Journal of Inorganic Materials ›› 2024, Vol. 39 ›› Issue (3): 291-298.DOI: 10.15541/jim20230488

Special Issue: 【信息功能】电介质储能材料(202506); 【信息功能】介电、铁电、压电材料(202506); 【信息功能】纪念殷之文先生诞辰105周年虚拟学术专辑

• RESEARCH ARTICLE • Previous Articles Next Articles

LIU Song1,2( ), ZHANG Faqiang2, LUO Jin1(

), ZHANG Faqiang2, LUO Jin1( ), LIU Zhifu2(

), LIU Zhifu2( )

)

Received:2023-10-20

Revised:2023-11-20

Published:2024-03-20

Online:2023-12-19

Contact:

LUO Jin, associate professor. E-mail: jluuky2014@njtech.edu.cn;About author:LIU Song (1999-), male, Master candidate. E-mail: 202161203172@njtech.edu.cn

Supported by:CLC Number:

LIU Song, ZHANG Faqiang, LUO Jin, LIU Zhifu. 0.9BaTiO3-0.1Bi(Mg1/2Ti1/2)O3 Ferroelectric Thin Films: Preparation and Energy Storage[J]. Journal of Inorganic Materials, 2024, 39(3): 291-298.

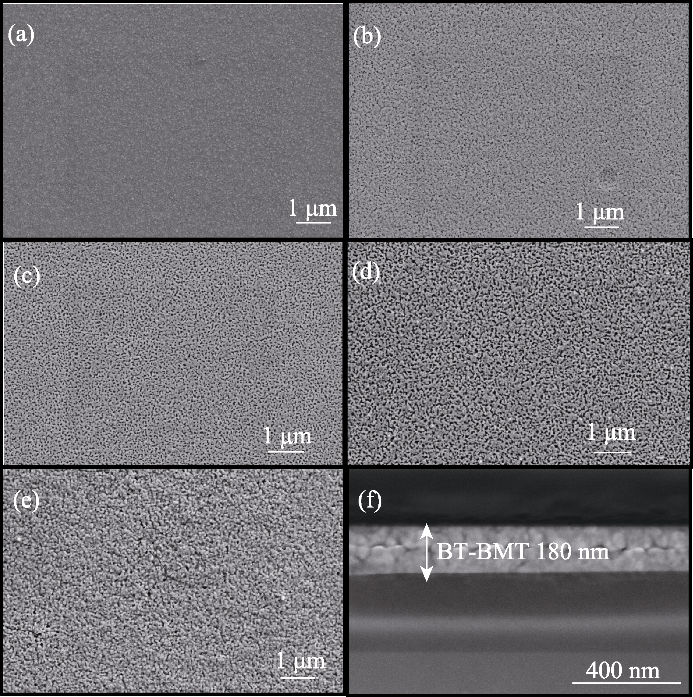

Fig. 2 SEM images of thin films annealed at different temperatures (a) 700 ℃; (b) 750 ℃; (c) 800 ℃; (d) 850 ℃; (e) 900 ℃; (f) Cross-section structure of thin films annealed at 750 ℃

