Journal of Inorganic Materials ›› 2020, Vol. 35 ›› Issue (1): 19-28.DOI: 10.15541/jim20190272

Special Issue: MAX相和MXene材料; 副主编黄庆研究员专辑; 计算材料论文精选(2020); 【虚拟专辑】分离膜,复相陶瓷(2020~2021)

Previous Articles Next Articles

HUANG Ye-Yan1,2,XU Kai1,WU Bo2,LI Peng1,CHANG Ke-Ke1( ),HUANG Feng1,HUANG Qing1

),HUANG Feng1,HUANG Qing1

Received:2019-06-03

Revised:2019-07-22

Published:2020-01-20

Online:2019-10-23

About author:HUANG Ye-Yan(1995-), female, PhD candidate. E-mail:huangyeyan@nimte.ac.cn

Supported by:CLC Number:

HUANG Ye-Yan, XU Kai, WU Bo, LI Peng, CHANG Ke-Ke, HUANG Feng, HUANG Qing. Review on Metastable Phase Diagrams: Application Roles in Specialty Ceramic Coatings[J]. Journal of Inorganic Materials, 2020, 35(1): 19-28.

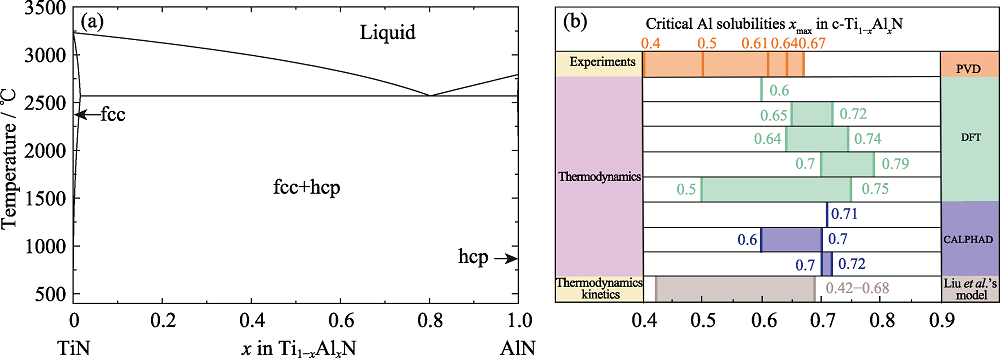

Fig. 1 The phase diagram of TiAlN (a) The stable TiN-AlN pseudo binary phase diagram[61], among which the Al solubilities of fcc phase is negligible; (b) The critical Al solubilities (xmax) in Ti1-xAlxN by different calculation methods compared with the experimental data[35-37, 40-41, 49-52, 61-66]

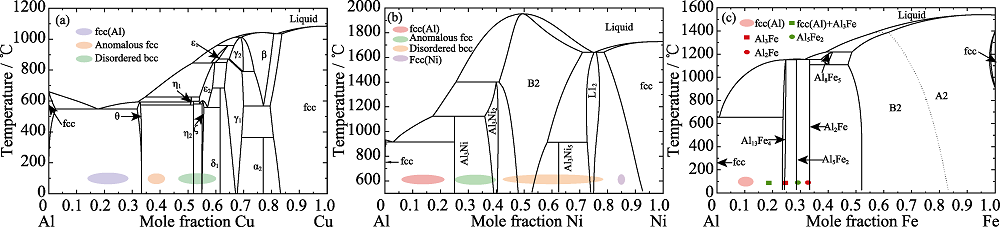

Fig. 3 Structure of the coatings deposited at room temperature compared with the phase diagrams of (a) Al-Cu[59,71], (b) Al-Ni[59,72] and (c) Al-Fe[59,70]

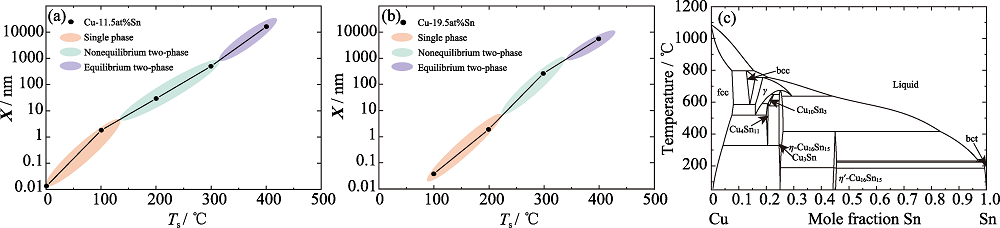

Fig. 4 (a) Diffusion distance versus temperature of Cu-11.5at% Sn obtained by Saunders and Miodownik[60] based on diffusion equation; (b) Diffusion distance versus temperature of Cu-19.5at% Sn[60] obtained by Saunders and Miodownik based on diffusion equation; (c) Phase diagram of the Cu-Sn system[73]

