Journal of Inorganic Materials ›› 2024, Vol. 39 ›› Issue (1): 17-31.DOI: 10.15541/jim20230345

• REVIEW • Previous Articles Next Articles

KE Xin1,2( ), XIE Bingqing1,2, WANG Zhong1,3(

), XIE Bingqing1,2, WANG Zhong1,3( ), ZHANG Jingguo1,3,4, WANG Jianwei1,3, LI Zhanrong1,3,4, HE Huijun1,3, WANG Limin1,3

), ZHANG Jingguo1,3,4, WANG Jianwei1,3, LI Zhanrong1,3,4, HE Huijun1,3, WANG Limin1,3

Received:2023-08-01

Revised:2023-10-12

Published:2024-01-20

Online:2023-11-22

Contact:

WANG Zhong, professor. E-mail: wzwz99@126.comAbout author:KE Xin (1997-), male, PhD candidate. E-mail: kexin0308@qq.com

Supported by:CLC Number:

KE Xin, XIE Bingqing, WANG Zhong, ZHANG Jingguo, WANG Jianwei, LI Zhanrong, HE Huijun, WANG Limin. Progress of Interconnect Materials in the Third-generation Semiconductor and Their Low-temperature Sintering of Copper Nanoparticles[J]. Journal of Inorganic Materials, 2024, 39(1): 17-31.

| Parameter | Si | GaAs | SiC | GaN | Diamond |

|---|---|---|---|---|---|

| Band gap/eV | 1.12 | 1.43 | 3.26 | 3.45 | 5.45 |

| Dielectric constant | 11.9 | 13.1 | 10.1 | 9 | 5.5 |

| Breakdown field/ (kV·cm-1) | 300 | 400 | 2200 | 2000 | 10000 |

| Electron mobility/(cm2·V-1·s-1) | 1500 | 8500 | 1000 | 1250 | 2200 |

| Hole mobility/ (cm2·V-1·s-1) | 600 | 400 | 115 | 850 | 850 |

| Thermal conductivity/ (W·cm-1·K-1) | 1.5 | 0.46 | 4.9 | 1.3 | 22 |

| Electron saturation drift velocity/(×107, cm·s-1) | 1 | 1 | 2 | 2.2 | 2.7 |

Table 1 Comparison on performance parameters of the main semiconductor material [10]

| Parameter | Si | GaAs | SiC | GaN | Diamond |

|---|---|---|---|---|---|

| Band gap/eV | 1.12 | 1.43 | 3.26 | 3.45 | 5.45 |

| Dielectric constant | 11.9 | 13.1 | 10.1 | 9 | 5.5 |

| Breakdown field/ (kV·cm-1) | 300 | 400 | 2200 | 2000 | 10000 |

| Electron mobility/(cm2·V-1·s-1) | 1500 | 8500 | 1000 | 1250 | 2200 |

| Hole mobility/ (cm2·V-1·s-1) | 600 | 400 | 115 | 850 | 850 |

| Thermal conductivity/ (W·cm-1·K-1) | 1.5 | 0.46 | 4.9 | 1.3 | 22 |

| Electron saturation drift velocity/(×107, cm·s-1) | 1 | 1 | 2 | 2.2 | 2.7 |

| Material | Temperature/℃ | Relative market price* | Relative performance | ||

|---|---|---|---|---|---|

| Bonding | IMC | Thermal conductivity | Electrical conductivity | ||

| Cu-Sn | 280 | 415(Cu6Sn5) | Cu: 0.5 | Cu: 4.4 | Cu: 4.1 |

| 676(Cu3Sn) | Sn: 0.8 | ||||

| Ni-Sn | 300 | 800(Ni3Sn3) | Ni: 1 | Ni: 1 | Ni: 1 |

| Sn: 0.8 | |||||

| Au-Sn | 250 | 419(AuSn) | Au: 2600 | Au: 3.5 | Au: 3.1 |

| Sn: 0.8 | |||||

| Ag-Sn | 250 | 480(Ag3Sn) | Ag: 63 | Ag: 4.7 | Ag: 4.4 |

| Sn: 0.8 | |||||

| Ag-In | 200 | 495 | Ag: 63 | Ag: 4.7 | Ag: 4.7 |

| In: 37.5 | |||||

| Au-In | 175 | 880 | Au: 2600 | Au: 3.1 | Au: 3.1 |

| In: 37.5 | |||||

Table 2 Various TLP bonding materials and their properties[60]

