Journal of Inorganic Materials ›› 2023, Vol. 38 ›› Issue (2): 163-169.DOI: 10.15541/jim20220106

Special Issue: 【能源环境】热电材料(202506)

• RESEARCH ARTICLE • Previous Articles Next Articles

HUA Siheng( ), YANG Dongwang, TANG Hao, YUAN Xiong, ZHAN Ruoyu, XU Zhuoming, LYU Jianan, XIAO Yani, YAN Yonggao(

), YANG Dongwang, TANG Hao, YUAN Xiong, ZHAN Ruoyu, XU Zhuoming, LYU Jianan, XIAO Yani, YAN Yonggao( ), TANG Xinfeng(

), TANG Xinfeng( )

)

Received:2022-03-02

Revised:2022-05-09

Published:2023-02-20

Online:2022-05-27

Contact:

YAN Yonggao, professor. E-mail: yanyonggao@whut.edu.cn;About author:HUA Siheng (1997-), male, Master candidate. E-mail: si.heng_0-1@whut.edu.cn

Supported by:CLC Number:

HUA Siheng, YANG Dongwang, TANG Hao, YUAN Xiong, ZHAN Ruoyu, XU Zhuoming, LYU Jianan, XIAO Yani, YAN Yonggao, TANG Xinfeng. Effect of Surface Treatment of n-type Bi2Te3-based Materials on the Properties of Thermoelectric Units[J]. Journal of Inorganic Materials, 2023, 38(2): 163-169.

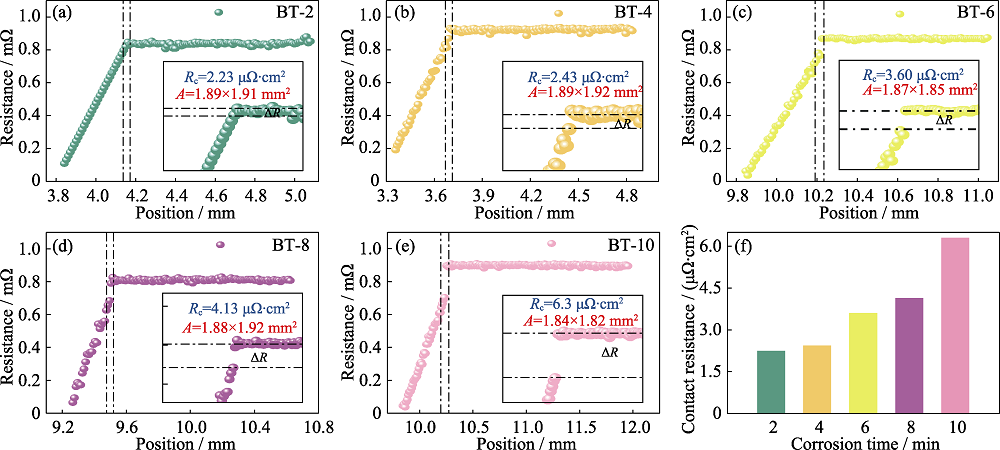

Fig. 1 Test curves of contact resistances between BT-x(x=2 (a), 4 (b), 6 (c), 8(d), 10 (e)) materials and Ni barrier layers, and (f) histogram of contact resistance for BT-x A: Test sample cross-sectional area; Rc: Contact resistance; ΔR: Resistance mutation value

