Journal of Inorganic Materials ›› 2025, Vol. 40 ›› Issue (4): 405-414.DOI: 10.15541/jim20240439

Special Issue: 【结构材料】陶瓷基复合材料(202512)

• RESEARCH ARTICLE • Previous Articles Next Articles

GOU Yanzi1( ), KANG Weifeng1, WANG Pengren2

), KANG Weifeng1, WANG Pengren2

Received:2024-10-18

Revised:2024-11-18

Published:2025-04-20

Online:2024-11-25

About author:GOU Yanzi (1984-), associate professor. E-mail: y.gou2012@hotmail.com

Supported by:CLC Number:

GOU Yanzi, KANG Weifeng, WANG Pengren. Influence of Sintering Conditions on Preparation of Nearly Stoichiometric SiC Fibers with Highly Crystalline Microstructure[J]. Journal of Inorganic Materials, 2025, 40(4): 405-414.

| Sample | O content/(%, in mass) | C/Si atomic ratio | Tensile strength/GPa | Young’s modulus/GPa | Diameter/μm |

|---|---|---|---|---|---|

| Si-C-O-Al fiber | 8.93 | 1.33 | 2.27 | 204 | 11.6 |

| Intermediate SiC fiber | 0.98 | 1.06 | 1.54 | 283 | 10.8 |

Table 1 Chemical composition and mechanical properties of Si-C-O-Al fibers and intermediate fibers

| Sample | O content/(%, in mass) | C/Si atomic ratio | Tensile strength/GPa | Young’s modulus/GPa | Diameter/μm |

