Journal of Inorganic Materials ›› 2015, Vol. 30 ›› Issue (1): 1-8.DOI: 10.15541/jim20140313

• Orginal Article • Next Articles

LI Ge-Yang

Received:2014-06-18

Revised:2014-09-08

Published:2015-01-20

Online:2014-12-29

Supported by:CLC Number:

LI Ge-Yang. Comment on Experiment Fundament of Veprek’s nc-TiN/a-Si3N4 Model and Its “Exceed Diamond Hardness”[J]. Journal of Inorganic Materials, 2015, 30(1): 1-8.

Fig. 4 Hultman microstructural model of nanocomposite films[33],Si3N4 tissue is amorphous (lSi3N4>0.7 nm)(a) and part of tissue forms epitaxial pseudo-crystal (lSi3N4≤0.5-0.7 nm)(b)

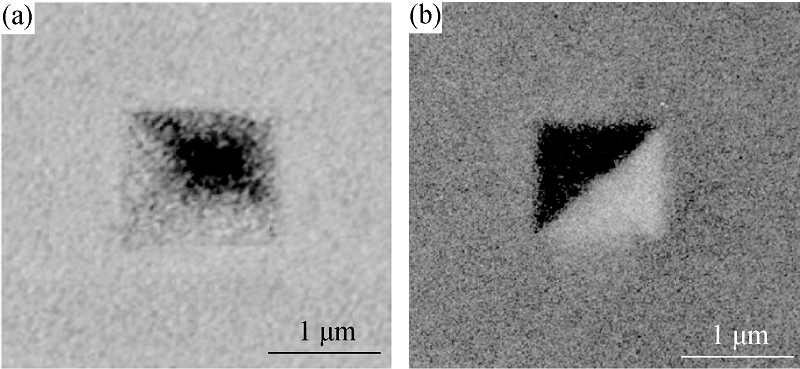

Fig. 7 Two indentation SEM images of ultra-hardness composite films provided by Veprek. The hardness is only 51 GPa[58] compares with the claimed 138.4 GPa[8] (a) and the hardness is over 100 GPa[27] (b) computed by the scale on the SEM images

| [1] | LIU A Y, COHEN M L.Prediction of new low compressibility solids.Science, 1989, 245(4920): 841-842. |

| [2] | NIEDERHOFER A, NESLÁDEK P, MÄNNLING H D, et al. Structural properties, internal stress and thermal stability of nc-TiN/a-Si3N4, nc-TiN/TiSix and nc-(Ti1-yAlySix)N superhard nanocomposite coatings reaching the hardness of diamond. Surface and Coatings Technology, 1999, 120-121: 173-178. |

| [3] | VEPŘEK S. The search for novel, superhard materials.Journal of Vacuum Science and Technology A: Vacuum, Surfaces and Films, 1999, 17(5): 2401-2420. |

| [4] | NIEDERHOFER A, MOTO K, NESLADEK P, et al.Diamond is not the Hardest Material Anymore: Ultrahard Nanocomposites nc-TiN/a-Si3N4, Presented at 4th Int. in Symp. presented at 4th Int. Symp. Plasma Chemistry, Prague, Czech Republic, 2-6 August 1999. |

| [5] | VEPREK S, NIEDERHOFER A, MOTO K, et al.Nanocomposites nc-TiN/a-Si3N4/a- and nc-TiSi2 with hardness exceeding 100 GPa and high fracture toughness.Materials Research Society Symposium - Proceedings, 2000, 581: 321-326. |

| [6] | MÄNNLING H D, PATIL D S, MOTO K, et al. Thermal stability of superhard nanocomposite coatings consisting of immiscible nitrides. Surface and Coatings Technology, 2001, 146-147: 263-267. |

| [7] | VEPREK S, ARGON A S. Mechanical properties of superhard nanocomposites. Surface and Coatings Technology, 2001, 146-147: 175-182. |

| [8] | VEPREK S, ARGON A S.Towards the understanding of mechanical properties of super- and ultrahard nanocomposites.Journal of Vacuum Science and Technology B: Microelectronics and Nanometer Structures, 2002, 20(2): 650-664. |

| [9] | VEPREK S, MUKHERJEE S, KARVANKOVA P, et al.Limits to the strength of super- and ultrahard nanocomposite coatings.Journal of Vacuum Science and Technology A: Vacuum, Surfaces and Films, 2003, 21(3): 532-544. |