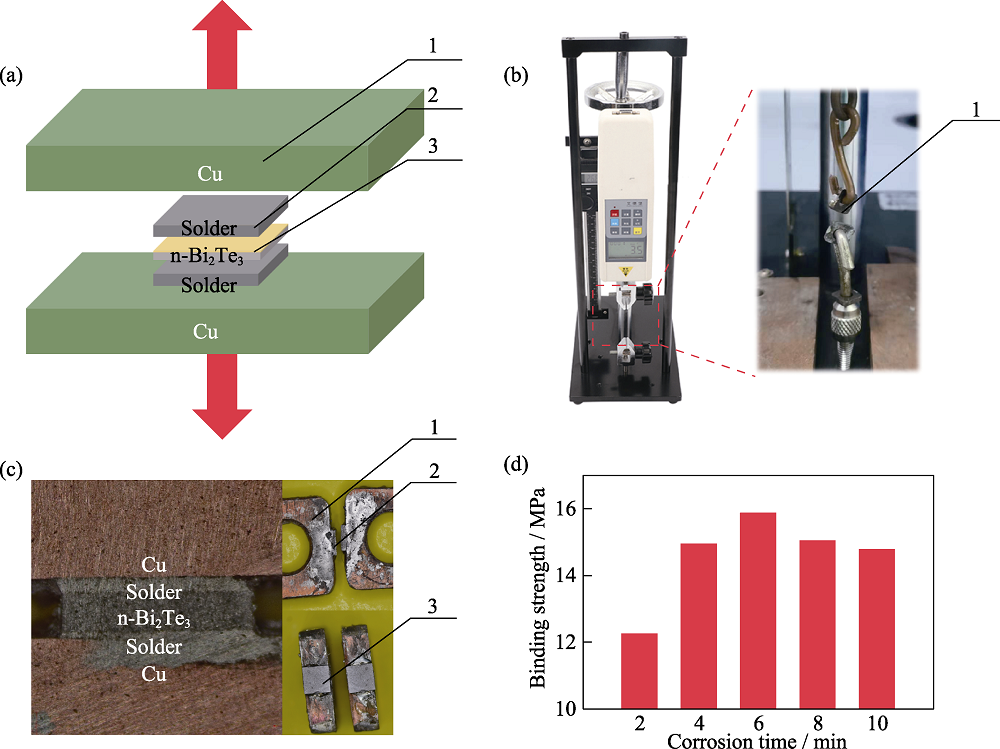

Fig. 2 Interface bonding strength test (a) Schematic diagram of tensile strength test model; (b) Picture of tensile test equipment; (c) Pictures of tensile test object; (d) Histogram of bonding strength for BT-x; 1: copper ring, 2: SAC305 solder, 3: BT-x

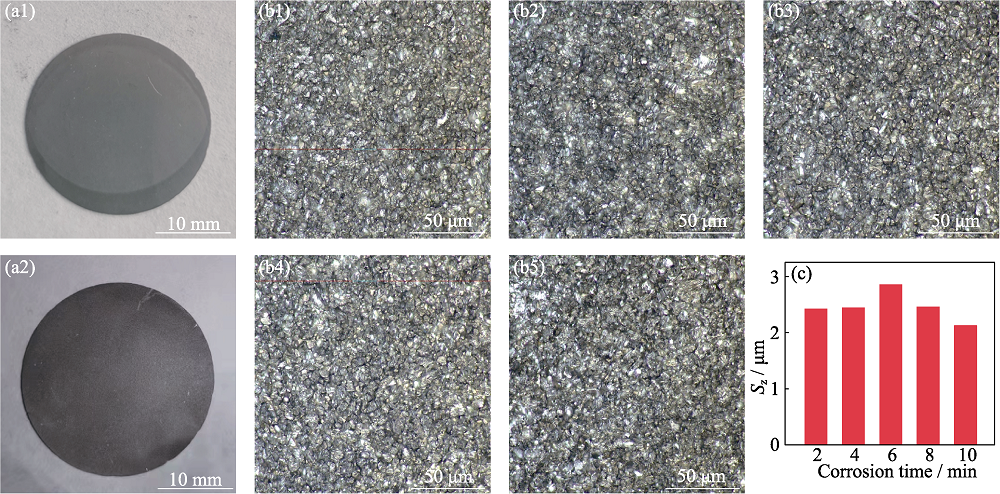

Fig. 3 Digital photos of BT-4 sample before (a1) and after (a2) corrosion, optical microstructures of BT-x(x=2 (b1), 4 (b2), 6 (b3), 8 (b4), 10 (b5)) surfaces, and (c) histogram of roughness for BT-x