|---|---|---|---|---|---|

| Si-C-O-Al fiber | 8.93 | 1.33 | 2.27 | 204 | 11.6 |

| Intermediate SiC fiber | 0.98 | 1.06 | 1.54 | 283 | 10.8 |

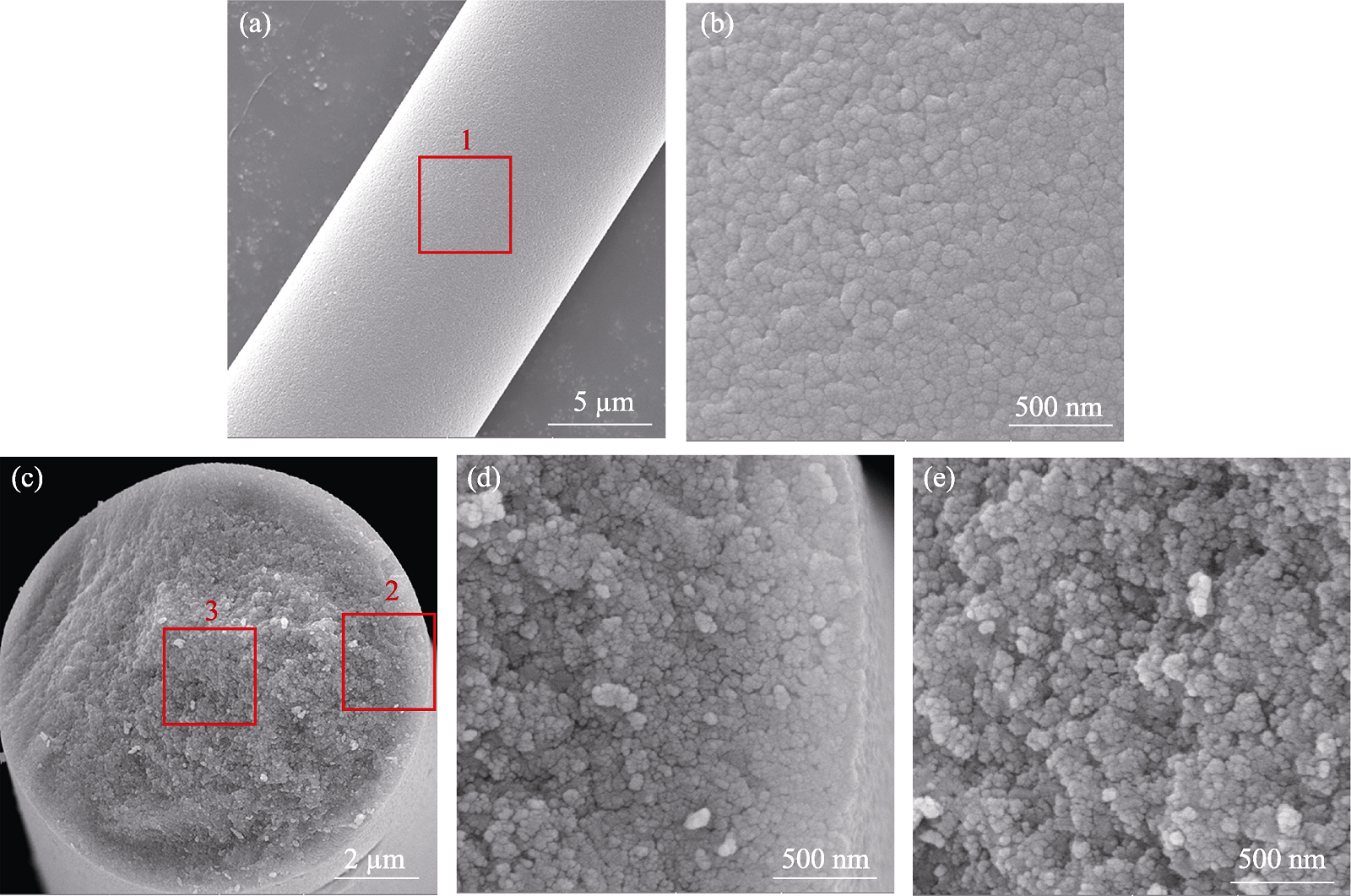

Fig. 1 SEM images of the intermediate fibers (a) Fiber surface; (b) Magnified region 1; (c) Fiber cross section; (d) Magnified region 2; (e) Magnified region 3

| Sample | C/% | Si/% | O/% | Al/% | C/Si atomic ratio |

|---|---|---|---|---|---|

| SiC (SF)-1600-1 h | 31.88 | 67.50 | 0.80 | <1.00 | 1.10 |

| SiC (SF)-1700-1 h | 32.37 | 66.31 | 0.82 | <1.00 | 1.14 |

| SiC (SF)-1800-1 h | 31.48 | 67.41 | 0.61 | <1.00 | 1.09 |

| SiC (SF)-1900-1 h | 33.04 | 66.14 | 0.32 | <1.00 | 1.17 |

| SiC (SF)-2000-1 h | 38.27 | 61.13 | 0.10 | <1.00 | 1.46 |

Table 2 Chemical composition (mass fraction) of the SiC (SF) fibers sintered at different temperatures

