Journal of Inorganic Materials ›› 2020, Vol. 35 ›› Issue (1): 35-40.DOI: 10.15541/jim20190184

Special Issue: MAX相和MXene材料; 副主编黄庆研究员专辑; 计算材料论文精选(2020); 【虚拟专辑】层状MAX,MXene及其他二维材料

Previous Articles Next Articles

CHEN Lei-Lei1,DENG Zi-Xuan1,LI Mian1,LI Peng1,CHANG Ke-Ke1,2( ),HUANG Feng1,DU Shi-Yu1,HUANG Qing1

),HUANG Feng1,DU Shi-Yu1,HUANG Qing1

Received:2019-04-29

Revised:2019-07-25

Published:2020-01-20

Online:2019-09-20

About author:CHEN Lei-Lei(1993-), male, Master candidate. E-mail:chenleilei@nimte.ac.cn

Supported by:CLC Number:

CHEN Lei-Lei, DENG Zi-Xuan, LI Mian, LI Peng, CHANG Ke-Ke, HUANG Feng, DU Shi-Yu, HUANG Qing. Phase Diagrams of Novel MAX Phases[J]. Journal of Inorganic Materials, 2020, 35(1): 35-40.

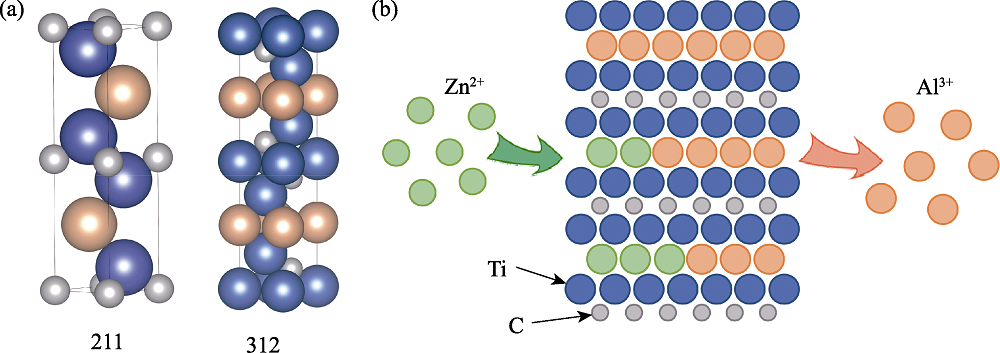

Fig. 1 (a) Crystal structures of MAX phases in 211 and 312 type; (b) Schematic of synthesizing Ti2ZnC via an A-elements substitution reaction in a molten salts bath[6]

| Phase | Lattice parameter/nm | Enthalpy of formation/ (kJ?mol-1?atom-1) | |

|---|---|---|---|

| a | c | ||

| Ti2AuC | 0.3073 | 1.3755 | -66.260 |

| Ti2IrC | 0.2981 | 1.3377 | -75.383 |

| Ti2ZnC | 0.3059 | 1.3726 | -55.925 |

| Ti3AuC2 | 0.3087 | 1.8650 (1.856)* | -76.083 |

| Ti3IrC2 | 0.3025 | 1.8196 | -80.800 |

| Ti3ZnC2 | 0.3078 (0.3094)# | 1.8613 (1.8721)# | -69.105 |

Table 1 Calculated lattice parameters and formation enthalpy of MAX phases

| Phase | Lattice parameter/nm | Enthalpy of formation/ (kJ?mol-1?atom-1) | |

|---|---|---|---|

| a | c | ||

| Ti2AuC | 0.3073 | 1.3755 | -66.260 |

| Ti2IrC | 0.2981 | 1.3377 | -75.383 |

| Ti2ZnC | 0.3059 | 1.3726 | -55.925 |

| Ti3AuC2 | 0.3087 | 1.8650 (1.856)* | -76.083 |

| Ti3IrC2 | 0.3025 | 1.8196 | -80.800 |

| Ti3ZnC2 | 0.3078 (0.3094)# | 1.8613 (1.8721)# | -69.105 |

| [1] |

CHING W Y, MO Y, ARYAL S , et al. Intrinsic mechanical properties of 20 MAX-phase compounds. Journal of the American Ceramic Society, 2013,96(7):2292-2297.

DOI URL |

| [2] |

SUN Z M . Progress in research and development on MAX phases: a family of layered ternary compounds. International Materials Reviews, 2011,56(3):143-166.

DOI URL |

| [3] | BARSOUM M W . The M N+1AXN phases: a new class of solids. Progress in Solid State Chemistry of Materials, 2000,28:201-281. |

| [4] |

FASHANDI H, DAHLQVIST M, LU J , et al. Synthesis of Ti3AuC2, Ti3Au2C2 and Ti3IrC2 by noble metal substitution reaction in Ti3SiC2 for high-temperature-stable Ohmic contacts to SiC. Nature Materials, 2017,16:814.

