, YANG Huan. Effect of B4C Content on Mechanical Properties and Oxidation Resistance of (Ti0.25Zr0.25Hf0.25Ta0.25)B2-B4C Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 697-706. |

| [14] | SU Yi, SHI Yangfan, JIA Chenglan, CHI Pengtao, GAO Yang, MA Qingsong, CHEN Sian. Microstructure and Properties of C/HfC-SiC Composites Prepared by Slurry Impregnation Assisted Precursor Infiltration Pyrolysis [J]. Journal of Inorganic Materials, 2024, 39(6): 726-732. |

| [15] | ZHANG Rui, ZHANG Kan, YUAN Mengya, GU Xinlei, ZHENG Weitao. Nitrogen Vacancy Regulated Lattice Distortion on Improvement of (NbMoTaW)Nx Thin Films: Mechanical Properties and Wear Resistance [J]. Journal of Inorganic Materials, 2024, 39(6): 715-725. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||