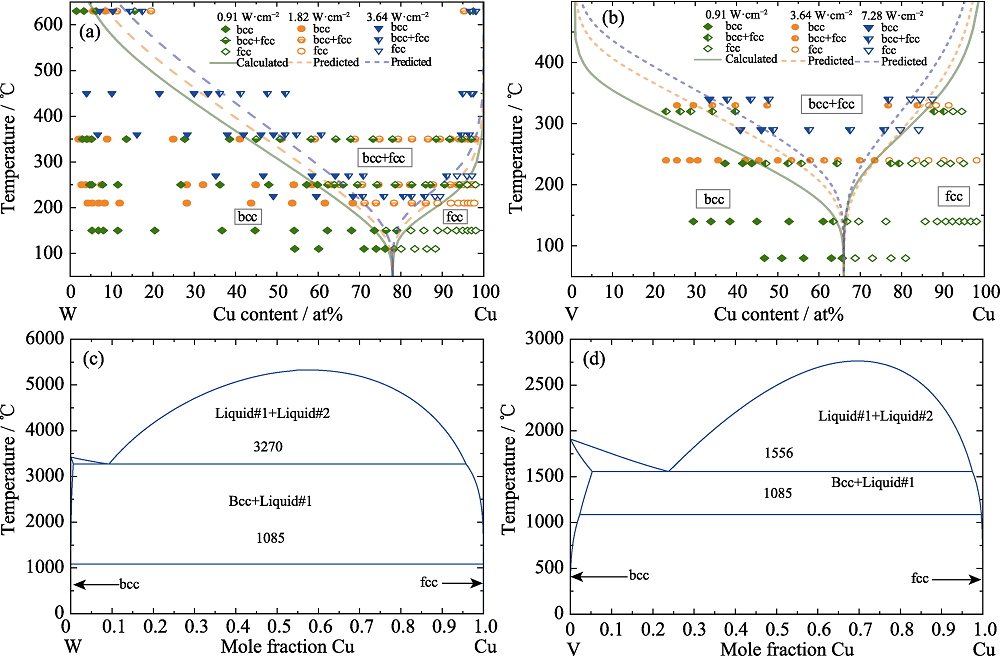

Fig. 6 (a) Calculated and predicted metastable Cu-W phase formation diagram compared with the experimental data[58]; (b) Calculated and predicted metastable Cu-V phase formation diagram compared with the experimental data[58]; (c) Phase diagram of the Cu-W system[74]; (d) Phase diagram of the Cu-V system[75]

