Journal of Inorganic Materials ›› 2017, Vol. 32 ›› Issue (6): 615-620.DOI: 10.15541/jim20160489

• Orginal Article • Previous Articles Next Articles

SUN Dan-Dan1, ZHANG Jia-Liang2, WU Yan-Qing3, ZHANG Zhong-Qiu4, LIU Da-Kang5

Received:2016-08-29

Revised:2016-10-09

Published:2017-06-20

Online:2017-05-27

About author:SUN Dan-Dan. E-mail: sdd1133556@163.com

Supported by:CLC Number:

SUN Dan-Dan, ZHANG Jia-Liang, WU Yan-Qing, ZHANG Zhong-Qiu, LIU Da-Kang. Raw-material Pre-milling on Physical Property of BaTiO3 Piezoelectric Ceramics[J]. Journal of Inorganic Materials, 2017, 32(6): 615-620.

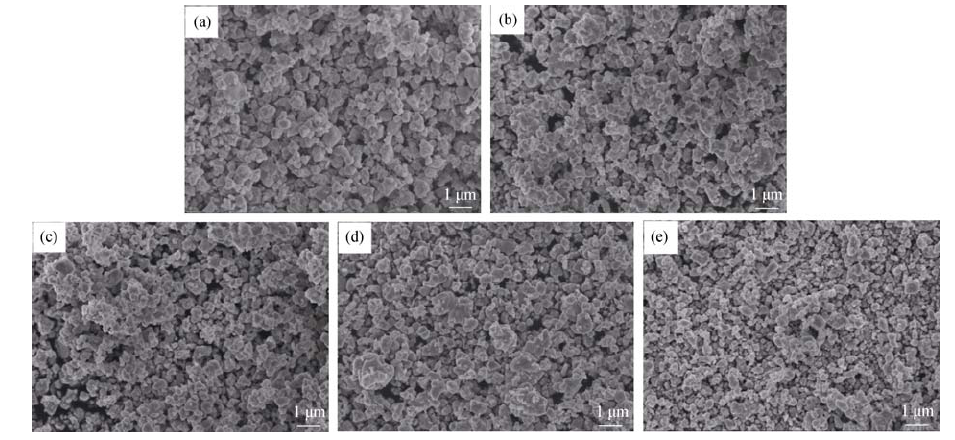

Fig. 2 SEM images of BaTiO3 ceramic powders(a) Prepared with untreated BaCO3 powders; (b)-(e) Prepared with ball-milling BaCO3 powders for 4, 6, 8, and 10 h, respectively

| Premilling time/h | Sinter. temp. /℃ | ρ/% | g/μm | d33/(pC·N-1) | ε’ at 1 kHz | tanδ/% | TO-T/℃ | TC/℃ |

|---|---|---|---|---|---|---|---|---|

| 0 | 1210 | 95.6 | 3.4 | 370 | 3212 | 3.1 | - | - |

| 1220 | 97.8 | 3.5 | 410 | 3370 | 3.1 | 27.8 | 121.8 | |

| 4 | 1230 | 96.5 | 1.3 | 450 | 3547 | 3.1 | 25.6 | 121.5 |

| 6 | 1230 | 96.9 | 1.9 | 440 | 3350 | 2.9 | 27.2 | 122.6 |

| 8 | 1230 | 96.1 | 1.4 | 470 | 4133 | 2.9 | 28.2 | 120.6 |

| 10 | 1230 | 95.7 | 1.4 | 465 | 3560 | 3.1 | 25.8 | 122.1 |

Table 1 Physical properties of BaTiO3 ceramics prepared with ball-milling BaCO3 powders for different time

| Premilling time/h | Sinter. temp. /℃ | ρ/% | g/μm | d33/(pC·N-1) | ε’ at 1 kHz | tanδ/% | TO-T/℃ | TC/℃ |