| Sample | C/% | Si/% | O/% | Al/% | C/Si atomic ratio |

|---|---|---|---|---|---|

| SiC (SF)-1600-1 h | 31.88 | 67.50 | 0.80 | <1.00 | 1.10 |

| SiC (SF)-1700-1 h | 32.37 | 66.31 | 0.82 | <1.00 | 1.14 |

| SiC (SF)-1800-1 h | 31.48 | 67.41 | 0.61 | <1.00 | 1.09 |

| SiC (SF)-1900-1 h | 33.04 | 66.14 | 0.32 | <1.00 | 1.17 |

| SiC (SF)-2000-1 h | 38.27 | 61.13 | 0.10 | <1.00 | 1.46 |

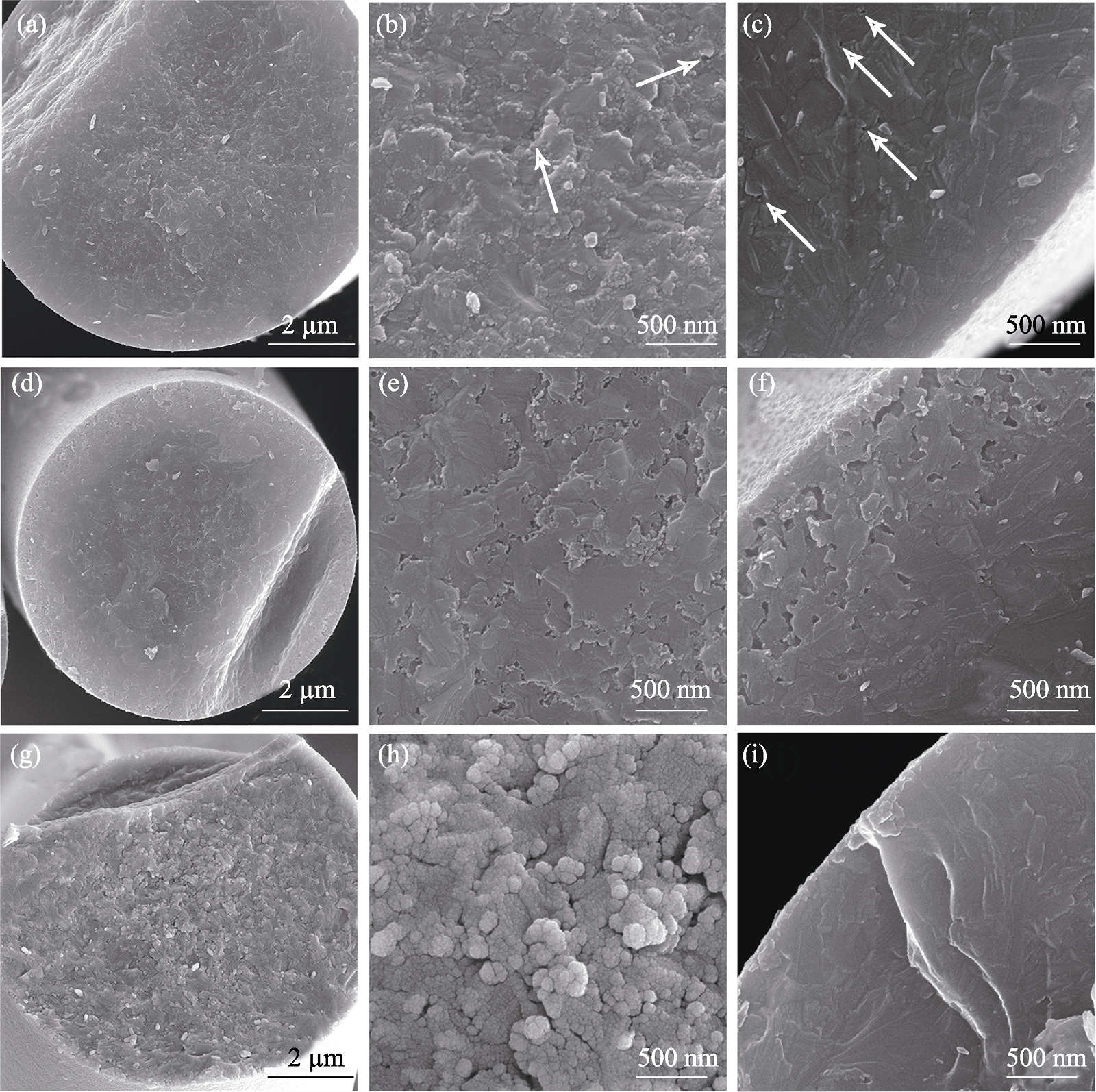

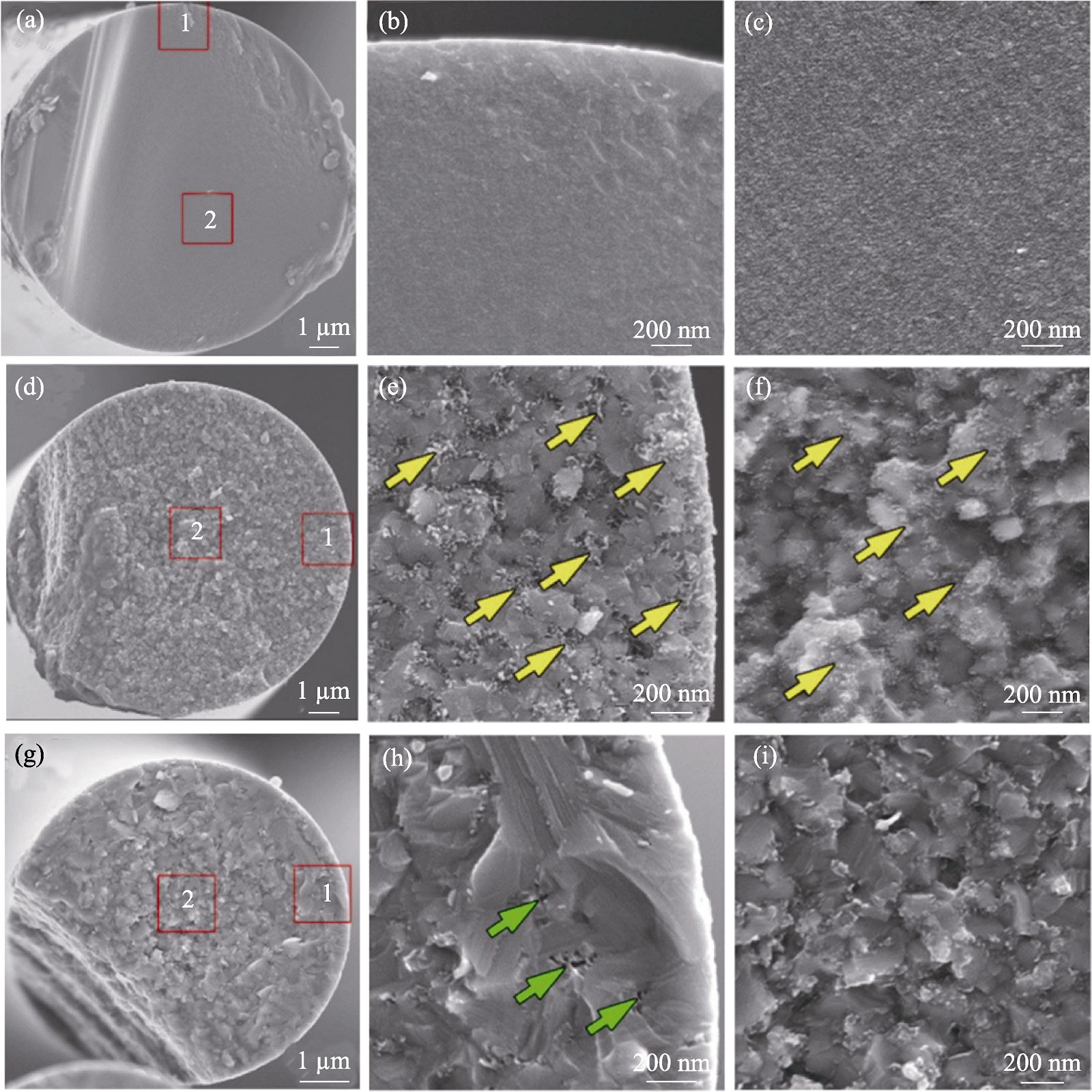

Fig. 7 Cross-sectional morphologies of the SiC (SF) fibers sintered at 1800 ℃ for different durations (a-c) SiC (SF)-1800-10 min; (d-f) SiC (SF)-1800-30 min; (g-i) SiC (SF)-1800-2 h

