Journal of Inorganic Materials ›› 2024, Vol. 39 ›› Issue (1): 32-44.DOI: 10.15541/jim20230365

Special Issue: 【能源环境】储能电池(202506); 【能源环境】锂离子电池(202412)

• REVIEW • Previous Articles Next Articles

HU Mengfei1,2( ), HUANG Liping1, LI He2, ZHANG Guojun1(

), HUANG Liping1, LI He2, ZHANG Guojun1( ), WU Houzheng2(

), WU Houzheng2( )

)

Received:2023-08-10

Revised:2023-11-02

Published:2024-01-20

Online:2023-11-10

Contact:

ZHANG Guojun, professor. E-mail: gjzhang@dhu.edu.cn;About author:About author:HU Mengfei (1993-), female, PhD. E-mail: mfhu1993@163.com

Supported by:CLC Number:

HU Mengfei, HUANG Liping, LI He, ZHANG Guojun, WU Houzheng. Research Progress on Hard Carbon Anode for Li/Na-ion Batteries[J]. Journal of Inorganic Materials, 2024, 39(1): 32-44.

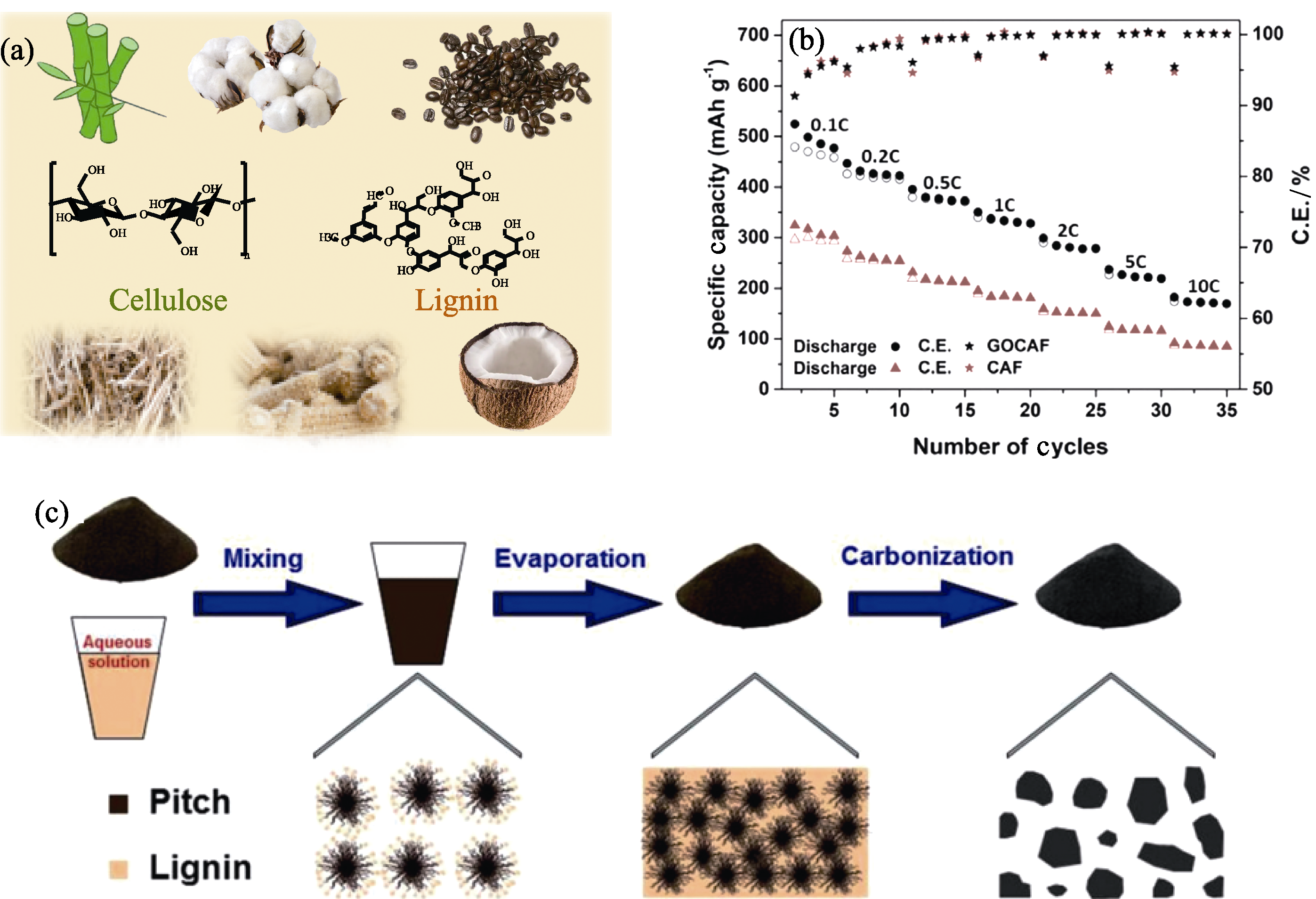

Fig. 3 Biomass carbon precursors and their properties (a) General biomass carbon precursors; (b) Rate performance and Coulombic efficiency of carbon from coffee waste in LIB[16]; (c) Schematic of synthesis and proposed mechanism of pitch/lignin-derived carbon[22]

