Journal of Inorganic Materials ›› 2023, Vol. 38 ›› Issue (7): 800-806.DOI: 10.15541/jim20220736

Special Issue: 【能源环境】热电材料(202506)

• RESEARCH ARTICLE • Previous Articles Next Articles

XIAO Yani1( ), LYU Jianan1,2, LI Zhenming3, LIU Mingyang3, LIU Wei3, REN Zhigang4, LIU Hongjing4, YANG Dongwang1(

), LYU Jianan1,2, LI Zhenming3, LIU Mingyang3, LIU Wei3, REN Zhigang4, LIU Hongjing4, YANG Dongwang1( ), YAN Yonggao1(

), YAN Yonggao1( )

)

Received:2022-12-05

Revised:2023-02-23

Published:2023-03-15

Online:2023-03-15

Contact:

YANG Dongwang, research assistant. E-mail: ydongwang@whut.edu.cn;About author:XIAO Yani (1999-), female, Master candidate. E-mail: 303587@whut.edu.cn

Supported by:CLC Number:

XIAO Yani, LYU Jianan, LI Zhenming, LIU Mingyang, LIU Wei, REN Zhigang, LIU Hongjing, YANG Dongwang, YAN Yonggao. Hygrothermal Stability of Bi2Te3-based Thermoelectric Materials[J]. Journal of Inorganic Materials, 2023, 38(7): 800-806.

| Parameter at room temperature | n-type Bi2Se0.21Te2.79 | p-type Bi0.4Sb1.6Te3 | |||

|---|---|---|---|---|---|

| 0 h | 600 h | 0 h | 600 h | ||

| σ / (×104, S·m-1) | 9.45 | 7.79 | 9.12 | 8.69 | |

| S / (μV·K-1) | 219 | 224 | 243 | 220 | |

| n / (×1019, cm-3) | 1.25 | 1.32 | 1.52 | 1.47 | |

| μ / (cm2·V-1·s-1) | 470 | 369 | 375 | 370 | |

| PF / (mW·m-1·K-2) | 4.54 | 3.90 | 5.41 | 4.21 | |

| κ / (W·m-1·K-1) | 1.40 | 1.48 | 1.31 | 1.29 | |

| ZT | 0.97 | 0.79 | 1.24 | 0.97 | |

Table 1 Room temperature thermoelectric performance of n-type Bi2Se0.21Te2.79 and p-type Bi0.4Sb1.6Te3 materials before and after storage in hygrothermal environment (85 ℃, 85% RH) for 600 h

| Parameter at room temperature | n-type Bi2Se0.21Te2.79 | p-type Bi0.4Sb1.6Te3 | |||

