Journal of Inorganic Materials ›› 2026, Vol. 41 ›› Issue (1): 119-128.DOI: 10.15541/jim20250052

• RESEARCH LETTER • Previous Articles Next Articles

YUAN Wang1,2,3( ), HU Jianbao1,2(

), HU Jianbao1,2( ), ZHOU Liang1,2,3, KAN Yanmei1,2, ZHANG Xiangyu1,2, DONG Shaoming1,2(

), ZHOU Liang1,2,3, KAN Yanmei1,2, ZHANG Xiangyu1,2, DONG Shaoming1,2( )

)

Received:2025-02-12

Revised:2025-04-02

Published:2026-01-20

Online:2025-04-09

Contact:

HU Jianbao, professor. E-mail: hujianbao@mail.sic.ac.cn;About author:YUAN Wang (2001-), male, PhD candidate. E-mail: yuanwang22@mails.ucas.ac.cn

Supported by:CLC Number:

YUAN Wang, HU Jianbao, ZHOU Liang, KAN Yanmei, ZHANG Xiangyu, DONG Shaoming. Effect of Argon Atmosphere Heat Treatment on Mechanical Properties and Microstructural Evolution of Shicolon-II SiC Fibers[J]. Journal of Inorganic Materials, 2026, 41(1): 119-128.

| Fiber | Diameter/μm | C/Si | Oxygen/% (in atom) | Young's modulus/GPa | Average tensile strength/GPa |

|---|---|---|---|---|---|

| Shincolon-II | 8.1±1.0 | 1.46 | 1.4 | 326.6 | 3.682 |

Table 1 Relevant parameters of Shincolon-II SiC fibers

| Fiber | Diameter/μm | C/Si | Oxygen/% (in atom) | Young's modulus/GPa | Average tensile strength/GPa |

|---|---|---|---|---|---|

| Shincolon-II | 8.1±1.0 | 1.46 | 1.4 | 326.6 | 3.682 |

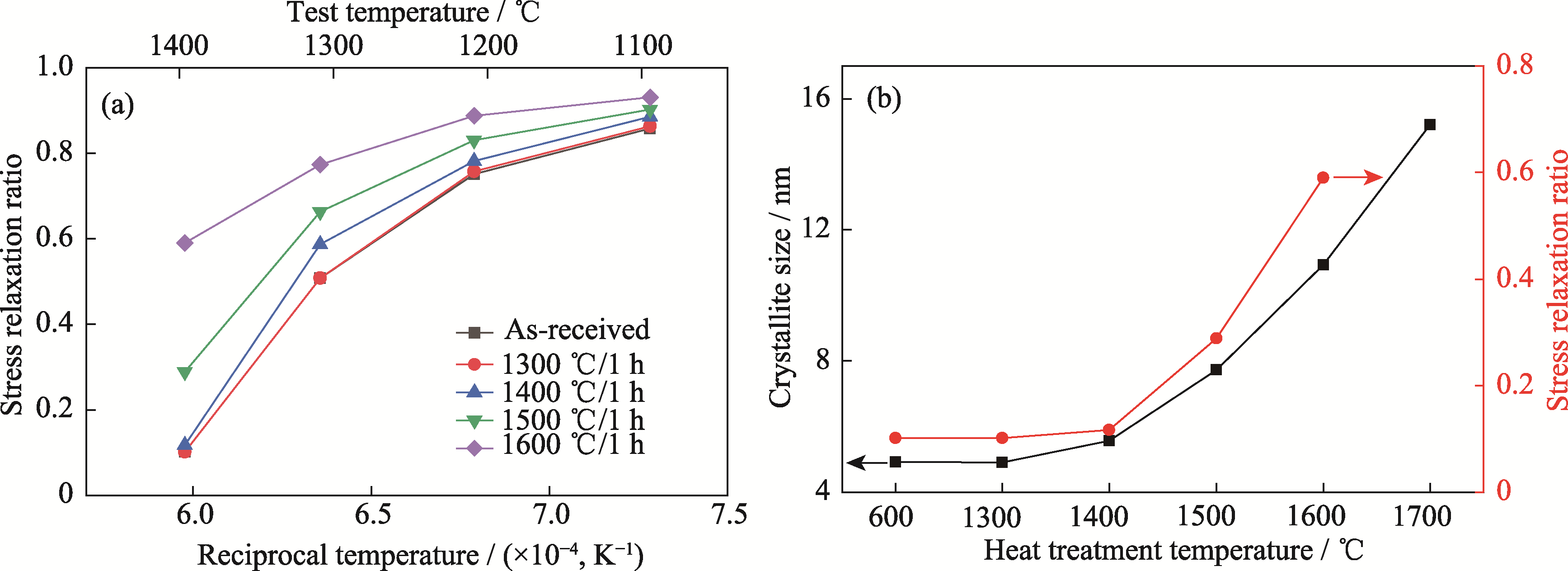

Fig. 3 (a) Stress relaxation ratio of heat-treated fibers at different test temperature; (b) β-SiC grain size and 1400 ℃ BSR results of different heat-treated fibers