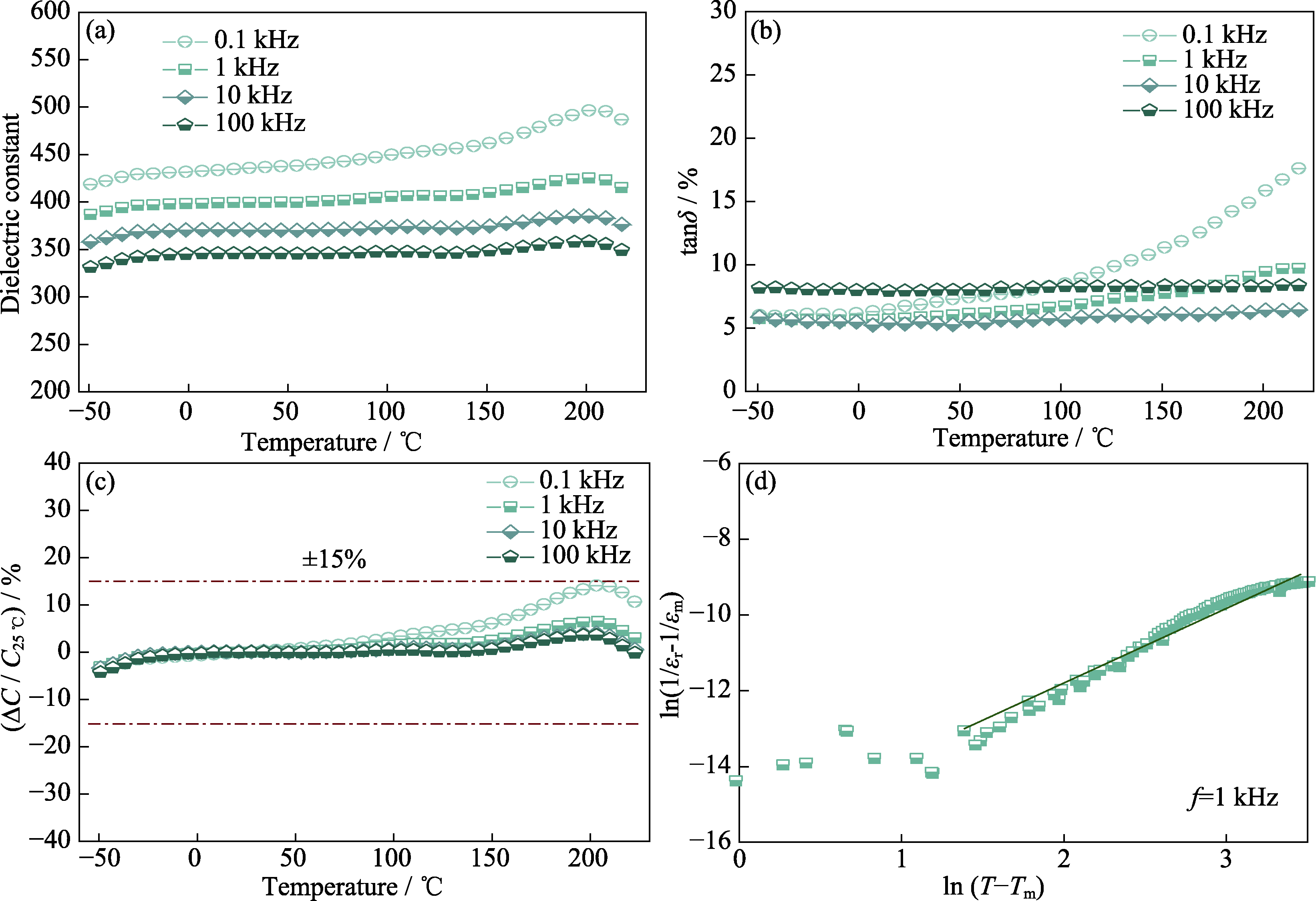

Fig. 3 Dielectric properties of 0.9BT-0.1BMT thin films annealed at 750 ℃ and tested at different frequencies (a-c) Temperature-dependent (a) dielectric constant, (b) loss tangent and (c) capacitance of 0.9BT-0.1BMT thin films annealed at 750 ℃; (d) Function of ln(1/εr−1/εm) versus ln(T−Tm) measured under 1 kHz with symbols standing for experiment data and solid line indicating fitting to the modified Curie-Weiss law