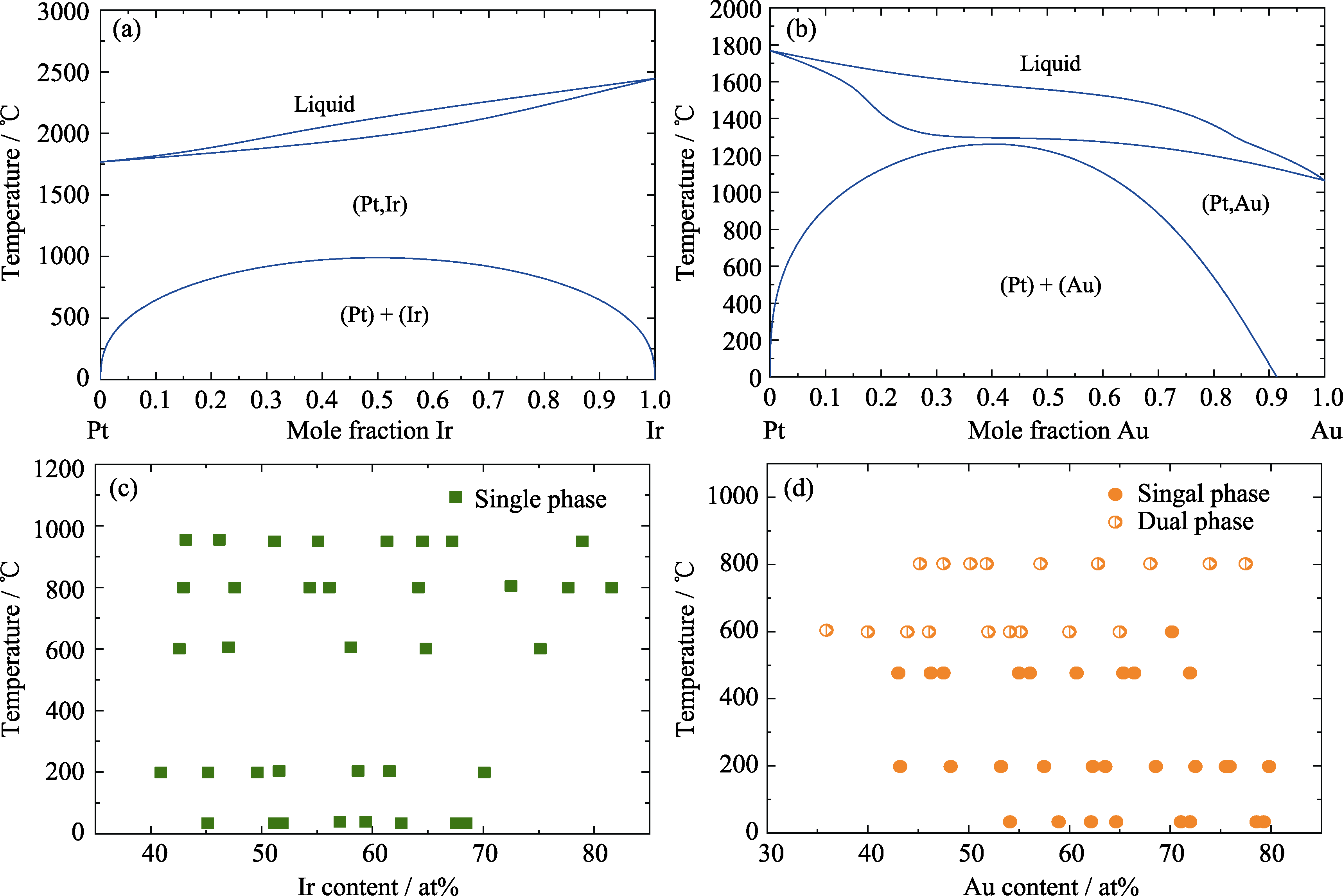

Fig. 7 (a) Phase diagram of the Pt-Ir[86] system; (b) Phase diagram of the Pt-Au system[87]; (c) Phase formation of the Pt-Ir[85] sputtered thin films; (d) Phase formation of the Pt-Au[85] sputtered thin films