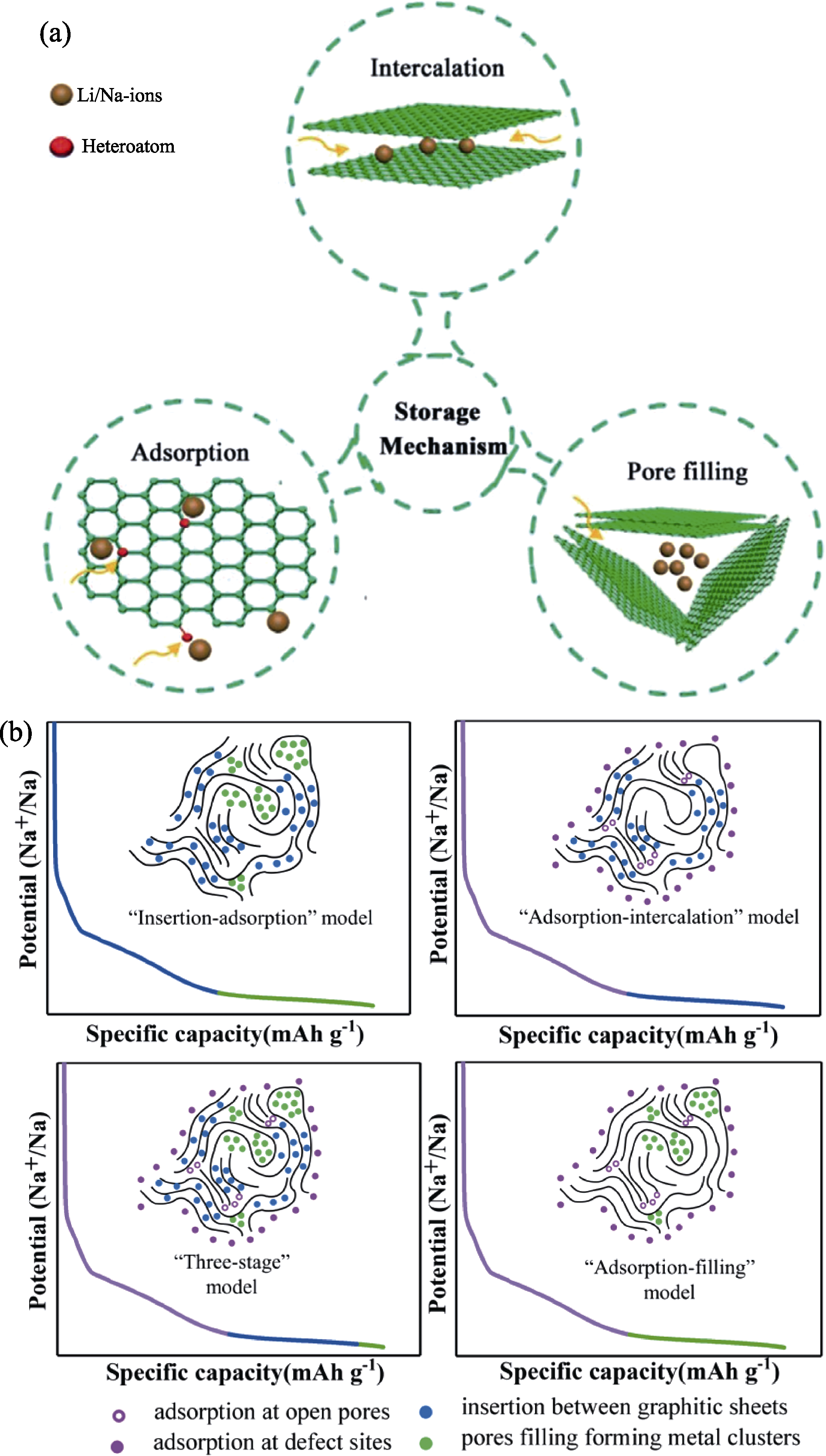

Fig. 4 (a) Three different mechanisms of lithium/sodium ion storage in hard carbon[28], and (b) four different models of sodium storage in hard carbon[39]