|---|---|---|---|---|---|

| 0 h | 600 h | 0 h | 600 h | ||

| σ / (×104, S·m-1) | 9.45 | 7.79 | 9.12 | 8.69 | |

| S / (μV·K-1) | 219 | 224 | 243 | 220 | |

| n / (×1019, cm-3) | 1.25 | 1.32 | 1.52 | 1.47 | |

| μ / (cm2·V-1·s-1) | 470 | 369 | 375 | 370 | |

| PF / (mW·m-1·K-2) | 4.54 | 3.90 | 5.41 | 4.21 | |

| κ / (W·m-1·K-1) | 1.40 | 1.48 | 1.31 | 1.29 | |

| ZT | 0.97 | 0.79 | 1.24 | 0.97 | |

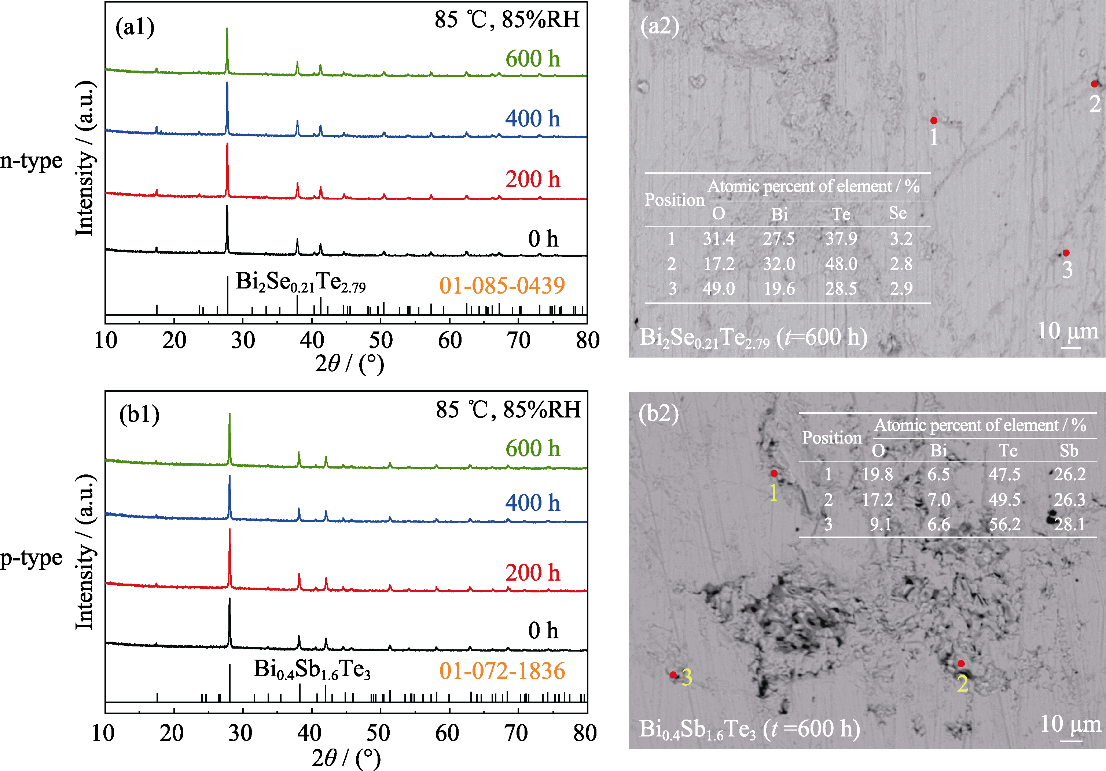

Fig. 1 (a1, b1) XRD patterns of samples after storage in hygrothermal environment for different time with (a2, b2) EDS results of material surface after storage in hygrothermal environment for 600 h (a1, a2) n-type Bi2Se0.21Te2.79; (b1, b2) p-type Bi0.4Sb1.6Te3

