Journal of Inorganic Materials ›› 2020, Vol. 35 ›› Issue (1): 29-34.DOI: 10.15541/jim20190400

Special Issue: MAX相和MXene材料; 陶瓷基复合材料; 结构陶瓷论文精选(2020); 【虚拟专辑】层状MAX,MXene及其他二维材料

Previous Articles Next Articles

DANG Xiao-Lin,FAN Xiao-Meng( ),YIN Xiao-Wei(

),YIN Xiao-Wei( ),MA Yu-Zhao,MA Xiao-Kang

),MA Yu-Zhao,MA Xiao-Kang

Received:2019-08-08

Revised:2019-09-26

Published:2020-01-20

Online:2019-10-25

About author:DANG Xiao-Lin (1996-), female, PhD candidate. E-mail:dangxl@mail.nwpu.edu.cn

Supported by:CLC Number:

DANG Xiao-Lin, FAN Xiao-Meng, YIN Xiao-Wei, MA Yu-Zhao, MA Xiao-Kang. Research Progress on Multi-functional Integration MAX Phases Modified Continuous Fiber-reinforced Ceramic Matrix Composites[J]. Journal of Inorganic Materials, 2020, 35(1): 29-34.

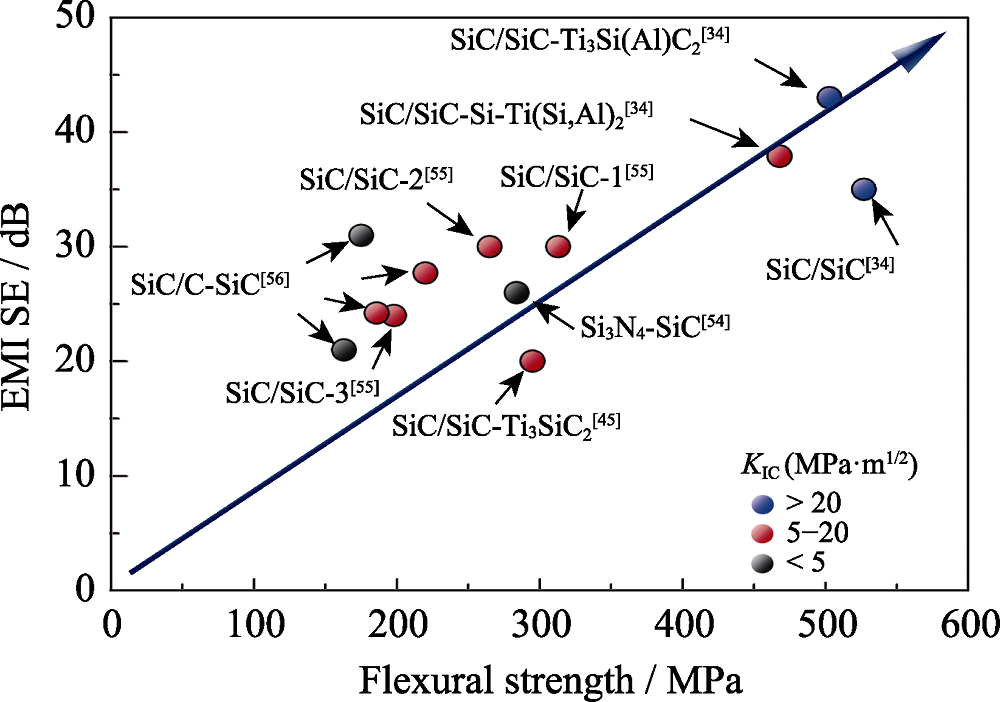

Fig. 5 The flexural strength, fracture toughness and electromagnetic interference (EMI) shielding effectiveness of SiC/ SiC-based composites[34,45,54-56]

| [1] |

YIN X W, CHENG L F, ZHANG L T , et al. Fibre-reinforced multifunctional SiC matrix composite materials. Int. Mater. Rev., 2017,62(3):117-172.

DOI URL |

| [2] |

NASLAIN R . Design, preparation and properties of non-oxide CMCs for application in engines and nuclear reactors: an overview. Compos. Sci. Technol., 2004,64(2):155-170.