|---|---|---|---|---|---|---|---|---|

| 0 | 1210 | 95.6 | 3.4 | 370 | 3212 | 3.1 | - | - |

| 1220 | 97.8 | 3.5 | 410 | 3370 | 3.1 | 27.8 | 121.8 | |

| 4 | 1230 | 96.5 | 1.3 | 450 | 3547 | 3.1 | 25.6 | 121.5 |

| 6 | 1230 | 96.9 | 1.9 | 440 | 3350 | 2.9 | 27.2 | 122.6 |

| 8 | 1230 | 96.1 | 1.4 | 470 | 4133 | 2.9 | 28.2 | 120.6 |

| 10 | 1230 | 95.7 | 1.4 | 465 | 3560 | 3.1 | 25.8 | 122.1 |

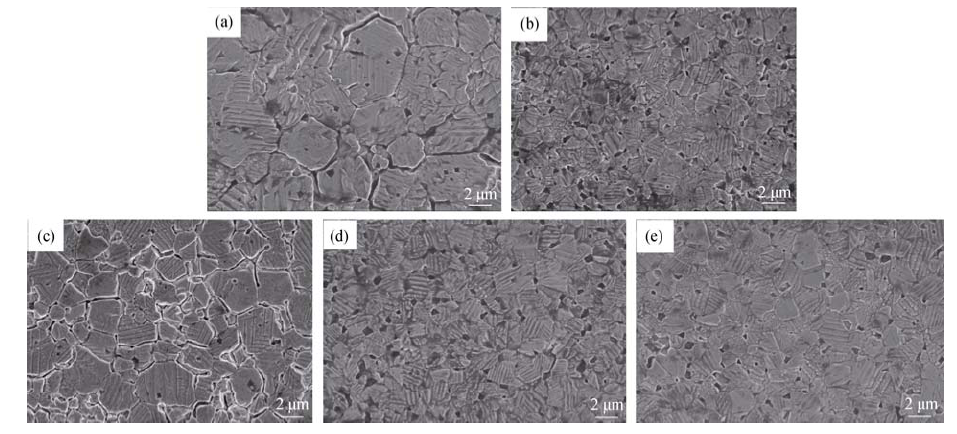

Fig. 4 SEM images of microstructure for various BaTiO3 ceramics prepared with ball-milling BaCO3 powders for different time(a) Prepared with untreated BaCO3 powder; (b)-(e) Prepared with ball-milling BaCO3 powders for 4, 6, 8, and 10 h, respectively

| [1] | JAFFE B, COOK W R, JAFFE H. Piezoelectric Ceramics.London : Academic Press, 1971: 53-114. |

| [2] | TAKAHASHI H, NUMAMOTO Y, TANI J, et al.Domain properties of high-performance barium titanate ceramics.Japanese Journal of Applied Physics, 2007, 46(10S): 7044-7047. |

| [3] | KARAKI T, YAN K, MIYAMOTO T, et al.Lead-free piezoelectric ceramics with large dielectric and piezoelectric constants manufactured from BaTiO3 nano-powder.Japanese Journal of Applied Physics, 2007, 46(2L): L97-L98. |

| [4] | WADA S, TAKEDA K, MURAISHI T, et al.Preparation of [110] grain oriented barium titanate ceramics by templated grain growth method and their piezoelectric properties.Japanese Journal of Applied Physics, 2007, 46(10S): 7039-7043. |

| [5] | SHAO S F, ZHANG J L, ZHANG Z, et al.High piezoelectric properties and domain configuration in BaTiO3 ceramics obtained through the solid-state reaction route.Journal of Physics D: Applied Physics, 2008, 41(12): 125408. |

| [6] | ZHENG P, ZHANG J L, TAN Y Q, et al.Grain-size effects on dielectric and piezoelectric properties of poled BaTiO3 ceramics.Acta Mater., 2012, 60(s13-14): 5022-5030. |

| [7] | HUAN Y, WANG X, FANG J, et al.Grain size effects on piezoelectric properties and domain structure of BaTiO3 ceramics prepared by two‐step sintering.Journal of the American Ceramic Society, 2013, 96(11): 3369-3371. |

| [8] | ZHANG J L, JI P F, WU Y Q, et al.Strong piezoelectricity exhibited by large-grained BaTiO3 ceramics.Applied Physics Letters, 2014, 104(22): 222909. |

| [9] | TAN Y Q, ZHANG J L, WU Y Q, et al.Unfolding grain size effects in barium titanate ferroelectric ceramics.Scientific Reports, 2015, 5: 9953. |

| [10] | WANG J C, ZHENG P, YIN R Q, et al.Different piezoelectric grain size effects in BaTiO3 ceramics.Ceramics International, 2015, 41(10): 14165-14171. |

| [11] | ZHENG P, ZHANG J L, SHAO S F, et al.Piezoelectric properties and stabilities of CuO-modified Ba(Ti,Zr)O3 ceramics.Applied Physics Letters, 2009, 94(3): 2902. |

| [12] | LIU W F, REN X B.Large piezoelectric effect in Pb-free ceramics.Physical Review Letters, 2009, 103(25): 257602. |

| [13] | ZHANG J L, ZHANG Z, SHAO S F, et al.High piezoelectric performance and relevant physical mechanism of CuO-modified Ba(Ti0.96Sn0.04)O3 ceramics.Journal of Advanced Dielectrics, 2011, 1(01): 79-84. |