| Material | Temperature/℃ | Relative market price* | Relative performance | ||

|---|---|---|---|---|---|

| Bonding | IMC | Thermal conductivity | Electrical conductivity | ||

| Cu-Sn | 280 | 415(Cu6Sn5) | Cu: 0.5 | Cu: 4.4 | Cu: 4.1 |

| 676(Cu3Sn) | Sn: 0.8 | ||||

| Ni-Sn | 300 | 800(Ni3Sn3) | Ni: 1 | Ni: 1 | Ni: 1 |

| Sn: 0.8 | |||||

| Au-Sn | 250 | 419(AuSn) | Au: 2600 | Au: 3.5 | Au: 3.1 |

| Sn: 0.8 | |||||

| Ag-Sn | 250 | 480(Ag3Sn) | Ag: 63 | Ag: 4.7 | Ag: 4.4 |

| Sn: 0.8 | |||||

| Ag-In | 200 | 495 | Ag: 63 | Ag: 4.7 | Ag: 4.7 |

| In: 37.5 | |||||

| Au-In | 175 | 880 | Au: 2600 | Au: 3.1 | Au: 3.1 |

| In: 37.5 | |||||

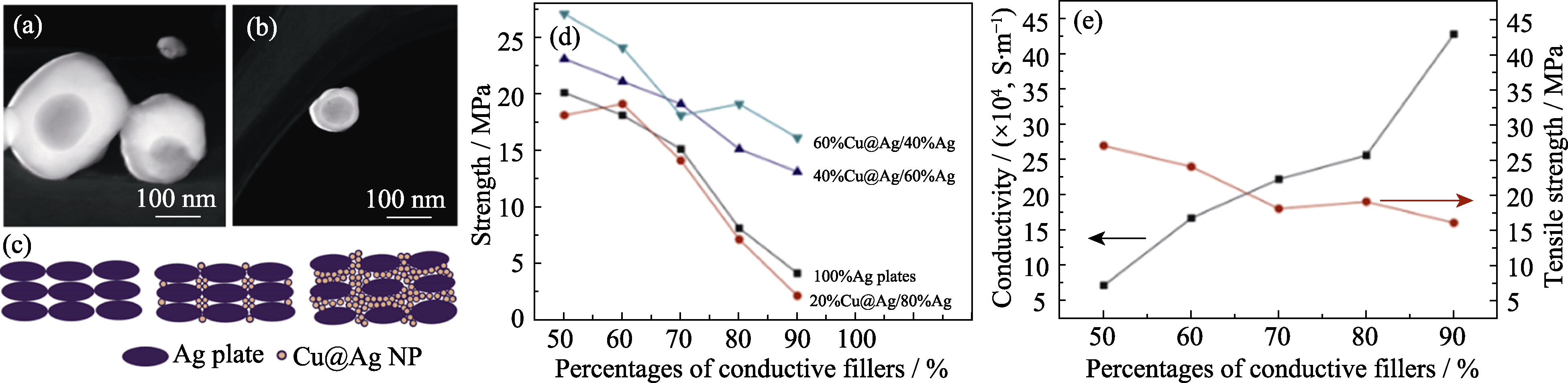

Fig. 7 Cu@Ag nanoparticles and performance characterization[85] (a, b) STEM images of Cu@Ag nanoparticles; (c) Schematic diagram of the filling effect of nanoparticles on silver conductive adhesive; (d) Influence of the conductive fillers’ percentages on the strength of the conductive adhesives; (e) Dependence of conductive fillers’ percentages on the strength and conductivity of conductive adhesive with 60%Cu@Ag/40% Ag plates

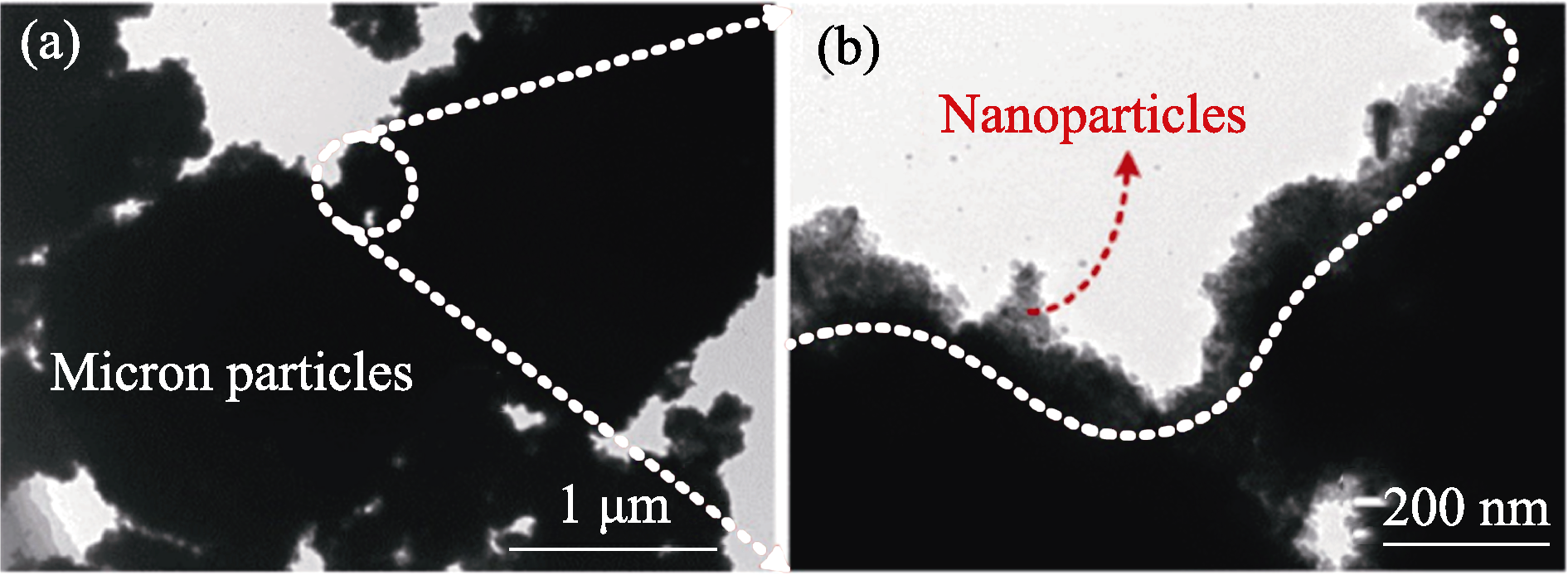

Fig. 8 Structures of micro-nano copper particles mixed with different particle sizes[90] (a) TEM image showing micron particles; (b) TEM image showing nanoparticles