| [10] | VEPREK S, MUKHERJEE S, KARVANKOVA P, et al.Hertzian analysis of the self-consistency and reliability of the indentation hardness measurements on superhard nanocomposite coatings.Thin Solid Films, 2003, 436(2): 220-231. |

| [11] | NESLÁDEK P, VEPŘEK S. Superhard nanocrystalline composites with hardness of diamond.Physica Status Solidi (A) Applied Research, 2000, 177(1): 53-62. |

| [12] | VEPREK S, NIEDERHOFER A, MOTO K, et al. Composition, nanostructure and origin of the ultrahardness in nc-TiN/a- Si3N4/a- and nc-TiSi2 nanocomposites with Hv=80 to ≥105 GPa. Surface and Coatings Technology, 2000, 133-134: 152-159. |

| [13] | MENG W J, ZHANG X D, SHI B, et al.Microstructure and mechanical properties of Ti-Si-N coatings.Journal of Materials Research, 2002, 17(10): 2628-2632. |

| [14] | KIM S H, KIM J K, KIM K H.Influence of deposition conditions on the microstructure and mechanical properties of Ti-Si-N films by DC reactive magnetron sputtering.Thin Solid Films, 2002, 420: 360-365. |

| [15] | HU X P, HAN Z H, LI G Y, et al.Microstructure and properties of Ti-Si-N nanocomposite films.Journal of Vacuum Science and Technology A: Vacuum, Surfaces and Films, 2002, 20(6): 1921-1926. |

| [16] | PATSCHEIDER J, ZEHNDER T, DISERENS M.Structure- performance relations in nanocomposite coatings.Surface and Coatings Technology, 2001, 146: 201-208. |

| [17] | ZHANG C H, LUO J B, LI W Z, et al.The study of the microstructure of TiN and Ti1-xSixNy coatings.Acta Physica Sinica, 2004, 53(1): 182-188. |

| [18] | ZHAO H Y, FAN Q L, SONG L X, et al.Research status and development of superhard nanocomposite films.Journal of Inorganic Materials, 2004, 19(1): 9-16. |

| [19] | VEPŘEK S, REIPRICH S, LI S Z. Superhard nanocrystalline composite materials: The TiN/Si3N4 system.Applied Physics Letters, 1995, 66: 2640. |

| [20] | VEPŘEK S, REIPRICH S. A concept for the design of novel superhard coatings.Thin Solid Films, 1995, 268(1/2): 64-71. |

| [21] | VEPŘEK S, HAUSSMANN M, REIPRICH S, et al. Novel thermodynamically stable and oxidation resistant superhard coating materials. Surface and Coatings Technology, 1996, 86-87(1): 394-401. |

| [22] | CHRISTIANSEN S, ALBRECHT M, STRUNK H P, et al.Microstructure of novel superhard nanocrystalline-amorphous composites as analyzed by high resolution transmission electron microscopy.Journal of Vacuum Science and Technology B: Microelectronics and Nanometer Structures, 1998, 16(1): 19-22. |

| [23] | PROCHÁZKA J, KARVÁNKOVÁ P, VEPŘEK-HEIJMAN M G J, et al. Conditions required for achieving superhardness of ≥45 GPa in nc-TiN/a-Si3N4 nanocomposites.Materials Science and Engineering A, 2004, 384(1/2): 102-116. |

| [24] | VEPREK S, VEPREK-HEIJMAN M G J, KARVANKOVA P, et al. Different approaches to superhard coatings and nanocomposites.Thin Solid Films, 2005, 476(1): 1-29. |

| [25] | KARVANKOVA P, VEPREK-HEIJMAN M G J, AZINOVIC D, et al. Properties of superhard nc-TiN/a-BN and nc-TiN/a-BN/a- TiB2 nanocomposite coatings prepared by plasma induced chemical vapor deposition.Surface and Coatings Technology, 2006, 200(9): 2978-2989. |

| [26] | KONG M, ZHAO W J, WEI L, et al.Investigations on the microstructure and hardening mechanism of TiN/Si3N4 nanocomposite coatings.Journal of Physics D: Applied Physics, 2007, 40(9): 2858-2863. |