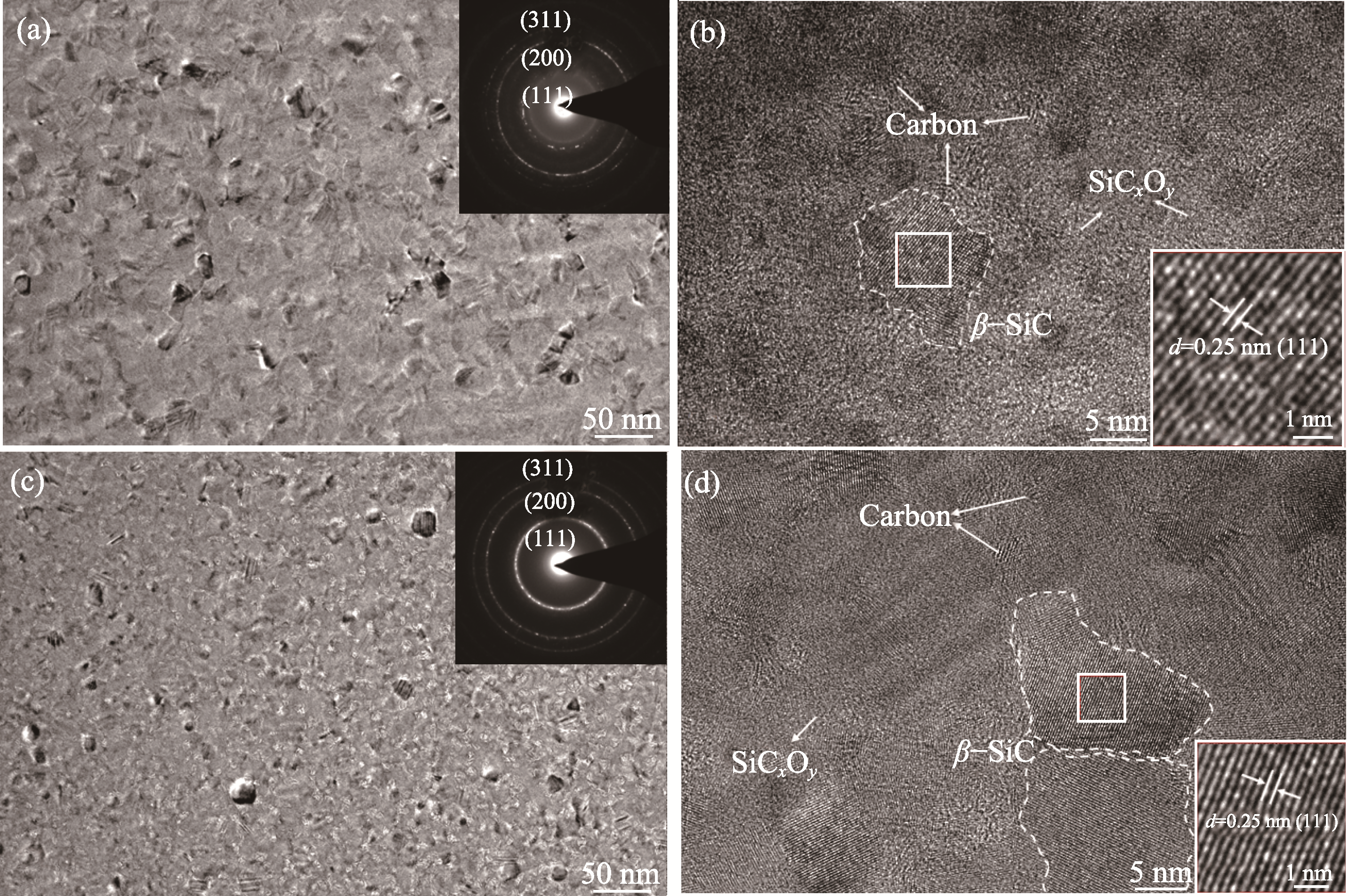

Fig. 4 TEM and HRTEM images of as-received fiber (a, b), fiber after heat treatment at 1500 ℃ (c, d), and corresponding SAED images (insets in (a, c))