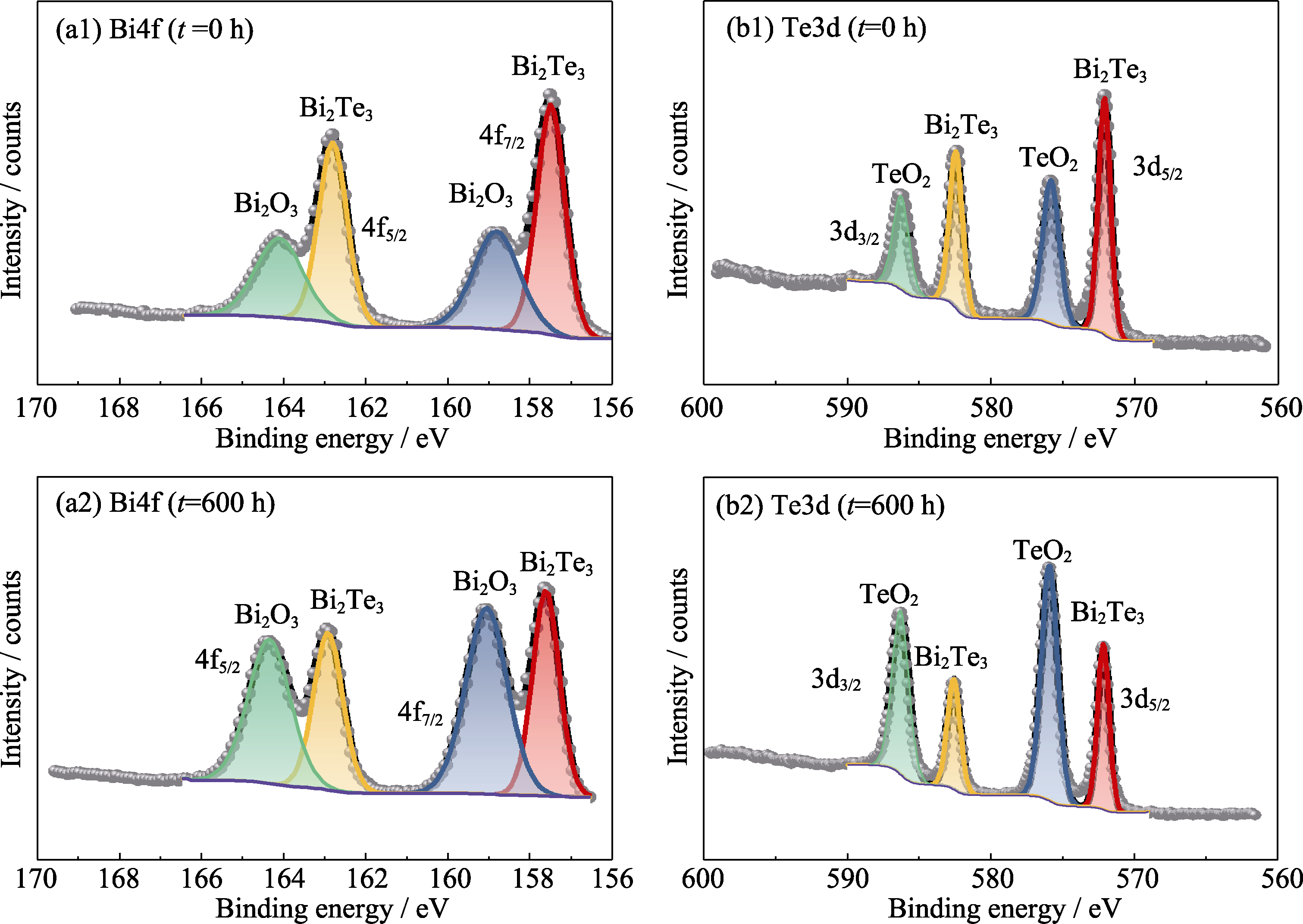

Fig. 2 Surface XPS spectra of n-type Bi2Se0.21Te2.79 material (a1-b1) before and (a2-b2) after storage in hygrothermal environment for 600 h (a1, a2) Bi4f; (b1, b2) Te3d

