Journal of Inorganic Materials ›› 2026, Vol. 41 ›› Issue (3): 331-339.DOI: 10.15541/jim20250258

• RESEARCH ARTICLE • Previous Articles Next Articles

ZHENG Chen1( ), WANG Xiangning2, YUAN Henan1, YANG Jiawei1, LI Chuanjian3(

), WANG Xiangning2, YUAN Henan1, YANG Jiawei1, LI Chuanjian3( ), WANG Huadong1(

), WANG Huadong1( )

)

Received:2025-06-17

Revised:2025-08-04

Published:2025-09-11

Online:2025-09-11

Contact:

WANG Huadong, senior engineer. E-mail: wanghuadonglq@126.com;About author:ZHENG Chen (1992-), male, senior engineer. E-mail:zhengchen2603@163.com

CLC Number:

ZHENG Chen, WANG Xiangning, YUAN Henan, YANG Jiawei, LI Chuanjian, WANG Huadong. Mechanical Property Failure of Alumina Fiber Reinforced Silica Composite[J]. Journal of Inorganic Materials, 2026, 41(3): 331-339.

| Parameter | Value |

|---|---|

| Thermal conductivity/(W·m-1·K-1) | 0.644 (300 ℃) |

| Average linear expansion coefficient/K-1 | 5.26×10-6 (RT-800 ℃) |

Table 1 Basic thermal properties of alumina fiber reinforced silica composite

| Parameter | Value |

|---|---|

| Thermal conductivity/(W·m-1·K-1) | 0.644 (300 ℃) |

| Average linear expansion coefficient/K-1 | 5.26×10-6 (RT-800 ℃) |

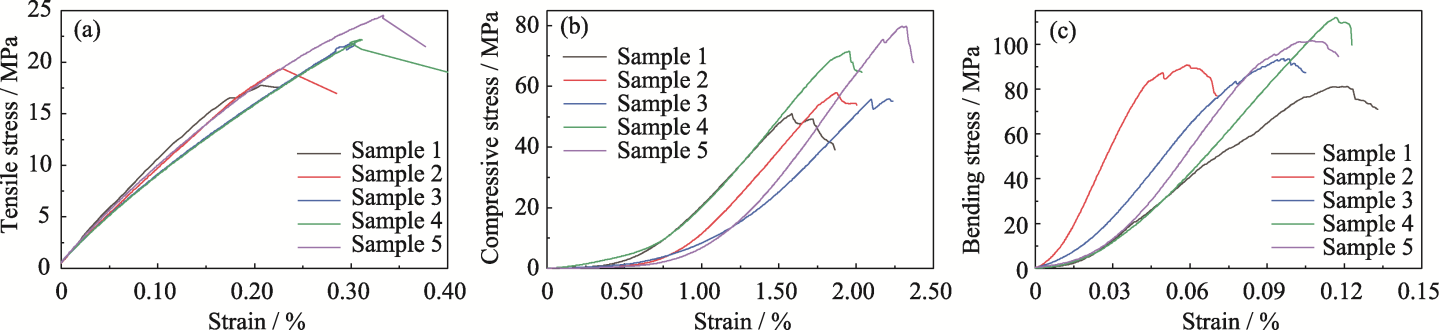

Fig. 5 Mechanical property test results of alumina fiber reinforced silica composite (a) Tensile stress-strain curves; (b) Compressive stress-strain curves; (c) Bending stress-strain curves Colorful figures are available on website

| Sample | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Tensile strength/MPa | 17.8 | 19.4 | 21.8 | 22.2 | 24.5 |

| Compressive strength/MPa | 51.0 | 58.0 | 55.9 | 71.5 | 79.8 |

| Bending strength/MPa | 81.2 | 90.6 | 93.5 | 111.9 | 101.6 |

Table 2 Mechanical properties of alumina fiber reinforced silica composite

| Sample | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Tensile strength/MPa | 17.8 | 19.4 | 21.8 | 22.2 | 24.5 |