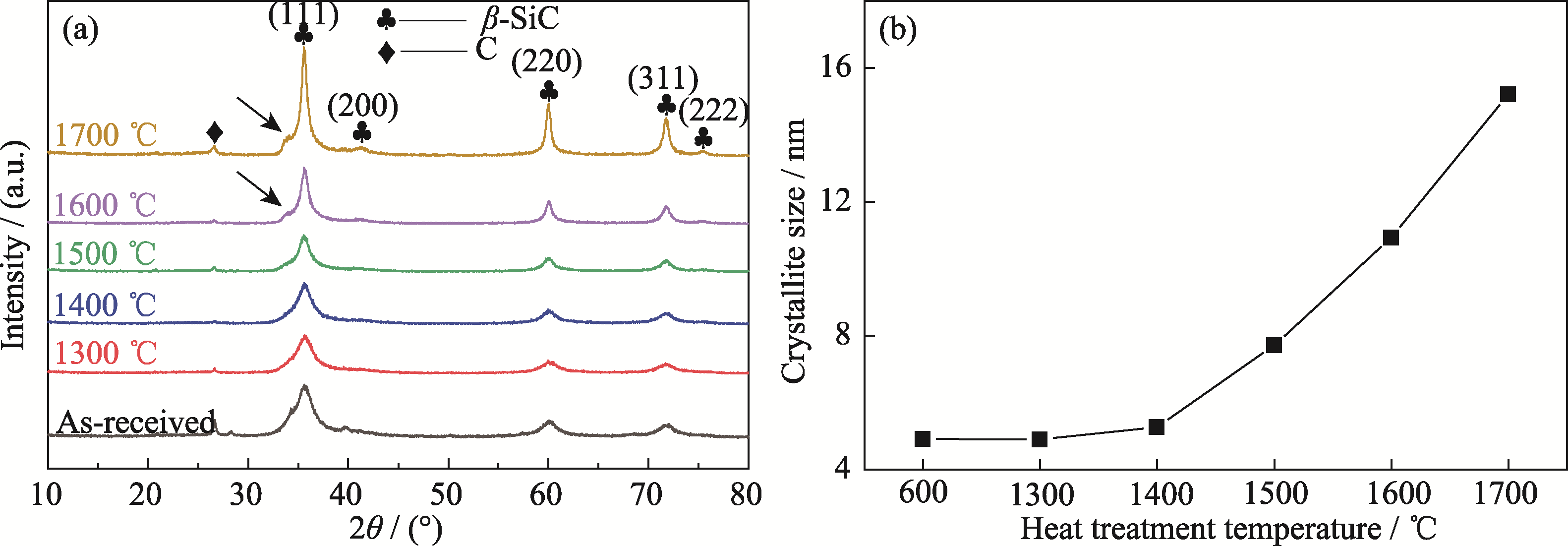

Fig. 5 XRD patterns of Shicolon-II SiC fibers after argon treatment at different temperatures (a) and size of β-SiC crystallites versus heat treatment temperature (b)

| [1] |

PADTURE N P. Advanced structural ceramics in aerospace propulsion. Nature Materials, 2016, 15(8): 804.

DOI |

| [2] |

VIX-GUTERL C, EHRBURGER P. Effect of thermal treatment on the reactivity of SiC-based fibres. Journal of Materials Science, 1996, 31(20): 5363.

DOI URL |

| [3] |

IVEKOVIĆ A, NOVAK S, DRAŽIĆ G, et al. Current status and prospects of SiCf/SiC for fusion structural applications. Journal of the European Ceramic Society, 2013, 33(10): 1577.

DOI URL |

| [4] |

MAZERAT S, PAILLER R. Simulating the variability and scale effect for slow crack growth in Hi-Nicalon SiC-based tows: a parametric study. Journal of the European Ceramic Society, 2021, 41(14): 6834.

DOI URL |

| [5] |

SOMMERS A, WANG Q, HAN X, et al. Ceramics and ceramic matrix composites for heat exchangers in advanced thermal systems—a review. Applied Thermal Engineering, 2010, 30(11/12): 1277.