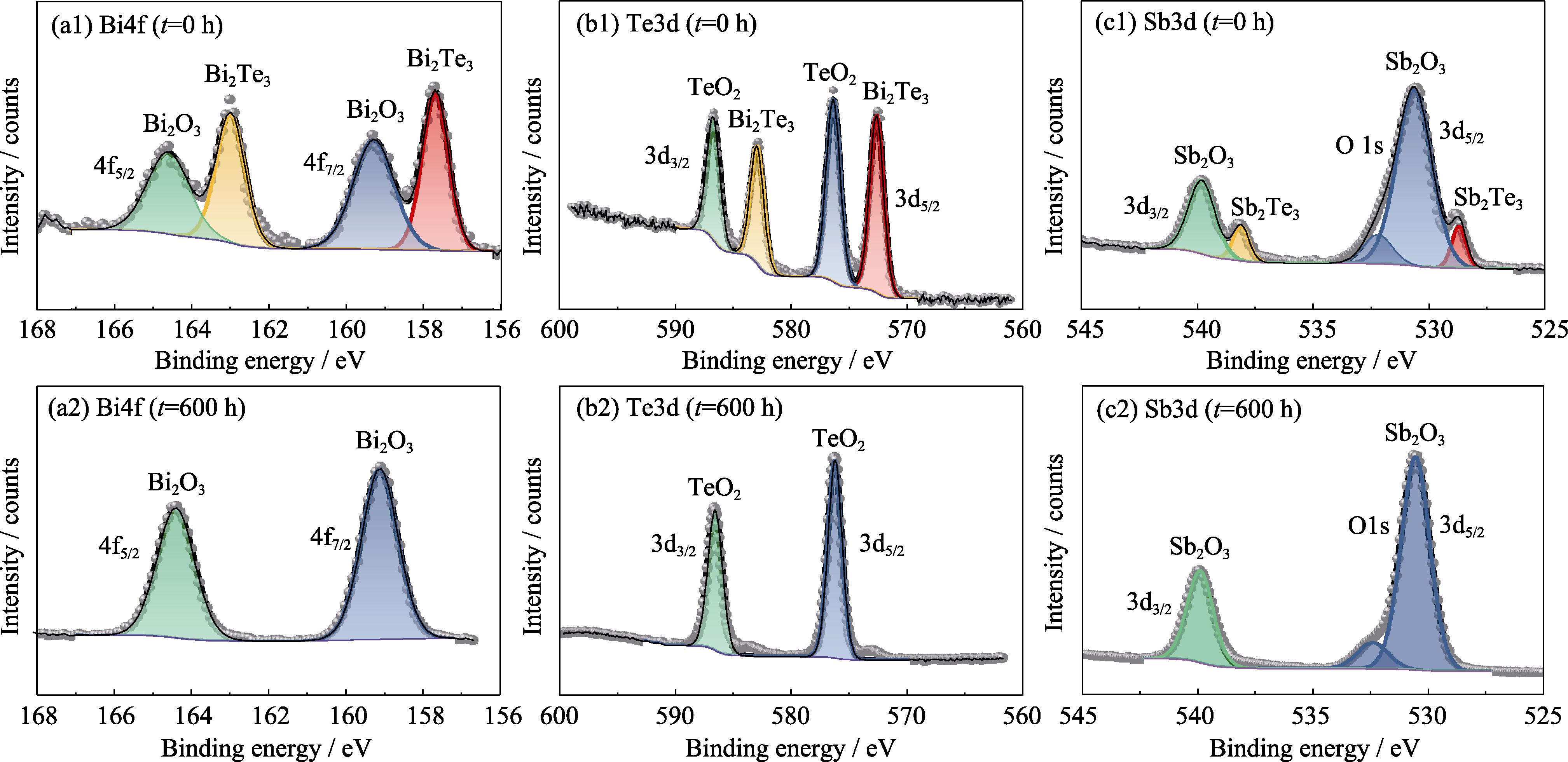

Fig. 3 Surface XPS spectra of p-type Bi0.4Sb1.6Te3 material (a1-c1) before and (a2-c2) after storage in hygrothermal environment for 600 h (a1, a2) Bi4f; (b1, b2) Te3d; (c1, c2) Sb3d

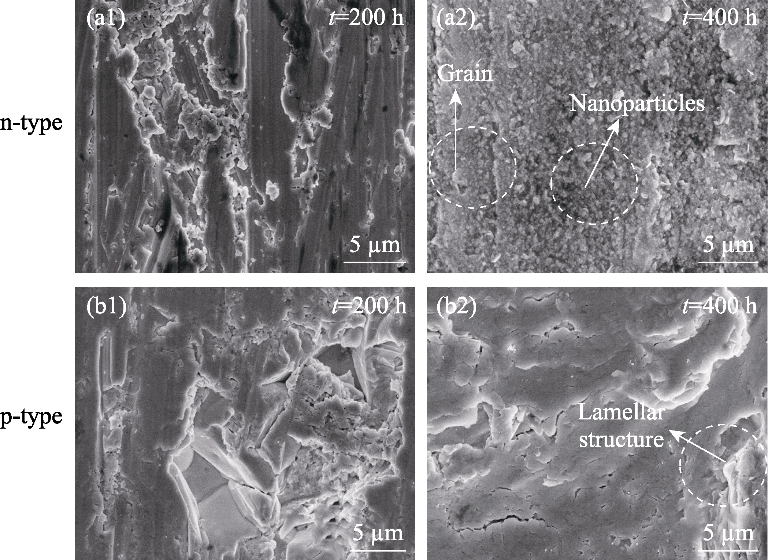

Fig. 4 FESEM images of (a1, a2) n-type Bi2Se0.21Te2.79 and (b1, b2) p-type Bi0.4Sb1.6Te3 material (a1, b1) before and (a2, b2) after storage in hygrothermal environment for 600 h