| Compressive strength/MPa | 51.0 | 58.0 | 55.9 | 71.5 | 79.8 |

| Bending strength/MPa | 81.2 | 90.6 | 93.5 | 111.9 | 101.6 |

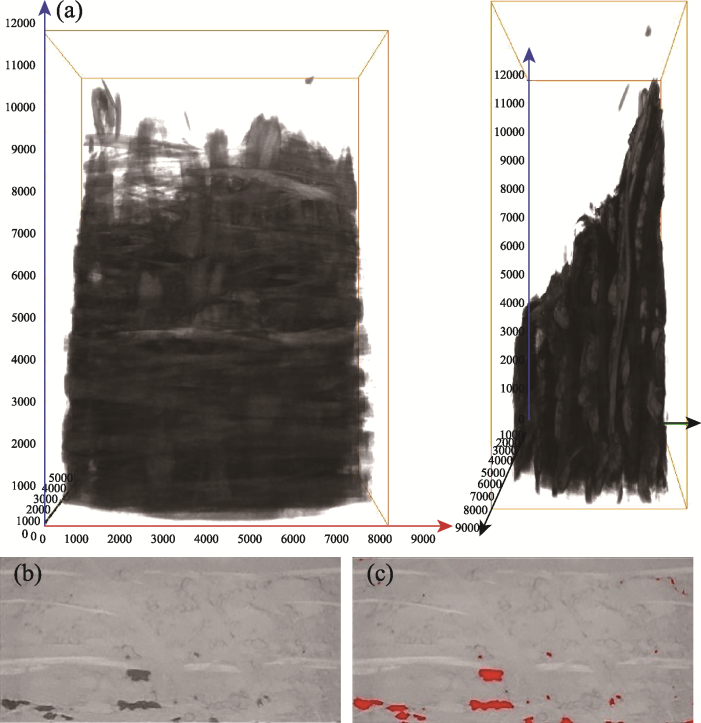

Fig. 6 (a) Reconstructed stereogram from different angles, (b) inner slice image and (c) quantitative statistical results of cross-sectional defect/porosity analysis of tensile fracture sample

| Sample | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Tensile strength/MPa | 17.8 | 19.4 | 21.8 | 22.2 | 24.5 |

| Porosity/% | 15.2 | 10.4 | 8.9 | 3.7 | 2.2 |

Table 3 Tensile strengths and porosities of tensile samples of alumina fiber reinforced silica composite

| Sample | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Tensile strength/MPa | 17.8 | 19.4 | 21.8 | 22.2 | 24.5 |

| Porosity/% | 15.2 | 10.4 | 8.9 | 3.7 | 2.2 |

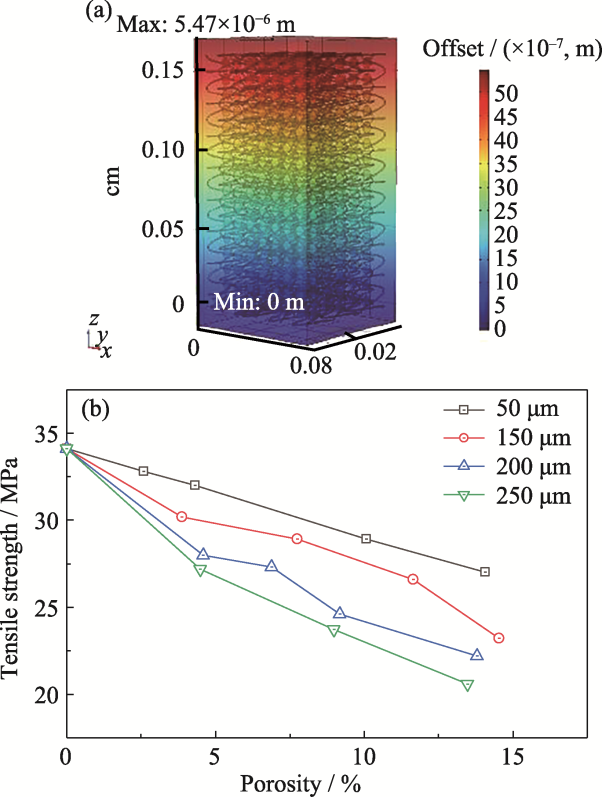

Fig. 7 (a) Position shift (strain) of the composite model during tensile fracture; (b) Critical porosities corresponding to different tensile strengths of composite materials with different pore defect radii