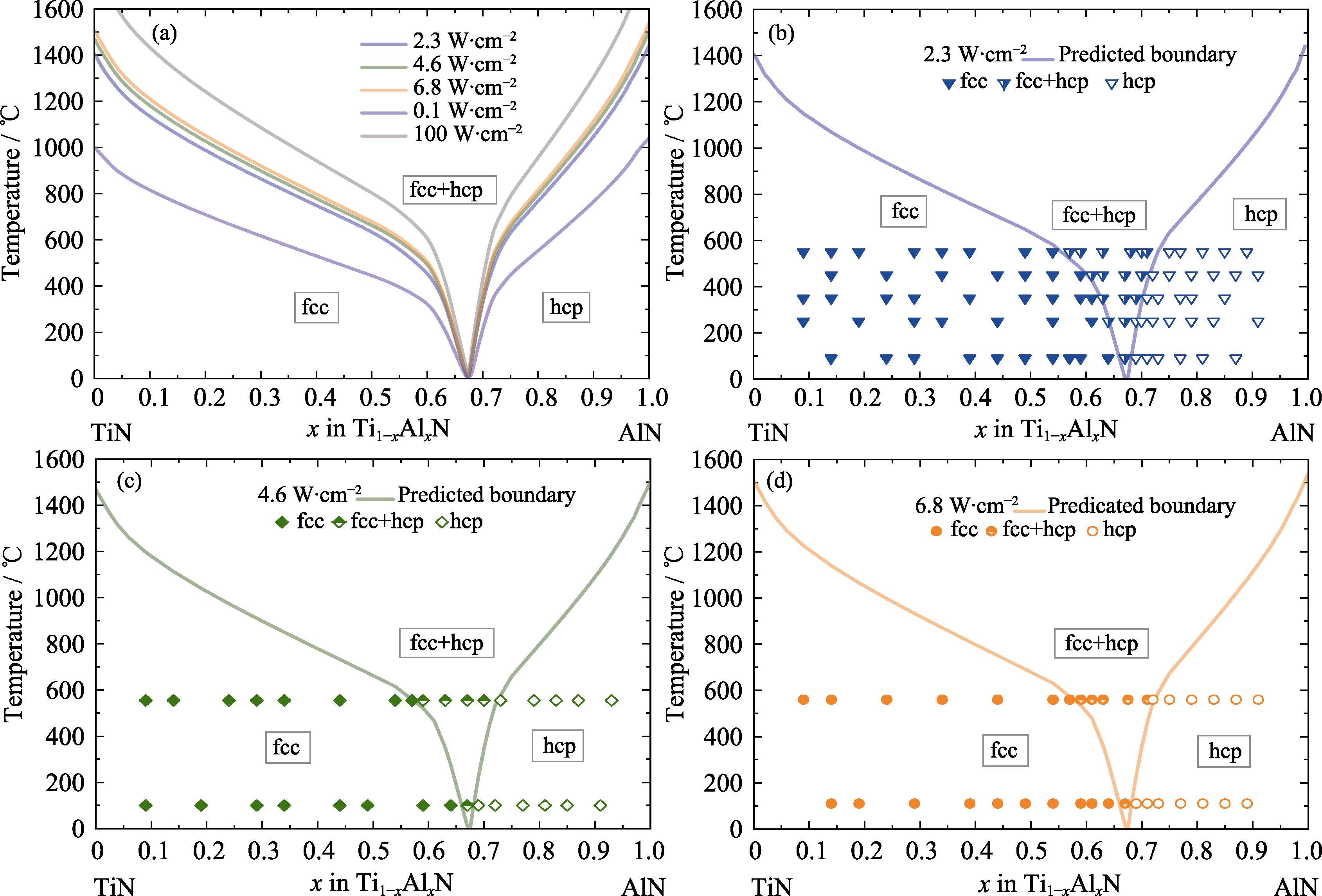

Fig. 8 Metastable Ti1-xAlxN phase formation diagrams (a) The predicted diagrams at different power densities; (b) The predicted diagram compared with the experimental data with power density of 2.3 W?cm-2 at 100-550 ℃; (c) The predicted diagram compared with the experimental data with power density of 4.6 W?cm-2 at 100-550 ℃; (d) The predicted diagram compared with the experimental data with power density of 6.8 W?cm-2 at 100-550 ℃

| [1] |

ENDRINO J C, ÅRHAMMAR C, GUTIÉRREZ C , et al. Spectral evidence of spinodal decomposition, phase transformation and molecular nitrogen formation in supersaturated TiAlN films upon annealing. Acta Materialia, 2011,59(2):6287-6296.

DOI URL |

| [2] |

RACHBAUER R, GENGLER J J, VOEVODIN A A , et al. Temperature driven evolution of thermal, electrical, and optical properties of Ti-Al-N coatings. Acta Materialia, 2012,60:2091-2096.

DOI URL PMID |

| [3] |

MAYRHOFER P, RACHBAUER R, HOLEC D , et al. Protective transition metal nitride coatings. Comprehensive Materials Processing, 2014,4:355-387.

DOI URL PMID |

| [4] |

NORRBY N, ROGSTRÖM L JOHANSSON-JÕESAAR M P , et al. In situ X-ray scattering study of the cubic to hexagonal transformation of AlN in Ti1-xAlxN. Acta Materialia, 2014,73:205-214.

DOI URL |

| [5] |

SCHRAMM I C, JÖESAAR M P J, JENSEN J , et al. Impact of nitrogen vacancies on the high temperature behavior of (Ti1-xAlx)Ny alloys. Acta Materialia, 2016,119:218-228.

DOI URL |

| [6] |

ZOU H K, CHEN L, CHANG K K , et al. Enhanced hardness and age-hardening of TiAlN coatings through Ru addition. Scripta Materialia, 2019,162:382-386.

DOI URL |

| [7] |

RAJAN S T, KARTHIKA M, BENDAVID A , et al. Apatite layer growth on glassy Zr48Cu36Al8Ag8 sputtered titanium for potential biomedical applications. Applied Surface Science, 2016,369:501-509.

DOI URL |

| [8] |

CAI C N, ZHANG C, SUN Y S , et al. ZrCuFeAlAg thin film metallic glass for potential dental applications. Intermetallics, 2017,86:80-87.

DOI URL |

| [9] |

LEE C M, CHU J P, CHANG W Z , et al. Fatigue property improvements of Ti-6Al-4V by thin film coatings of metallic glass and TiN: a comparison study. Thin Solid Films, 2014,561:33-37.

DOI URL |

| [10] |

TSAI P H, LIN Y Z, LI J B , et al. Sharpness improvement of surgical blade by means of ZrCuAlAgSi metallic glass and metallic glass thin film coating. Intermetallics, 2012,31:127-131.

DOI URL |

| [11] |

TSAI P H, LI T H, HSU K T , et al. Effect of coating thickness on the cutting sharpness and durability of Zr-based metallic glass thin film coated surgical blades. Thin Solid Films, 2016,618:36-41.

DOI URL |

| [12] |

CHU J P, JANG J S C, HUANG J C , et al. Thin film metallic glasses: unique properties and potential applications. Thin Solid Films, 2012,520:5097-5122.

DOI URL |

| [13] | GORDON R G . Criteria for choosing transparent conductors. MRS Bulletin, 2000,25:52-57. |

| [14] |

CHENG C H, TING J M . Transparent conducting GZO, Pt/GZO, and GZO/Pt/GZO thin films. Thin Solid Films, 2007,516:203-207.

DOI URL PMID |

| [15] |

KIM D . Improved electrical and optical properties of GZO films with a thin TiO2 buffer layer deposited by RF magnetron sputtering. Ceramics International, 2014,40:1457-1460.

DOI URL |

| [16] |

WANG H L, SUN Y H, FANG L , et al. Growth and characterization of high transmittance GZO films prepared by Sol-Gel method. Thin Solid Films, 2016,615:19-24.

DOI URL |

| [17] |

LU L F, SHEN H L, FENG J , et al. The enhanced conductivity of AZO thin films on soda lime glass with an ultrathin Al2O3 buffer layer. Physica B, 2010,405:3320-3323.

DOI URL |

| [18] |

SHEN H L, ZHANG H, LU L F , et al. Preparation and properties of AZO thin films on different substrates. Progress in Natural Science: Materials International, 2010,20:44-48.