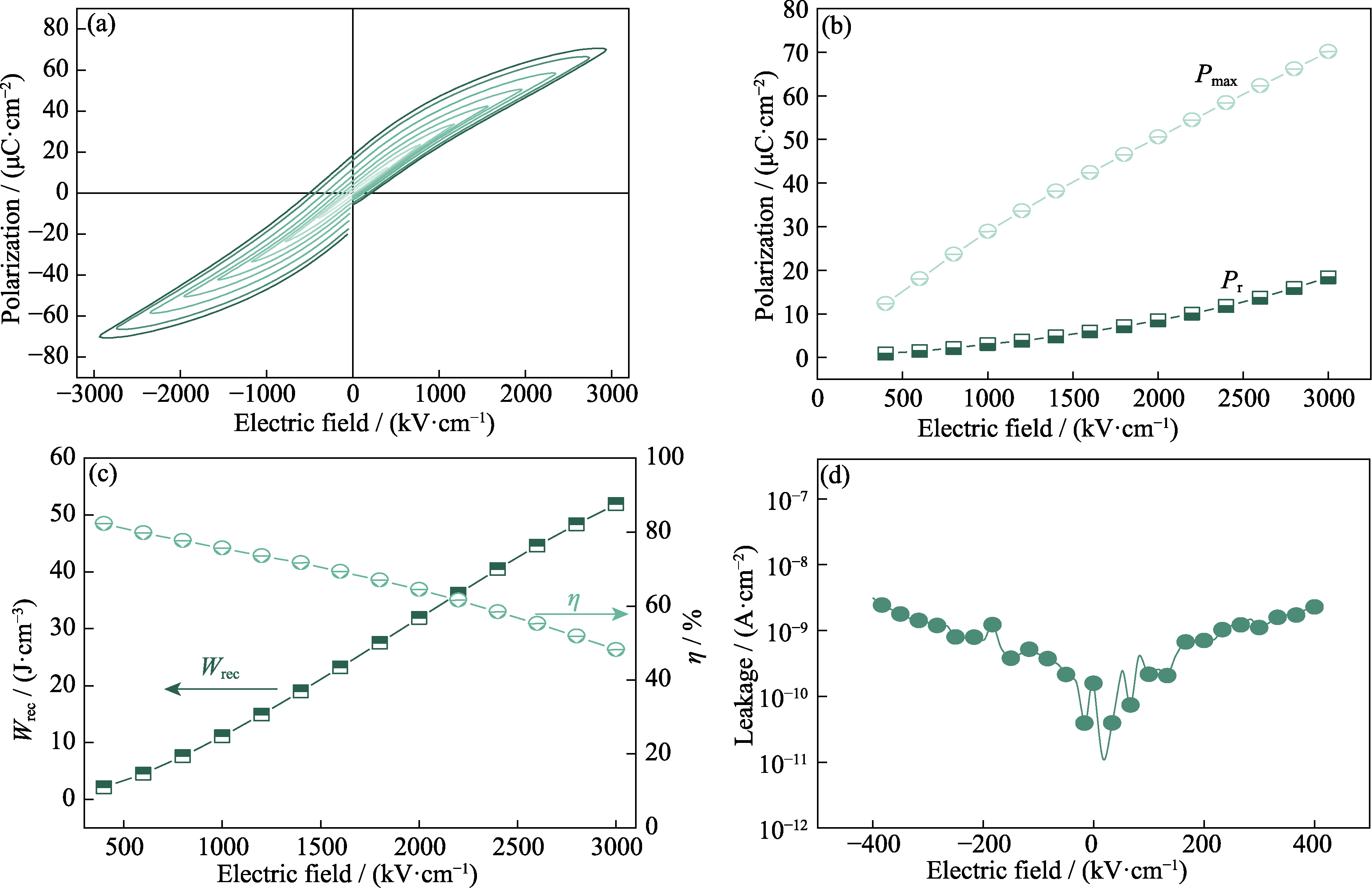

Fig. 4 Electrical performance of 0.9BT-0.1BMT thin films tested at room temperature (a) P-E loops; (b) Pmax and Pr measured at different electric fields; (c) Wrec and η measured at different electric fields; (d) Leakage current of thin films at 400 kV/cm