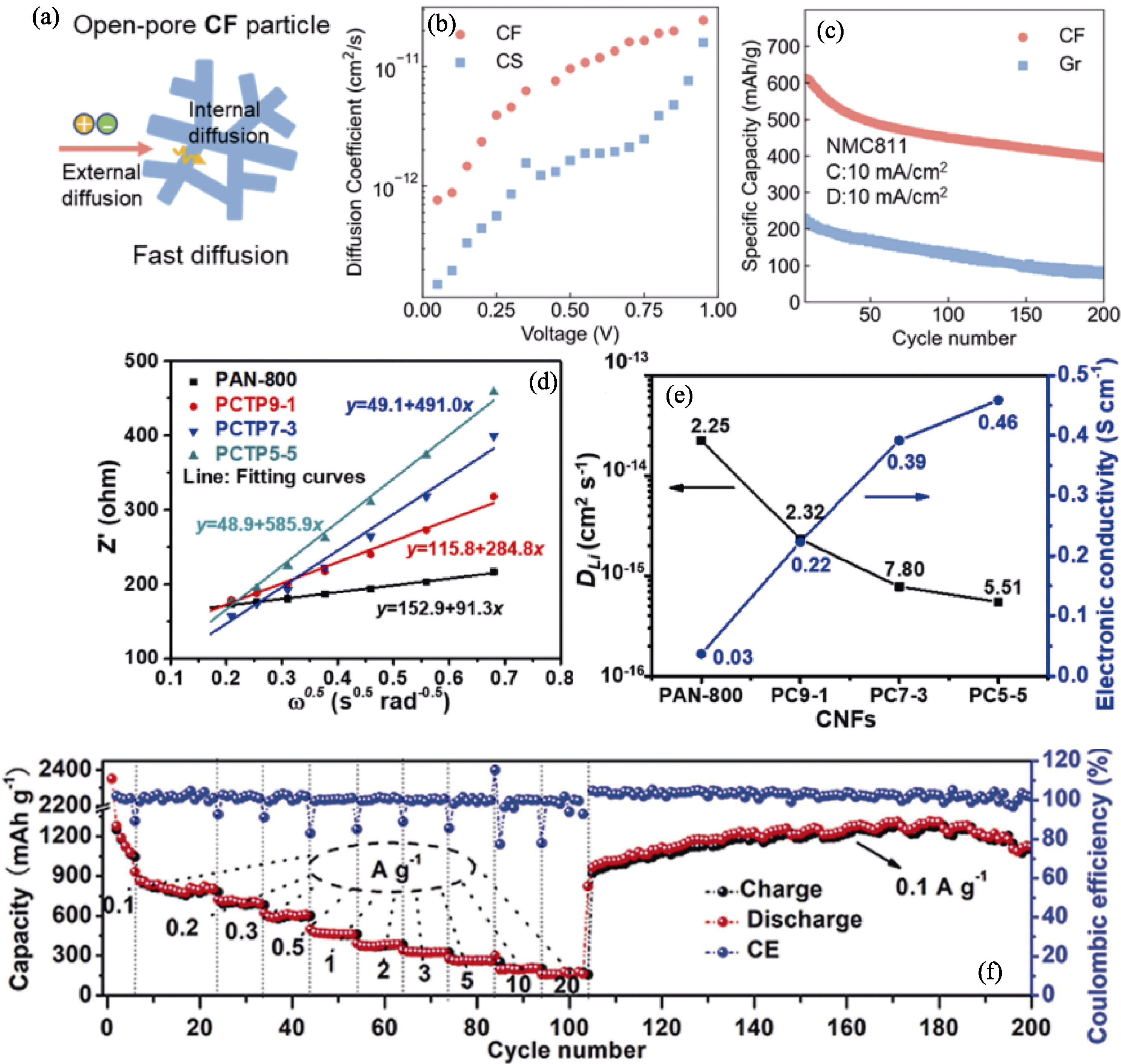

Fig. 5 Hard carbon in fast-charging application (a) Schematic of ion diffusion pathways in carbon fiber (CF); (b) Lithium-ion diffusion coefficient of CF and carbon sphere (CS) measured by potentiostatic intermittent titration technique (PITT); (c) Cycling performance of Li||CF and Li||graphite cells[45]; (d) Z'-ω0.5 plots in low-frequency region calculated from electrochemical impedance spectroscopy (EIS) measurement; (e) DLi and electrical conductivity plots of CNFs[47] in which the mass ratio of polyacrylonitrile to pitch can be tuned as 10/0, 9/1, 7/3, and 5/5 for PAN-800, PCTP9-1, PCTP7-3, PCTP5-5, respectively; (f) Rate performance of N-GCNs in LIBs from 0.1 to 20 A·g-1 (CE: Coulombic efficiency)[49]

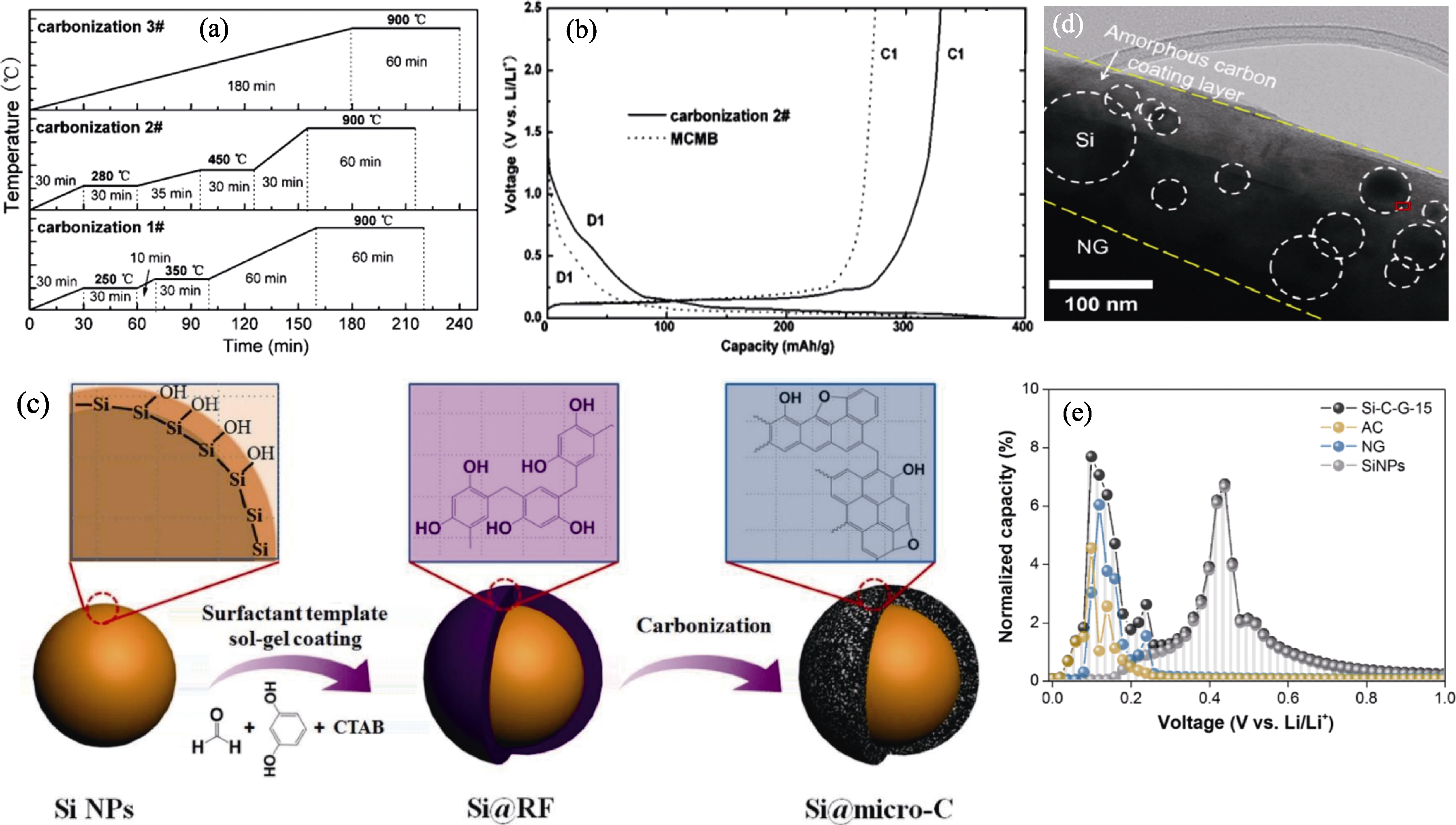

Fig. 6 Hard carbon as coating layer for anode (a) Multistep heating in different carbonization procedures; (b) Charge-discharge profiles of the sample with carbonization 2# in (a)[50]; (c) Illustration of resorcinol-formaldehyde resin (RF) coated nano Si[53]; (d) TEM image of Si-C-G-15 composite; (e) PITT results of Si-C-G-15 and capacity contributions of each component (AC: amorphous carbon; NG: natural graphite; SiNPs: silicon nano-particles)[54]