DOI URL |

| [19] | SUBRAMANYAM T K, GOUTHAM P, PAVAN KUMAR S , et al. Optimization of sputtered AZO thin films for device application. Materials Today: Proceedings, 2018,5:10851-10859. |

| [20] | LÜ K, ZHU B L, LI K , et al. Effect of hydrogen and Cu interlayer on the optical and electrical properties of GZO thin film. Journal of Inorganic Materials, 2014,29(5):494-497. |

| [21] | CHEN D, LÜ J G, HUANG J Y , et al. Performances of GaN-based LEDs with AZO films as transparent electrodes. Journal of Inorganic Materials, 2013,28(6):650-652. |

| [22] | QIN X J, HAN S H Z, ZHAO L , et al. Fabrication of transparent conductive Al-doped ZnO thin films by aerosol-assisted chemical vapour deposition. Journal of Inorganic Materials, 2011,26(6):608-611. |

| [23] |

AYDOGAN E, WEAVER J S, MALOY S A , et al. Microstructure and mechanical properties of FeCrAl alloys under heavy ion irradiations. Journal of Nuclear Materials, 2018,503:250-262.

DOI URL |

| [24] |

DRYEPONDT S, UNOCIC K A, HOELZER D T , et al. Development of low-Cr ODS FeCrAl alloys for accident-tolerant fuel cladding. Journal of Nuclear Materials, 2018,501:59-71.

DOI URL |

| [25] |

GUSSEV M N, CAKMAK E, FIELD K G , et al. Impact of neutron irradiation on mechanical performance of FeCrAl alloy laser-beam weldments. Journal of Nuclear Materials, 2018,504:221-233.

DOI URL |

| [26] |

HOGGAN R E, HE L F, HARP J M , et al. Interdiffusion behavior of U3Si2 with FeCrAl via diffusion couple studies. Journal of Nuclear Materials, 2018,502:356-369.

DOI URL |

| [27] |

JIN D L, NI N, GUO Y , et al. Corrosion of the bonding at FeCrAl/ Zr alloy interfaces in steam. Journal of Nuclear Materials, 2018,508:411-422.

DOI URL |

| [28] |

PARK D, MOUCHE P A, ZHONG W C , et al. TEM/STEM study of zircaloy-2 with protective FeAl(Cr) layers under simulated BWR environment and high-temperature steam exposure. Journal of Nuclear Materials, 2018,502:95-105.

DOI URL |

| [29] |

TANG C C, JIANU A, STEINBRUECK M , et al. Influence of composition and heating schedules on compatibility of FeCrAl alloys with high-temperature steam. Journal of Nuclear Materials, 2018,511:496-507.

DOI URL |

| [30] |

CHANG K K, MENG F P, GE F F , et al. Theory-guided bottom- up design of the FeCrAl alloys as accident tolerant fuel cladding materials. Journal of Nuclear Materials, 2019,516:63-72.

DOI URL |

| [31] |

CAIRNEY J M, HARRIS S G, MUNROE P R , et al. Transmission electron microscopy of TiN and TiAlN thin films using specimens prepared by focused ion beam milling. Surface and Coatings Technology, 2004,183:239-246.

DOI URL |

| [32] |

RACHBAUER R, STERGAR E, MASSL S , et al. Three-dimensional atom probe investigations of Ti-Al-N thin films. Scripta Materialia, 2009,61:725-728.

DOI URL |

| [33] | WEBER F R, FONTAINE F, SCHEIB M, , et al. Cathodic arc evaporation of (Ti, Al) N coatings and (Ti, Al) N/TiN multilayer-coatings-correlation between lifetime of coated cutting tools, structural and mechanical film properties. Surface and Coatings Technology, 2004,177-178:227-232 |

| [34] |

MÜNZ W D . A new alternative to TiN coatings. Journal of Vacuum Science and Technology A, 1986,4(6):2717-2725.

DOI URL PMID |

| [35] |

WAHLSTRÖM U, HULTMAN L, SUNDGREN J E , et al. Crystal growth and microstructure of polycrystalline Ti1-xAlxN alloy films deposited by ultra-high-vacuum dual-target magnetron sputtering. Thin Solid Films, 1993,235:62-70.

DOI URL |

| [36] |

ZHOU M, MAKINO Y, NOSE M , et al. Phase transition and properties of Ti-Al-N thin films prepared by rf-plasma assisted magnetron sputtering. Thin Solid Films, 1999,339:203-208.

DOI URL |

| [37] |

HÖRLING A, HULTMAN L, ODÉN M , et al. Mechanical properties and machining performance of Ti1-xAlxN-coated cutting tools. Surface and Coatings Technology, 2005,191:384-392.

DOI URL PMID |

| [38] |

KUTSCHEJ K, MAYRHOFER P, KATHREIN M , et al. Structure, mechanical and tribological properties of sputtered Ti1-xAlxN coatings with 0.5≤x≤0.75. Surface and Coatings Technology, 2005,200:2358-2365.