| Sample | C/% | Si/% | O/% | Al/% | C/Si atomic ratio |

|---|---|---|---|---|---|

| SiC (SF)-1800-10 min | 31.82 | 66.93 | 0.75 | <1.00 | 1.11 |

| SiC (SF)-1800-1 h | 31.48 | 67.41 | 0.61 | <1.00 | 1.09 |

| SiC (SF)-1800-2 h | 31.54 | 67.96 | 0 | <1.00 | 1.08 |

Table 3 Chemical composition (mass fraction) of the SiC (SF) fibers sintered at 1800 ℃ for different durations

| Sample | C/% | Si/% | O/% | Al/% | C/Si atomic ratio |

|---|---|---|---|---|---|

| SiC (SF)-1800-10 min | 31.82 | 66.93 | 0.75 | <1.00 | 1.11 |

| SiC (SF)-1800-1 h | 31.48 | 67.41 | 0.61 | <1.00 | 1.09 |

| SiC (SF)-1800-2 h | 31.54 | 67.96 | 0 | <1.00 | 1.08 |

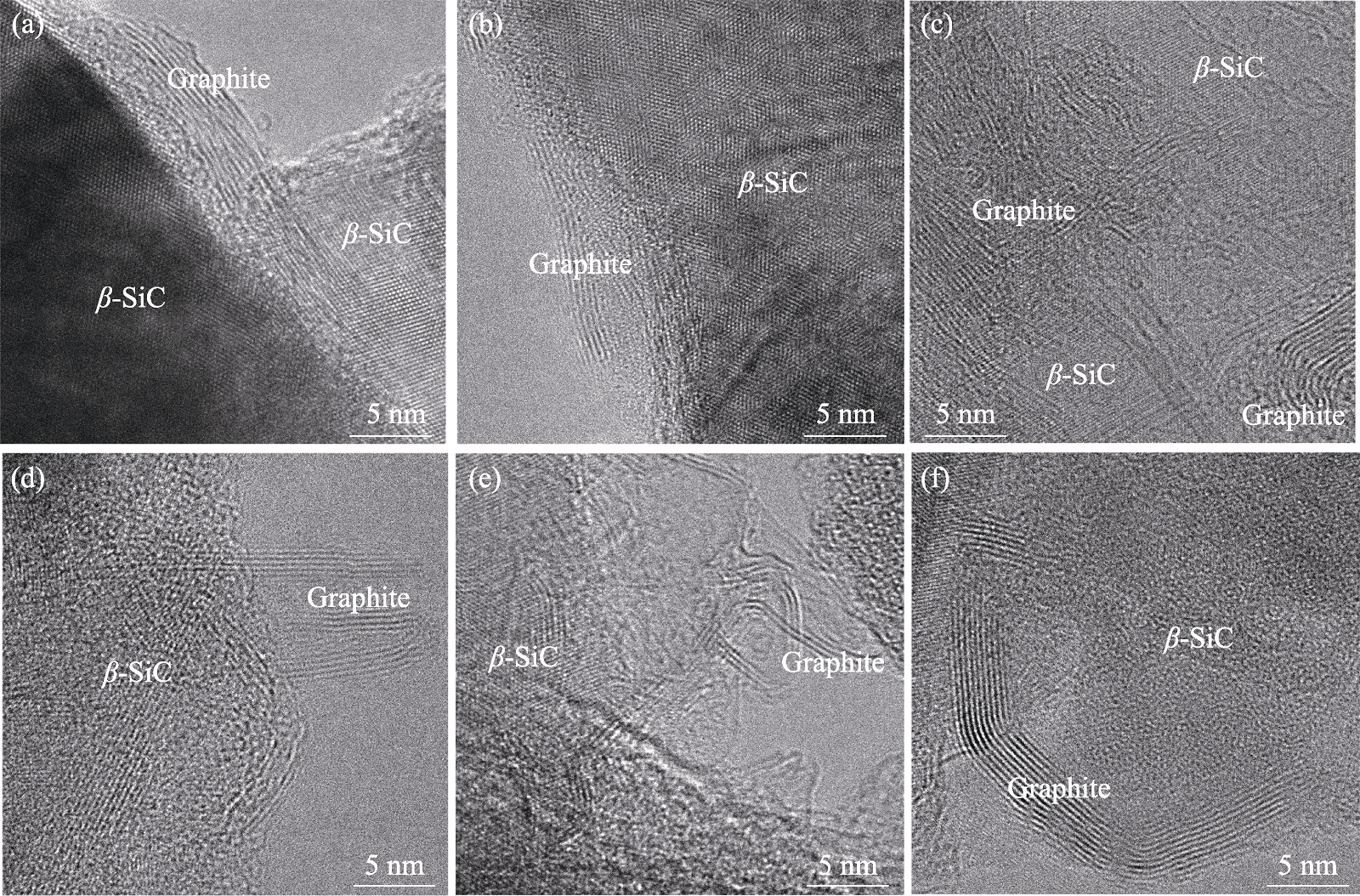

Fig. 8 HRTEM images of the SiC (SF) fibers sintered at 1800 ℃ for different durations (a, b) SiC (SF)-1800-10 min; (c, d) SiC (SF)-1800-30 min; (e, f) SiC (SF)-1800-2 h