DOI URL |

| [3] |

KRENKEL W, BERNDT F . C/C-SiC composites for space applications and advanced friction systems. Materials Science & Engineering A (Structural Materials: Properties, Microstructure and Processing), 2005,412(1):177-181.

DOI URL PMID |

| [4] |

MA Q S, LIU H T, PAN Y , et al. Research progress on the application of C/SiC composites in scramjet. J. Inorg. Mater., 2013,28(3):247-255.

DOI URL |

| [5] | 张立同 . 纤维增韧碳化硅陶瓷复合材料—模拟、表征与设计. 北京: 化学工业出版社, 2009. |

| [6] |

NOWOTNY V . Strukturchemie einiger verbindungen der übergangsmetalle mit den elementen C, Si, Ge, Sn. Prog. Solid State Chem., 1971,5(71):27-70.

DOI URL |

| [7] |

BARSOUM M W, EI-RAGHY T . Synthesis and characterization of a remarkable ceramic: Ti3SiC2. J. Am. Ceram. Soc., 1996,79(7):1953-1956.

DOI URL |

| [8] |

LI M, LI Y B, LUO K , et al. Synthesis of novel MAX phase Ti3ZnC2 via A-site-element-substitution approach J. Inorg. Mater., 2019,34(1):60-64.

DOI URL PMID |

| [9] |

ZHANG J, LIU B, WANG J Y , et al. Low-temperature instability of Ti2SnC: a combined transmission electron microscopy, differential scanning calorimetry, and x-ray diffraction investigations. J. Mater. Res., 2009,24(1):39-49.

DOI URL |

| [10] |

SUN Z M . Progress in research and development on MAX phases: a family of layered ternary compounds. Int. Mater. Rev., 2013,56(3):143-166.

DOI URL |

| [11] |

BARSOUM M W, RADOVIC M . Elastic and mechanical properties of the MAX phases. Ann. Rev. Mater. Res., 2011,41(1):195-227.

DOI URL PMID |

| [12] |

BARSOUM M W, EI-RAGHY T . The MAX phases: unique new carbide and nitride materials. Am. Sci., 2001,89(4):334-343.

DOI URL |

| [13] |

YANG C P, JIAO G Q, WANG B . Effects of interface properties on tensile strength of ceramic matrix composites. J. Inorg. Mater., 2009,24(5):919-923.

DOI URL PMID |

| [14] |

SNEAD L L, BURCHELL T D, KATOH Y . Swelling of nuclear graphite and high quality carbon fiber composite under very high irradiation temperature. J. Nucl. Mater., 2008,381(1/2):55-61.

DOI URL |

| [15] |

KATOH Y, OZAWA K, SHIH C , et al. Continuous SiC fiber, CVI SiC matrix composites for nuclear applications: properties and irradiation effects. J. Nucl. Mater., 2014,448(1/2/3):448-476.

DOI URL |

| [16] |

LI M, ZHOU X B, YANG H , et al. The critical issues of SiC materials for future nuclear systems. Scripta Mater., 2018,143:149-153.

DOI URL |

| [17] |

MA Y Z, YIN X W, FAN X M , et al. Modification and toughening of 3D needled C/SiC composite by deformable MAX phase-based matrix. Mat. Sci. Eng. A, 2018,712:397-405.

DOI URL |

| [18] |

WHITTLE K R, BLACKFORD M G, AUGHTERSON R D , et al. Radiation tolerance of Mn+1AXn phases, Ti3AlC2 and Ti3SiC2. Acta Mater., 2010,58(13):4362-4368.

DOI URL |

| [19] |

WANG C X, YANG T F, TRACY C L , et al. Role of the X and n factors in ion-irradiation induced phase transformations of Mn+1AXn phases. Acta Mater., 2018,144:432-446.

DOI URL |

| [20] |

WANG C X, YANG T F, TRACY C L , et al. Disorder in Mn+1AXn phases at the atomic scale. Nat. Commun., 2019,10(1):622.

DOI URL PMID |

| [21] |

WANG C X, YANG T F, XIAO J R , et al. Irradiation-induced structural transitions in Ti2AlC. Acta Mater., 2015,98:197-205.