DOI URL |

| [6] | WANG P R, LIU F Q, WANG H, et al. A review of third generation SiC fibers and SiCf/SiC composites. Journal of Materials Science & Technology, 2019, 35(12): 2743. |

| [7] |

KATOH Y, SNEAD L L, HENAGER C H, et al. Current status and recent research achievements in SiC/SiC composites. Journal of Nuclear Materials, 2014, 455(1/2/3): 387.

DOI URL |

| [8] |

CHOLLON G, PAILLER R, NASLAIN R, et al. Thermal stability of a PCS-derived SiC fibre with a low oxygen content (Hi-Nicalon). Journal of Materials Science, 1997, 32(2): 327.

DOI |

| [9] |

SMITH P R, GAMBONE M L, WILLIAMS D S, et al. Heat treatment effects on SiC fiber. Journal of Materials Science, 1998, 33(24): 5855.

DOI |

| [10] |

SACKS M D. Effect of composition and heat treatment conditions on the tensile strength and creep resistance of SiC-based fibers. Journal of the European Ceramic Society, 1999, 19(13/14): 2305.

DOI URL |

| [11] |

BHATT R T, ELDRIDGE J I. Heat treatment effects on microstructure and properties of CVI SiC/SiC composites with Sylramic™-iBN SiC fibers. Journal of the European Ceramic Society, 2023, 43(6): 2376.

DOI URL |

| [12] |

BHATT R T, JASKOWIAK M H. Creep and cyclic durability of CVI SiC/SiC composites. Journal of the European Ceramic Society, 2024, 44(7): 4437.

DOI URL |

| [13] |

DONG H N, GAO X G, ZHANG S, et al. Effects of heat treatment on the mechanical properties at elevated temperatures of plain- woven SiC/SiC composites. Journal of the European Ceramic Society, 2022, 42(2): 412.

DOI URL |

| [14] |

YAJIMA S, HAYASHI J, OMORI M. Continuous silicon carbide fiber of high tensile strength. Chemistry Letters, 1975, 4(9): 931.

DOI URL |

| [15] |

BUNSELL A R, PIANT A. A review of the development of three generations of small diameter silicon carbide fibres. Journal of Materials Science, 2006, 41(3): 823.

DOI URL |

| [16] | JONES R E, PETRAK D, RABE J, et al. SYLRAMIC™ SiC fibers for CMC reinforcement. Journal of Nuclear Materials, 2000, 283-287: 556. |

| [17] |

ZHANG Y, WU C L, WANG Y D, et al. A detailed study of the microstructure and thermal stability of typical SiC fibers. Materials Characterization, 2018, 146: 91.

DOI URL |

| [18] |

TAKEDA M, IMAI Y, ICHIKAWA H, et al. Thermal stability of SiC fiber prepared by an irradiation-curing process. Composites Science and Technology, 1999, 59(6): 793.

DOI URL |

| [19] |

SHA J J, PARK J S, HINOKI T, et al. Tensile properties and microstructure characterization of Hi-NicalonTM SiC fibers after loading at high temperature. International Journal of Fracture, 2006, 142(1): 1.

DOI URL |

| [20] |

DONG S M, CHOLLON G, LABRUGÈRE C, et al. Characterization of nearly stoichiometric SiC ceramic fibres. Journal of Materials Science, 2001, 36(10): 2371.

DOI |

| [21] |

YUAN Q, LI Y Q, SONG Y C. Microstructure and thermal stability of low-oxygen SiC fibers prepared by an economical chemical vapor curing method. Ceramics International, 2017, 43(12): 9128.

DOI URL |

| [22] |

BODET R, LAMON J, JIA N Y, et al. Microstructural stability and creep behavior of Si-C-O (Nicalon) fibers in carbon monoxide and argon environments. Journal of the American Ceramic Society, 1996, 79(10): 2673.

DOI URL |

| [23] |

KISTER G, HARRIS B. Tensile properties of heat-treated nicalon and hi-nicalon fibres. Composites Part A: Applied Science and Manufacturing, 2002, 33(3): 435.

DOI URL |

| [24] |

JIA N Y, BODET R, TRESSLER R E. Effects of microstructural instability on the creep behavior of Si-C-O (Nicalon) fibers in argon. Journal of the American Ceramic Society, 1993, 76(12): 3051.