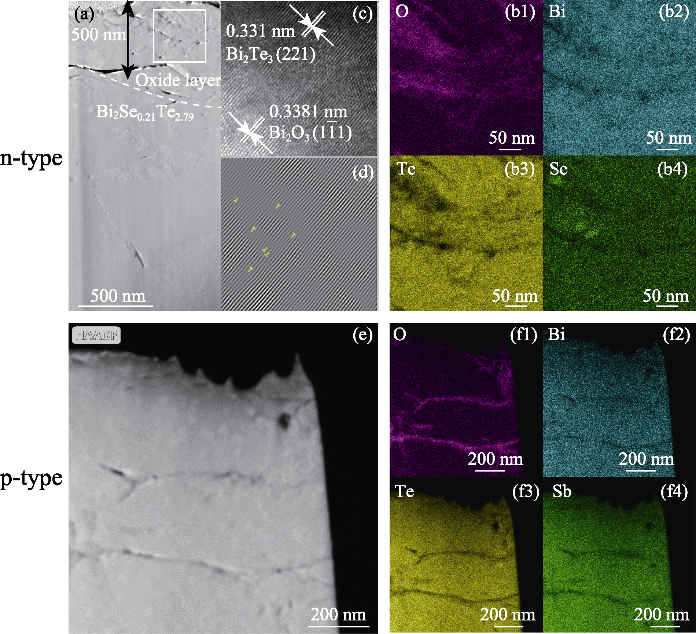

Fig. 5 (a) TEM image of the area close to the surface of n-type Bi2Se0.21Te2.79 material exposed to hygrothermal environment for 600 h; (b) elemental surface distribution profiles of the square region in (a); (c) HRTEM image of the square region in (a); (d) IFFT image of (c); (e) HAADF-STEM image of the area close to the surface of p-type Bi0.4Sb1.6Te3 material exposed to hygrothermal environment and (f) its elemental surface distribution profiles of the region (b1, f1) O; (b2, f2) Bi; (b3, f3) Te; (b4)Se; (f4) Sb

Fig. S1 Thermoelectric performance of n-type Bi2Se0.21Te2.79 in hygrothermal environment (85 ℃, 85% RH) (a) Electrical conductivity; (b) Seebeck coefficient; (c) Room temperature carrier concentration and carrier mobility; (d) Power factor; (e) Thermal conductivity; (f) ZT

Fig. S2 Thermoelectric performance of p-type Bi0.4Sb1.6Te3 in hygrothermal environment (85 ℃, 85% RH) (a) Electrical conductivity; (b) Seebeck coefficient; (c) Room temperature carrier concentration and carrier mobility; (d) Power factor; (e) Thermal conductivity; (f) ZT

Fig. S3 FESEM images of samples exposed to hygrothermal environment for different time n-type Bi2Se0.21Te2.79: (a1) 200 h; (a2) 400 h; p-type Bi0.4Sb1.6Te3: (b1) 200 h; (b2) 400 h

| [1] |

CORNETT J, CHEN B, HAIDAR S, et al. Fabrication and characterization of Bi2Te3-based chip-scale thermoelectric energy harvesting devices. Journal of Electronic Materials, 2016, 46(5):2844.

DOI URL |

| [2] |

LIU C, ZHAO K, FAN Y, et al. A flexible thermoelectric film based on Bi2Te3 for wearable applications. Functional Materials Letters, 2021, 15(1):2251005.

DOI URL |

| [3] | NOZARIASBMARZ A, DYCUS J H, CABRAL M J, et al. Efficient self-powered wearable electronic systems enabled by microwave processed thermoelectric materials. Applied Energy, 2021, 283: 116211. |

| [4] | HOU C C, VAN TOAN N, ONO T. High density micro-thermoelectric generator based on electrodeposition of Bi2Te3 and Sb2Te3. 2022 IEEE 35th International Conference on Micro Electro Mechanical Systems Conference (MEMS), Tokyo, 2022: 600-603. |

| [5] |

YAN Q, KANATZIDIS M G. High-performance thermoelectrics and challenges for practical devices. Nature Materials, 2022, 21(5):503.