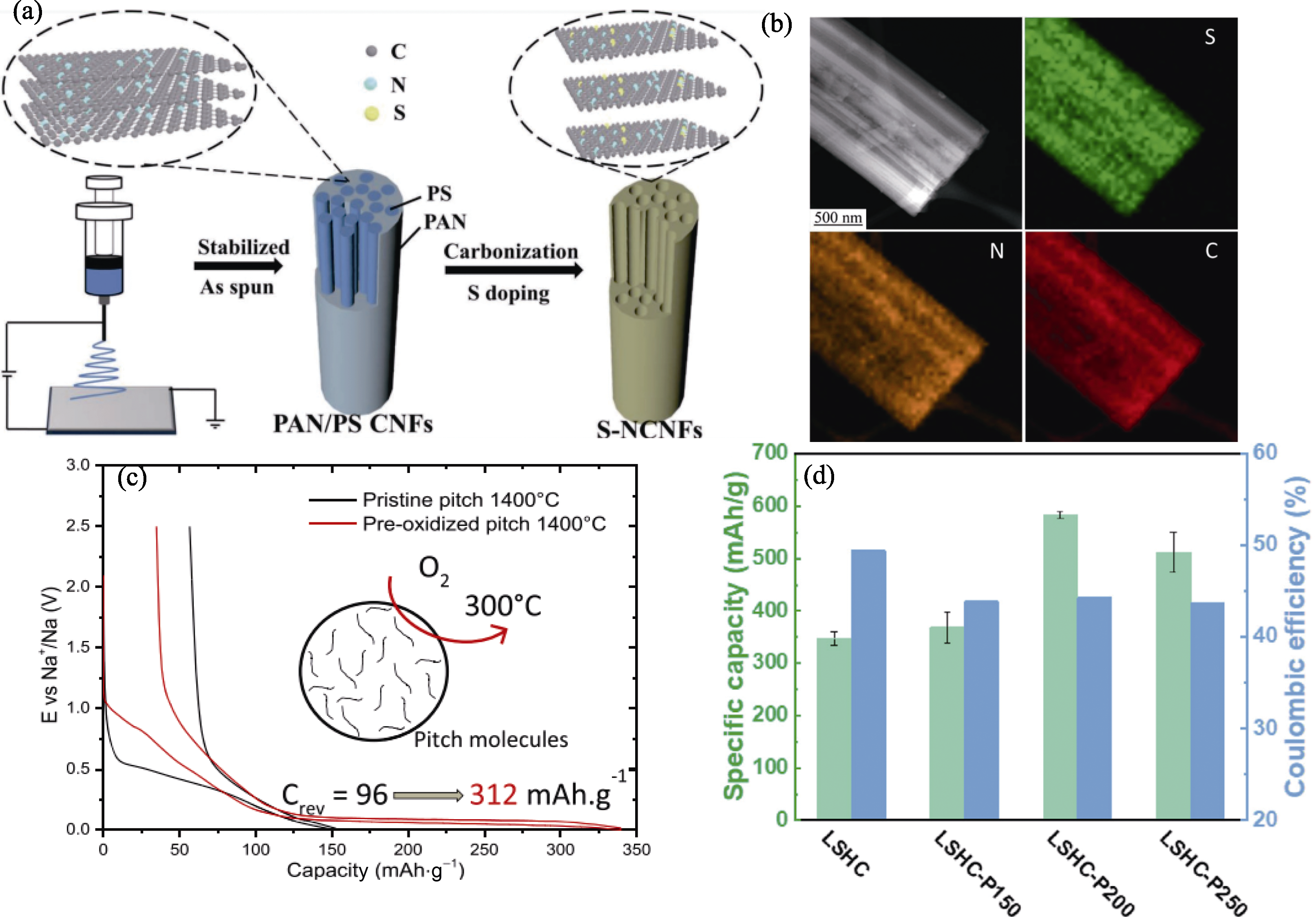

Fig. 7 Doping and pre-oxidation strategies (a) Schematic illustration of fabrication process of S-NCNFs; (b) TEM image of S-NCNFs and corresponding S, N, and C elemental mappings[62]: (c) Capacity of hard carbon derived from pitch (HCP) with and without pre-oxidization[64]; (d) Specfic capacity and initial Coulombic efficiency of lignin spheres hard carbon (LSHC) with pre-oxidation at different temperatures[65]