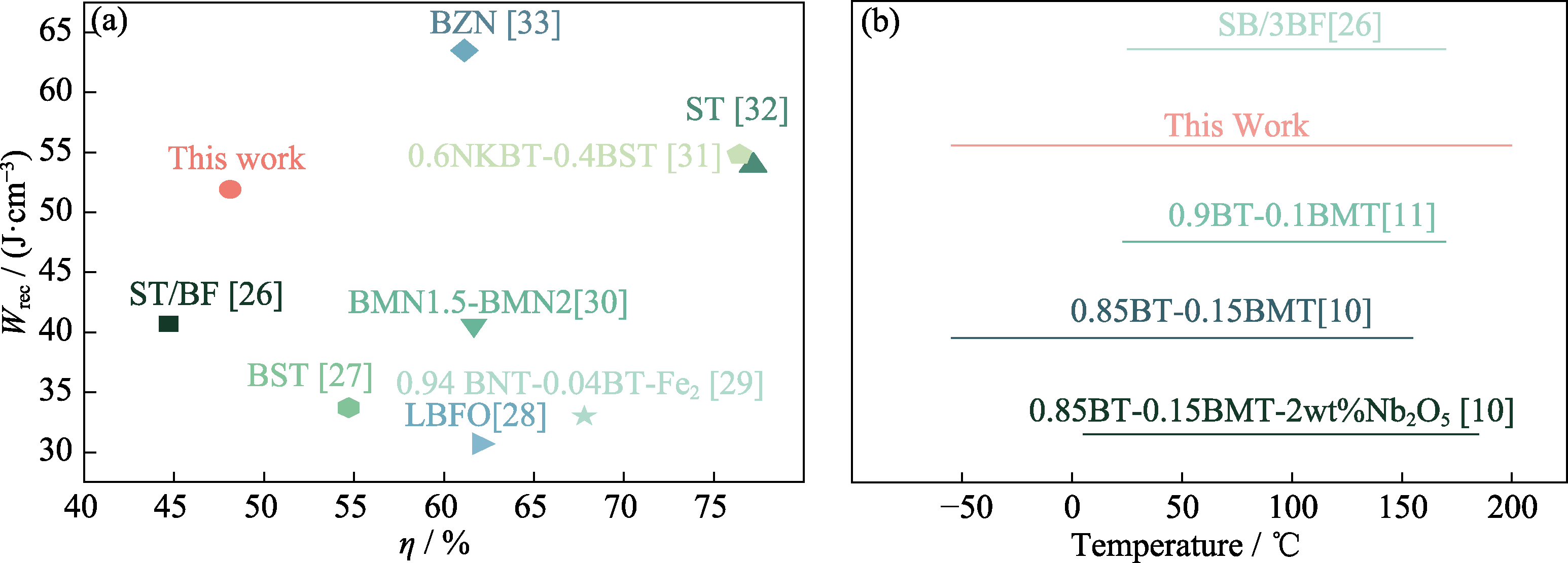

Fig. 5 Property comparison for materials prepared in this work with other materials (a) Energy storage performance [26⇓⇓⇓⇓⇓⇓-33]; (b) Meet ∆C/C25℃≤±15% temperature range[10-11,26]

Fig. 6 Effects of (a-c) frequency, (d-f) temperature and (g-i) switching cycles on P-E loops, Pmax, Pr, and energy storage performance of 0.9BT-0.1BMT thin films

Fig. 7 Discharge characteristics of 0.9BT-0.1BMT film capacitors (a) Curves of overdamped discharge current; (b) Time dependence of Wdis at various electric fields; (c) Values of Wdis and τ0.9 at different electric fields; (d) Overdamped discharge current curves at 1388 kV/cm with different temperatures; (e) Time dependence of Wdis at different temperatures; (f) Values of Wdis and τ0.9 at different temperatures; Colorful figures are available on website

| [1] | DU JINHUA, LI YONG, SUN NINGNING, et al. Energy storage behavior of inorganic dielectric materials. Journal of Silicate, 2022, 50(3): 608. |

| [2] | YANG MINZHENG, JIANG JIANYONG, SHEN YANG. Recent progress in dielectric energy storage materials with high energy density. Journal of Silicate, 2021, 49(7): 14. |

| [3] |

HONG K, LEE T H, SUH J M, et al. Perspectives and challenges in multilayer ceramic capacitors for next generation electronics. Journal of Materials Chemistry C, 2019, 7(32): 9782.