DOI URL |

| [25] |

MO R, YIN X W, YE F, et al. Mechanical and microwave absorbing properties of Tyranno® ZMI fiber annealed at elevated temperatures. Ceramics International, 2017, 43(12): 8922.

DOI URL |

| [26] |

YOUNGBLOOD G E, LEWINSOHN C, JONES R H, et al. Tensile strength and fracture surface characterization of Hi-Nicalon™ SiC fibers. Journal of Nuclear Materials, 2001, 289(1/2): 1.

DOI URL |

| [27] |

WILSON M, OPILA E. A review of SiC fiber oxidation with a new study of Hi-Nicalon SiC fiber oxidation. Advanced Engineering Materials, 2016, 18(10): 1698.

DOI URL |

| [28] | HUGUET-GARCIA J, JANKOWIAK A, MIRO S,et al. In situ TEM annealing of ion-amorphized Hi Nicalon S and Tyranno SA 3 SiC fibers. Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms, 2016, 374: 76. |

| [29] |

CAO S Y, WANG J, WANG H. Formation mechanism of large SiC grains on SiC fiber surfaces during heat treatment. CrystEngComm, 2016, 18(20): 3674.

DOI URL |

| [30] |

MORIMOTO T, OGASAWARA T. Potential strength of Nicalon™, Hi Nicalon™, and Hi Nicalon Type S™ monofilaments of variable diameters. Composites Part A: Applied Science and Manufacturing, 2006, 37(3): 405.

DOI URL |

| [31] |

TOBIN Z, KERNS P, NISLY N, et al. Hi-NICALON™ type S fiber tow surface desizing and decarburization via heat treatment. Ceramics International, 2021, 47(23): 33709.

DOI URL |

| [32] |

MAH T, HECHT N L, MCCULLUM D E, et al. Thermal stability of SiC fibres (Nicalon®). Journal of Materials Science, 1984, 19(4): 1191.

DOI URL |

| [33] |

GOU Y Z, WANG H, JIAN K. Formation of carbon-rich layer on the surface of SiC fiber by sintering under vacuum for superior mechanical and thermal properties. Journal of the European Ceramic Society, 2017, 37(3): 907.

DOI URL |

| [34] |

ZHANG S N, ZHONG Z H, HUA Y, et al. Properties of super heat-resistant silicon carbide fibres with in situ BN coating. Journal of the European Ceramic Society, 2022, 42(14): 6404.

DOI URL |

| [35] |

GOSSET D, COLIN C, JANKOWIAK A, et al. X-ray diffraction study of the effect of high-temperature heat treatment on the microstructural stability of third-generation SiC fibers. Journal of the American Ceramic Society, 2013, 96(5): 1622.

DOI URL |

| [36] |

BHATT R T, SOLA’ F, EVANS L J, et al. Microstructural, strength, and creep characterization of Sylramic™, Sylramic™-iBN and super Sylramic™-iBN SiC fibers. Journal of the European Ceramic Society, 2021, 41(9): 4697.

DOI URL |

| [37] |

CHEN X H, SUN Z G, NIU X M, et al. Evolution of the structure and mechanical performance of Cansas-II SiC fibres after thermal treatment. Ceramics International, 2021, 47(19): 27217.

DOI URL |

| [38] |

CHEN Y H, CHEN Z K, ZHANG R Q, et al. Structural evolution and mechanical properties of Cansas-III SiC fibers after thermal treatment up to 1700 ℃. Journal of the European Ceramic Society, 2021, 41(10): 5036.

DOI URL |

| [39] |

XIAO Y, MA C L, XU H, et al. Mechanical properties and microstructural evolution of Cansas-III SiC fibers after thermal exposure in different atmospheres. Ceramics International, 2022, 48(22): 32804.

DOI URL |

| [40] | SHA J J, NOZAWA T, PARK J S, et al. Effect of heat treatment on the tensile strength and creep resistance of advanced SiC fibers. Journal of Nuclear Materials, 2004, 329: 592. |

| [41] |

MORSCHER G N, DICARLO J A. A simple test for thermomechanical evaluation of ceramic fibers. Journal of the American Ceramic Society, 1992, 75(1): 136.

DOI URL |

| [42] |

CAO S Y, WANG J, WANG H. High-temperature behavior and degradation mechanism of SiC fibers annealed in Ar and N2 atmospheres. Journal of Materials Science, 2016, 51(9): 4650.