DOI URL PMID |

| [5] |

LI M, LI Y, LUO K , et al. Synthesis of novel MAX phase Ti3ZnC2 via A-site-element-substitution approach. Journal of Inorganic Materials, 2019,34(1):60-64.

DOI URL |

| [6] |

LI M, LU J, LUO K , et al. Element replacement approach by reaction with Lewis acidic molten salts to synthesize nanolaminated MAX phases and MXenes. Journal of the American Chemical Society, 2019,141(11):4730-4737.

DOI URL PMID |

| [7] |

KRESSE G, FURTHMÜLLER J . Efficient iterative schemes for ab initi total-energy calculations using a plane-wave basis set. Physical Review B, 1996,54(16):11169-11186.

DOI URL PMID |

| [8] |

LIU S, CHANG K, MRÁZ S , et al.Modeling of metastable phase formation for sputtered Ti1-xAlxN thin films. Acta Materialia, 2019,165:615-625.

DOI URL PMID |

| [9] |

CHANG K, TO BABEN M, MUSIC D , et al. Estimation of the activation energy for surface diffusion during metastable phase formation. Acta Materialia, 2015,98:135-140.

DOI URL |

| [10] |

JOUBERT D, KRESSE G . From ultrasoft pseudopotentials to the projector augmented-wave method. Physical Review B, 1999,59(3):1758-1775.

DOI URL PMID |

| [11] |

BURKE K, ERNZERHOF M, PERDEW J P . Generalized gradient approximation made simple. Physical Review Letters, 1996,77(18):3865-3868.

DOI URL PMID |

| [12] |

DINSDALE A T . SGTE data for pure elements. Calphad, 1991,15(4):317-425.

DOI URL PMID |

| [13] |

REDLICH O, KISTER A T . Thermodynamics of nonelectrolyte solutions-xyt relations in a binary system. Industrial & Engineering Chemistry, 1948,40(2):341-345.

DOI URL PMID |

| [14] |

CHANG K, DU Y, SUN W , et al. Thermodynamic assessment of the V-Zn system supported by key experiments and first-principles calculations. Calphad, 2010,34(1):75-80.

DOI URL |

| [15] |

CHEN L, ZHANG Z, HUANG Y ,et al. Thermodynamic description of the Fe-Cu-C system. Calphad, 2019,64:225-235.

DOI URL PMID |

| [16] |

GORBACHEV I I, POPOV V V . Analysis of the solubility of carbides, nitrides, and carbonitrides in steels using methods of computer thermodynamics: III. Solubility of carbides, nitrides, and carbonitrides in the Fe-Ti-C, Fe-Ti-N, and Fe-Ti-C-N systems. Physics of Metals & Metallography, 2009,108(5):484-495.

DOI URL PMID |

| [17] |

LUO W, JIN Z, LIU H ,et al. Thermodynamic assessment of the Au-Ti system. Calphad, 2001,25(1):19-26.

DOI URL |

| [18] |

WANG C, GUO Y, YONG L , et al. Thermodynamic assessment of the Ti-Ir System. Journal of Phase Equilibria & Diffusion, 2014,35(3):269-275.

DOI URL PMID |

| [19] | DENG Z, ZHAO D, HUANG Y , et al. Unpublished research. 2018. |

| [20] |

HÄMÄLÄINEN M, ISOMÄKI I . Thermodynamic evaluation of the C-Co-Zn system. Journal of Alloys and Compounds, 2005,392(1):220-224.

DOI URL PMID |

| [21] |

OKAMOTO H, MASSALSKI T B . The Au-C (Gold-Carbon) system. Bulletin of Alloy Phase Diagrams, 1984,5(4):378-379.

DOI URL PMID |

| [22] |

NADLER M R, KEMPTER C P . Some solidus temperatures in several metal-carbon systems. Journal of Physical Chemistry, 1960,64(10):1468-1471.

DOI URL |

| [23] |

FASHANDI H, LAI C C, DAHLQVIST M , et al. Ti2Au2C and Ti3Au2C2 formed by solid state reaction of gold with Ti2AlC and Ti3AlC2. Chemical Communications, 2017,53(69):9554-9557.