DOI URL |

| [4] |

DUNN B, KAMATH H, TARASCON J M. Electrical energy storage for the grid: a battery of choices. Science, 2011, 334(6058): 928.

DOI PMID |

| [5] |

DANG Z M, YUAN J K, YAO S H, et al. Flexible nanodielectric materials with high permittivity for power energy storage. Advanced Materials, 2013, 25(44): 6334.

DOI URL |

| [6] |

BEUERLEIN M A, KUMAR N, USHER T M, et al. Current understanding of structure-processing-property relationships in BaTiO3-Bi(M)O3 dielectrics. Journal of the American Ceramic Society, 2016, 99(9): 2849.

DOI URL |

| [7] | MOKI S, KIMURA J, KANEKO N, et al. Structural and dielectric properties of BaTiO3-Bi(Mg1/2Ti1/2)O3 thin films fabricated by chemical solution deposition. Japanese Journal of Applied Physics, 2014, 53(9S): 9PA11.1. |

| [8] |

HU Q, JIN L, WANG T, et al. Dielectric and temperature stable energy storage properties of 0.88BaTiO3-0.12Bi(Mg1/2Ti1/2)O3 bulk ceramics. Journal of Alloys and Compounds, 2015, 640: 416.

DOI URL |

| [9] |

XIE J, YAO Z, HAO H, et al. A novel lead-free bismuth magnesium titanate thin films for energy storage applications. Journal of the American Ceramic Society, 2019, 102(7): 3819.

DOI URL |

| [10] |

XIONG B, HAO H, ZHANG S, et al. Structure, dielectric properties and temperature stability of BaTiO3-Bi(Mg1/2Ti1/2)O3perovskite solid solutions. Journal of the American Ceramic Society, 2011, 94(10): 3412.

DOI URL |

| [11] |

ZHANG Q, LI Z, LI F, et al. Structural and dielectric properties of Bi(Mg1/2Ti1/2)O3-BaTiO3lead-free ceramics. Journal of the American Ceramic Society, 2011, 94(12): 4335.

DOI URL |

| [12] |

ZHANG L L, TAN G Q, CHENG M, et al. Effects of annealing temperature on morphology and dielectric property of BiFeO3films. Key Engineering Materials, 2012, 512-515: 1736.

DOI URL |

| [13] |

SUN X H, HOU S, LUO Z M, et al. Enhanced the dielectric and tunable properties of BZNT thin films through adjusting annealing process. Applied Mechanics and Materials, 2012, 252: 211.

DOI URL |

| [14] |

YAO K, YU S, ENG-HOCK TAY F. Residual stress analysis in ferroelectric Pb(Zr0.52Ti0.48)O3 thin films fabricated by a Sol-Gel process. Applied Physics Letters, 2003, 82(25): 4540.

DOI URL |

| [15] |

GALLEGOS-MELGAR A, ESPINOSA-ARBELAEZ D G, FLORES-RUIZ F J, et al. Ferroelectric properties of manganese doped (Bi1/2Na1/2)TiO3and (Bi1/2Na1/2)TiO3-BaTiO3 epitaxial thin films. Applied Surface Science, 2015, 359: 923.

DOI URL |

| [16] | GENG W, CHEN X, PAN L, et al. Improved crystallization, domain, and ferroelectricity by controlling lead/oxygen vacancies in Mn- doped PZT thin films. Materials Characterization, 2021, 176: 1. |

| [17] |

LI M D, TANG X G, ZENG S M, et al. Giant electrocaloric effect in BaTiO3-Bi(Mg1/2Ti1/2)O3 lead-free ferroelectric ceramics. Journal of Alloys and Compounds, 2018, 747: 1053.

DOI URL |

| [18] | TANG B, ZHANG S, YUAN Y, et al. Latest progress of curie point shift of barium titanate ceramic and its mechanisms. Journal of Vacuum Science and Technology, 2008(2): 6. |

| [19] |

UCHIDA H, SAIKI A, WAKIYA N, et al. Effect of the residual stress induced by external stress application on dielectric properties of epitaxial lead titanate film. Journal of the Ceramic Society of Japan, 2000, 108(1253): 21.