| [27] | VEPREK S, VEPREK-HEIJMAN M G J. Limits to the preparation of superhard nanocomposites: Impurities, deposition and annealing temperature.Thin Solid Films, 2012, 522: 274-282. |

| [28] | VEPREK S, MÄNNLING H D, KARVANKOVA P, et al. The issue of the reproducibility of deposition of superhard nanocomposites with hardness of ≥50 GPa.Surface and Coatings Technology, 2006, 200(12/13): 3876-3885. |

| [29] | HU X P, ZHANG H J, DAI J W, et al.Study on the superhardness mechanism of Ti-Si-N nanocomposite films: Influence of the thickness of the Si3N4 interfacial phase.Journal of Vacuum Science and Technology A: Vacuum, Surfaces and Films, 2005, 23(1): 114-117. |

| [30] | SÖDERBERG H, ODÉN M, MOLINA-ALDAREGUIA J M, et al. Nanostructure formation during deposition of TiN/SiN nanomultilayer films by reactive dual magnetron sputtering.Journal of Applied Physics, 2005, 97: 114327. |

| [31] | SÖDERBERG H, ODÉN M, LARSSON T, et al. Epitaxial stabilization of cubic-SiN in TiN/SiN multilayers.Applied Physics Letters, 2006, 88: 191902. |

| [32] | SÖDERBERG H, ODÉN M, FLINK A, et al. Growth and characterization of TiN/SiN (001) superlattice films.Journal of Materials Research, 2007, 22(11): 3255-3264. |

| [33] | HULTMAN L, BAREÑO J, FLINK A, et al. Interface structure in superhard TiN-SiN nanolaminates and nanocomposites: film growth experiments and ab initio calculations.Physical Review B, 2007, 75(15): 155437. |

| [34] | MEI F H, SHAO N, HU X P, et al.Microstructure and mechanical properties of reactively sputtered Ti-Si-N nanocomosite films.Materials Letters, 2005, 59(19/20): 2442-2445. |

| [35] | KIM I W, LI Q, MARKS L D, et al.Critical thickness for transformation of epitaxially stabilized cubic AlN in superlattices.Applied Physics Letters, 2001, 78(7): 892-894. |

| [36] | MADAN A, KIM I, CHENG S, et al.Stabilization of cubic AlN in epitaxial AlN/TiN superlattices.Physical Review Letters, 1997, 78(9): 1743. |

| [37] | 冯端, 师昌绪, 刘治国. 材料科学导论. 北京: 化学工业出版社, 2002: 588. |

| [38] | DONG Y S, ZHAO W J, YUE J L, et al.Crystallization of Si3N4 layers and its influences on the microstructure and mechanical properties of ZrN/Si3N4 nanomultilayers.Applied Physics Letters, 2006, 89(12): 121916. |

| [39] | LI G Q, LI Y G.Crystallization of amorphous Si3N4 and superhardness effect in HfC/Si3N4 nanomultilayers.Applied Surface Science, 2011, 257(13): 5799-5802. |

| [40] | WEN M, MENG Q N, HU C Q, et al.Structure and mechanical properties of δ-NbN/SiNx and δ′-NbN/SiNx nano-multilayer films deposited by reactive magnetron sputtering.Surface and Coatings Technology, 2009, 203(12): 1702-1708. |

| [41] | LAO J J, SHAO N, MEI F H, et al. Mutual promotion effect of crystal growth in TiN/SiC nanomultilayers. Applied Physics Letters, 2005, 86(1): 011902-1-3. |

| [42] | WEI L, MEI F H, SHAO N, et al. Template-induced crystallization of amorphous SiO2 and its effects on the mechanical properties of TiN/SiO2 nanomultilayers. Applied Physics Letters, 2005, 86(2): 021919-1-3. |

| [43] | WEI L, KONG M, DONG Y S, et al. Crystallization of Al2O3 and its effects on the mechanical properties in TiN/Al2O3 nanomultilayers. Journal of Applied Physics, 2005, 98(7): 074302-1-4. |

| [44] | YUE J L, LIU Y, ZHAO W J, et al.Crystallization of AlON and its effects on the growth and hardness of reactively synthesized VN/AlON nanomultilayer.Scripta Materialia, 2006, 55(10): 895-898. |