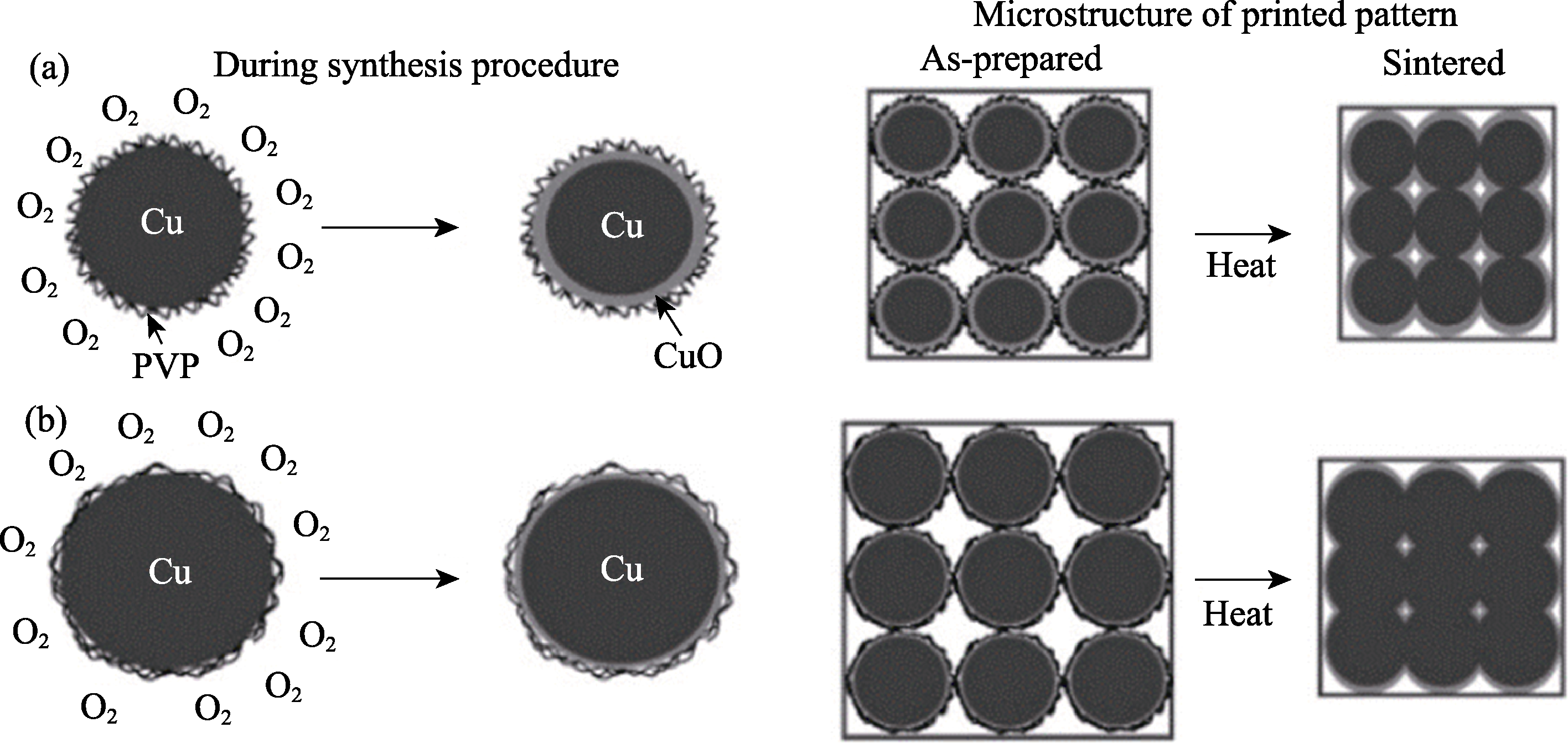

Fig. 10 Schematic diagram of oxidation effect of surface layer of copper nanoparticles on the sintering performance[94] (a) With CuO outer layer; (b) No CuO outer layer

| Particle size | Appearance | Sintering process | Electrical conductivity/ (μΩ·cm) | Shearing performance/ MPa | Ref. |

|---|---|---|---|---|---|

| 10 and 1000 nm particle compound | Irregular | Ar, 250 ℃, 2 MPa, 15 min | 5.44 | 45.6 | [ |

| 200 nm, 1000 nm | Spherical | N2, 350 ℃, 0.4 MPa | - | 40 | [ |

| 530 nm | Irregular | 97% N2-3% H2, 300 ℃, 30 min | - | 23 | [ |

| 60-100 nm | Angular | N2, 200 ℃, 60 min | 18 | - | [ |

| Thick 200 nm, length 3-5 μm | Spherical | N2, 275 ℃, 10 MPa, 30 min | - | 50 | [ |

| 30-400 nm | Angular | N2, 300 ℃, 0.4 MPa, 30 min | - | 24.8 | [ |

| 6.5 nm | Spherical | Ar, 250 ℃, 5 MPa, 30 min | - | 36.2 | [ |

| 100 nm | Spherical | Air, 225 ℃, 8 MPa, 10 min | 59±7 | 28.7±1.6 | [ |

| 500 nm | Angular | HCOOH, 275 ℃, 5 MPa, 30 min | - | 70 | [ |

| 60.5 nm | Spherical | 95% Ar-5% H2, 300 ℃, 1.08 MPa, 60 min | 11.2 | 31.88 | [ |

| 30 nm | Spherical | 95% N2-5% H2, 320 ℃, 10 MPa, 5 min | 3.16 | 51.7 | [ |

| 54-64 nm | Sphere-like | H2, 400 ℃, 1.2 MPa, 5 min | - | 37.7 | [ |

| 5 nm | Sphere-like | 95% Ar-5% H2, 250 ℃, 1.08 MPa, 60 min | 4.1 | 25.36 | [ |

| 400-1200 nm | Sphere-like | Air, 200 ℃, 50 s | 54±2 | - | [ |

| 300-400 nm | Sphere-like | N2, 200 ℃, 30 min | 139±24 | - | [ |

| 1-3 μm | Sphere-like | Air, 180 ℃, 5 min | 30 | - | [ |

| 200 nm | Spherical | Air, 300 ℃, 2 MPa, 1 min | - | 21.8 | [ |

| 50 nm | Spherical | Air, 220 ℃, 5 min | - | 30 | [ |

| 10 nm | Spherical | N2, 200 ℃, 30 min | 14.0±4.5 | - | [ |

| 6.5 nm | Spherical | Air, 175 ℃, 2 MPa, 10 min | - | 35.1 | [ |

| 60 nm | Sphere-like | 95% Ar-5% H2, 250 ℃, 10 MPa, 60 min | - | 32.4 | [ |

| 4.4 nm | Angular | N2, 150 ℃, 30 min | 52 | - | [ |

| Tens to hundreds of nanometers | Irregular | Vacuum, 300 ℃, 0.4 MPa,30 min | - | 20 | [ |

| <10 nm | Angular | Ar, 250 ℃, 3 MPa, 30 min | 5.1 | - | [ |

Table 3 Comparison of various low-temperature sintering processes and their performance

| Particle size | Appearance | Sintering process | Electrical conductivity/ (μΩ·cm) | Shearing performance/ MPa | Ref. |

|---|---|---|---|---|---|

| 10 and 1000 nm particle compound | Irregular | Ar, 250 ℃, 2 MPa, 15 min | 5.44 | 45.6 | [ |

| 200 nm, 1000 nm | Spherical | N2, 350 ℃, 0.4 MPa | - | 40 | [ |

| 530 nm | Irregular | 97% N2-3% H2, 300 ℃, 30 min | - | 23 | [ |

| 60-100 nm | Angular | N2, 200 ℃, 60 min | 18 | - | [ |

| Thick 200 nm, length 3-5 μm | Spherical | N2, 275 ℃, 10 MPa, 30 min | - | 50 | [ |