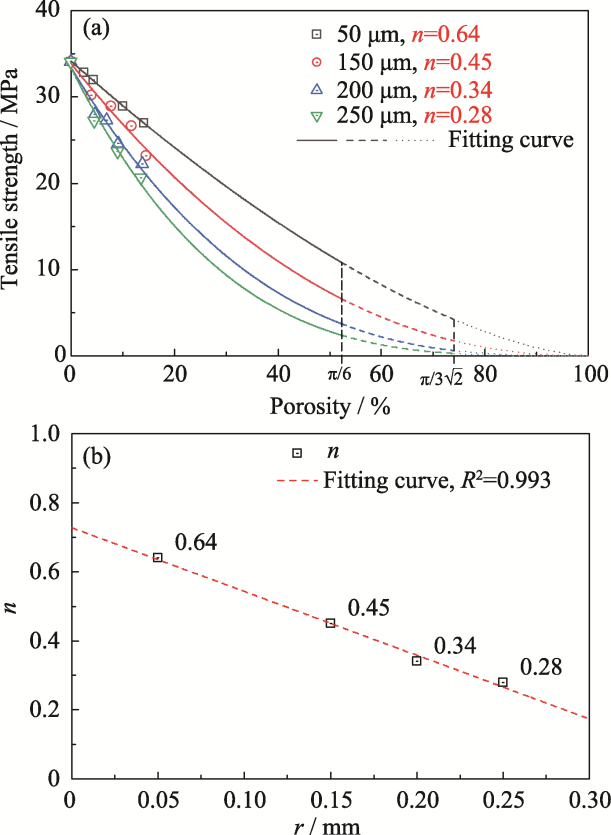

Fig. 8 (a) Relationship between tensile strength and porosity under different pore defect radii; (b) Relationship between exponential factor n and pore defect radius r

| [1] | RITCHIE R O. The conflicts between strength and toughness. Nature Materials, 2011, 10(11): 817. |

| [2] | DONALD I, MCMILLAN P. Ceramic-matrix composites. Journal of Materials Science, 1976, 11: 949. |

| [3] | NASLAIN R R. Fiber-reinforced ceramic matrix composites: state of the art, challenge and perspective. Kompozyty (Composites), 2005, 5(1): 3. |

| [4] | PETERS A B, ZHANG D, CHEN S, et al. Materials design for hypersonics. Nature Communications, 2024, 15: 3328. |

| [5] | ALAM M A, YA H, SAPUAN S, et al. Recent advancements in advanced composites for aerospace applications:a review//MAZLAN N, SAPUAN S M, ILYAS R A. Advanced composites in aerospace engineering applications. Switzerland: Springer Nature, 2022: 319-339. |

| [6] | KAYA H. The application of ceramic-matrix composites to the automotive ceramic gas turbine. Composites Science and Technology, 1999, 59(6): 861. |

| [7] | PRAMANIK S, MANNA A, TRIPATHY A, et al. Current advancements in ceramic matrix composites//KAR K K. Composite materials:processing, applications, characterizations. Berlin: Springer, 2017: 457-496. |

| [8] | ATAOLLAHI O A, PRAMANIK S, SHIRAZI S F, et al. A comparison in mechanical properties of cermets of calcium silicate with Ti-55Ni and Ti-6Al-4V alloys for hard tissues replacement. The Scientific World Journal, 2014, 2014: 616804. |

| [9] | MAHMOUDINEZHAD S, SADI M, GHIASIRAD H, et al. A comprehensive review on the current technologies and recent developments in high-temperature heat exchangers. Renewable and Sustainable Energy Reviews, 2023, 183: 113467. |

| [10] | RASHID A B, HAQUE M, ISLAM S M M, et al. Breaking boundaries with ceramic matrix composites: a comprehensive overview of materials, manufacturing techniques, transformative applications, recent advancements, and future prospects. Advances in Materials Science and Engineering, 2024, 2024: 2112358. |

| [11] | SHRIVASTAVA S, RAJAK D K, JOSHI T, et al. Ceramic matrix composites: classifications, manufacturing, properties, and applications. Ceramics, 2024, 7(2): 652. |

| [12] | 张俊敏, 蔡飞燕, 靳喜海, 等. 连续纤维增强陶瓷基复合材料研究与应用进展. 陶瓷学报, 2023, 44(2): 195. |

| [13] | RAMACHANDRAN K, BEAR J C, JAYASEELAN D D. Oxide-based ceramic matrix composites for high-temperature environments: a review. Advanced Engineering Materials, 2025, 27(7): 2402000. |

| [14] | WANG Y, LIU H T, CHENG H F, et al. Research progress on oxide/oxide ceramic matrix composites. Journal of Inorganic Materials, 2014, 29(7): 673. |

| [15] | DHANASEKAR S, GANESAN A T, RANI T L, et al. A comprehensive study of ceramic matrix composites for space applications. Advances in Materials Science and Engineering, 2022, 2022: 1. |