| Sample | Tensile strength/ GPa | Young’s modulus/ GPa | Fiber diameter/ μm | Chemical formula |

|---|---|---|---|---|

| SiC (SF) | 1.88 | 373 | 11.2 | SiC1.04O0.02Al<0.01 |

| SiC (SG) | 2.96 | 268 | 11.6 | SiC1.31O0.05 |

Table 4 Mechanical properties of SiC (SF) and SiC (SG) fibers

| Sample | Tensile strength/ GPa | Young’s modulus/ GPa | Fiber diameter/ μm | Chemical formula |

|---|---|---|---|---|

| SiC (SF) | 1.88 | 373 | 11.2 | SiC1.04O0.02Al<0.01 |

| SiC (SG) | 2.96 | 268 | 11.6 | SiC1.31O0.05 |

| Sample | D peak/cm-1 | G peak/cm-1 | ID/IG | ||

|---|---|---|---|---|---|

| Position | FWHM | Position | FWHM | ||

| SiC (SF)-1600-1 h | 1357 | 56.0 | 1590 | 47.0 | 1.41 |

| SiC (SF)-1800-1 h | 1358 | 51.4 | 1593 | 42.2 | 1.01 |

| SiC (SF)-2000-1 h | 1357 | 49.3 | 1585 | 28.8 | 0.31 |

Table S1 Raman results of the SiC (SF) fibers sintered at 1600-2000 ℃ for 1 h

| Sample | D peak/cm-1 | G peak/cm-1 | ID/IG | ||

|---|---|---|---|---|---|

| Position | FWHM | Position | FWHM | ||

| SiC (SF)-1600-1 h | 1357 | 56.0 | 1590 | 47.0 | 1.41 |

| SiC (SF)-1800-1 h | 1358 | 51.4 | 1593 | 42.2 | 1.01 |

| SiC (SF)-2000-1 h | 1357 | 49.3 | 1585 | 28.8 | 0.31 |

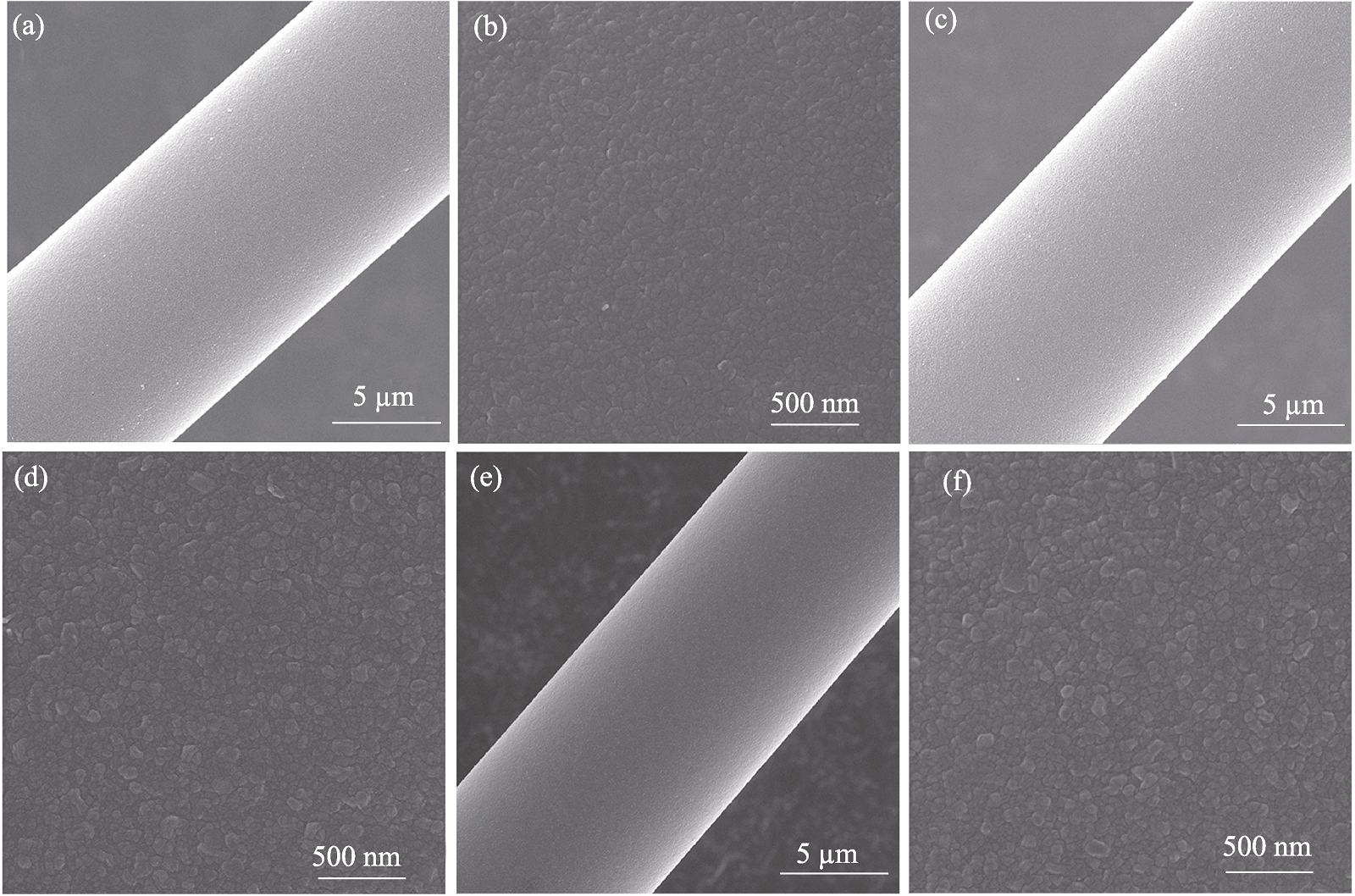

Fig. S4 Surface morphologies of the SiC (SF) fibers sintered at 1800 ℃ for different durations (a, b) SiC (SF)-1800-10 min; (c, d) SiC (SF)-1800-30 min; (e, f) SiC (SF)-1800-2 h

Fig. S8 SEM images of fracture morphologies for the fibers F-1 (a-c), F-2 (d-f) and F-3 (g-i) More details of the fracture surfaces can be found in the enlarged images for the outer parts (b, e, h) as indicated by red square 1 and the core parts (c, f, i) as indicated by red square 2[25]

| [1] | KANG W, CHEN J, ZHANG Y, et al. SiC fibers with different diameters exhibiting excellent high-temperature resistance and oxidation resistance. Journal of Materials Research and Technology, 2023, 23: 1559. |

| [2] | CHEN J, ZHANG Y, YAN D, et al. Flexible ultrafine nearly stoichiometric polycrystalline SiC fibers with excellent oxidation resistance and superior thermal stability up to 1900 ℃. Journal of the European Ceramic Society, 2022, 42(5): 1938. |