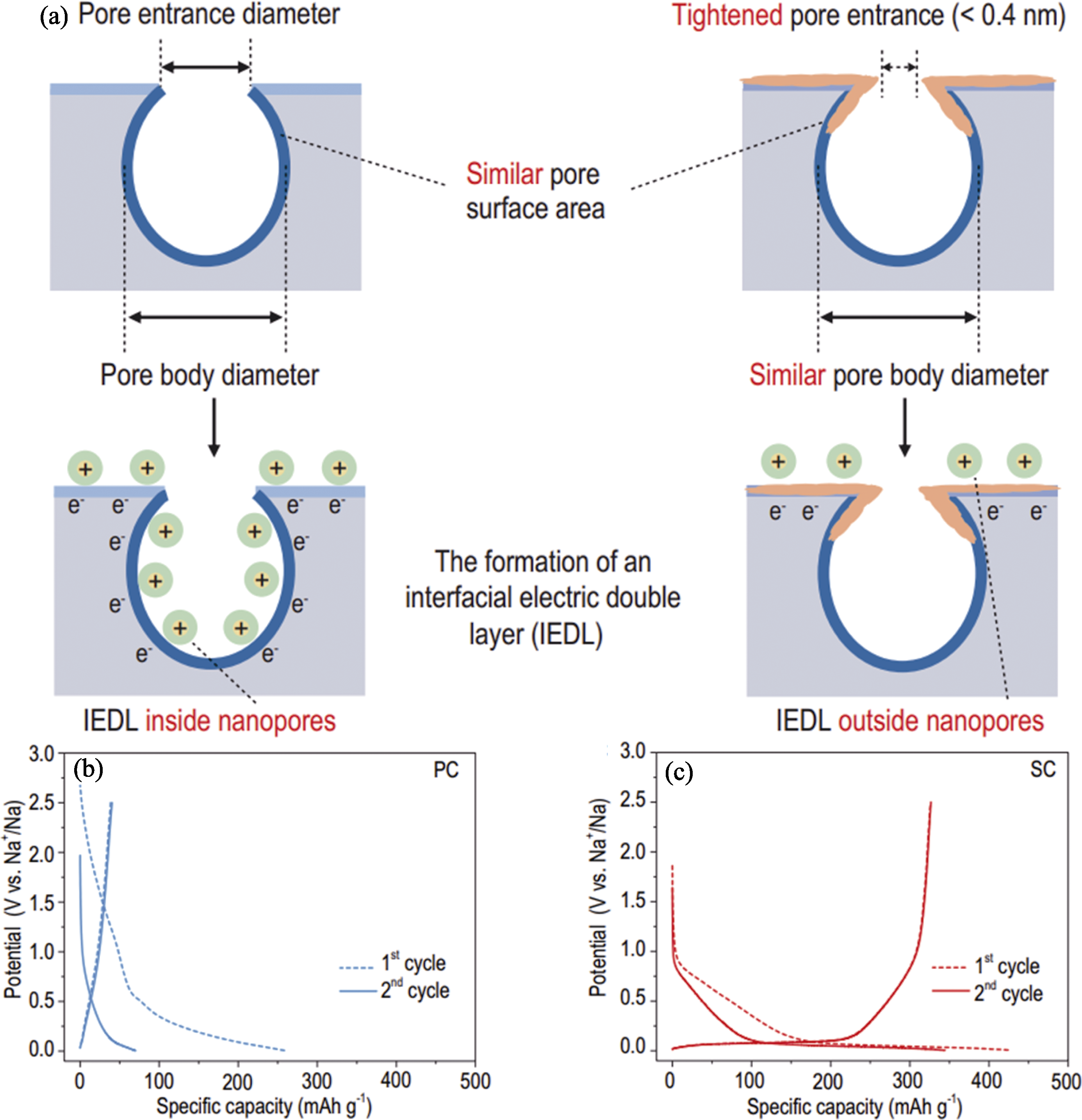

Fig. 8 (a) Schematic showing the control of the nanopores in a typical porous carbon (left) to produce molecular sieve carbon (right), and comparison between their different IEDLs, charge/discharge curves for first two cycles of (b) porous carbon and (c) molecular seive carbon anodes[66]

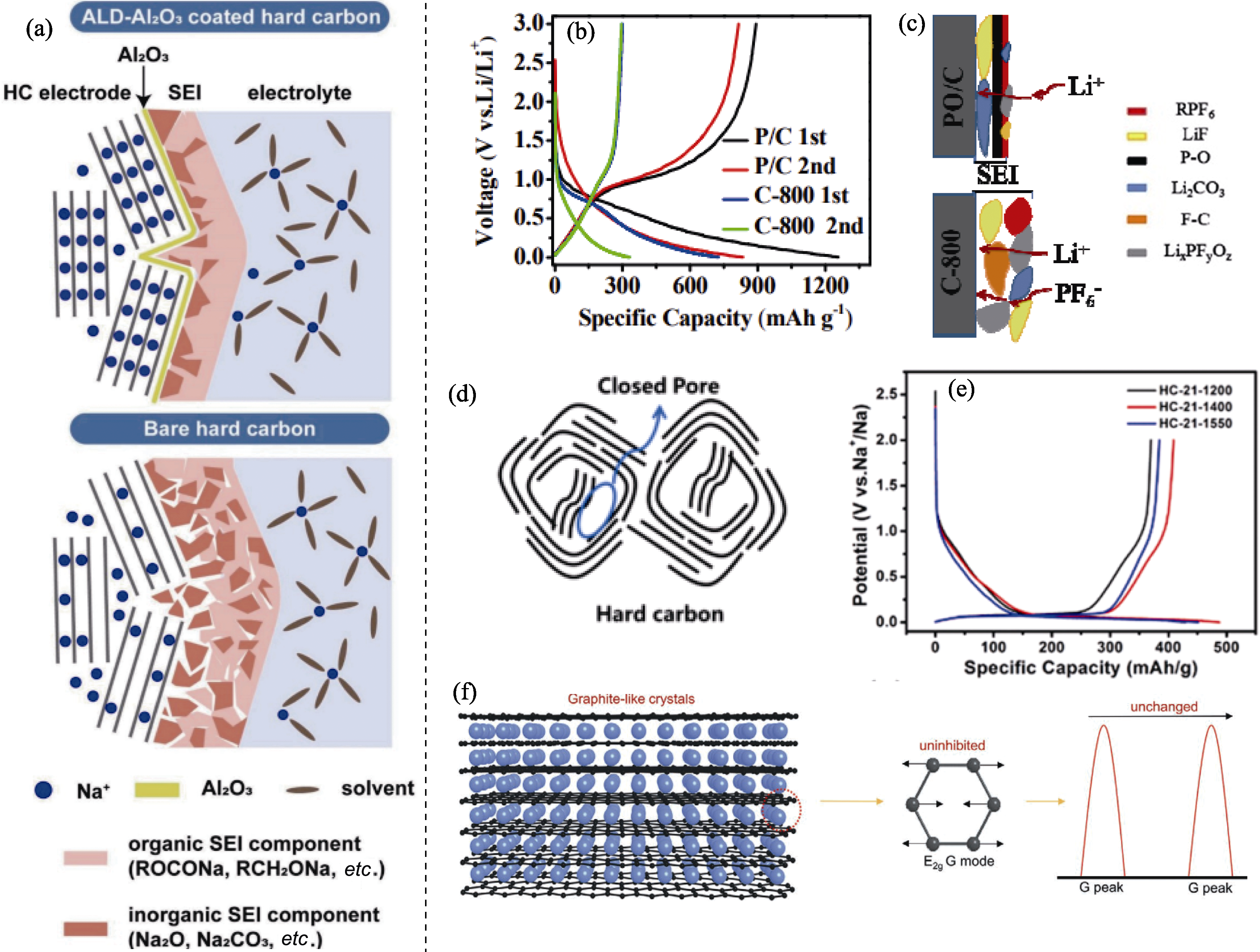

Fig. 9 Strategies for improving initial Coulombic efficiency (a) Schematic of the influence of ALD-Al2O3 coating on hard carbon[67]; (b) Charge/discharge curves of P-doped C (PO/C) and C prepared at 800 ℃ without doping (C-800) at 0.1 A·g-1; (c) Illustration of different compositions of the SEI on the surface of PO/C electrode[68]; (d) Illustration of closed pore in hard carbon; (e) Galvanostatic initial discharge-charge profiles of HC-21-x (x: pyrolysis temperature)[70]; (f) Schematic illustration of Na storage mechanism in HC-GLC electrode[73]

| [1] | LU J, CHEN Z W, PAN F, et al. High-performance anode materials for rechargeable lithium-ion batteries. Electrochem. Energy Rev., 2018, 1: 35. |

| [2] | DOU X W, HASA I, SAUREL D, et al. Hard carbons for sodium-ion batteries: structure, analysis, sustainability, and electrochemistry. Mater. Today, 2019, 23: 87. |

| [3] |

SAUREL D, ORAYECH B, XIAO B, et al. From charge storage mechanism to performance: a roadmap toward high specific energy sodium-ion batteries through carbon anode optimization. Adv. Energy Mater., 2018, 8(17):1703268.