| 30-400 nm | Angular | N2, 300 ℃, 0.4 MPa, 30 min | - | 24.8 | [ |

| 6.5 nm | Spherical | Ar, 250 ℃, 5 MPa, 30 min | - | 36.2 | [ |

| 100 nm | Spherical | Air, 225 ℃, 8 MPa, 10 min | 59±7 | 28.7±1.6 | [ |

| 500 nm | Angular | HCOOH, 275 ℃, 5 MPa, 30 min | - | 70 | [ |

| 60.5 nm | Spherical | 95% Ar-5% H2, 300 ℃, 1.08 MPa, 60 min | 11.2 | 31.88 | [ |

| 30 nm | Spherical | 95% N2-5% H2, 320 ℃, 10 MPa, 5 min | 3.16 | 51.7 | [ |

| 54-64 nm | Sphere-like | H2, 400 ℃, 1.2 MPa, 5 min | - | 37.7 | [ |

| 5 nm | Sphere-like | 95% Ar-5% H2, 250 ℃, 1.08 MPa, 60 min | 4.1 | 25.36 | [ |

| 400-1200 nm | Sphere-like | Air, 200 ℃, 50 s | 54±2 | - | [ |

| 300-400 nm | Sphere-like | N2, 200 ℃, 30 min | 139±24 | - | [ |

| 1-3 μm | Sphere-like | Air, 180 ℃, 5 min | 30 | - | [ |

| 200 nm | Spherical | Air, 300 ℃, 2 MPa, 1 min | - | 21.8 | [ |

| 50 nm | Spherical | Air, 220 ℃, 5 min | - | 30 | [ |

| 10 nm | Spherical | N2, 200 ℃, 30 min | 14.0±4.5 | - | [ |

| 6.5 nm | Spherical | Air, 175 ℃, 2 MPa, 10 min | - | 35.1 | [ |

| 60 nm | Sphere-like | 95% Ar-5% H2, 250 ℃, 10 MPa, 60 min | - | 32.4 | [ |

| 4.4 nm | Angular | N2, 150 ℃, 30 min | 52 | - | [ |

| Tens to hundreds of nanometers | Irregular | Vacuum, 300 ℃, 0.4 MPa,30 min | - | 20 | [ |

| <10 nm | Angular | Ar, 250 ℃, 3 MPa, 30 min | 5.1 | - | [ |

| [1] |

TSUYOSHI F, JUAN C B, JEREMY J, et al. Power conversion with SiC devices at extremely high ambient temperature. IEEE Transactions on Power Electronics, 2007, 22(4):1321.

DOI URL |

| [2] |

TSUYOSHI F, HIROYASU I, MASASHI S, et al. Characterization of SiC power module for high switching frequency operation. IEICE Electronics Express, 2010, 7(14):1008.

DOI URL |

| [3] | JOHNSON R W, PALMER M, WANG C, et al. Packaging materials and approaches for high temperature SiC power devices. Advancing Microelectronics, 2004, 31(1):8. |

| [4] |

MCCLUSKEY F P, DASH M, WANG Z, et al. Reliability of high temperature solder alternatives. Microelectronics Reliability, 2006, 46(9/10/11): 1910.

DOI URL |

| [5] | 中华人民共和国科学技术部. “十三五”材料领域科技创新专项规划(2017), 306082017496. 北京: 中华人民共和国科学技术部, 2017: 1-29. |

| [6] | XIE M, GAN Y, WANG H. Research on the strategy of new material power for 2035. Strategic Study of CAE, 2020, 22(5):1. |

| [7] | MA Y, TU X J. Global IC industry: growth, migration and remodeling. Information and Communications Technology and Policy, 2022, 48(5):68. |

| [8] | HUANG F L, ZHU H. Semiconductor integrated circuit business unit management strategy. Manager Journal, 2020, 8: 58. |

| [9] | WANG X. Application status and development trend of semiconductor materials. Lamps & Lighting, 2022, 1: 67. |

| [10] | CAO J, ZHANG Z Q. Advances in silicon carbide power module packaging technology. Applications of IC, 2018, 35(8):20. |

| [11] | WANG R D. Advanced packaging promotes new development of semiconductor industry. China Integrated Circuit, 2022, 31(4):26. |

| [12] | WU Y B, DAI X P, WANG Y G, et al. Research progress on advanced interconnect technologies in IGBT power module packaging. High Power Converter Technology, 2015 (2): 6. |

| [13] | YUAN G Z. Micro-scale mechanical properties of lead-free solder joint interconnect interfaces for electronic packaging. Taiyuan: Master's Thesis, Taiyuan University of Technology, 2016. |

| [14] | XU H Y, XU H Y, ZANG L K, et al. Advances in low-temperature sintered copper-based electronic pastes for power device chip interconnects. Electronic Components & Materials, 2022, 41(1):9. |

| [15] | DONG Z Z. Research on some key issues of low-power silicon carbide integrated modules. Hangzhou: Master's Thesis, Zhejiang University, 2022. |

| [16] | HARTNETT A, BUERKI S.Process and reliability advantages of AuSn eutectic die-attach. IMAPS 2009 International Symposium on Microelectronics. San Jose, CA(US), 2009: 470-474. |

| [17] | HUMSTON G, JACOBSON D. Principles of soldering and brazing. Materials Park, OH, USA: ASM International, 1993. |

| [18] | FAN J L. Controlled preparation and low-temperature sintering of silver/copper nanoparticles and their interconnection applications in microelectronic packaging. Shenzhen: Doctoral dissertation, University of Chinese Academy of Sciences (Shenzhen Institutes of Advanced Technology, Chinese Academy of Sciences), 2020. |

| [19] | SHEN B W, LIU G H, GAO L Q, et al. Research progress of new low temperature lead-free solder. Precious Metals, 2022, 43(S1):1. |

| [20] | GANESAN SANKA, PECHT MICHAEL. Lead-free electronics. Hoboken N.J.: Wiley-Interscience, 2006. |

| [21] |

ZHANG H W, MINTER J, LEE N C. A brief review on high- temperature, Pb-free die-attach materials. Journal of Electronic Materials, 2019, 48(1):201.

DOI |

| [22] |

MANIKAM V R, CHEONG K Y. Die attach materials for high temperature applications: a review. IEEE Transactions on Components Packaging and Manufacturing Technology, 2011, 1(4):457.