DOI URL |

| [39] |

RAFAJA D, POKLAD A, SCHREIBER G , et al. On the preferred orientation in Ti1-xAlxN and Ti1-x-yAlxSiyN thin films. Zeitschrift für Metallkunde, 2005,96:738-742.

DOI URL PMID |

| [40] |

GRECZYNSKI G, LU J, JOHANSSON M , et al. Role of Tin + and Aln + ion irradiation(n=1, 2) during Ti1-xAlxN alloy film growth in a hybrid HIPIMS/magnetron mode. Surface and Coatings Technology, 2012,206:4202-4211.

DOI URL |

| [41] |

GROSSMANN B, SCHALK N, CZETTL C , et al. Phase composition and thermal stability of arc evaporated Ti1-xAlxN hard coatings with 0.4≤x≤0.67. Surface and Coatings Technology, 2017,309:687-693.

DOI URL |

| [42] |

HANS M, MUSIC D, CHEN Y T , et al. Crystallite size-dependent metastable phase formation of TiAlN coatings. Scientific Reports, 2017,7(16096):1-7.

DOI URL PMID |

| [43] | SPENCER P, HOLLECK H . Application of a thermochemical data-bank system to the calculation of metastable phase formation during PVD od carbide, nitride and boride coatings. High Temperature Science, 1990,27:295-309. |

| [44] |

STOLTEN H, SPENCER P, NEUSCHÜTZ D , et al. Estimation of formation enthalpies for transition metal mono nitrides, carbides and oxides. Journal de Chimie Physique, 1993,90:209-219.

DOI URL |

| [45] |

CHEN Q, SUNDMAN B . Thermodynamic assessment of the Ti-Al-N system. Journal of Phase Equilibria, 1998,19(20):146-160.

DOI URL |

| [46] | ZENG K J, SCHMID-FETAER R . Thermodynamic Modeling and Applications of the Ti-Al-N Phase Diagram. Thermodynamics of Alloy Formation, 1997, 275-293. |

| [47] | SPENCER P . Thermodynamic prediction of metastable coating structures in PVD processes. Zeitschrift für Metallkunde, 2001,92:1145-1150. |

| [48] |

HUGOSSON H W, HÖGBERG H, ALGREN M , et al. Theory of the effects of substitutions on the phase stabilities of Ti1-xAlxN. Journal of Applied Physics, 2003,93(8):4505-4511.

DOI URL |

| [49] | MAYRHOFER P, MUSIC D, SCHNEIDER J , et al. Influence of the Al distribution on the structure, elastic properties, and phase stability of supersaturated Ti1-xAlxN. Journal of Applied Physics, 2006,100:1-5. |

| [50] |

HOLEC D, ROVERE F, MAYRHOFER P H , et al. Pressure- dependent stability of cubic and wurtzite phases within the TiN-AlN and CrN-AlN systems. Scripta Materialia, 2010,62:349-352.

DOI URL |

| [51] |

EUCHNER H, MAYRHOFER P . Vacancy-dependent stability of cubic and wurtzite Ti1-xAlxN. Surface and Coatings Technology, 2015,275:214-218.

DOI URL PMID |

| [52] |

SHULUMBA N, HELLMAN O, RAZA Z , et al. Lattice vibrations change the solid solubility of an alloy at high temperatures. Physical Review Letters, 2016,117(11):1-6.

DOI URL PMID |

| [53] |

SANGIOVANNI D, EDSTRÖM D, HULTMAN L , et al. Dynamics of Ti, N, and TiNx (x= 1-3) admolecule transport on TiN (001) surfaces. Physical Review B, 2012,8:1-10.

DOI URL |

| [54] |

SANGIOVANNI D, EDSTRÖM D, HULTMAN L , et al. Ab initio.and classical molecular dynamics simulations of N2 desorption from TiN (001) surfaces. Surface Science, 2014,624:25-31.

DOI URL |

| [55] | SANGIOVANNI D, ALLING B, STENETEG P , et al. Self- interstitial diffusion, and Frenkel-pair formation/dissociation in B1 TiN studied by ab initio and classical molecular dynamics with optimized potentials. Physical Review B, 2015,91:1-17. |

| [56] | ALLING B, STENETEG P, THOLANDER C , et al. Configurational disorder effects on adatom mobilities on Ti1-xAlxN (001) surfaces from first principles. Physical Review B, 2012,85(24):1-5. |

| [57] |

CHANG K K, TO BABEN M, MUSIC D , et al. Estimation of the activation energy for surface diffusion during metastable phase formation. Acta Materialia, 2015,98:135-140.

DOI URL |

| [58] |

CHANG K K, MUSIC D, TO BABEN M , et al. Modeling of metastable phase formation diagrams for sputtered thin films. Science and Technology of Advanced Materials, 2016,17:210-219.

DOI URL PMID |

| [59] | CANTOR B, CAHN R . Metastable alloy phases by co-sputtering. Acta Materialia, 1976,24:845-852. |

| [60] |

SAUNDERS N, MIODOWNIK A P . Phase formation in co-deposited metallic alloy thin flms. Journal of Materials Science, 1987,22:629-637.