| [3] | XIANG Y, WU S, YU J, et al. Long-time oxidation behavior of the nearly stoichiometric polycrystal-line SiC fibers under air atmosphere at different temperatures. Journal of the European Ceramic Society, 2024, 44(6):3569. |

| [4] | SHAN J, MO G, SUN Q, et al. Fabrication of SiC (OAl) and SiC (Al) fibers by melt-spinning, UV curing, thermolysis and sintering of photo-sensitive polyvinylaluminocarbosilane. Journal of the European Ceramic Society, 2024, 44(6):3501. |

| [5] | MORSCHER G N, HURST J, BREWER D. Intermediate- temperature stress rupture of a woven Hi-Nicalon, BN-interphase, SiC-matrix composite in air. Journal of the American Ceramic Society, 2000, 83(6):1441. |

| [6] | KATOH Y, SNEAD L L, HENAGER C H, et al. Current status and critical issues for development of SiC composites for fusion applications. Journal of Nuclear Materials, 2007, 367: 659. |

| [7] | PANAKARAJUPALLY R P, MIRZA F, EL RASSI J, et al. Solid particle erosion behavior of melt-in-filtrated SiC/SiC ceramic matrix composites (CMCs) in a simulated turbine engine environ- ment. Composites Part B: Engineering, 2021, 216: 108860. |

| [8] | ARREGUI-MENA J D, KOYANAGI T, CAKMAK E, et al. Qualitative and quantitative analysis of neutron irradiation effects in SiC/SiC composites using X-ray computed tomography. Composites Part B: Engineering, 2022, 238: 109896. |

| [9] | ZHANG S, GAO X, HAN X, et al. Prediction of strength and constitutive response of SiC/SiC composites considering fiber failure. Composites Part B: Engineering, 2019, 163: 252. |

| [10] | BHATT R, ELDRIDGE J. Heat treatment effects on microstructure and properties of CVI SiC/SiC composites with SylramicTM-iBN SiC fibers. Journal of the European Ceramic Society, 2023, 43(6):2376. |

| [11] | ZHAO Z, LIAO W, CHEN J, et al. Advanced research on the preparation and application of carbide ceramic fibers. Journal of Advanced Ceramics, 2024, 13(9):1291. |

| [12] | LV X, YUE M, FENG X, et al. Rare earth mono-silicates as oxidation resistant interphase for SiCf/SiC CMC: investigation of SiCf/Yb2SiO5 model composites. Journal of Advanced Ceramics, 2022, 11(5):702. |