DOI URL |

| [22] |

WANG X H, ZHOU Y C . Layered machinable and electrically conductive Ti2AlC and Ti3AlC2 ceramics: a review. J. Mater. Sci. Technol., 2010,26(5):385-416.

DOI URL |

| [23] |

FAKIH H, JACQUES S, DEZELLUS O , et al. Phase equilibria and reactive chemical vapor deposition (RCVD) of Ti3SiC2. Journal of Phase Equilibria and Diffusion, 2008,29(3):239-246.

DOI URL |

| [24] |

JACQUES S, FAKIH H, VIALA J C . Reactive chemical vapor deposition of Ti3SiC2 with and without pressure pulses: effect on the ternary carbide texture. Thin Solid Films, 2010,518(18):5071-5077.

DOI URL |

| [25] |

FILBERT-DEMUT I, TRAVITZKY N, MOTZ G , et al. Polymer derived ceramics reinforced with Ti3SiC2 coated SiC fibers: a feasibility study. Mater. Lett., 2015,145:229-231.

DOI URL |

| [26] |

FILBERT-DEMUT I, BEI G, HÖSCHEN T , et al. Influence of Ti3SiC2 fiber coating on interface and matrix cracking in an SiC fiber-reinforced polymer-derived ceramic. Adv. Eng. Mater., 2015,17(8):1142-1148.

DOI URL |

| [27] |

LEE H G, KIM D, JEONG Y S , et al. Formation of Ti3SiC2 interphase of SiC fiber by electrophoretic deposition method. Journal of the Korean Ceramic Society, 2016,53(1):87-92.

DOI URL |

| [28] |

LEE H G, KIM D, PARK J Y , et al. Formation of Ti3SiC2 interphase coating on SiCf/SiC composite by electrophoretic deposition. Inter. J. Appl. Ceram. Tec., 2017,15(3):602-610.

DOI URL |

| [29] |

LI M, WANG K, WANG J , et al. Preparation of TiC/Ti2AlC coating on carbon fiber and investigation of the oxidation resistance properties. J. Am. Ceram. Soc., 2018,101(11):5269-5280.

DOI URL |

| [30] |

GILBERT C J, BLOYER D R, BARSOUM M W , et al. Fatigue- crack growth and fracture properties of coarse and fine-grained Ti3SiC2. Scripta Mater., 2000,42(8):761-767.

DOI URL |

| [31] |

YIN X W, HE S S, ZHANG L T , et al. Fabrication and characterization of a carbon fibre reinforced carbon-silicon carbide- titanium silicon carbide hybrid matrix composite. Mat. Sci. Eng. A-Struct., 2010,527(3):835-841.

DOI URL |

| [32] |

LU C Y, YIN X W, LI X M . A novel in-situ synthesis route of Ti3SiC2-SiC composite by liquid silicon infiltration. J. Inorg. Mater., 2010,25(9):1003-1008.

DOI URL |

| [33] |

FAN X M, YIN X W, WANG L , et al. Processing, microstructure and ablation behavior of C/SiC-Ti3SiC2 composites fabricated by liquid silicon infiltration. Corros. Sci., 2013,74:98-105.

DOI URL |

| [34] |

MA X K, YIN X W, FAN X M , et al. Microstructure and properties of dense Tyranno-ZMI SiC/SiC containing Ti3Si(Al)C2 with plastic deformation toughening mechanism. J. Eur. Ceram. Soc., 2018,38(4):1069-1078.

DOI URL |

| [35] |

DONG N, CHEN L Q, YIN X W , et al. Fabrication and electromagnetic interference shielding effectiveness of Ti3Si(Al)C2 modified Al2O3/SiC composites. Ceram. Int., 2016,42(8):9448-9454.

DOI URL |

| [36] |

FAN X M, YIN X W, CHEN L Q , et al. Mechanical behavior and electromagnetic interference shielding properties of C/SiC-Ti3Si(Al)C2. J. Am. Ceram. Soc., 2016,99(5):1717-1724.

DOI URL |

| [37] |

LENZ F, KRENKEL W . Fabrication of fiber composites with a MAX phase matrix by reactive melt infiltration. IOP Conference Series: Materials Science and Engineering, 2011,18(20):202030.