DOI URL |

| [4] |

HAO J, WANG Y X, CHI C X, et al. Enhanced storage capability by biomass-derived porous carbon for lithium-ion and sodium- ion batteries anodes. Sustain. Energy Fuels, 2018, 2(10):2358.

DOI URL |

| [5] | FROMM O, HECKMANN A, RODEHORST U C, et al. Carbons from biomass precursors as anode materials for lithium ion batteries: new insights into carbonization and graphitization behavior and into their correlation to electrochemical performance. Carbon, 2018, 128: 147. |

| [6] | MARTÍNEZ-SANZ M, PETTOLINO F, FLANAGAN B, et al. Structure of cellulose microfibrils in mature cotton fibres. Carbohydr. Polym., 2017, 175: 450. |

| [7] | LEE C M, KAFLE K, BELIAS D W, et al. Comprehensive analysis of cellulose content, crystallinity, and lateral packing in gossypium hirsutum and gossypium barbadense cotton fibers using sum frequency generation, infrared and Raman spectroscopy, and X-ray diffraction. Cellulose, 2015, 22: 971. |

| [8] | CHEN Y Y, WANG Q, CHEN N J, et al. Internally-externally molecules-scissored ramie carbon for high performance electric double layer supercapacitors. Electrochim. Acta, 2023, 439: 141583. |

| [9] | GHOSH S, SANTHOSH R, JENIFFER S, et al. Natural biomass derived hard carbon and activated carbons as electrochemical supercapacitor electrodes. Sci. Rep., 2019, 9: 16315. |

| [10] | ZHU Y E, GU H C, CHEN Y N, et al. Hard carbon derived from corn straw piths as anode materials for sodium ion batteries. Ionics, 2018, 24: 1075. |

| [11] |

YANG Z W, GUO H J, LI F F, et al. Cooperation of nitrogen- doping and catalysis to improve the Li-ion storage performance of lignin-based hard carbon. J. Energy Chem., 2018, 27(5):1390.

DOI URL |

| [12] | ZHANG H M, ZHANG W F, MING H, et al. Design advanced carbon materials from lignin-based interpenetrating polymer networks for high performance sodium-ion batteries. Chem. Eng. J., 2018, 341: 280. |

| [13] | CHANG Z Z, YU B J, WANG C Y, et al. Influence of H2 reduction on lignin-based hard carbon performance in lithium ion batteries. Electrochim. Acta, 2015, 176: 1352. |

| [14] | JAYARAMAN S, JAIN A, ULAGANATHAN M, et al. Li-ion vs. Na-ion capacitors: a performance evaluation with coconut shell derived mesoporous carbon and natural plant based hard carbon. Chem. Eng. J., 2017, 316: 506. |

| [15] | JAIN A, ARAVINDAN V, JAYARAMAN S, et al. Activated carbons derived from coconut shells as high energy density cathode material for Li-ion capacitors. Sci. Rep., 2013, 3: 3002. |

| [16] | GÓMEZ-URBANO J L, MORENO-FERNÁNDEZ G, ARNAIZ M, et al. Chemical, graphene-coffee waste derived carbon composites as electrodes for optimized lithium ion capacitors. Carbon, 2020, 162: 273. |

| [17] | WANG L, SCHNEPP Z, TITIRICI M M, et al. Rice husk-derived carbon anodes for lithium ion batteries. J. Mater. Chem. A, 2013, 1: 5269. |

| [18] |

MING J, WU Y Q, LIANG G F, et al. Sodium salt effect on hydrothermal carbonization of biomass: a catalyst for carbon-based nanostructured materials for lithium-ion battery applications. Green Chem., 2013, 15(10):2722.

DOI URL |

| [19] |

HAN P, YANG B, QIU Z, et al. Air-expansion induced hierarchically porous carbonaceous aerogels from biomass materials with superior lithium storage properties. RSC Adv., 2016, 6(9):7591.

DOI URL |

| [20] | NI J F, HUANG Y Y, GAO L J. A high-performance hard carbon for Li-ion batteries and supercapacitors application. J. Power Sources, 2013, 223: 306. |

| [21] |

XU R, SUN N, ZHOU H Y, et al. Hard carbon anodes derived from phenolic resin/sucrose cross-linking network for high-performance sodium-ion batteries. Battery Energy, 2023, 2(2):20220054.

DOI URL |

| [22] | LI Y, HU Y, LI H, et al. A superior low-cost amorphous carbon anode made from pitch and lignin for sodium-ion batteries. J. Mater. Chem. A, 2016, 4: 96. |

| [23] | LI Y, MU L, HU Y, et al. Pitch-derived amorphous carbon as high performance anode for sodium-ion batteries. Energy Storage Mater., 2016, 2: 139. |

| [24] |

XIE L J, CHENG T, BI Z H, et al. Hard carbon anodes for next-generation Li-ion batteries: review and perspective. Adv. Energy Mater., 2016, 11(38):2101650.

DOI URL |

| [25] | DOEFF M M, MA Y P, VISCO S J, et al. Electrochemical insertion of sodium into carbon. J. Electrochem. Soc., 1993, 140: L169. |

| [26] | STEVENS D A, DAHN J R. High capacity anode materials for rechargeable sodium-ion batteries. J. Electrochem. Soc., 2000, 147: 1271. |

| [27] |

WU X, CHEN Y L, XING Z, et al. Advanced carbon-based anodes for potassium-ion batteries. Adv. Energy Mater., 2019, 9(21):1900343.

DOI URL |

| [28] |

ZHANG L P, WANG W, LU S, et al. Carbon anode materials: a detailed comparison between Na-ion and K-ion batteries. Adv. Energy Mater., 2021, 11(11):2003640.

DOI URL |

| [29] |

YANG G J, LI X Y, GUAN Z R X, et al. Insights into Lithium and sodium storage in porous carbon. Nano Lett., 2020, 20(5):3836.

DOI PMID |

| [30] |

WINTER M, BESENHARD J O, SPAHR M E, et al. Insertion electrode materials for rechargeable lithium batteries. Adv. Mater., 1998, 10(10):725.

DOI URL |

| [31] | DAHN J R, ZHENG T, LIU Y H, et al. Mechanisms for lithium insertion in carbonaceous materials. Science, 1995, 270: 590. |

| [32] | STEVENSA D A, DAHN J R. The mechanisms of lithium and sodium insertion in carbon materials. J. Electrochem. Soc., 2001, 148: A803. |

| [33] | IRISARRI E, PONROUCH A, PALACIN M R. Review-hard carbon negative electrode materials for sodium-ion batteries. J. Electrochem. Soc., 2015, 162: A2476. |

| [34] |

QIU S, XIAO L F, SUSHKO M L, et al. Manipulating adsorption- insertion mechanisms in nanostructured carbon materials for high-efficiency sodium ion storage. Adv. Energy Mater., 2017, 7(17):1700403.