| [45] | ZHAO W J, KONG M, WU Y, et al.Pseudocrystallization of SiO2 and superhardness effects of AlN/SiO2 nanomultilayers.Journal of Applied Physics, 2008, 103(4): 043506. |

| [46] | YU L H, DONG S T, DONG S R, et al.Epitaxial growth and mechanical properties of AlN/Si3N4 nanostructured multilayerscta Physica Sinica, 2008, 57(8): 5151-5158. |

| [47] | LI G Q, LI Y G.Coherent growth and superhardness effect of heterostructure h-TiB2/c-VC nanomultilayers.Vacuum, 2011, 86(4): 476-479. |

| [48] | ZHANG R F, ARGON A S, VEPREK S.Electronic structure, stability, and mechanism of the decohesion and shear of interfaces in superhard nanocomposites and heterostructures.Physical Review B - Condensed Matter and Materials Physics, 2009, 79(24): 245426. |

| [49] | ZHANG R F, ARGON A S, VEPREK S.Friedel oscillations are limiting the strength of superhard nanocomposites and heterostructures.Physical Review Letters, 2009, 102(1): 015503. |

| [50] | VEPREK S, KARVANKOVA P, VEPREK-HEIJMAN M G J. Possible role of oxygen impurities in degradation of nc-TiN/a- Si3N4 nanocomposites.Journal of Vacuum Science and Technology B: Microelectronics and Nanometer Structures, 2005, 23(6): L17-L21. |

| [51] | VEPREK S, VEPREK-HEIJMAN M G. Concept for the Design of Superhard Nanocomposites with High Thermal Stability: Their Preparation, Properties, and Industrial Applications. Nanostructured Coatings, Springer Press, 2006: 347-406. |

| [52] | ZHANG R F, VEPREK S.Phase stabilities of self-organized nc-TiN/a-Si3N4 nanocomposites and of Ti1-xSixNy solid solutions studied by abinitio calculation and thermodynamic modeling.Thin Solid Films, 2008, 516(8): 2264-2275. |

| [53] | MA D Y, MA S L, XU K W, et al.Hardness degradation of Ti-Si- N coatings induced by oxygen impurity and its mechanisms.Materials Letters, 2005, 59(7): 838-841. |

| [54] | MA D Y, MA S L, XU K W, et al.Impact of residual oxygen on hardness of nano structured TiN+Si3N4 film.Acta Metallurgica Sinica, 2004, 40(10): 1037-1040. |

| [55] | LI S, SHI Y, PENG H. Plasma Chem.Plasma Process, 1992, 22: 287-297. |

| [56] | ZHANG R F, LEGUT D, LIN Z J, et al.Stability and strength of transition-metal tetraborides and triborides.Physical Review Letters, 2012, 108(25): 255502. |

| [57] | HAO S Q, DELLEY B, VEPREK S, et al.Superhard nitride- based nanocomposites: role of interfaces and effect of impurities.Physical Review Letters, 2006, 97(8): 086102. |

| [58] | FISCHER-CRIPPS A, BULL S, SCHWARZER N.Critical review of claims for ultra-hardness in nanocomposite coatings.Philosophical Magazine, 2012, 92(13): 1601-1630. |

| [59] | PAN L, BAI Y Z, ZHANG D, et al.Ti-Si-N films prepared by magnetron sputtering.Rare Metals, 2012, 31(2): 183-188. |

| [60] | PATSCHEIDER J, HELLGREN N, HAASCH R T, et al.Electronic structure of the SiNx/TiN interface: a model system for superhard nanocomposites.Physical Review B, 2011, 83(12): 125124. |

| [1] | MU Haojie, ZHANG Yuanjiang, YU Bin, FU Xiumei, ZHOU Shibin, LI Xiaodong. Preparation and Properties of ZrO2 Doped Y2O3-MgO Nanocomposite Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 281-289. |

| [2] | FAN Wugang, CAO Xiong, ZHOU Xiang, LI Ling, ZHAO Guannan, ZHANG Zhaoquan. Anticorrosion Performance of 8YSZ Ceramics in Simulated Aqueous Environment of Pressurized Water Reactor [J]. Journal of Inorganic Materials, 2024, 39(7): 803-809. |