DOI |

| [6] | YUAN X, L Z, SHAO Y, et al. Bi2Te3-based wearable thermoelectric generator with high power density: from structure design to application. Journal of Materials Chemistry C, 2022, 10: 6456. |

| [7] |

FRANCIOSO L, DE PASCALI C, FARELLA I, et al. Flexible thermoelectric generator for ambient assisted living wearable biometric sensors. Journal of Power Sources, 2011, 196(6):3239.

DOI URL |

| [8] | LU Z, ZHANG H, MAO C, et al. Silk fabric-based wearable thermoelectric generator for energy harvesting from the human body. Applied Energy, 2016, 164: 57. |

| [9] | WANG Y, SHI Y, MEI D, et al. Wearable thermoelectric generator to harvest body heat for powering a miniaturized accelerometer. Applied Energy, 2018, 215: 690. |

| [10] |

ZOU Q, SHANG H, HUANG D, et al. Bi2Te3-based flexible thermoelectric generator for wearable electronics. Applied Physics Letters, 2022, 120(2):023903.

DOI URL |

| [11] | YOU H, LI Z, SHAO Y, et al. Flexible Bi2Te3-based thermoelectric generator with an ultra-high power density. Applied Thermal Engineering 2022, 202: 117818. |

| [12] |

XU Z, YANG D, YUAN X, et al. Objective evaluation of wearable thermoelectric generator: from platform building to performance verification. Review of Scientific Instruments, 2022, 93(4):045105.

DOI URL |

| [13] |

HENDRICKS T J, KARRI N K. Micro- and nano-technology: a critical design key in advanced thermoelectric cooling systems. Journal of Electronic Materials, 2009, 38(7):1257.

DOI URL |

| [14] |

TANG X, LI Z, LIU W, et al. A comprehensive review on Bi2Te3- based thin films: thermoelectrics and beyond. Interdisciplinary Materials, 2022, 1(1):88.

DOI URL |

| [15] | MAMUR H, BHUIYAN M R A, KORKMAZ F, et al. A review on bismuth telluride (Bi2Te3) nanostructure for thermoelectric applications. Renewable and Sustainable Energy Reviews, 2018, 82: 4159. |

| [16] | ZHU W, WEI P, ZHANG J, et al. Fabrication and excellent performances of bismuth telluride-based thermoelectric devices. ACS Applied Materials & Interfaces, 2022, 14(10):12276. |

| [17] | LIN Y, WU X, LI Y, et al. Revealing multi-stage growth mechanism of Kirkendall voids at electrode interfaces of Bi2Te3-based thermoelectric devices with in-situ TEM technique. Nano Energy, 2022, 102: 107736. |

| [18] |

TASHIRO M, SUKENAGA S, IKEMOTO K, et al. Interfacial reactions between pure Cu, Ni, and Ni-Cu alloys and p-type Bi2Te3bulk thermoelectric material. Journal of Materials Science, 2021, 56(29):16545.

DOI |

| [19] |

CHEN L, BAI S, SHI X, et al. High temperature interfacial stability of Fe/Bi0.5Sb1.5Te3thermoelectric elements. Journal of Inorganic Materials, 2021, 36(2):197.

DOI URL |

| [20] |

ZHENG Y, TAN X Y, WAN X, et al. Thermal stability and mechanical response of Bi2Te3-based materials for thermoelectric applications. ACS Applied Energy Materials, 2019, 3(3): 2078.

DOI URL |

| [21] | LIN C F, HAU N Y, HUANG Y T, et al. Synergetic effect of Bi2Te3 alloys and electrodeposition of Ni for interfacial reactions at solder/Ni/Bi2Te3 joints. Journal of Alloys and Compounds, 2017, 708: 220. |

| [22] |

JIANG C, FAN X A, HU J, et al. Thermal stability of zone melting p-type (Bi, Sb)2Te3 ingots and comparison with the corresponding powder metallurgy samples. Journal of Electronic Materials, 2018, 47(7):4038.