| [13] | YAJIMA S, HASEGAWA Y, OKAMURA K, et al. Development of high tensile strength silicon carbide fibre using an organosilicon polymer precursor. Nature, 1978, 273(5663):525. |

| [14] | YAJIMA S, OKAMURA K, HAYASHI J, et al. Synthesis of continuous SiC fibers with high tensile strength. Journal of the American Ceramic Society, 1976, 59(7/8):324. |

| [15] | KANG W, ZHANG Q, GOU Y. Fabrication of highly crystalline titanium-containing SiC fibers with different boron contents exhibiting excellent electromagnetic wave absorption. Journal of Materials Science, 2024, 59(7):2739. |

| [16] | ZHANG Q, CHEN T, KANG W, et al. Synthesis of polytitanocarbosilane and preparation of Si-C-Ti-B fibers. Processes, 2023, 11: 1189. |

| [17] | WU S, GOU Y, XIANG Y, et al. Effect of long-time annealing at high temperature on the microstructure and mechanical properties of different types of SiC fibers. Composites Part A: Applied Science and Manufacturing, 2024, 185: 108291. |

| [18] | GOU Y, KANG W, ZHANG Q. Preparation of nearly stoichiometric SiC(Ti) fibers with highly crystalline microstructure from polytitanocarbosilane. Journal of Inorganic Materials, 2024, 39(12):1377. |

| [19] | BUNSELL A R, PIANT A. A review of the development of three generations of small diameter silicon carbide fibres. Journal of Materials Science, 2006, 41(3):823. |

| [20] | WANG P, LIU F, WANG H, et al. A review of third generation SiC fibers and SiCf/SiC composites. Journal of Materials Science and Technology, 2019, 35(12):2743. |

| [21] | SCHAWALLER D, CLAUSS B, BUCHMEISER M R. Ceramic filament fibers-a review. Macromolecular Materials and Engineering, 2012, 297(6):502. |

| [22] | ISHIKAWA T, KOHTOKU Y, KUMAGAWA K, et al. High- strength alkali-resistant sintered SiC fibre stable to 2200 ℃. Nature, 1998, 391(6669):773. |

| [23] | TAKEDA M, SAEKI A, SAKAMOTO J I, et al. Effect of hydrogen atmosphere on pyrolysis of cured polycarbosilane fibers. Journal of the American Ceramic Society, 2000, 83(5):1063. |

| [24] | BHATT R, SOLA F, EVANS L, et al. Microstruc-tural, strength, and creep characterization of Sylramic™, Sylramic™-iBN and super Sylramic™-iBN SiC fibers. Journal of the European Ceramic Society, 2021, 41(9):4697. |

| [25] | ZHANG Y, WU C, WANG Y, et al. A detailed study of the microstructure and thermal stability of typical SiC fibers. Materials Characterization, 2018, 146: 91. |

| [26] | GOU Y, JIAN K, WANG H, et al. Fabrication of nearly stoichiometric polycrystalline SiC fibers with excellent high-temperature stability up to 1900 ℃. Journal of the American Ceramic Society, 2018, 101(5): 2050. |

| [27] | WANG P, GOU Y, WANG H, et al. Revealing the formation mechanism of the skin-core structure in nearly stoichiometric polycrystalline SiC fibers. Journal of the European Ceramic Society, 2020, 40(6):2295. |

| [28] |

YUAN Q, SONG Y. Effect of SiCxOy decomposition on densification of SiCO (Al) fibers during sintering process. Journal of Inorganic Materials, 2016, 31(12):1320.

DOI |

| [29] | USUKAWA R, ODA H, ISHIKAWA T, et al. Conversion process of amorphous Si-Al-C-O fiber into nearly stoichiometric SiC polycrystalline fiber. Journal of the Korean Ceramic Society, 2016, 53(6):610. |

| [30] | OKAMURA K, SHIMOO T, SUZUYA K, et al. SiC-based ceramic fibers prepared via organic-to-inorganic conversion process-a review. Journal of the Ceramic Society of Japan, 2006, 114(1330):445. |

| [31] | JACOBSON N S, KLINE S E. A thermoanalytical study of the conversion of amorphous Si-Ti-C-O fibers to SiC. International Journal of Applied Ceramic Technology, 2012, 9(4):816. |

| [32] | SNEAD L L, NOZAWA T, KATOH Y, et al. Hand-book of SiC properties for fuel performance modeling. Journal of Nuclear Materials, 2007, 371(1/3):329. |

| [33] | VAN DER BERG N, MALHERBE J B, BOTHA A, et al. Thermal etching of SiC. Applied Surface Science, 2012, 258(15):5561. |

| [34] | ZHANG Y, CHEN J, YAN D, et al. Conversion of silicon carbide fibers to continuous graphene fibers by vacuum annealing. Carbon, 2021, 182: 435. |

| [35] | ZHANG Y, CHEN T, CHEN J, et al. The effects of annealing atmosphere and intrinsic component on high temperature evolution behaviors of SiC fibers. Materials Science and Engineering: A, 2022, 848: 143363. |