DOI URL |

| [35] |

CAO Y L, XIAO L F, SUSHKO M L, et al. Sodium ion insertion in hollow carbon nanowires for battery applications. Nano Lett., 2012, 12(7):3783.

DOI PMID |

| [36] |

DING J, WANG H L, LI Z, et al. Carbon nanosheet frameworks derived from peat moss as high performance sodium ion battery anodes. ACS Nano, 2013, 7(12):11004.

DOI PMID |

| [37] |

HU Y S, LU Y X. 2019 Nobel prize for the Li-ion batteries and new opportunities and challenges in Na-ion batteries. ACS Energy Lett., 2019, 4(11):2689.

DOI URL |

| [38] |

LI Y M, HU Y S, TITIRICI M M, et al. Hard carbon microtubes made from renewable cotton as high-performance anode material for sodium-ion batteries. Adv. Energy Mater., 2016, 6(18):1600659.

DOI URL |

| [39] | CHEN X Y, LIU C Y, FANG Y J, et al. Understanding of the sodium storage mechanism in hard carbon anodes. Carbon Energy, 2021, 4: 1133. |

| [40] |

WANG Z H, FENG X, BAI Y, et al. Probing the energy storage mechanism of quasi-metallic Na in hard carbon for sodium-ion batteries. Adv. Energy Mater., 2021, 11(11):2003854.

DOI URL |

| [41] | ZHENG J, YU K F, WANG X F, et al. Nitrogen self-doped porous carbon based on sunflower seed hulls as excellent double anodes for potassium/sodium ion batteries. Diam. Relat. Mater., 2023, 131: 109593. |

| [42] |

TANG K, FU L J, WHITE R J, et al. Hollow carbon nanospheres with superior rate capability for sodium-based batteries. Adv. Energy Mater., 2012, 2(7):873.

DOI URL |

| [43] |

GAO T, HAN Y, FRAGGEDAKIS D, et al. Interplay of lithium intercalation and plating on a single graphite particle. Joule, 2021, 5(2):393.

DOI URL |

| [44] | LI S Q, WANG K, ZHANG G F, et al. Fast charging anode materials for lithium-ion batteries: current status and perspectives. Adv. Funct. Mater., 2022, 32: 2200796. |

| [45] | GONG H X, CHEN Y L, CHEN S C, et al. Fast-charging of hybrid lithium-ion/lithium-metal anodes by nanostructured hard carbon host. ACS Energy Lett., 2022, 7: 4417. |

| [46] | QIU D, KANG C, LI M, et al. Biomass-derived mesopore- dominant hierarchical porous carbon enabling ultra-efficient lithium ion storage. Carbon, 2020, 162: 595. |

| [47] | LIU C, XIAO N, WANG Y W, et al. Carbon clusters decorated hard carbon nanofibers as high-rate anode material for lithium-ion batteries. Fuel Process Technol., 2018, 180: 173. |

| [48] | FU R S, CHANG Z Z, SHEN C X, et al. Surface oxo-functionalized hard carbon spheres enabled superior high-rate capability and long-cycle stability for Li-ion storage. Electrochim. Acta, 2018, 260: 430. |

| [49] | HUANG S F, LI Z P, WANG B, et al. N-doping and defective nanographitic domain coupled hard carbon nanoshells for high performance lithium/sodium storage. Adv. Funct. Mater., 2018, 28: 1706294. |

| [50] | ZHANG H L, LI F, LIU C, et al. Poly(vinyl chloride) (PVC) coated idea revisited: influence of carbonization procedures on PVC-coated natural graphite as anode materials for lithium ion batteries. J. Phys. Chem. C, 2008, 112: 7767. |

| [51] | LIN J H, CHEN C Y. Thickness-controllable coating on graphite surface as anode materials using glucose-based suspending solutions for lithium-ion battery. Surf. Coat. Technol., 2022, 436: 128270. |

| [52] | LIN J H, KO T H, KUO W S, et al. Mesophase pitch carbon coated with phenolic resin for the anode of lithium-ion batteries. Energy Fuels, 2010, 24: 4090. |

| [53] | LUO W, WANG Y X, CHOU S L, et al. Critical thickness of phenolic resin-based carbon interfacial layer for improving long cycling stability of silicon nanoparticle anodes. Nano Energy, 2016, 27: 255. |

| [54] | KIM S Y, LEE J, KIM B H, et al. Facile synthesis of carbon-coated silicon/graphite spherical composites for high- performance lithium-ion batteries. ACS Appl. Mater. Interf., 2016, 8: 12109. |

| [55] |

YAO Y X, YAN C, ZHANG Q. Emerging interfacial chemistry of graphite anodes in lithium-ion batteries. Chem. Commun., 2020, 56(93):14570.

DOI URL |

| [56] |

ZHAO L F, HU Z, LAI W H, et al. Hard carbon anodes: fundamental understanding and commercial perspectives for Na-ion batteries beyond Li-ion and K-ion counterparts. Adv. Energy Mater., 2021, 11(1):2002704.

DOI URL |

| [57] |

WU D Y, SUN F, QU Z B, et al. Multi-scale structure optimization of boron-doped hard carbon nanospheres boosting the plateau capacity for high performance sodium ion batteries. J. Mater. Chem. A, 2022, 10(33):17225.

DOI URL |

| [58] | CHEN C, WU M Q, XU Z Q, et al. Tailored N-doped porous carbon nanocomposites through MOF self-assembling for Li/Na batteries. J. Colloid Interf. Sci., 2019, 538: 267. |

| [59] | PEI Z, MENG Q, WEI L, et al. Toward efficient and high rate sodium-ion storage: a new insight from dopant-defect interplay in textured carbon anode materials. Energy Storage Mater., 2020, 28: 55. |

| [60] |

LI Z F, BOMMIER C, CHONG Z S, et al. Mechanism of Na-ion storage in hard carbon anodes revealed by heteroatom doping. Adv. Energy Mater., 2017, 7(18):1602894.