DOI |

| [23] | JIANG C, FAN X A, FENG B, et al. Thermal stability of p-type polycrystalline Bi2Te3-based bulks for the application on thermoelectric power generation. Journal of Alloys and Compounds, 2017, 692: 885. |

| [24] |

HU X, FAN X A, JIANG C, et al. Thermal stability of n-type zone- melting Bi2(Te, Se)3 alloys for thermoelectric generation. Materials Research Express, 2018, 6(3):035907.

DOI URL |

| [25] | TANG H, HUI B, YANG X, et al. Thermal stability and interfacial structure evolution of Bi2Te3-based micro thermoelectric devices. Journal of Alloys and Compounds, 2022, 896: 163090. |

| [26] | ARUN P, TYAGI P, VEDESHWAR, et al. Ageing effect of Sb2Te3 thin films ageing effect of Sb2Te3 thin films. Physica B: Condensed Matter, 2001, 307: 105. |

| [27] | BANDO H, KOIZUMI K, OIKAWA Y, et al. The time-dependent process of oxidation of the surface of Bi2Te3 studied by X-ray photoelectron spectroscopy. Journal of Physics: Condensed Matter, 2000, 12: 5607. |

| [28] | GUO J H, QIU F, ZHANG Y, et al. Surface oxidation properties in a topological insulator Bi2Te3 film. Chinese Physics Letters, 2013, 30: 106801. |

| [29] | MUSIC D, CHANG K, SCHMIDT P, et al. On atomic mechanisms governing the oxidation of Bi2Te3. Journal of Physics: Condensed Matter, 2017, 29: 485705. |

| [30] | SIROTINA A P, CALLAERT C, VOLYKHOV A A, et al. Mechanistic studies of gas reactions with multicomponent solids: what can we learn by combining NAP XPS and atomic resolution STEM/EDX? The Journal of Physical Chemistry C, 2019, 123: 26201. |

| [31] | THOMAS C R, VALLON M K, FRITH M G, et al. Surface oxidation of Bi2(Te,Se)3 topological insulators depends on cleavage accuracy. Chemistry of Materials, 2016, 28: 35. |

| [32] | QU Q, LIU B, LIANG J, et al. Expediting hydrogen evolution through topological surface states on Bi2Te3. ACS Catalysis, 2020, 10: 1656. |

| [33] | SHARMA P A, OHTA T, BRUMBACH M T, et al. Ex Situ photoelectron emission microscopy of polycrystalline bismuth and antimony telluride surfaces exposed to ambient oxidation. Applied Materials & Interfaces, 2021, 13: 18218. |

| [34] | LU B, HU S, LI W E, et al. Preparation and characterization of Sb2Te3 thin films by coevaporation. International Journal of Photoenergy, 2010, 4: 476589. |

| [35] |

NORIMASA O, KUROKAWA T, EGUCHI R, et al. Evaluation of thermoelectric performance of Bi2Te3 films as a function of temperature increase rate during heat treatment. Coatings, 2021, 11(1):38.

DOI URL |

| [36] | LI A, NAN P, WANG Y, et al. Chemical stability and degradation mechanism of Mg3Sb2-Bi thermoelectrics towards room-temperature applications. Acta Materialia, 2022, 239: 118301. |

| [37] | ZHAO Y, BURDA C. Chemical synthesis of Bi(0.5)Sb(1.5)Te3 nanocrystals and their surface oxidation properties. ACS Applied Materials & Interfaces, 2009, 1(6):1259. |

| [38] | JEONG K, PARK D, MAENG I, et al. Modulation of optoelectronic properties of the Bi2Te3nanowire by controlling the formation of selective surface oxidation. Applied Surface Science, 2021, 548: 149069. |

| [1] | CHENG Jun, ZHANG Jiawei, QIU Pengfei, CHEN Lidong, SHI Xun. Preparation and Thermoelectric Transport Properties of P-doped β-FeSi2 [J]. Journal of Inorganic Materials, 2024, 39(8): 895-902. |

| [2] | CHEN Hao, FAN Wenhao, AN Decheng, CHEN Shaoping. Improvement of Thermoelectric Performance of SnTe by Energy Band Optimization and Carrier Regulation [J]. Journal of Inorganic Materials, 2024, 39(3): 306-312. |