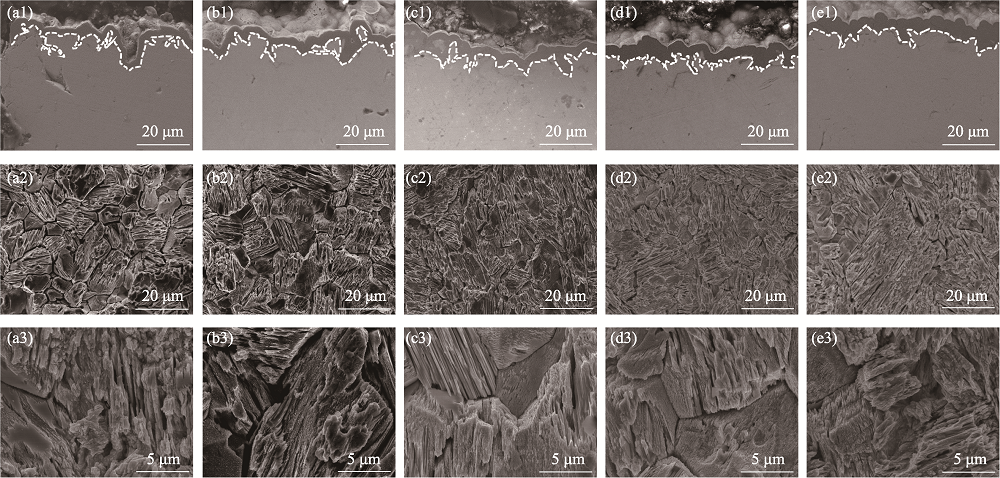

Fig. 4 Microstructures of material interfaces between BT-x(x=2 (a1-a3), 4 (b1-b3), 6 (c1-c3), 8 (d1-d3), 10 (e1-e3)) and Ni barrier layers (a1-e1) Interfacial backscattered image; (a2-e2, a3-e3) Secondary electron images of corrosion surfaces