DOI URL |

| [23] | VIVEK C, JESPER H, JOHN H. Design of lead-free candidate alloys for high-temperature soldering based on the Au-Sn system. Materials and Design, 2010, 31: 4638. |

| [24] | HARPSTER T J, NAJAFI K. Field-assisted bonding of glass to Si-Au eutectic solder for packaging applications. 16th IEEE Annual International Conference on Micro Electro Mechanical Systems. Kyoto, Japan: IEEE, 2003. |

| [25] | DREVIN B A, BADAWI F, LACROIX F, et al. Investigation of die attach for SiC power device for 300 ℃ applications. 9th European Conference on Silicon Carbide and Related Materials (ECSCRM 2012). Saint Petersburg, Russia: Trans Tech Publications Ltd, 2012. |

| [26] | HASSAM S, ROGEZ J, BAHARI Z. Experimental phase diagram of the AuSb-InSb section in the Au-In-Sb system. Journal of Chemical Thermodynamics, 2014, 70: 168. |

| [27] |

HUANG M L, HUANG F F, YANG Y C. Composition design of Sn-rich Sn-Au-Ag solders using cluster-plus-glue-atom model. Journal of Materials Science: Materials in Electronics, 2017, 28(15):11192.

DOI URL |

| [28] | LAU B L, HAN Y, ZHANG H Y, et al. Development of fluxles bonding using deposited gold-indium multi-layer composite for heterogeneous silicon micro-cooler stacking. IEEE 16th Electronics Packaging Technology Conference (EPTC). Marina Bay Sands, Singapore: IEEE, 2014. |

| [29] | KOSTOV A, GOMIDZELOVIC L, MILOSAVLJEVIC A, et al. Thermodynamic characterization of solder Au-Ga alloys. Materials Chemistry and Physics, 2020, 241: 122278. |

| [30] | XU J C, WU M F, PU J, et al. Novel Au-based solder alloys: a potential answer for electrical packaging problem. Advances in Materials Science and Engineering, 2020, 2020: 4969647. |

| [31] |

LEONARD B. Semiconductor joining by the solid-liquid-interdiffusion (SLID) proces. Journal of The Electrochemical Society, 1966, 113(12):1282.

DOI URL |

| [32] |

JUNG D H, SHARMAL A, MAYER M, et al. A review on recent advances in transient liquid phase (TLP) bonding for thermoelectric power module. Reviews on Advanced Materials Science, 2018, 53(2):147.

DOI URL |

| [33] | ROH M H, NISHIKAWA H, JUNG J P, et al. Trasient liquid phase bonding for power semiconductor. The Korean Microelectronics and Packaging Society, 2017, 24(1):27. |

| [34] |

MITTAL J, LIN K L. Diffusion of Cu and interfacial reactions during reflow of Sn-8.5Zn-0.5Ag-0.01Al-0.1Ga alloy on Ni/Cu substrate. Journal of Materials Research, 2012, 27(8):1142.

DOI URL |

| [35] |

YU C C, SU P C, BAI S J, et al. Nickel-tin solid-liquid inter- diffusion bonding. International Journal of Precision Engineering and Manufacturing, 2014, 15(1):143.

DOI URL |

| [36] |

HSU H H, HUANG Y T, HUANG S Y, et al. Evolution of the intermetallic compounds in Ni/Sn-2.5Ag/Ni microbumps for three-dimensional integrated circuits. Journal of Electronic Materials, 2015, 44(10):3888.

DOI URL |

| [37] |

SHIH W L, YANG T L, CHUANG H Y, et al. Inhibition of gold embrittlement in micro-joints for three-dimensional integrated circuits. Journal of Electronic Materials, 2014, 43(11):4262.

DOI URL |

| [38] |

CAO Y H, NING W G, LUO L. Wafer-level package with simultaneous TSV connection and cavity hermetic sealing by solder bonding for MEMS device. IEEE Transactions on Electronics Packaging Manufacturing, 2009, 32(3):125.

DOI URL |

| [39] |

HANG C J, TIAN Y H, ZHANG R, et al. Phase transformation and grain orientation of Cu-Sn intermetallic compounds during low temperature bonding process. Journal of Materials Science: Materials in Electronics, 2013, 24(10):3905.

DOI URL |

| [40] | YANG T L, AOKI T, MATSUMOTO K, et al. Full intermetallic joints for chip stacking by using thermal gradient bonding. Acta Materialia, 2016, 113: 90. |

| [41] | FENG J Y, HANG C J, TIAN Y H, et al. Growth kinetics of Cu6Sn5 intermetallic compound in Cu-liquid Sn interfacial reaction enhanced by electric current. Scientific Reports, 2018, 8: 1175. |

| [42] | LIU B L, TIAN Y H, WANG C X, et al. Ultrafast formation of unidirectional and reliable Cu3Sn-based intermetallic joints assisted by electric current. Intermetallics, 2017, 80: 26. |

| [43] | ZHAO H Y, LIU J H, LI Z L, et al. Non-interfacial growth of Cu3Sn in Cu/Sn/Cu joints during ultrasonic-assisted transient liquid phase soldering process. Materials Letters, 2017, 186: 283. |

| [44] |

ZHAO H Y, LIU J H, LI Z L, et al. A comparative study on the microstructure and mechanical properties of Cu6Sn5 and Cu3Sn joints formed by TLP soldering with/without the assistance of ultrasonic waves. Metallurgical and Materials Transactions A, 2018, 49(7):2739.

DOI |

| [45] |

CAIN S R, WILCOX J R, VENKATRAMAN R. A diffusional model for transient liquid phase bonding. Acta Materialia, 1997, 45(2):701.

DOI URL |

| [46] |

MARAUSKA S, CLAUS M, LISEC T, et al. Low temperature transient liquid phase bonding of Au/Sn and Cu/Sn electroplated material systems for MEMS wafer-level packaging. Microsystem Technologies, 2013, 19(8):1119.

DOI URL |

| [47] |

BOBZIN K, BAGCIVAN N, ZHAO L D, et al. Development of new transient liquid phase system Au-Sn-Au for microsystem technology. Frontiers of Mechanical Engineering in China, 2010, 5(4):370.

DOI URL |

| [48] |

TOLLEFSEN T A, LARSSON A, TAKLO M M V, et al. Au-Sn SLID bonding: a reliable HT interconnect and die attach technology. Metallurgical and Materials Transactions B, 2013, 44(2):406.

DOI URL |

| [49] |

RAUTIAINEN A, XU H, OSTERLUND E, et al. Microstructural characterization and mechanical performance of wafer-level SLID bonded Au-Sn and Cu-Sn seal rings for MEMS encapsulation. Journal of Electronic Materials, 2015, 44(11):4533.