| [3] | TIAN Zhen, JIANG Quanwei, LI Jianbo, YU Lifeng, KANG Huijun, WANG Tongmin. Simultaneous Optimization of Electrical and Thermal Transport Properties of BiSbSe1.50Te1.50 Thermoelectrics by Hot Deformation [J]. Journal of Inorganic Materials, 2024, 39(12): 1316-1324. |

| [4] | ZHANG Zhe, SUN Tingting, WANG Lianjun, JIANG Wan. Flexible Thermoelectric Films with Different Ag2Se Dimensions: Performance Optimization and Device Integration [J]. Journal of Inorganic Materials, 2024, 39(11): 1221-1227. |

| [5] | MENG Yuting, WANG Xuemei, ZHANG Shuxian, CHEN Zhiwei, PEI Yanzhong. Single- and Two-band Transport Properties Crossover in Bi2Te3 Based Thermoelectrics [J]. Journal of Inorganic Materials, 2024, 39(11): 1283-1291. |

| [6] | SU Haojian, ZHOU Min, LI Laifeng. Optimization of Thermoelectric Properties of SnTe via Multi-element Doping [J]. Journal of Inorganic Materials, 2024, 39(10): 1159-1166. |

| [7] | HE Danqi, WEI Mingxu, LIU Ruizhi, TANG Zhixin, ZHAI Pengcheng, ZHAO Wenyu. Heavy-Fermion YbAl3 Materials: One-step Synthesis and Enhanced Thermoelectric Performance [J]. Journal of Inorganic Materials, 2023, 38(5): 577-582. |

| [8] | HUA Siheng, YANG Dongwang, TANG Hao, YUAN Xiong, ZHAN Ruoyu, XU Zhuoming, LYU Jianan, XIAO Yani, YAN Yonggao, TANG Xinfeng. Effect of Surface Treatment of n-type Bi2Te3-based Materials on the Properties of Thermoelectric Units [J]. Journal of Inorganic Materials, 2023, 38(2): 163-169. |

| [9] | LI Jianbo, TIAN Zhen, JIANG Quanwei, YU Lifeng, KANG Huijun, CAO Zhiqiang, WANG Tongmin. Effects of Different Element Doping on Microstructure and Thermoelectric Properties of CaTiO3 [J]. Journal of Inorganic Materials, 2023, 38(12): 1396-1404. |

| [10] | WANG Pengjiang, KANG Huijun, YANG Xiong, LIU Ying, CHENG Cheng, WANG Tongmin. Inhibition of Lattice Thermal Conductivity of ZrNiSn-based Half-Heusler Thermoelectric Materials by Entropy Adjustment [J]. Journal of Inorganic Materials, 2022, 37(7): 717-723. |

| [11] | CHENG Cheng, LI Jianbo, TIAN Zhen, WANG Pengjiang, KANG Huijun, WANG Tongmin. Thermoelectric Property of In2O3/InNbO4 Composites [J]. Journal of Inorganic Materials, 2022, 37(7): 724-730. |

| [12] | LOU Xunuo, DENG Houquan, LI Shuang, ZHANG Qingtang, XIONG Wenjie, TANG Guodong. Thermal and Electrcial Transport Properities of Ge Doped MnTe Thermoelectrics [J]. Journal of Inorganic Materials, 2022, 37(2): 209-214. |

| [13] | JIN Min, BAI Xudong, ZHANG Rulin, ZHOU Lina, LI Rongbin. Metal Sulfide Ag2S: Fabrication via Zone Melting Method and Its Thermoelectric Property [J]. Journal of Inorganic Materials, 2022, 37(1): 101-106. |

| [14] | ZHANG Cencen, WANG Xue, PENG Liangming. Thermoelectric Transport Characteristics of n-type (PbTe)1-x-y(PbS)x(Sb2Se3)y Systems via Stepwise Addition of Dual Components [J]. Journal of Inorganic Materials, 2021, 36(9): 936-942. |

| [15] | YANG Qingyu, QIU Pengfei, SHI Xun, CHEN Lidong. Application of Entropy Engineering in Thermoelectrics [J]. Journal of Inorganic Materials, 2021, 36(4): 347-354. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||