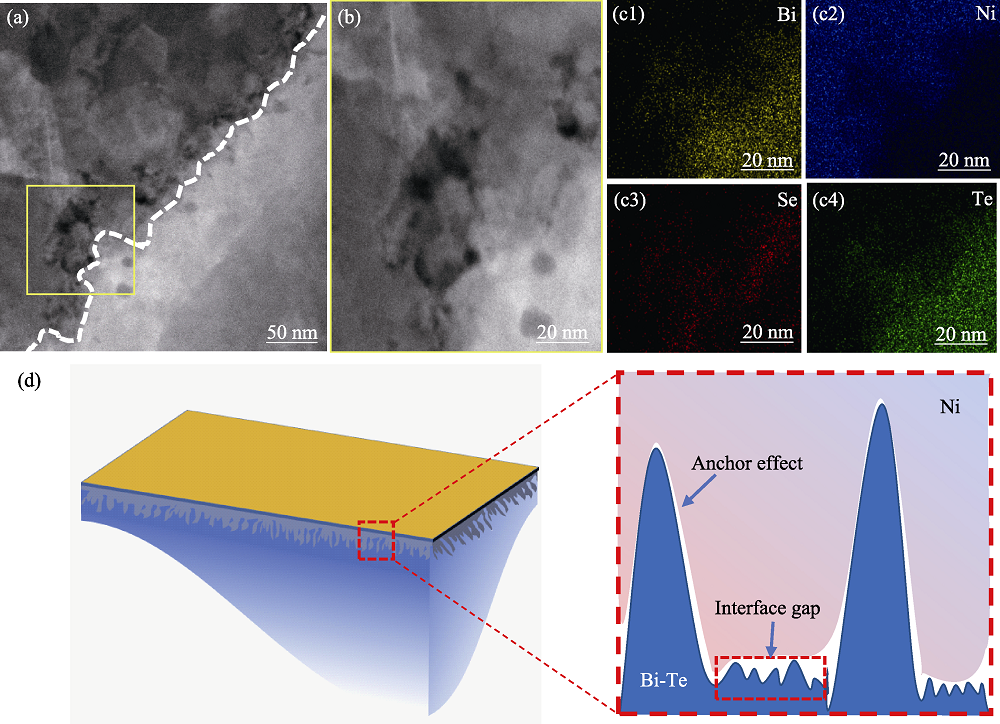

Fig. 5 (a) Fine microstructure of the interface between BT-4 material and Ni layer, (b) partially enlarged image and corresponding (c1) Bi, (c2) Ni, (c3) Se, (c4) Te surficial elemental distribution mappings, and (d) schematic diagram of interface structure between BT-4 material and Ni barrier layer

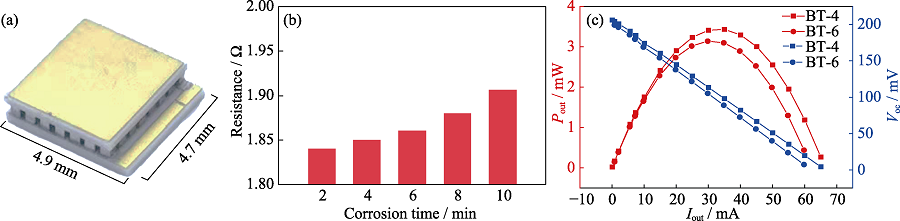

Fig. 6 Performance of micro thermoelectric device (a) Photo of micro thermoelectric device, (b) histogram of internal resistance of micro thermoelectric device prepared with BT-x, and (c) Volt-ampere curves and output power curves of micro thermoelectric devices prepared with BT-4 and BT-6

| Ref. | Contact resistance/ (μΩ·cm2) | Bonding strength/MPa | Device size/mm3 |

|---|---|---|---|

| LIU[ | <1 | 16 | 1.8×1.8×2.4 |

| TANG[ | 5.31 | 17.62 | 2×2×0.45 |

| This work (BT-4) | 2.43 | 14.95 | 2×2×0.45 |

Table 1 Contact resistance and tensile bonding strength parameters of n-type Bi2Te3 barrier layers

| Ref. | Contact resistance/ (μΩ·cm2) | Bonding strength/MPa | Device size/mm3 |

|---|---|---|---|

| LIU[ | <1 | 16 | 1.8×1.8×2.4 |

| TANG[ | 5.31 | 17.62 | 2×2×0.45 |

| This work (BT-4) | 2.43 | 14.95 | 2×2×0.45 |

| [1] |

CHEN W Y, SHI X L, ZOU J, et al. Thermoelectric coolers: progress, challenges, and opportunities. Small Methods, 2022, 6(2): 2101235.

DOI URL |

| [2] |

ROSENBERG Z B, WEINER N C, SHAHARIAR H, et al. Design of a scalable, flexible, and durable thermoelectric cooling device for soft electronics using Kirigami cut patterns. Flexible and Printed Electronics, 2022, 7(1): 015002.

DOI URL |

| [3] |

CUI Y J, WANG B L, WANG K F, et al. An analytical model to evaluate the fatigue crack effects on the hybrid photovoltaic- thermoelectric device. Renewable Energy, 2022, 182: 923.

DOI URL |

| [4] |

WU Z H, ZHANG S, LIU Z K, et al. Thermoelectric converter: strategies from materials to device application. Nano Energy, 2022, 91: 106692.

DOI URL |

| [5] |

LIU Y J, HOU S H, WANG X D, et al. Passive radiative cooling enables improved performance in wearable thermoelectric generators. Small, 2022, 18(10): 2106875.