| [3] | CHEN Qian, SU Haijun, JIANG Hao, SHEN Zhonglin, YU Minghui, ZHANG Zhuo. Progress of Ultra-high Temperature Oxide Ceramics: Laser Additive Manufacturing and Microstructure Evolution [J]. Journal of Inorganic Materials, 2024, 39(7): 741-753. |

| [4] | JIANG Lingyi, PANG Shengyang, YANG Chao, ZHANG Yue, HU Chenglong, TANG Sufang. Preparation and Oxidation Behaviors of C/SiC-BN Composites [J]. Journal of Inorganic Materials, 2024, 39(7): 779-786. |

| [5] | ZHENG Yawen, ZHANG Cuiping, ZHANG Ruijie, XIA Qian, RU Hongqiang. Fabrication of Boron Carbide Ceramic Composites by Boronic Acid Carbothermal Reduction and Silicon Infiltration Reaction Sintering [J]. Journal of Inorganic Materials, 2024, 39(6): 707-714. |

| [6] | XUE Yifan, LI Weijie, ZHANG Zhongwei, PANG Xu, LIU Yu. Process Control of PyC Interphases Microstructure and Uniformity in Carbon Fiber Cloth [J]. Journal of Inorganic Materials, 2024, 39(4): 399-408. |

| [7] | SUN Chuan, HE Pengfei, HU Zhenfeng, WANG Rong, XING Yue, ZHANG Zhibin, LI Jinglong, WAN Chunlei, LIANG Xiubing. SiC-based Ceramic Materials Incorporating GNPs Array: Preparation and Mechanical Characterization [J]. Journal of Inorganic Materials, 2024, 39(3): 267-273. |

| [8] | ZHENG Jiaqian, LU Xiao, LU Yajie, WANG Yingjun, WANG Zhen, LU Jianxi. Functional Bioadaptability in Medical Bioceramics: Biological Mechanism and Application [J]. Journal of Inorganic Materials, 2024, 39(1): 1-16. |

| [9] | HE Danqi, WEI Mingxu, LIU Ruizhi, TANG Zhixin, ZHAI Pengcheng, ZHAO Wenyu. Heavy-Fermion YbAl3 Materials: One-step Synthesis and Enhanced Thermoelectric Performance [J]. Journal of Inorganic Materials, 2023, 38(5): 577-582. |

| [10] | WU Shuang, GOU Yanzi, WANG Yongshou, SONG Quzhi, ZHANG Qingyu, WANG Yingde. Effect of Heat Treatment on Composition, Microstructure and Mechanical Property of Domestic KD-SA SiC Fibers [J]. Journal of Inorganic Materials, 2023, 38(5): 569-576. |

| [11] | XIE Jiaye, LI Liwen, ZHU Qiang. Contrastive Study on in Vitro Antibacterial Property and Biocompatibility of Three Clinical Pulp Capping Agents [J]. Journal of Inorganic Materials, 2023, 38(12): 1449-1456. |

| [12] | LI Jianbo, TIAN Zhen, JIANG Quanwei, YU Lifeng, KANG Huijun, CAO Zhiqiang, WANG Tongmin. Effects of Different Element Doping on Microstructure and Thermoelectric Properties of CaTiO3 [J]. Journal of Inorganic Materials, 2023, 38(12): 1396-1404. |

| [13] | WU Dongjiang, ZHAO Ziyuan, YU Xuexin, MA Guangyi, YOU Zhulin, REN Guanhui, NIU Fangyong. Direct Additive Manufacturing of Al2O3-TiCp Composite Ceramics by Laser Directed Energy Deposition [J]. Journal of Inorganic Materials, 2023, 38(10): 1183-1192. |

| [14] | ZHANG Ye, ZENG Yuping. Progress of Porous Silicon Nitride Ceramics Prepared via Self-propagating High Temperature Synthesis [J]. Journal of Inorganic Materials, 2022, 37(8): 853-864. |

| [15] | XIA Qian, SUN Shihao, ZHAO Yiliang, ZHANG Cuiping, RU Hongqiang, WANG Wei, YUE Xinyan. Effect of Boron Carbide Particle Size Distribution on the Microstructure and Properties of Reaction Bonded Boron Carbide Ceramic Composites by Silicon Infiltration [J]. Journal of Inorganic Materials, 2022, 37(6): 636-642. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||