DOI URL |

| [20] | OHNO T, GOTOH Y, SAKAMOTO N, et al. Low temperature processing of alkoxide-derived PMN thin films. IOP Conference Series: Materials Science and Engineering, 2012, 30: 012002. |

| [21] | 胡钰晴. 铁酸铋-钛酸钡铁电薄膜的制备与多功能特性研究. 上海: 上海师范大学硕士学位论文. 2020. |

| [22] | 汤卉. 铁酸铋-钛酸钡基陶瓷的制备、储能特性和电卡效应研究. 广州: 广东工业大学博士学位论文. 2022. |

| [23] |

SHVARTSMAN V V, LUPASCU D C, GREEN D J. Lead-free relaxor ferroelectrics. Journal of the American Ceramic Society, 2012, 95(1): 1.

DOI URL |

| [24] |

VIEHLAND D, JANG S J, CROSS L E, et al. Freezing of the polarization fluctuations in lead magnesium niobate relaxors. Journal of Applied Physics, 1990, 68(6): 2916.

DOI URL |

| [25] |

WANG J, LI Y, SUN N, et al. Bi(Mg0.5Ti0.5)O3 addition induced high recoverable energy-storage density and excellent electrical properties in lead-free Na0.5Bi0.5TiO3-based thick films. Journal of the European Ceramic Society, 2019, 39(2/3): 255.

DOI URL |

| [26] |

DIAO C, LIU H, LOU G, et al. Structure and electric properties of sandwich-structured SrTiO3/BiFeO3 thin films for energy storage applications. Journal of Alloys and Compounds, 2019, 781: 378.

DOI URL |

| [27] |

WANG Y, LIU X, SUN H, et al. Enhanced recoverable energy storage density of barium strontium titanate-based thin films with compositionally graded structure. Journal of Materials Science: Materials in Electronics, 2021, 32(2): 2193.

DOI |

| [28] |

SONG H, SON J Y. Energy storage and multiferroic properties of La-doped epitaxial BiFeO3 thin films according to La doping concentration. Journal of Energy Storage, 2023, 68(15): 107729.

DOI URL |

| [29] |

XIE Y, HAO H, HUANG Z, et al. Large energy-storage density with good dielectric property in bismuth sodium titanate-based thin films. Journal of Alloys and Compounds, 2021, 884: 161031.

DOI URL |

| [30] |

YU S, ZHANG C, WU M, et al. Energy storage and dielectric properties of a novel Bi1.5MgNb1.5O7-Bi2Mg2/3Nb4/3O7 thin film. Ceramics International, 2021, 47(1): 1238.

DOI URL |

| [31] |

DING J, ZHANG Y, ZHAI Y, et al. Optimized energy storage performances in morphotropic phase boundary (Na0.8K0.2)0.5Bi0.5TiO3- based lead-free ferroelectric thin films. Ceramics International, 2022, 48(5): 6062.

DOI URL |

| [32] |

DIAO C, LIU H, LI Z, et al. Simultaneously achieved high energy storage density and efficiency in Sol-Gel-derived amorphous Mn- doped SrTiO3 thin films. Journal of Alloys and Compounds, 2020, 845: 155636.

DOI URL |

| [33] |

WU M, YU S, WANG X, et al. Ultra-high energy storage density and ultra-wide operating temperature range in Bi2Zn2/3Nb4/3O7 thin film as a novel lead-free capacitor. Journal of Power Sources, 2021, 497: 229879.