| [36] | OKUMURA H, SAKUMA E, LEE J, et al. Raman scattering of SiC: application to the identification of heteroepitaxy of SiC polytypes. Journal of Applied Physics, 1987, 61(3):1134. |

| [37] | DONG S, CHOLLON G, LABRUGERE C, et al. Characterization of nearly stoichiometric SiC ceramic fibres. Journal of Materials Science, 2001, 36(10):2371. |

| [38] | LIPOWITZ J. Structure and properties of ceramic fibers prepared from organosilicon polymers. Journal of Inorganic and Organometallic Polymers and Materials, 1991, 1(3):277. |

| [1] | CHEN Bin, REN Ke, WANG Yiguang. Evolution of Mechanical Properties of Mini-SiCf/SiC Composites at High Temperatures over a Long Period of Time [J]. Journal of Inorganic Materials, 2025, 40(9): 971-980. |

| [2] | WEI Zhifan, CHEN Guoqing, ZU Yufei, LIU Yuan, LI Minghao, FU Xuesong, ZHOU Wenlong. ZrB2-HfSi2 Ceramics: Microstructure and Formation Mechanism of Core-rim Structure [J]. Journal of Inorganic Materials, 2025, 40(7): 817-825. |

| [3] | YANG Yan, ZHANG Faqiang, MA Mingsheng, WANG Yongzhe, OUYANG Qi, LIU Zhifu. Low Temperature Sintering of ZnAl2O4 Ceramics with CuO-TiO2-Nb2O5 Composite Oxide Sintering Aid [J]. Journal of Inorganic Materials, 2025, 40(6): 711-718. |

| [4] | JIANG Kun, LI Letian, ZHENG Mupeng, HU Yongming, PAN Qinxue, WU Chaofeng, WANG Ke. Research Progress on Low-temperature Sintering of PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 627-638. |

| [5] | YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 245-255. |

| [6] | FAN Wenkai, YANG Xiao, LI Honghua, LI Yong, LI Jiangtao. Pressureless Sintering of (Y0.2Gd0.2Er0.2Yb0.2Lu0.2)2Zr2O7 High-entropy Ceramic and Its High Temperature CMAS Corrosion Resistance [J]. Journal of Inorganic Materials, 2025, 40(2): 159-167. |

| [7] | LI Wei, XU Zhiming, GOU Yanzi, YIN Senhu, YU Yiping, WANG Song. Preparation and Performance of Sintered SiC Fiber-bonded Ceramics [J]. Journal of Inorganic Materials, 2025, 40(2): 177-183. |

| [8] | YU Zelong, TANG Chun, RAO Jiahao, GUO Heng, ZHOU Ying. Preparation and Economic Analysis of High-current-density Electrocatalysts for Alkaline Water Electrolysis [J]. Journal of Inorganic Materials, 2025, 40(12): 1405-1413. |

| [9] | MIAO Pengcheng, WANG Lijun, SHEN Ziyi, HUANG Li, YUAN Ningyi, DING Jianning. Micro-spherical Ag2Se: Solvothermal Synthesis and Thermoelectric Properties [J]. Journal of Inorganic Materials, 2025, 40(12): 1373-1378. |

| [10] | WANG Zhixiang, CHEN Ying, PANG Qingyang, LI Xin, WANG Genshui. Sintering Behaviour and Dielectric Properties of MnCO3-doped MgO-based Ceramics [J]. Journal of Inorganic Materials, 2025, 40(1): 97-103. |

| [11] | LIU Lei, GUO Ruihua, WANG Li, WANG Yan, ZHANG Guofang, GUAN Lili. Oxygen Reduction Reaction on Pt3Co High-index Facets by Density Functional Theory [J]. Journal of Inorganic Materials, 2025, 40(1): 39-46. |

| [12] | ZHANG Jinghui, LU Xiaotong, MAO Haiyan, TIAN Yazhou, ZHANG Shanlin. Effect of Sintering Additives on Sintering Behavior and Conductivity of BaZr0.1Ce0.7Y0.2O3-δ Electrolytes [J]. Journal of Inorganic Materials, 2025, 40(1): 84-90. |

| [13] | WANG Kanglong, YIN Jie, CHEN Xiao, WANG Li, LIU Xuejian, HUANG Zhengren. Effect of Particle Grading on Properties of Silicon Carbide Ceramics Prepared by Selective Laser Sintering Printing Combined with Solid-phase Sintering at Atmospheric Pressure [J]. Journal of Inorganic Materials, 2024, 39(7): 754-760. |

| [14] | LIU Yan, QIN Xianpeng, GAN Lin, ZHOU Guohong, ZHANG Tianjin, WANG Shiwei, CHEN Hetuo. Preparation of Sub-micron Spherical Y2O3 Particles and Transparent Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 691-696. |

| [15] | WANG Weiming, WANG Weide, SU Yi, MA Qingsong, YAO Dongxu, ZENG Yuping. Research Progress of High Thermal Conductivity Silicon Nitride Ceramics Prepared by Non-oxide Sintering Additives [J]. Journal of Inorganic Materials, 2024, 39(6): 634-646. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||