DOI URL |

| [50] |

LIN W P, LEE C C. Fluxless bonding of bismuth telluride chips to Alumina using Ag-In system for high temperature thermoelectric devices. IEEE Transactions on Components, Packaging, and Manufacturing Technology, 2011, 1(9):1311.

DOI URL |

| [51] |

LI J F, AGYAKWA P A, JOHNSON C M. Kinetics of Ag3Sn growth in Ag-Sn-Ag system during transient liquid phase soldering process. Acta Materialia, 2010, 58(9):3429.

DOI URL |

| [52] |

GOLLAS B, ALBERING J H, SCHMUT K, et al. Thin layer in situ XRD of electrodeposited Ag/Sn and Ag/In for low temperature isothermal diffusion soldering. Intermetallics, 2008, 16(8):962.

DOI URL |

| [53] |

LIS A, LEINENBACH C. Effect of process and service conditions on TLP-bonded components with (Ag,Ni-)Sn interlayer combinations. Journal of Electronic Materials, 2015, 44(11):4576.

DOI URL |

| [54] | SHAO H K, WU A P, BAO Y D, et al. Microstructure characterization and mechanical behavior for Ag3Sn joint produced by foil- based TLP bonding in air atmosphere. Materials Science & Engineering A, 2017, 680: 221. |

| [55] |

ZHANG W, RUYTHOOREN W. Study of the Au/In reaction for transnsient liquid-phase bonding and 3D chip stackaging. Journal of Electronic Materials, 2008, 37(8):1095.

DOI URL |

| [56] | YOON J W, LEE B S. Initial interfacial reactions of Ag/In/Ag and Au/In/Au joints during transient liquid phase bonding. Microelectronic Engineering, 2018, 201: 6. |

| [57] | CHOI W K, PREMACHANDRAN C S, CHIEW O S, et al. Development of novel intermetallic joints using thin film indium-based solder by low temperature bonding technology for 3D IC stacking. 2009 IEEE 59th Electronic Components and Technology Conference, San Diego, CA, USA, 2009: 333-338. |

| [58] |

LIN J C, HUANG L W, JANG G Y, et al. Solid-liquid interdiffusion bonding between In-coated silver thick films. Thin Solid Films, 2002, 410 (1/2): 212.

DOI URL |

| [59] | LEE C K, YU A B, YAN L L, et al. Characterization of intermediate In/Ag layers of low temperature fluxless solder based wafer bonding for MEMS packaging. Sensors and Actuators A: Physical, 2009, 154: 85. |

| [60] | MOKHTARI O. A review: formation of voids in solder joint during the transient liquid phase bonding process-causes and solutions. Microelectronics Reliability, 2019, 98: 95. |

| [61] | ZHANG W, YAO J J, ZHAN K, et al. Conductive adhesive research progress. Science & Technology Review, 2018, 36(10):56. |

| [62] | LI Y, LU D, WONG C P.Electrical conductive adhesives with nanotechnologies. New York: Springer New York, NY, 2010. |

| [63] | LI S H. Gold conductive adhesive. China Adhesives, 1998(6): 33. |

| [64] | WANG Y H, HUANG A, XIE H, et al. Isotropical conductive adhesives with very-long silver nanowires as conductive fillers. Journal of Materials Science: Materials Electronics, 2017, 28: 10. |

| [65] | XIONG S H, YANG R C, WU D, et al. The effect of silver powder morphology and size on the performance of conductive adhesives. Electronic Components & Materials, 2005, 24(8):14. |

| [66] | WAN C, WANG H Q, DU B, et al. The effect of silver powder morphology and surface treatment on the performance of conductive adhesives. Electronics Process Technology, 2011, 32(2):72. |

| [67] | QIAO W Y, BAO H, LI X H, et al. Research on electrical conductive adhesives filled with mixed filler. International Journal of Adhesion and Adhesives, 2014, 48: 159. |

| [68] | WU H P, WU X J, GE M Y, et al. Effect analysis of filler sizes on percolation threshold of isotropical conductive adhesives. Composites Science and Technology, 2007, 67: 1116. |

| [69] | YIM M J, LI Y, MOON K S, et al. Oxidation prevention and electrical property enhancement of copper-filled isotropically conductive adhesives. Journal of Electronic Materials, 2007, 36(10):1342. |

| [70] | LIU Y X, WANG X D, GU Y X, et al. Development of copper powder-added conductive adhesive. China Adhesives, 2008, 17(11):27. |

| [71] | PENG Y H, YANG C H, CHEN K T, et al. Study on synthesis of ultrafine Cu-Ag core-shell powders with high electrical conductivity. Applied Surface Science, 2012, 263: 38. |

| [72] |

HO L N, NISHIKAWA H, TAKEMOTO T. Effect of different copper fillers on the electrical resistivity of conductive adhesives. Journal of Materials Science Materials in Electronics, 2011, 22(5):538.

DOI URL |

| [73] | FAN Y Q, GU Y W, XIA X Y. Preparation and properties of fibrous copper powder conductive filler. Electronic Components & Materials, 2014, 33(8):25. |

| [74] | WANG J H, MIN H L. Research on nickel powder conductive acrylate pressure sensitive adhesive. Insulating Materials, 2006(5): 4. |

| [75] |

PU N W, PENG Y Y, WANG P C, et al. Application of nitrogen- doped graphene nanosheets in electrically conductive adhesives. Carbon, 2014, 67(2):449.

DOI URL |

| [76] |

MARCQ F, DEMONT P, MONFRAIX P, et al. Carbon nanotubes and silver flakes filled epoxy resin for new hybrid conductive adhesives. Microelectronics Reliability, 2011, 51(7):1230.

DOI URL |

| [77] |

YIM B S, KIM J M. Characteristics of isotropically conductive adhesive (ICA) filled with carbon nanotubes (CNTs) and low-melting-point alloy fillers. Materials Transactions, 2010, 51(12):2329.

DOI URL |

| [78] | WU H P, WU X J, LIU J F, et al. Properties of carbon nanotube- filled isotropic conductive adhesives. Acta Materiae Compositae Sinica, 2006, 23(2):9. |

| [79] |

AMOLI B M, TRINIDAD J, HU A, et al. Highly electrically conductive adhesives using silver nanoparticle (Ag NP)-decorated graphene: the effect of NPs sintering on the electrical conductivity improvement. Journal of Materials Science Materials in Electronics, 2015, 26(1):590.