DOI URL |

| [61] |

LI Y, YUAN Y, BAI Y, et al. Insights into the Na+ storage mechanism of phosphorus-functionalized hard carbon as ultrahigh capacity anodes. Adv. Energy Mater., 2018, 8(18):1702781.

DOI URL |

| [62] | SUN X Z, WANG C L, GONG Y, et al. A flexible sulfur-enriched nitrogen doped multichannel hollow carbon nanofibers film for high performance sodium storage. Small, 2018, 14: 1802218. |

| [63] | ZHAO P Y, TANG J J, WANG C Y, et al. A low-cost attempt to improve electrochemical performances of pitch-based hard carbon anodes in lithium-ion batteries by oxidative stabilization. J. Solid State Electrochem., 2017, 21: 555. |

| [64] | DAHER N, HUO D, DAVOISNE C, et al. Impact of preoxidation treatments on performances of pitch-based hard carbons for sodium-ion batteries. ACS Appl. Energy Mater., 2020, 3: 6501. |

| [65] | DU Y F, SUN G H, LI Y, et al. Pre-oxidation of lignin precursors for hard carbon anode with boosted lithium-ion storage capacity. Carbon, 2021, 178: 243. |

| [66] | LI Q, LIU X S, TAO Y, et al. Sieving carbons promise practical anodes with extensible low-potential plateaus for sodium batteries. Nat. Sci. Rev., 2022, 9: nwac084. |

| [67] | LU H, CHEN X, JIA Y, et al. Engineering Al2O3 atomic layer deposition: enhanced hard carbon-electrolyte interface towards practical sodium ion batteries. Nano Energy, 2019, 64: 103903. |

| [68] | TAO H C, DU S L, ZHANG F, et al. Achieving a high-performance carbon anode through the P-O bond for lithium-ion batteries. ACS Appl. Mater. Interf., 2018, 10: 34245. |

| [69] | GUO B K, SHU J, TANG K, et al. Nano-Sn/hard carbon composite anode material with high-initial Coulombic efficiency. J. Power Sources, 2008, 177: 205. |

| [70] | MENG Q, LU Y, DING F, et al. Tuning the closed pore structure of hard carbons with the highest Na storage capacity. ACS Energy Lett., 2019, 4: 2608. |

| [71] | WANG J C, ZHAO J H, HE X X, et al. Hard carbon derived from hazelnut shell with facile HCl treatment as high-initial-Coulombic-efficiency anode for sodium ion batteries. Sus. Mater. Technol., 2022, 33: e00446. |

| [72] | HAN Y J, CHUNG D B, NAKABAYASHI K, et al. Effect of heat pre-treatment conditions on the electrochemical properties of mangrove wood-derived hard carbon as an effective anode material for lithium-ion batteries. Electrochim. Acta, 2016, 213: 432. |

| [73] |

LI X, SUN J, ZHAO W, et al. Intergrowth of graphite-like crystals in hard carbon for highly reversible Na-ion storage. Adv. Funct. Mater., 2021, 32(2):2106980.

DOI URL |

| [1] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [2] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [3] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [4] | ZHANG Bihui, LIU Xiaoqiang, CHEN Xiangming. Recent Progress of Hybrid Improper Ferroelectrics with Ruddlesden-Popper Structure [J]. Journal of Inorganic Materials, 2025, 40(6): 587-608. |

| [5] | WU Jie, YANG Shuai, WANG Mingwen, LI Jinglei, LI Chunchun, LI Fei. Textured PT-based Piezoelectric Ceramics: Development, Status and Challenge [J]. Journal of Inorganic Materials, 2025, 40(6): 575-586. |

| [6] | JIANG Kun, LI Letian, ZHENG Mupeng, HU Yongming, PAN Qinxue, WU Chaofeng, WANG Ke. Research Progress on Low-temperature Sintering of PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 627-638. |

| [7] | TIAN Ruizhi, LAN Zhengyi, YIN Jie, HAO Nanjing, CHEN Hangrong, MA Ming. Microfluidic Technology Based Synthesis of Inorganic Nano-biomaterials: Principles and Progress [J]. Journal of Inorganic Materials, 2025, 40(4): 337-347. |

| [8] | ZHANG Jiguo, WU Tian, ZHAO Xu, YANG Fan, XIA Tian, SUN Shien. Improvement of Cycling Stability of Cathode Materials and Industrialization Process for Sodium-ion Batteries [J]. Journal of Inorganic Materials, 2025, 40(4): 348-362. |

| [9] | YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 245-255. |

| [10] | CHEN Guangchang, DUAN Xiaoming, ZHU Jinrong, GONG Qing, CAI Delong, LI Yuhang, YANG Donglei, CHEN Biao, LI Xinmin, DENG Xudong, YU Jin, LIU Boya, HE Peigang, JIA Dechang, ZHOU Yu. Advanced Ceramic Materials in Helicopter Special Structures: Research Progress and Application Prospect [J]. Journal of Inorganic Materials, 2025, 40(3): 225-244. |

| [11] | FAN Xiaobo, ZU Mei, YANG Xiangfei, SONG Ce, CHEN Chen, WANG Zi, LUO Wenhua, CHENG Haifeng. Research Progress on Proton-regulated Electrochemical Ionic Synapses [J]. Journal of Inorganic Materials, 2025, 40(3): 256-270. |

| [12] | HAIREGU Tuxun, GUO Le, DING Jiayi, ZHOU Jiaqi, ZHANG Xueliang, NUERNISHA Alifu. Research Progress of Optical Bioimaging Technology Assisted by Upconversion Fluorescence Probes in Tumor Imaging [J]. Journal of Inorganic Materials, 2025, 40(2): 145-158. |

| [13] | SUN Shujuan, ZHENG Nannan, PAN Haokun, MA Meng, CHEN Jun, HUANG Xiubing. Research Progress on Preparation Methods of Single-atom Catalysts [J]. Journal of Inorganic Materials, 2025, 40(2): 113-127. |

| [14] | TAO Guilong, ZHI Guowei, LUO Tianyou, OUYANG Peidong, YI Xinyan, LI Guoqiang. Progress on Key Technologies of Cavity-structured Thin Film Bulk Acoustic Wave Filter [J]. Journal of Inorganic Materials, 2025, 40(2): 128-144. |

| [15] | ZHOU Fan, TIAN Zhilin, LI Bin. Research Progress on Carbide Ultra-high Temperature Ceramic Anti-ablation Coatings for Thermal Protection System [J]. Journal of Inorganic Materials, 2025, 40(1): 1-16. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||