DOI URL |

| [6] |

YUSUF A, BALLIKAYA S. Electrical, thermomechanical and cost analyses of a low-cost thermoelectric generator. Energy, 2022, 241: 122934.

DOI URL |

| [7] |

TOHIDI F, HOLAGH S G, CHITSAZ A. Thermoelectric generators: a comprehensive review of characteristics and applications. Applied Thermal Engineering, 2022, 201(A): 117793.

DOI URL |

| [8] |

MASOUMI S, O'SHAUGHNESSY S, PAKDEL A. Organic-based flexible thermoelectric generators: from materials to devices. Nano Energy, 2022, 92: 106774.

DOI URL |

| [9] | HASAN M N, NAFEA M, NAYAN N, et al. Thermoelectric generator: materials and applications in wearable health monitoring sensors and internet of things devices. Advanced Materials Technologies, 2021: 2101203. |

| [10] |

ZAIA E W, GORDON M P, YUAN P Y, et al. Progress and perspective: soft thermoelectric materials for wearable and internet-of-things applications. Advanced Electronic Materials, 2019, 5(11): 1800823.

DOI URL |

| [11] |

ZHANG Q H, BAI S Q, CHEN L D. Technologies and applications of thermoelectric devices: current status, challenges and prospects. Journal of Inorganic Materials, 2019, 34(3): 279.

DOI URL |

| [12] |

CHENG J, HU X, LI Q. Influences of different barrier films on microstructures and electrical properties of Bi2Te3-based joints. Journal of Materials Science: Materials in Electronics, 2020, 31(17): 14714.

DOI URL |

| [13] |

HU X K, ZHANG S M, ZHAO F, et al. Thermoelectric device: contact interface and interface materials. Journal of Inorganic Materials, 2019, 34(3): 269.

DOI URL |

| [14] |

LIU W S, WANG H Z, WANG L J, et al. Understanding of the contact of nanostructured thermoelectric n-type Bi2Te2.7Se0.3 legs for power generation applications. Journal of Materials Chemistry A, 2013, 1(42): 13093.

DOI URL |

| [15] | WEITZMAN L H. Etching bismuth telluride. USA US30736863A. 1967. |

| [16] | 陈良杰. 用于半导体N/P型致冷晶片表面电镀前处理的粗化液及相关的电镀前处理工艺. 中国 CN101701348A. 2010. |

| [17] | 蔡新志, 朱刘, 李德全. 碲铋基晶片的表面处理方法. 中国 CN107723767B. 2019. |

| [18] |

TANG H, BAI H, YANG X, et al. Thermal stability and interfacial structure evolution of Bi2Te3-based micro thermoelectric devices. Journal of Alloys and Compounds, 2022, 896: 163090.

DOI URL |

| [19] |

GUPTA R P, MCCARTY R, SHARP J. Practical contact resistance measurement method for bulk Bi2Te3-based thermoelectric devices. Journal of Electronic Materials, 2014, 43(6): 1608.

DOI URL |

| [20] |

GUPTA R P, XIONG K, WHITE J B, et al. Low resistance Ohmic contacts to Bi2Te3 using Ni and Co metallization. Journal of the Electrochemical Society, 2010, 157(6): H666.

DOI URL |

| [21] |

BEN KHEDIM M, CAGNON L, ANDRE E, et al. Contact resistance optimization for development of thermoelectric modules based on bismuth telluride nanowires. AIP Advances, 2021, 11(5): 055109.

DOI URL |

| [22] | KONG X, WEI Z, CAO L, et al. Controllable electrical contact resistance between Cu and oriented-Bi2Te3 film via interface tuning. 2017, 9(30): 25606. |

| [23] |

ZHU X, CAO L, ZHU W, et al. Enhanced interfacial adhesion and thermal stability in bismuth telluride/nickel/copper multilayer films with low electrical contact resistance. Advanced Materials Interfaces, 2018, 5(23): 1801279.