DOI URL |

| [80] | MA M Z, MA H R, ZENG J F, et al. In situ hydrothermal synthesis of graphene-based nanosilver and its application in conductive adhesives. Journal of Shihezi University (Natural Science), 2017, 35(1):12. |

| [81] | SU Y, DAI Y Q, LIAO B, et al. Research progress of conductive filler for conductive adhesive. China Adhesives, 2018, 27(10):52. |

| [82] |

BEHNAM M A, HU A M, ZHOU N Y, et al. Recent progresses on hybrid micro-nano filler systems for electrically conductive adhesives (ECAs) applications. Journal of Materials Science: Materials in Electronics, 2015, 26(7):4730.

DOI URL |

| [83] | ZHANG W F. Pressureless sintering of micrometer silver pastes for electrical connections and their properties. Fuzhou: Master's Thesis, Fujian Normal University, 2019. |

| [84] | ZUO X. Preparation and performance study of high thermal conductive adhesive. China Adhesives, 2022, 31(10):47. |

| [85] |

ZHANG J G, LIANG M H, HU Q, et al. Cu@Ag nanoparticles doped micron-sized Ag plates for conductive adhesive with enhanced conductivity. International Journal of Adhesion and Adhesives, 2020, 102(1):102657.

DOI URL |

| [86] | YANG J L, DONG C C, LUO J. Advances in low-temperature sintering of nanosilver in novel power module packages. Materials Reports, 2019, 33(S2):360. |

| [87] |

SCHWARZBAUER H, KUHNERT R. Novel large area joining technique for improved power device performance. IEEE Transactions on Industry Applications, 1991, 27(1):93.

DOI URL |

| [88] | HIROSHI N, TOMOAKJ H, TADASHI T. Effects of joining conditions on joint strength of Cu/Cu joint using Cu nanoparticle paste. The Open Surface Science Journal, 2011, 3: 60. |

| [89] | HERRING C. Diffusional viscosity of a polycrystalline solid. Journal of Applied Physics, 1950, 21(5):4375. |

| [90] |

PENG Y, MOU Y, LIU J X, et al. Fabrication of high-strength Cu-Cu joint by low-temperature sintering micron-nano Cu composite paste. Journal of Materials Science: Materials in Electronics, 2020, 31(11):8456.

DOI |

| [91] |

GAO Y, ZHANG H, LI W L, et al. Die bonding performance using bimodal Cu particle paste under different sintering atmospheres. Journal of Electronic Materials, 2017, 46(7):4575.

DOI URL |

| [92] |

MASTUDA T, YAMAGIWA D, FURUSAWA H, et al. Reduction behavior of surface oxide on submicron copper particles for pressureless sintering under reducing atmosphere. Journal of Electronic Materials, 2021, 51(1):1.

DOI |

| [93] |

LI Y, QI T K, CHEN M, et al. Mixed ink of copper nanoparticles and copper formate complex with low sintering temperatures. Journal of Materials Science: Materials in Electronics, 2016, 27(11):11432.

DOI URL |

| [94] |

JEONG S, WOO K, KIM D, et al. Controlling the thickness of the surface oxide layer on Cu nanoparticles for the fabrication of conductive structures by ink-jet printing. Advanced Functional Materials, 2008, 18(5):679.

DOI URL |

| [95] | BHOGARAJU S K, CONTI F, KOTADIA H R, et al. Novel approach to copper sintering using surface enhanced brass micro flakes for microelectronics packaging. Journal of Alloys and Compounds, 2020, 844: 156043. |

| [96] | GAO Y, LI W L, CHEN C T, et al. Novel copper particle paste with self-reduction and self-protection characteristics for die attachment of power semiconductor under a nitrogen atmosphere. Materials and Design, 2018, 160: 1265. |

| [97] |

MOU Y, LIU J X, CHENG H, et al. Facile preparation of self- reducible Cu nanoparticle paste for low temperature Cu-Cu bonding. JOM, 2019, 71(9):3076.

DOI |

| [98] |

WANG X C, ZHANG Z Q, FENG Y Y, et al. Anti-oxidative copper nanoparticle paste for Cu-Cu bonding at low temperature in air. Journal of Materials Science: Materials in Electronics, 2021, 33(2):817.

DOI |

| [99] |

JANG S, SEO Y, CHOI J, et al. Sintering of inkjet printed copper nanoparticles for flexible electronics. Scripta Materialia, 2010, 62(5):258.

DOI URL |

| [100] | XIANG D L, HIROSHI N. Improved joint strength with sintering bonding using microscale Cu particles by an oxidation-reduction process. IEEE 66th Electronic Components and Technology Conference, Las Vegas, USA, 2016: 455-460. |

| [101] |

YAMAKAWA T, TAKEMOTO T, SHIMODA M, et al. Influence of joining conditions on bonding strength of joints: efficacy of low-temperature bonding using Cu nanoparticle paste. Journal of Electronic Materials, 2013, 42(6):1260.

DOI URL |

| [102] |

LI J L, XU Y, ZHAO X L, et al. Enhancement and mechanism of copper nanoparticle sintering in activated formic acid atmosphere at low temperature. ECS Journal of Solid State Science and Technology, 2021, 10(5):054004.

DOI |

| [103] |

LI J J, YU X, SHI T L, et al. Low-temperature and low-pressure Cu-Cu bonding by highly sinterable Cu nanoparticle paste. Nanoscale Research Letters, 2017, 12(1):255.

DOI PMID |

| [104] | LIU J D, CHEN H T, JI H J, et al. Highly conductive Cu-Cu joint formation by low-temperature sintering of formic acid-treated Cu nanoparticles. ACS Applied Materials & Interfaces, 2016, 8(48):33289. |

| [105] | PA X, ZHOU J C, ZHANG J G, et al. Study on preparation and application of nano-copper powder for power semiconductor device packaging. China International Forum on Solid State Lighting & International Forum on Wide Bandgap Semiconductors China, Shenzhen, 2019: 54-58. |

| [106] | KOBAYASHI Y, SHIROCHI T, YASUDA Y, et al. A metal-metal bonding process using metallic copper nanoparticles prepared in aqueous solution. International Journal of Adhesion & Adhesives, 2014, 3(2):114. |

| [107] |

LI J J, LIANG Q H, FAN T L, et al. Design of Cu nanoaggregates composed of ultra-small Cu nanoparticles for Cu-Cu thermocompression bonding. Journal of Alloys and Compounds, 2019, 772(2019):793.