DOI URL |

| [1] | DONG Chenyu, ZHENG Weijie, MA Yifan, ZHENG Chunyan, WEN Zheng. Characterizations by Piezoresponse Force Microscopy on Relaxor Properties of Pb(Mg,Nb)O3-PbTiO3 Ultra-thin Films [J]. Journal of Inorganic Materials, 2025, 40(6): 675-682. |

| [2] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [3] | WU Lukang, FU Zhengqian, YU Ziyi, YANG Jun, ZHOU Bin, CHEN Xuefeng, XU Fangfang. Application of Electron Energy-loss Spectroscopy to BaTiO3 Multi-layer Ceramic Capacitors [J]. Journal of Inorganic Materials, 2025, 40(6): 683-689. |

| [4] | SHEN Hao, CHEN Qianqian, ZHOU Boxiang, TANG Xiaodong, ZHANG Yuanyuan. Preparation and Energy Storage Properties of A-site La/Sr Co-doped PbZrO3 Thin Films [J]. Journal of Inorganic Materials, 2024, 39(9): 1022-1028. |

| [5] | CHEN Ze, ZHI Chunyi. MXene Based Zinc Ion Batteries: Recent Development and Prospects [J]. Journal of Inorganic Materials, 2024, 39(2): 204-214. |

| [6] | WEN Zhipeng, WEI Yi, HOU Xianghua, GUO Jiawen, LI Qu, ZHU Manqing, ZHANG Jiahao, PAN Kai, WU Lian. Research Progress of Bentonite-based Functional Materials in Electrochemical Energy Storage [J]. Journal of Inorganic Materials, 2024, 39(12): 1301-1315. |

| [7] | DING Ling, JIANG Rui, TANG Zilong, YANG Yunqiong. MXene: Nanoengineering and Application as Electrode Materials for Supercapacitors [J]. Journal of Inorganic Materials, 2023, 38(6): 619-633. |

| [8] | XIE Bing, CAI Jinxia, WANG Tongtong, LIU Zhiyong, JIANG Shenglin, ZHANG Haibo. Research Progress of Polymer-based Multilayer Composite Dielectrics with High Energy Storage Density [J]. Journal of Inorganic Materials, 2023, 38(2): 137-147. |

| [9] | KANG Wenshuo, GUO Xiaojie, ZOU Kai, ZHAO Xiangyong, ZHOU Zhiyong, LIANG Ruihong. Enhanced Resistivity Induced by the Second Phase with Layered Structure in BiFeO3-BaTiO3 Ceramics [J]. Journal of Inorganic Materials, 2023, 38(12): 1420-1426. |

| [10] | WEI Tingting, XU Huarui, ZHU Guisheng, LONG Shenfeng, ZHANG Xiuyun, ZHAO Yunyun, JIANG Xupeng, SONG Jinjie, GUO Ningjie, GONG Yipeng. Preparation and Properties of BaTiO3 Ceramics by Low Temperature Cold Sintering [J]. Journal of Inorganic Materials, 2022, 37(8): 903-910. |

| [11] | ZHAO Yuyao, OUYANG Jun. Columnar Nanograined BaTiO3 Ferroelectric Thin Films Integrated on Si with a Sizable Dielectric Tunability [J]. Journal of Inorganic Materials, 2022, 37(6): 596-602. |

| [12] | XIAO Shulin, DAI Zhonghua, LI Dingyan, ZHANG Fanbo, YANG Lihong, REN Xiaobing. Electrical and Optical Property of Lanthanum Oxide Doped Potassium Sodium Niobate Ceramics [J]. Journal of Inorganic Materials, 2022, 37(5): 520-526. |

| [13] | YE Fen, JIANG Xiangping, CHEN Yunjing, HUANG Xiaokun, ZENG Renfen, CHEN Chao, NIE Xin, CHENG Hao. Dielectric and Energy Storage Property of (0.96NaNbO3-0.04CaZrO3)-xFe2O3 Antiferroelectric Ceramics [J]. Journal of Inorganic Materials, 2022, 37(5): 499-506. |

| [14] | ZHAO Wei, XU Yang, WAN Yingjie, CAI Tianxun, MU Jinxiao, HUANG Fuqiang. Metal Cyanamides/Carbodiimides: Structure, Synthesis and Electrochemical Energy Storage Performance [J]. Journal of Inorganic Materials, 2022, 37(2): 140-151. |

| [15] | LI Sheng, SONG Guoqiang, ZHANG Yuanyuan, TANG Xiaodong. Preparation and Physical Property of BTO-based Multiferroic Ceramics [J]. Journal of Inorganic Materials, 2022, 37(1): 79-85. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||