| [1] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [2] | WU Lukang, FU Zhengqian, YU Ziyi, YANG Jun, ZHOU Bin, CHEN Xuefeng, XU Fangfang. Application of Electron Energy-loss Spectroscopy to BaTiO3 Multi-layer Ceramic Capacitors [J]. Journal of Inorganic Materials, 2025, 40(6): 683-689. |

| [3] | MU Haojie, ZHANG Yuanjiang, YU Bin, FU Xiumei, ZHOU Shibin, LI Xiaodong. Preparation and Properties of ZrO2 Doped Y2O3-MgO Nanocomposite Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 281-289. |

| [4] | FAN Wugang, CAO Xiong, ZHOU Xiang, LI Ling, ZHAO Guannan, ZHANG Zhaoquan. Anticorrosion Performance of 8YSZ Ceramics in Simulated Aqueous Environment of Pressurized Water Reactor [J]. Journal of Inorganic Materials, 2024, 39(7): 803-809. |

| [5] | CHEN Qian, SU Haijun, JIANG Hao, SHEN Zhonglin, YU Minghui, ZHANG Zhuo. Progress of Ultra-high Temperature Oxide Ceramics: Laser Additive Manufacturing and Microstructure Evolution [J]. Journal of Inorganic Materials, 2024, 39(7): 741-753. |

| [6] | JIANG Lingyi, PANG Shengyang, YANG Chao, ZHANG Yue, HU Chenglong, TANG Sufang. Preparation and Oxidation Behaviors of C/SiC-BN Composites [J]. Journal of Inorganic Materials, 2024, 39(7): 779-786. |

| [7] | ZHENG Yawen, ZHANG Cuiping, ZHANG Ruijie, XIA Qian, RU Hongqiang. Fabrication of Boron Carbide Ceramic Composites by Boronic Acid Carbothermal Reduction and Silicon Infiltration Reaction Sintering [J]. Journal of Inorganic Materials, 2024, 39(6): 707-714. |

| [8] | XUE Yifan, LI Weijie, ZHANG Zhongwei, PANG Xu, LIU Yu. Process Control of PyC Interphases Microstructure and Uniformity in Carbon Fiber Cloth [J]. Journal of Inorganic Materials, 2024, 39(4): 399-408. |

| [9] | SUN Chuan, HE Pengfei, HU Zhenfeng, WANG Rong, XING Yue, ZHANG Zhibin, LI Jinglong, WAN Chunlei, LIANG Xiubing. SiC-based Ceramic Materials Incorporating GNPs Array: Preparation and Mechanical Characterization [J]. Journal of Inorganic Materials, 2024, 39(3): 267-273. |

| [10] | LIU Song, ZHANG Faqiang, LUO Jin, LIU Zhifu. 0.9BaTiO3-0.1Bi(Mg1/2Ti1/2)O3 Ferroelectric Thin Films: Preparation and Energy Storage [J]. Journal of Inorganic Materials, 2024, 39(3): 291-298. |

| [11] | ZHENG Jiaqian, LU Xiao, LU Yajie, WANG Yingjun, WANG Zhen, LU Jianxi. Functional Bioadaptability in Medical Bioceramics: Biological Mechanism and Application [J]. Journal of Inorganic Materials, 2024, 39(1): 1-16. |

| [12] | HE Danqi, WEI Mingxu, LIU Ruizhi, TANG Zhixin, ZHAI Pengcheng, ZHAO Wenyu. Heavy-Fermion YbAl3 Materials: One-step Synthesis and Enhanced Thermoelectric Performance [J]. Journal of Inorganic Materials, 2023, 38(5): 577-582. |

| [13] | WU Shuang, GOU Yanzi, WANG Yongshou, SONG Quzhi, ZHANG Qingyu, WANG Yingde. Effect of Heat Treatment on Composition, Microstructure and Mechanical Property of Domestic KD-SA SiC Fibers [J]. Journal of Inorganic Materials, 2023, 38(5): 569-576. |

| [14] | XIE Jiaye, LI Liwen, ZHU Qiang. Contrastive Study on in Vitro Antibacterial Property and Biocompatibility of Three Clinical Pulp Capping Agents [J]. Journal of Inorganic Materials, 2023, 38(12): 1449-1456. |

| [15] | LI Jianbo, TIAN Zhen, JIANG Quanwei, YU Lifeng, KANG Huijun, CAO Zhiqiang, WANG Tongmin. Effects of Different Element Doping on Microstructure and Thermoelectric Properties of CaTiO3 [J]. Journal of Inorganic Materials, 2023, 38(12): 1396-1404. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||