DOI URL |

| [108] |

QI T K, WANG X C, YANG J F, et al. Rapid low temperature sintering in air of copper submicron particles with synergistic surface-activation and anti-oxidative protection. Journal of Materials Science: Materials in Electronics, 2019, 30(13):12669.

DOI |

| [109] |

QI T K, ZHANG Z Q, LI Y, et al. A low temperature self- reducible copper hydroxide amino-alcohol complex catalyzed by formic acid for conductive copper films. Journal of Materials Chemistry C, 2018, 6(42):11320.

DOI URL |

| [110] |

AKIHIRO Y, YOHEI T, INDRA W F. Synthesis of copper conductive film by low-temperature thermal decomposition of coppereaminediol complexes under an air atmosphere. Materials Chemistry and Physics, 2014, 148(1/2):299.

DOI URL |

| [111] |

KIM M I, LEE J H. Die attachment by extremely fast pressure-assisted sintering of 200 nm Cu particles. Electronic Materials Letters, 2021, 17(3):286.

DOI |

| [112] | YANG Z, SADIE C S, MARK G, et al. High bond strength Cu joints fabricated by rapid and pressureless in situ reduction- sintering of Cu nanoparticles. Materials Letters, 2020, 276: 128260. |

| [113] |

DENG D Y, CHENG Y R, JIN Y X, et al. Antioxidative effect of lactic acid-stabilized copper nanoparticles prepared in aqueous solution. Journal of Materials Chemistry, 2012, 22(45):23989.

DOI URL |

| [114] | MOU Y, CHENG H, PENG Y, et al. Fabrication of reliable Cu-Cu joints by low temperature bonding isopropanol stabilized Cu nanoparticles in air. Materials Letters, 2018, 229: 353. |

| [115] | MOU Y, PENG Y, ZHANG Y, et al. Cu-Cu bonding enhancement at low temperature by using carboxylic acid surface-modified Cu nanoparticles. Materials Letters, 2018, 227: 179. |

| [116] |

SUGIYAMA T, KANZAKI M, ARAKAWA R, et al. Low- temperature sintering of metallacyclic stabilized copper nanoparticles and adhesion enhancment of conductive copper film to a polyimide substrate. Journal of Materials Science: Materials in Electronics, 2016, 27(7):7540.

DOI URL |

| [117] |

GAO Y, LI W L, ZHANG H, et al. Size-controllable synthesis of bimodal Cu particles by polyol method and their application in die bonding for power devices. IEEE Transactions on Components Packaging and Manufacturing Technology, 2018, 8(12): 2190.

DOI URL |

| [118] |

MOU Y, WANG H, PENG Y, et al. Enhanced heat dissipation of high-power light-emitting diodes by Cu nanoparticle paste. IEEE Electron Device Letters, 2019, 40(6):949.

DOI URL |

| [1] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [2] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [3] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [4] | ZHANG Bihui, LIU Xiaoqiang, CHEN Xiangming. Recent Progress of Hybrid Improper Ferroelectrics with Ruddlesden-Popper Structure [J]. Journal of Inorganic Materials, 2025, 40(6): 587-608. |

| [5] | WU Jie, YANG Shuai, WANG Mingwen, LI Jinglei, LI Chunchun, LI Fei. Textured PT-based Piezoelectric Ceramics: Development, Status and Challenge [J]. Journal of Inorganic Materials, 2025, 40(6): 575-586. |

| [6] | YANG Yan, ZHANG Faqiang, MA Mingsheng, WANG Yongzhe, OUYANG Qi, LIU Zhifu. Low Temperature Sintering of ZnAl2O4 Ceramics with CuO-TiO2-Nb2O5 Composite Oxide Sintering Aid [J]. Journal of Inorganic Materials, 2025, 40(6): 711-718. |

| [7] | JIANG Kun, LI Letian, ZHENG Mupeng, HU Yongming, PAN Qinxue, WU Chaofeng, WANG Ke. Research Progress on Low-temperature Sintering of PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 627-638. |

| [8] | TIAN Ruizhi, LAN Zhengyi, YIN Jie, HAO Nanjing, CHEN Hangrong, MA Ming. Microfluidic Technology Based Synthesis of Inorganic Nano-biomaterials: Principles and Progress [J]. Journal of Inorganic Materials, 2025, 40(4): 337-347. |

| [9] | ZHANG Jiguo, WU Tian, ZHAO Xu, YANG Fan, XIA Tian, SUN Shien. Improvement of Cycling Stability of Cathode Materials and Industrialization Process for Sodium-ion Batteries [J]. Journal of Inorganic Materials, 2025, 40(4): 348-362. |

| [10] | YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 245-255. |

| [11] | CHEN Guangchang, DUAN Xiaoming, ZHU Jinrong, GONG Qing, CAI Delong, LI Yuhang, YANG Donglei, CHEN Biao, LI Xinmin, DENG Xudong, YU Jin, LIU Boya, HE Peigang, JIA Dechang, ZHOU Yu. Advanced Ceramic Materials in Helicopter Special Structures: Research Progress and Application Prospect [J]. Journal of Inorganic Materials, 2025, 40(3): 225-244. |

| [12] | FAN Xiaobo, ZU Mei, YANG Xiangfei, SONG Ce, CHEN Chen, WANG Zi, LUO Wenhua, CHENG Haifeng. Research Progress on Proton-regulated Electrochemical Ionic Synapses [J]. Journal of Inorganic Materials, 2025, 40(3): 256-270. |

| [13] | HAIREGU Tuxun, GUO Le, DING Jiayi, ZHOU Jiaqi, ZHANG Xueliang, NUERNISHA Alifu. Research Progress of Optical Bioimaging Technology Assisted by Upconversion Fluorescence Probes in Tumor Imaging [J]. Journal of Inorganic Materials, 2025, 40(2): 145-158. |

| [14] | SUN Shujuan, ZHENG Nannan, PAN Haokun, MA Meng, CHEN Jun, HUANG Xiubing. Research Progress on Preparation Methods of Single-atom Catalysts [J]. Journal of Inorganic Materials, 2025, 40(2): 113-127. |

| [15] | TAO Guilong, ZHI Guowei, LUO Tianyou, OUYANG Peidong, YI Xinyan, LI Guoqiang. Progress on Key Technologies of Cavity-structured Thin Film Bulk Acoustic Wave Filter [J]. Journal of Inorganic Materials, 2025, 40(2): 128-144. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||