DOI URL |

| [24] |

ZOU X, SARIYEV B, CHEN K, et al. Enhanced interfacial bonding strength between metal and polymer via synergistic effects of particle anchoring and chemical bonding. Journal of Manufacturing Processes, 2021, 68: 558.

DOI URL |

| [25] |

TAYLOR P J, MADDUX J R, MEISSNER G, et al. Controlled improvement in specific contact resistivity for thermoelectric materials by ion implantation. Applied Physics Letters, 2013, 103(4): 043902.

DOI URL |

| [26] | HILL L R. Method of bonding bismuth-containing bodies. USA US3110100A, 1963. |

| [27] | KAZEMI D, YAFTIAN M R, KOLEV S D. Selective extraction of Bi(III) from sulfate solutions by a poly(vinyl chloride) based polymer inclusion membrane incorporating bis(2-ethylhexyl) phosphoric acid as the extractant. Reactive & Functional Polymers, 2021, 164: 104935. |

| [28] | TERAMOTO I, TAKAYANAGI S. Dislocation etch pits on bismuth telluride crystals. Journal of Applied Physics, 1961, 32(1): 119. |

| [29] | CHEN K K, ZHENG Y J. Selective extracting Te from tellurium richen residue containing precious metals by H2SO4-H2O2 solutions. Chinese Journal of Rare Metals, 2013, 37(6): 946. |

| [30] | FU S J, LI Z X, WANG S L, et al. Extracting tellurium from alkaline residue. Chinese Journal of Rare Metals, 2011, 35(1): 124. |

| [31] | LIU B G, HUANG X J. Patents technical reviews of metallurgical extraction of bismuth. Guangdong Chemical Industry, 2018, 45(4): 111. |

| [32] |

BOGREKCI I, DURAKBASA M N, DEMIRCIOGLU P. Comparison between 3D digital and optical microscopes for the surface measurement by computer vision. At-Automatisierungstechnik, 2013, 61(3): 195.

DOI URL |

| [33] |

LEI G F, LIU Q S, PENG X X, et al. Experimental study on mechanical properties of fractured rock mass under different anchoring modes. European Journal of Environmental and Civil Engineering, 2020, 24(7): 931.

DOI URL |

| [34] |

YUAN C, CHEN W S, PHAM T M, et al. New epoxy anchor for better bonding between FRP sheets and concrete. Construction and Building Materials, 2020, 248: 118628.

DOI URL |

| [1] | MENG Yuting, WANG Xuemei, ZHANG Shuxian, CHEN Zhiwei, PEI Yanzhong. Single- and Two-band Transport Properties Crossover in Bi2Te3 Based Thermoelectrics [J]. Journal of Inorganic Materials, 2024, 39(11): 1283-1291. |

| [2] | XIAO Yani, LYU Jianan, LI Zhenming, LIU Mingyang, LIU Wei, REN Zhigang, LIU Hongjing, YANG Dongwang, YAN Yonggao. Hygrothermal Stability of Bi2Te3-based Thermoelectric Materials [J]. Journal of Inorganic Materials, 2023, 38(7): 800-806. |

| [3] | DENG Yuan, LI Na, WANG Yao, YANG Meng. In-situ Fabrication of Bi2Te3-Te Sheet-rods Using Te Nanowires as Template [J]. Journal of Inorganic Materials, 2010, 25(6): 664-668. |

| [4] | LIU Song-Xiu,LIU Hong-Mei,HUANG Kai-Xun. Preparation of Single Crystalline Bi2Te3 Nanorods through Chemical Reduction at Low Temperature [J]. Journal of Inorganic Materials, 2008, 23(2): 305-308. |

| [5] | WANG Wei,JIA Fa-Long,HUANG Qing-Hua,ZHANG Wei-Ling,GUO He-Tong,SHEN Yu-Tian. Electrochemical Assembled p-type Bi2Te3 Thermoelectric Materials with Nanowire Array Structure [J]. Journal of Inorganic Materials, 2004, 19(3): 517-522. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||