DOI URL PMID |

| [1] | ZHANG Yuchen, LU Zhiyao, HE Xiaodong, SONG Guangping, ZHU Chuncheng, ZHENG Yongting, BAI Yuelei. Predictions of Phase Stability and Properties of S-group Elements Containing MAX Borides [J]. Journal of Inorganic Materials, 2024, 39(2): 225-232. |

| [2] | LIU Yanyan, XIE Xi, LIU Zengqian, ZHANG Zhefeng. Metal Matrix Composites Reinforced by MAX Phase Ceramics: Fabrication, Properties and Bioinspired Designs [J]. Journal of Inorganic Materials, 2024, 39(2): 145-152. |

| [3] | DING Haoming, LI Mian, LI Youbing, CHEN Ke, XIAO Yukun, ZHOU Jie, TAO Quanzheng, Johanna Rosen, YIN Hang, BAI Yuelei, ZHANG Bikun, SUN Zhimei, WANG Junjie, ZHANG Yiming, HUANG Zhenying, ZHANG Peigen, SUN Zhengming, HAN Meikang, ZHAO Shuang, WANG Chenxu, HUANG Qing. Progress in Structural Tailoring and Properties of Ternary Layered Ceramics [J]. Journal of Inorganic Materials, 2023, 38(8): 845-884. |

| [4] | DING Jianxiang, ZHANG Kaige, LIU Dongming, ZHENG Wei, ZHANG Peigen, SUN Zhengming. Ag-based Electrical Contact Material Reinforced by Ti3AlC2 Ceramic and Its Derivative Ti3C2Tx [J]. Journal of Inorganic Materials, 2022, 37(5): 567-573. |

| [5] | LI Youbing, QIN Yanqing, CHEN Ke, CHEN Lu, ZHANG Xiao, DING Haoming, LI Mian, ZHANG Yiming, DU Shiyu, CHAI Zhifang, HUANG Qing. Molten Salt Synthesis of Nanolaminated Sc2SnC MAX Phase [J]. Journal of Inorganic Materials, 2021, 36(7): 773-778. |

| [6] | ZHANG Xiao, LI Youbing, CHEN Ke, DING Haoming, CHEN Lu, LI Mian, SHI Rongrong, CHAI Zhifang, HUANG Qing. Tailoring MAX Phase Magnetic Property Based on M-site and A-site Double Solid Solution [J]. Journal of Inorganic Materials, 2021, 36(12): 1247-1255. |

| [7] | JIN Sen, WANG Zuo-Tong, DU Ya-Qiong, HU Qian-Ku, YU Jian-Gong, ZHOU Ai-Guo. Hot-pressing Sintering of Double-A-layer MAX Phase Mo2Ga2C [J]. Journal of Inorganic Materials, 2020, 35(1): 41-45. |

| [8] | DANG Xiao-Lin, FAN Xiao-Meng, YIN Xiao-Wei, MA Yu-Zhao, MA Xiao-Kang. Research Progress on Multi-functional Integration MAX Phases Modified Continuous Fiber-reinforced Ceramic Matrix Composites [J]. Journal of Inorganic Materials, 2020, 35(1): 29-34. |

| [9] | LI Mian, HUANG Qing. Recent Progress and Prospects of Ternary Layered Carbides/Nitrides MAX Phases and Their Derived Two-dimensional Nanolaminates MXenes [J]. Journal of Inorganic Materials, 2020, 35(1): 1-7. |

| [10] | LI Mian, LI You-Bing, LUO Kan, LU Jun, EKLUND Per, PERSSON Per, ROSEN Johanna, HULTMAN Lars, DU Shi-Yu, HUANG Zheng-Ren, HUANG Qing. Synthesis of Novel MAX Phase Ti3ZnC2 via A-site-element-substitution Approach [J]. Journal of Inorganic Materials, 2019, 34(1): 60-64. |

| [11] | SUN Qing, QI Qi, ZHANG Jian, PAN Fang-Zhen, SHENG Jia-Wei. Structure and Adsorption Property of Magnetic ZnFe2O4-halloysite Composite Material [J]. Journal of Inorganic Materials, 2018, 33(4): 390-396. |

| [12] | PENG Ben, QIU Gui-Bo, YUE Chang-Sheng, ZHANG Mei, GUO Ming. Controllable Synthesis of One-dimensional β-SiAlON Materials [J]. Journal of Inorganic Materials, 2014, 29(7): 706-710. |

| [13] | QIU Rui-Hao, LI Yong-Xiang, ZHANG Wen-Qing. Phase Competition in Bismuth Layered Structure Based on First Principles Thermodynamics [J]. Journal of Inorganic Materials, 2014, 29(11): 1156-1160. |

| [14] | WANG Huan, ZHANG Hua, JIN Hong-Jian, ZHAO Wen-Wen. Effect of Fuel Amount on Synthesis of Gd0.8Sr0.2CoO3-δ Cathode Material by Glycine-nitrate Process [J]. Journal of Inorganic Materials, 2013, 28(8): 818-824. |

| [15] | ZHU Zhi-PING, HUANG Ke-Long, ZHOUYi. Study on Kinetics, Thermodynamics and Mechanism for Carbon Nanotubes Adsorbing Humic Acid [J]. Journal of Inorganic Materials, 2011, 26(2): 170-174. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||