DOI URL |

| [1] | ZHANG Yongheng, CHEN Jixin. Preparation and Properties of Ytterbium Aluminosilicate Glass and SiC Modified h-BN-based Composites [J]. Journal of Inorganic Materials, 2026, 41(1): 37-44. |

| [2] | HAN Weiwei, HUANG Dong, LI Tingsong, LI Jiang. Sm:LuAG/Nd:LuAG Composite Laser Ceramics with Cladding Structure: Fabrication and Properties [J]. Journal of Inorganic Materials, 2026, 41(1): 113-118. |

| [3] | CHEN Bin, REN Ke, WANG Yiguang. Evolution of Mechanical Properties of Mini-SiCf/SiC Composites at High Temperatures over a Long Period of Time [J]. Journal of Inorganic Materials, 2025, 40(9): 971-980. |

| [4] | ZHONG Weimin, ZHAO Ke, WANG Kewei, LIU Dianguang, LIU Jinling, AN Linan. Effect of Oscillatory Pressure Amplitude on Microstructures and Wear Resistance of Tungsten Carbide [J]. Journal of Inorganic Materials, 2025, 40(9): 964-970. |

| [5] | SUN Yuxuan, WANG Zheng, SHI Xue, SHI Ying, DU Wentong, MAN Zhenyong, ZHENG Liaoying, LI Guorong. Defect Dipole Thermal-stability to the Electro-mechanical Properties of Fe Doped PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 545-551. |

| [6] | CHEN Yi, QIU Haipeng, CHEN Mingwei, XU Hao, CUI Heng. SiC/SiC Composite: Matrix Boron Modification and Mechanical Properties [J]. Journal of Inorganic Materials, 2025, 40(5): 504-510. |

| [7] | CUI Ning, ZHANG Yuxin, WANG Lujie, LI Tongyang, YU Yuan, TANG Huaguo, QIAO Zhuhui. Single-phase Formation Process and Carbon Vacancy Regulation of (TiVNbMoW)Cx High-entropy Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 511-520. |

| [8] | LI Ziwei, GONG Weilu, CUI Haifeng, YE Li, HAN Weijian, ZHAO Tong. (Zr, Hf, Nb, Ta, W)C-SiC Composite Ceramics: Preparation via Precursor Route and Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 271-280. |

| [9] | GAO Chenguang, SUN Xiaoliang, CHEN Jun, LI Daxin, CHEN Qingqing, JIA Dechang, ZHOU Yu. SiBCN-rGO Ceramic Fibers Based on Wet Spinning Technology: Microstructure, Mechanical and Microwave-absorbing Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 290-296. |

| [10] | MU Haojie, ZHANG Yuanjiang, YU Bin, FU Xiumei, ZHOU Shibin, LI Xiaodong. Preparation and Properties of ZrO2 Doped Y2O3-MgO Nanocomposite Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 281-289. |

| [11] | ZHENG Yuanshun, YU Jian, YE Xianfeng, LIANG Dong, ZHU Wanting, NIE Xiaolei, WEI Ping, ZHAO Wenyu, ZHANG Qingjie. Boosting the Thermoelectric Performance of Full-Heusler Fe2VAl Alloy via Substituting Al Site with V [J]. Journal of Inorganic Materials, 2025, 40(12): 1425-1432. |

| [12] | WANG Yueyue, HUANG Jiahui, KONG Hongxing, LI Huaizhu, YAO Xiaohong. Silver Loaded Radial Mesoporous Silica: Preparation and Application in Dental Resins [J]. Journal of Inorganic Materials, 2025, 40(1): 77-83. |

| [13] | FAN Wugang, CAO Xiong, ZHOU Xiang, LI Ling, ZHAO Guannan, ZHANG Zhaoquan. Anticorrosion Performance of 8YSZ Ceramics in Simulated Aqueous Environment of Pressurized Water Reactor [J]. Journal of Inorganic Materials, 2024, 39(7): 803-809. |

| [14] | CHEN Qian, SU Haijun, JIANG Hao, SHEN Zhonglin, YU Minghui, ZHANG Zhuo. Progress of Ultra-high Temperature Oxide Ceramics: Laser Additive Manufacturing and Microstructure Evolution [J]. Journal of Inorganic Materials, 2024, 39(7): 741-753. |

| [15] | JIANG Lingyi, PANG Shengyang, YANG Chao, ZHANG Yue, HU Chenglong, TANG Sufang. Preparation and Oxidation Behaviors of C/SiC-BN Composites [J]. Journal of Inorganic Materials, 2024, 39(7): 779-786. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||