| [16] | 蔡德龙, 陈斐, 何凤梅, 等. 高温透波陶瓷材料研究进展. 现代技术陶瓷, 2019, 40(Z1): 4. |

| [17] | PARK S J, SEO M K. Interface science and composites. Oxford: Elsevier, 2011: 555-619. |

| [18] | WALOCK M J, HENG V, NIETO A, et al. High temperature durability of oxide-oxide ceramic matrix composites exposed to engine relevant conditions. Proceedings of the 12th Pacific Rim Conference on Ceramic and Glass Technology, Hoboken, 2018: 329-342. |

| [19] | ASHOK B, KANNAN C, MASON B, et al. Towards safer and smarter design for lithium-ion-battery-powered electric vehicles: a comprehensive review on control strategy architecture of battery management system. Energies, 2022, 15(12): 4227. |

| [20] | JIA Y N, CAO X, JIAO X L, et al. Preparation of alumina ceramic continuous fibers with inorganic acidic aluminum sol as precursor. Journal of Inorganic Materials, 2023, 38(11): 1257. |

| [21] | WANG X G, YANG Q Q, LIN G L, et al. High temperature tensile property of domestic 550-grade continuous alumina ceramic fiber. Journal of Inorganic Materials, 2022, 37(6): 629. |

| [22] | KRENKEL W. Ceramic matrix composites: fiber reinforced ceramics and their applications. Weinheim: John Wiley & Sons, 2008. |

| [23] | TARIQ M, HANIF F, ASHRAF A. Overview of NextelTM based structures for space applications. Journal of Space Technology, 2011, 1(1): 88. |

| [24] | 焦秀玲, 陈代荣. 氧化铝基陶瓷连续纤维研究进展. 硅酸盐学报, 2024, 52(8): 2738. |

| [25] | 刘海韬, 姜如, 孙逊, 等. 连续氧化铝纤维增韧陶瓷基复合材料. 北京: 科学出版社, 2022: 55-58. |

| [26] | YANG J Y, WEAVER J H, ZOK F W, et al. Processing of oxide composites with three-dimensional fiber architectures. Journal of the American Ceramic Society, 2009, 92(5): 1087. |

| [27] | SCOLA A, EBERLING-FUX N, TURENNE S, et al. New liquid processing of oxide/oxide 3D wowen ceramic matrix composites. Journal of the American Ceramic Society, 2018, 102(6): 3256. |

| [28] | 冻瑞岚, 彭志航, 向阳, 等. 氧化铝纤维增强氧化铝陶瓷基复合材料的组成及制备工艺的研究进展. 材料工程, 2023, 51(10): 27. |

| [29] | XIANG Y, WEN J, WANG Y, et al. Degradation of Al2O3f/SiO2 composites exposed to Na2SO4 environment and MMH/N2O4 bipropellants test. International Journal of Applied Ceramic Technology, 2020, 17(5): 2114. |

| [30] | XIAO H, WU J M, CHEN A N, et al. Alumina fiber-reinforced silica matrix composites with improved mechanical properties prepared by a novel DCC-HVCI method. Ceramics International, 2017, 43(18): 16436. |

| [31] | LIU P S, FU C, LI T F, et al. Relationship between tensile strength and porosity for high porosity metals. Science in China Series E: Technological Sciences, 1999, 42(1): 100. |

| [32] | LIU P S, WANG X S, LUO H Y. Relationship between tensile strength and porosity for foamed metals under equal speed biaxial tension. Materials Science and Technology, 2003, 19(7): 985. |

| [33] | 张兆杭, 崔少康, 谭志勇, 等. C/C-SiC缎纹编织复合材料孔隙缺陷的建模及其拉伸性能仿真. 复合材料学报, 2020, 37(8): 1969. |

| [34] | HAN D, YE F, CHENG L, et al. Matrix cracking of 2D SiC/SiC composite characterized by in situ SEM and nano-CT. Ceramics International, 2023, 49(8): 12508. |

| [35] | LI X, PAN K, ZHANG F, et al. An overview of tensile and shear failure mechanisms of silicon carbide-based ceramic matrix composites. Journal of Materials Research and Technology, 2024, 33: 2924. |

| [1] | SHI Jinyu, LEI Yiming, WANG Chenxu, ZHANG Jie, WANG Jingyang. Ion Irradiation Damage Behavior in Titanium Carbide with Different Stoichiometry [J]. Journal of Inorganic Materials, 2026, 41(3): 322-330. |