DOI URL PMID |

| [61] |

LIU S D, CHANG K K, MRÁZ S , et al. Modeling of metastable phase formation for sputtered Ti1-xAlxN thin films. Acta Materialia, 2019,165:615-625.

DOI URL PMID |

| [62] |

KIM K H, LEE S H . Comparative studies of TiN and Ti1-xAlxN by plasma-assisted chemical vapor deposition using a TiCl4/AlCl3/N2/ H2/Ar gas mixture. Thin Solid Films, 1996,283:165-170.

DOI URL |

| [63] |

LEE S H, KIM B J, KIM H H , et al. Structural analysis of AlN and (Ti1-xAlx) N coatings made by plasma enhanced chemical vapor deposition. Journal of Applied Physics, 1996,80(3):1469-1473.

DOI URL |

| [64] | PRANGE R, CREMER R, NEUSCHÜTZ D , et al. Plasma- enhanced CVD of Plasma- enhanced CVD of (Ti,Al) N films from chloridic precursors in a DC glow discharge. Surface and Coatings Technology 2000, 133-134:208-214. |

| [65] |

ENDLER I, HÖHN M, HERRMANN M , et al. Novel aluminum- rich Ti1-xAlxN coatings by LPCVD. Surface and Coatings Technology, 2008,203:530-533.

DOI URL PMID |

| [66] |

TODT T, ZALESAK J, DANIEL R , et al. Al-rich cubic Al0. 8Ti0. 2N coating with self-organized nano-lamellar microstructure: thermal and mechanical properties. Surface and Coatings Technology, 2016,291:89-93.

DOI URL |

| [67] | GROVENOR C R M, HENTZELL H T G, SMITH D A , et al. The development of grain structure during growth of metallic films. Acta Materialia The development of grain structure during growth of metallic films. Acta Materialia, 1984,32(5):(5):773-781. |

| [68] |

PETROV I, BARNA P B, HULTMAN L , et al. Microstructural evolution during film growth. Journal of Vacuum Science & Technology A, 2003,21(5):S117-S128.

DOI URL PMID |

| [69] | EINSTEIN A . Elementare teorie der brownschen bewegung. Z Elektrochem, 1908,14:371-381. |

| [70] |

SUNDMAN B, OHNUMA I, DUPIN N , et al. An assessment of the entire Al-Fe system including D03 ordering. Acta Materialia, 2009,57:2896-2908.

DOI URL |

| [71] |

LIANG S M, SCHMID-FETZER R . Thermodynamic assessment of the Al-Cu-Zn system, part II: Al-Cu binary system. CALPHAD, 2015,51:252-260.

DOI URL |

| [72] |

ZHOU C Y, CUI J X, GUO C P , et al. Thermodynamic description of the Al-Ge-Ni system over the whole composition and temperature ranges. CALPHAD, 2017,58:138-150.

DOI URL |

| [73] |

LI M, DU Z M, GUO C , et al. Thermodynamic optimization of the Cu-Sn and Cu-Nb-Sn systems. Journal of Alloys and Compounds, 2009,477:104-117.

DOI URL |

| [74] |

SUBRAMANINA P R, LAUGHLIN D E . Cu-W (copper tungsten). Indian Institute of Metals, 1991,12:76-79.

DOI URL PMID |

| [75] |

ZHAO J R, DU Y, ZHANG L J , et al. Thermodynamic reassessment of the Cu-V system supported by key experiments. CALPHAD, 2008,32:252-255.

DOI URL |

| [76] |

WEILAND R, LUPTON D F, FISCHER B , et al. High-temperature mechanical properties of the platinum group metals. Platinum Metals Review, 2006,50(4):158-170.

DOI URL PMID |

| [77] |

GANSKE G, SLAVCHEVA E, VAN OOYEN A , et al. Sputtered platinum-iridium layers as electrode material for functional electrostimulation. Thin Solid Films, 2011,519:3965-3970.

DOI URL |

| [78] |

TSENG S F, LEE C T, Huang K C , et al. Mechanical properties of Pt-Ir and Ni-Ir binary alloys for glass-molding dies coating. Journal of Nanoscience and Nanotechnology, 2011,11(10):8682-8688.

DOI URL |

| [79] |

YI A Y, JAIN A . Compression molding of aspherical glass lenses-a combined experimental and numerical analysis. Journal of the American Ceramic Society, 2005,88(3):579-586.

DOI URL |

| [80] | KLOCKE F, DAMBON O, YI A Y , et al. Process Chain for the Replication of Complex Optical Glass Components. Berlin Heidelberg: Springer, 2013: 119-132. |

| [81] | MA K J, CHIEN H H, CHUAN W H , et al. Design of protective coatings for glass lens molding. Key Engineering Materials Design of protective coatings for glass lens molding. Key Engineering Materials, 2008,364-366:655-661. |

| [82] |

KLOCKE F, DAMBON O, GEORGIADIS K , et al. Comparison of nitride and noble metal coatings for precision glass molding tools. Key Engineering Materials, 2010,438:9-6.