DOI URL |

| [38] |

LENZ F, KRENKEL W . Carbon fiber reinforced ceramics based on reactive melt infiltration processes. Journal of the Korean Ceramic Society, 2012,49(4):287-294.

DOI URL |

| [39] |

SPENCER C B, CÓRDOBA J M, OBANDO N H , et al. The reactivity of Ti2AlC and Ti3SiC2 with SiC fibers and powders up to temperatures of 1550 ℃. J. Am. Ceram. Soc., 2011,94(6):1737-1743.

DOI URL |

| [40] |

ZHANG J W, HU C F, WANG Y G , et al. Interfacial reactions between polymer derived SiC fiber and Ti3Si(Al)C2. Key Eng. Mater., 2013,544:238-244.

DOI URL |

| [41] |

GUO S Q, HU C F, GAO H , et al. SiC(SCS-6) fiber-reinforced Ti3AlC2 matrix composites: interfacial characterization and mechanical behavior. J. Eur. Ceram. Soc., 2015,35(5):1375-1384.

DOI URL |

| [42] |

GUO S Q . Improvement of mechanical properties of SiC(SCS-6) fibre-reinforced Ti3AlC2 matrix composites with Ti barrier layer. J. Eur. Ceram. Soc., 2016,36(6):1349-1358.

DOI URL |

| [43] |

YANG J S, DONG S M, XU C Y . Mechanical response and microstructure of 2D carbon fiber reinforced ceramic matrix composites with SiC and Ti3SiC2 fillers. Ceram. Int., 2016,42(2):3019-3027.

DOI URL |

| [44] | YANG J S, DONG S M, HE P , et al. Fabrication Fabrication and properties of Cf/Ti3SiC2-SiC composites using Ti3SiC2 as inert filler. Key Eng. Mater., 2012,512-515:681-684. |

| [45] |

MU Y, ZHOU W C, WAN F , et al. High-temperature dielectric and electromagnetic interference shielding properties of SiCf/SiC composites using Ti3SiC2 as inert filler. Composites Part A: Applied Science and Manufacturing, 2015,77:195-203.

DOI URL |

| [46] |

SONG G M, LI S B, ZHAO C X , et al. Ultra-high temperature ablation behavior of Ti2AlC ceramics under an oxyacetylene flame. J. Eur. Ceram. Soc., 2011,31(5):855-862.

DOI URL |

| [47] |

SHEN X T, LI K Z, LI H J , et al. Microstructure and ablation properties of zirconium carbide doped carbon/carbon composites. Carbon, 2010,48(2):344-351.

DOI URL |

| [48] |

SONG G M, WANG Y J, ZHOU Y . Elevated temperature ablation resistance and thermophysical properties of tungsten matrix composites reinforced with ZrC particles. J. Mater. Sci., 2001,36(19):4625-4631.

DOI URL |

| [49] |

HU S J, LI S B, LI H L , et al. Oxyacetylene torch testing and microstructural characterization of a Cr2AlC ceramic. J. Alloys Compd., 2018,740:77-81.

DOI URL |

| [50] |

LI H L, LI S B, ZHANG L Q , et al. Synthesis and ultra-high temperature ablation behavior of a ZrC/Cr2AlC composite. Ceram. Int., 2016,42(5):5686-5692.

DOI URL |

| [51] |

ZHOU Y C, HE L F, LIN Z J , et al. Synthesis and structure- property relationships of a new family of layered carbides in Zr-Al(Si)-C and Hf-Al(Si)-C systems. J. Eur. Ceram. Soc., 2013,33(15/16):2831-2865.

DOI URL |

| [52] |

MA Y Z, YIN X W, FAN X M , et al. Ablation behavior of Zr-Al(Si)-C layered carbides modified 3D needled C/SiC composites. Adv. Eng. Mater., 2019,21(6):1800936.

DOI URL |

| [53] |

FAN X M, YIN X W, CAI Y Z , et al. Mechanical and electromagnetic interference shielding behavior of C/SiC composite containing Ti3SiC2. Adv. Eng. Mater., 2018,20(2):1700590.

DOI URL |

| [54] |

LI X M, ZHANG L T, YIN X W , et al. Effect of chemical vapor infiltration of SiC on the mechanical and electromagnetic properties of Si3N4-SiC ceramic. Scripta Mater., 2010,63(6):657-660.