| [2] | ZHANG Yunbo, WANG Bing, LI Wei, SONG Quzhi, DU Yi’ang, WANG Yingde. Size Effect of Nanosheet on BN Fibers Derived from BNNS/Polyborazine Hybrid Precursor [J]. Journal of Inorganic Materials, 2026, 41(3): 359-369. |

| [3] | YUAN Wang, HU Jianbao, ZHOU Liang, KAN Yanmei, ZHANG Xiangyu, DONG Shaoming. Effect of Argon Atmosphere Heat Treatment on Mechanical Properties and Microstructural Evolution of Shicolon-II SiC Fibers [J]. Journal of Inorganic Materials, 2026, 41(1): 119-128. |

| [4] | ZHANG Yongheng, CHEN Jixin. Preparation and Properties of Ytterbium Aluminosilicate Glass and SiC Modified h-BN-based Composites [J]. Journal of Inorganic Materials, 2026, 41(1): 37-44. |

| [5] | SUN Yuxuan, WANG Zheng, SHI Xue, SHI Ying, DU Wentong, MAN Zhenyong, ZHENG Liaoying, LI Guorong. Defect Dipole Thermal-stability to the Electro-mechanical Properties of Fe Doped PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 545-551. |

| [6] | CHEN Yi, QIU Haipeng, CHEN Mingwei, XU Hao, CUI Heng. SiC/SiC Composite: Matrix Boron Modification and Mechanical Properties [J]. Journal of Inorganic Materials, 2025, 40(5): 504-510. |

| [7] | CUI Ning, ZHANG Yuxin, WANG Lujie, LI Tongyang, YU Yuan, TANG Huaguo, QIAO Zhuhui. Single-phase Formation Process and Carbon Vacancy Regulation of (TiVNbMoW)Cx High-entropy Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 511-520. |

| [8] | LI Ziwei, GONG Weilu, CUI Haifeng, YE Li, HAN Weijian, ZHAO Tong. (Zr, Hf, Nb, Ta, W)C-SiC Composite Ceramics: Preparation via Precursor Route and Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 271-280. |

| [9] | GAO Chenguang, SUN Xiaoliang, CHEN Jun, LI Daxin, CHEN Qingqing, JIA Dechang, ZHOU Yu. SiBCN-rGO Ceramic Fibers Based on Wet Spinning Technology: Microstructure, Mechanical and Microwave-absorbing Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 290-296. |

| [10] | MU Haojie, ZHANG Yuanjiang, YU Bin, FU Xiumei, ZHOU Shibin, LI Xiaodong. Preparation and Properties of ZrO2 Doped Y2O3-MgO Nanocomposite Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 281-289. |

| [11] | WANG Yueyue, HUANG Jiahui, KONG Hongxing, LI Huaizhu, YAO Xiaohong. Silver Loaded Radial Mesoporous Silica: Preparation and Application in Dental Resins [J]. Journal of Inorganic Materials, 2025, 40(1): 77-83. |

| [12] | WANG Hao, LIU Xuechao, ZHENG Zhong, PAN Xiuhong, XU Jintao, ZHU Xinfeng, CHEN Kun, DENG Weijie, TANG Meibo, GUO Hui, GAO Pan. Performance of Lateral 4H-SiC Photoconductive Semiconductor Switches by Extrinsic Backside Trigger [J]. Journal of Inorganic Materials, 2024, 39(9): 1070-1076. |

| [13] | MA Wen, SHEN Zhe, LIU Qi, GAO Yuanming, BAI Yu, LI Rongxing. Preparation of Y2O3 Coating by Suspension Plasma Spraying and Its Resistance to Plasma Etching [J]. Journal of Inorganic Materials, 2024, 39(8): 929-936. |

| [14] | FAN Wugang, CAO Xiong, ZHOU Xiang, LI Ling, ZHAO Guannan, ZHANG Zhaoquan. Anticorrosion Performance of 8YSZ Ceramics in Simulated Aqueous Environment of Pressurized Water Reactor [J]. Journal of Inorganic Materials, 2024, 39(7): 803-809. |

| [15] | WU Yuhao, PENG Renci, CHENG Chunyu, YANG Li, ZHOU Yichun. First-principles Study on Mechanical Properties and Melting Curve of HfxTa1-xC System [J]. Journal of Inorganic Materials, 2024, 39(7): 761-768. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||