DOI URL |

| [83] |

BOBZIN K, BAGCIVAN N, EWERING M , et al. Influence of interlayer thickness of a thin noble metal MSIP-PVD coating on compound and system properties for glass lens moulding. Production Engineering, 2012,6:311-318.

DOI URL |

| [84] | BOBZIN K, BAGCIVAN N, BRÖGELMANN T , et al. Development and qualification of a MSIP PVD iridium coating for precision glass moulding. Materials Sciences and Application, 2013,44(8):673-678. |

| [85] |

SAKSENA A, CHIEN Y C, CHANG K K , et al. Metastable phase formation of Pt-X (X= Ir, Au) thin flms. Scientific Reports, 2018,8(1):10198.

DOI URL PMID |

| [86] |

YAMABE-MITARAI Y, AOYAGI T, ABE T , et al. An investigation of phase separation in the Ir-Pt binary system. Journal of Alloys and Compounds, 2009,484:327-334.

DOI URL |

| [87] |

XU X N, REN Y P, LI C F , et al. Thermodynamic assessment of Au-Pt system. Transactions of Nonferrous Metals Society of China, 2012,22:1432-1436.

DOI URL |

| [1] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [2] | TANG Xinli, DING Ziyou, CHEN Junrui, ZHAO Gang, HAN Yingchao. In vivo Distribution and Metabolism of Calcium Phosphate Nanomaterials Based on Fluorescent Labeling with Rare Earth Europium Ions [J]. Journal of Inorganic Materials, 2025, 40(7): 754-764. |

| [3] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [4] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [5] | ZHANG Bihui, LIU Xiaoqiang, CHEN Xiangming. Recent Progress of Hybrid Improper Ferroelectrics with Ruddlesden-Popper Structure [J]. Journal of Inorganic Materials, 2025, 40(6): 587-608. |

| [6] | WU Jie, YANG Shuai, WANG Mingwen, LI Jinglei, LI Chunchun, LI Fei. Textured PT-based Piezoelectric Ceramics: Development, Status and Challenge [J]. Journal of Inorganic Materials, 2025, 40(6): 575-586. |

| [7] | JIANG Kun, LI Letian, ZHENG Mupeng, HU Yongming, PAN Qinxue, WU Chaofeng, WANG Ke. Research Progress on Low-temperature Sintering of PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 627-638. |

| [8] | TIAN Ruizhi, LAN Zhengyi, YIN Jie, HAO Nanjing, CHEN Hangrong, MA Ming. Microfluidic Technology Based Synthesis of Inorganic Nano-biomaterials: Principles and Progress [J]. Journal of Inorganic Materials, 2025, 40(4): 337-347. |

| [9] | ZHANG Jiguo, WU Tian, ZHAO Xu, YANG Fan, XIA Tian, SUN Shien. Improvement of Cycling Stability of Cathode Materials and Industrialization Process for Sodium-ion Batteries [J]. Journal of Inorganic Materials, 2025, 40(4): 348-362. |

| [10] | YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 245-255. |

| [11] | CHEN Guangchang, DUAN Xiaoming, ZHU Jinrong, GONG Qing, CAI Delong, LI Yuhang, YANG Donglei, CHEN Biao, LI Xinmin, DENG Xudong, YU Jin, LIU Boya, HE Peigang, JIA Dechang, ZHOU Yu. Advanced Ceramic Materials in Helicopter Special Structures: Research Progress and Application Prospect [J]. Journal of Inorganic Materials, 2025, 40(3): 225-244. |

| [12] | FAN Xiaobo, ZU Mei, YANG Xiangfei, SONG Ce, CHEN Chen, WANG Zi, LUO Wenhua, CHENG Haifeng. Research Progress on Proton-regulated Electrochemical Ionic Synapses [J]. Journal of Inorganic Materials, 2025, 40(3): 256-270. |

| [13] | HAIREGU Tuxun, GUO Le, DING Jiayi, ZHOU Jiaqi, ZHANG Xueliang, NUERNISHA Alifu. Research Progress of Optical Bioimaging Technology Assisted by Upconversion Fluorescence Probes in Tumor Imaging [J]. Journal of Inorganic Materials, 2025, 40(2): 145-158. |

| [14] | SUN Shujuan, ZHENG Nannan, PAN Haokun, MA Meng, CHEN Jun, HUANG Xiubing. Research Progress on Preparation Methods of Single-atom Catalysts [J]. Journal of Inorganic Materials, 2025, 40(2): 113-127. |

| [15] | TAO Guilong, ZHI Guowei, LUO Tianyou, OUYANG Peidong, YI Xinyan, LI Guoqiang. Progress on Key Technologies of Cavity-structured Thin Film Bulk Acoustic Wave Filter [J]. Journal of Inorganic Materials, 2025, 40(2): 128-144. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||