DOI URL |

| [55] |

MU Y, ZHOU W C, WANG C , et al. Mechanical and electromagnetic shielding properties of SiCf/SiC composites fabricated by combined CVI and PIP process. Ceram. Int., 2014,40(7):10037-10041.

DOI URL |

| [56] |

WANG H Y, ZHU D M, MU Y , et al. Effect of SiC/C preform densities on the mechanical and electromagnetic interference shielding properties of dual matrix SiC/C-SiC composites. Ceram. Int., 2015,41(10):14094-14100.

DOI URL |

| [1] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [2] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [3] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [4] | ZHANG Bihui, LIU Xiaoqiang, CHEN Xiangming. Recent Progress of Hybrid Improper Ferroelectrics with Ruddlesden-Popper Structure [J]. Journal of Inorganic Materials, 2025, 40(6): 587-608. |

| [5] | WU Jie, YANG Shuai, WANG Mingwen, LI Jinglei, LI Chunchun, LI Fei. Textured PT-based Piezoelectric Ceramics: Development, Status and Challenge [J]. Journal of Inorganic Materials, 2025, 40(6): 575-586. |

| [6] | JIANG Kun, LI Letian, ZHENG Mupeng, HU Yongming, PAN Qinxue, WU Chaofeng, WANG Ke. Research Progress on Low-temperature Sintering of PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 627-638. |

| [7] | TIAN Ruizhi, LAN Zhengyi, YIN Jie, HAO Nanjing, CHEN Hangrong, MA Ming. Microfluidic Technology Based Synthesis of Inorganic Nano-biomaterials: Principles and Progress [J]. Journal of Inorganic Materials, 2025, 40(4): 337-347. |

| [8] | ZHANG Jiguo, WU Tian, ZHAO Xu, YANG Fan, XIA Tian, SUN Shien. Improvement of Cycling Stability of Cathode Materials and Industrialization Process for Sodium-ion Batteries [J]. Journal of Inorganic Materials, 2025, 40(4): 348-362. |

| [9] | YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 245-255. |

| [10] | CHEN Guangchang, DUAN Xiaoming, ZHU Jinrong, GONG Qing, CAI Delong, LI Yuhang, YANG Donglei, CHEN Biao, LI Xinmin, DENG Xudong, YU Jin, LIU Boya, HE Peigang, JIA Dechang, ZHOU Yu. Advanced Ceramic Materials in Helicopter Special Structures: Research Progress and Application Prospect [J]. Journal of Inorganic Materials, 2025, 40(3): 225-244. |

| [11] | FAN Xiaobo, ZU Mei, YANG Xiangfei, SONG Ce, CHEN Chen, WANG Zi, LUO Wenhua, CHENG Haifeng. Research Progress on Proton-regulated Electrochemical Ionic Synapses [J]. Journal of Inorganic Materials, 2025, 40(3): 256-270. |

| [12] | HAIREGU Tuxun, GUO Le, DING Jiayi, ZHOU Jiaqi, ZHANG Xueliang, NUERNISHA Alifu. Research Progress of Optical Bioimaging Technology Assisted by Upconversion Fluorescence Probes in Tumor Imaging [J]. Journal of Inorganic Materials, 2025, 40(2): 145-158. |

| [13] | SUN Shujuan, ZHENG Nannan, PAN Haokun, MA Meng, CHEN Jun, HUANG Xiubing. Research Progress on Preparation Methods of Single-atom Catalysts [J]. Journal of Inorganic Materials, 2025, 40(2): 113-127. |

| [14] | TAO Guilong, ZHI Guowei, LUO Tianyou, OUYANG Peidong, YI Xinyan, LI Guoqiang. Progress on Key Technologies of Cavity-structured Thin Film Bulk Acoustic Wave Filter [J]. Journal of Inorganic Materials, 2025, 40(2): 128-144. |

| [15] | ZHOU Fan, TIAN Zhilin, LI Bin. Research Progress on Carbide Ultra-high Temperature Ceramic Anti-ablation Coatings for Thermal Protection System [J]. Journal of Inorganic Materials, 2025, 40(1): 1-16. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||