Journal of Inorganic Materials ›› 2019, Vol. 34 ›› Issue (7): 721-726.DOI: 10.15541/jim20180447

Previous Articles Next Articles

ZHANG Xiao-Chen1,WANG Xue-Mei2,WANG Chun-Lei2( )

)

Received:2018-09-20

Revised:2018-11-13

Published:2019-07-20

Online:2019-06-26

Supported by:CLC Number:

ZHANG Xiao-Chen, WANG Xue-Mei, WANG Chun-Lei. Influences of Sintering Methods on Microstructure and Physical Property of (K,Na,Li)(Nb,Sb,Ta)O3 Piezoelectric Ceramics[J]. Journal of Inorganic Materials, 2019, 34(7): 721-726.

| Sample | Sintering conditions | ρ/(g?cm-3) | d33/(pC?N-1) | kp |

|---|---|---|---|---|

| CS | 1090 ℃, 5 h | 4.40 | 363 | 0.48 |

| TSS-1 | 1130 ℃/1050 ℃, 4 h | 4.43 | 369 | 0.47 |

| TSS-2 | 1140 ℃/1050 ℃, 4 h | 4.44 | 370 | 0.43 |

| TSS-3 | 1150 ℃/1040 ℃, 4 h | 4.36 | 358 | 0.44 |

| TSS-4 | 1150 ℃/1050 ℃, 4 h | 4.47 | 387 | 0.49 |

| TSS-5 | 1150 ℃/1060 ℃, 4 h | 4.42 | 378 | 0.48 |

| TSS-6 | 1160 ℃/1050 ℃, 4 h | 4.35 | 379 | 0.46 |

Table 1 Physical property of KNLNST ceramics prepared under different sintering conditions

| Sample | Sintering conditions | ρ/(g?cm-3) | d33/(pC?N-1) | kp |

|---|---|---|---|---|

| CS | 1090 ℃, 5 h | 4.40 | 363 | 0.48 |

| TSS-1 | 1130 ℃/1050 ℃, 4 h | 4.43 | 369 | 0.47 |

| TSS-2 | 1140 ℃/1050 ℃, 4 h | 4.44 | 370 | 0.43 |

| TSS-3 | 1150 ℃/1040 ℃, 4 h | 4.36 | 358 | 0.44 |

| TSS-4 | 1150 ℃/1050 ℃, 4 h | 4.47 | 387 | 0.49 |

| TSS-5 | 1150 ℃/1060 ℃, 4 h | 4.42 | 378 | 0.48 |

| TSS-6 | 1160 ℃/1050 ℃, 4 h | 4.35 | 379 | 0.46 |

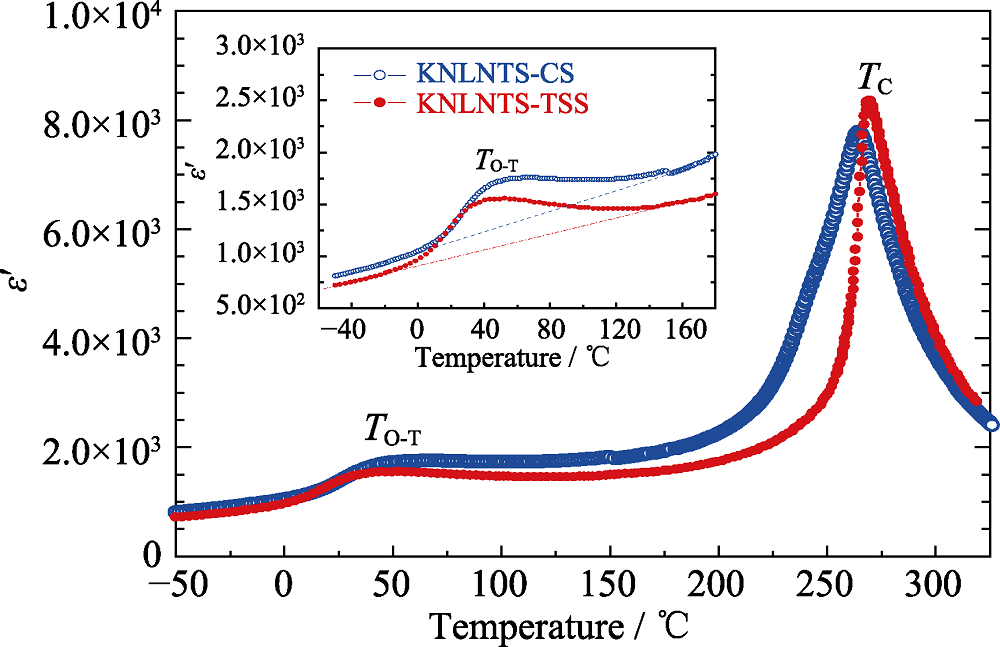

Fig. 2 Temperature dependence of dielectric permittivity ε' of two representative unpoled KNLNST ceramics, prepared by conventional sintering and two-step sintering, respectively. Inset is partially enlarged curves of dielectric temperature peak of the phase transition from orthorhombic to tetragonal phase

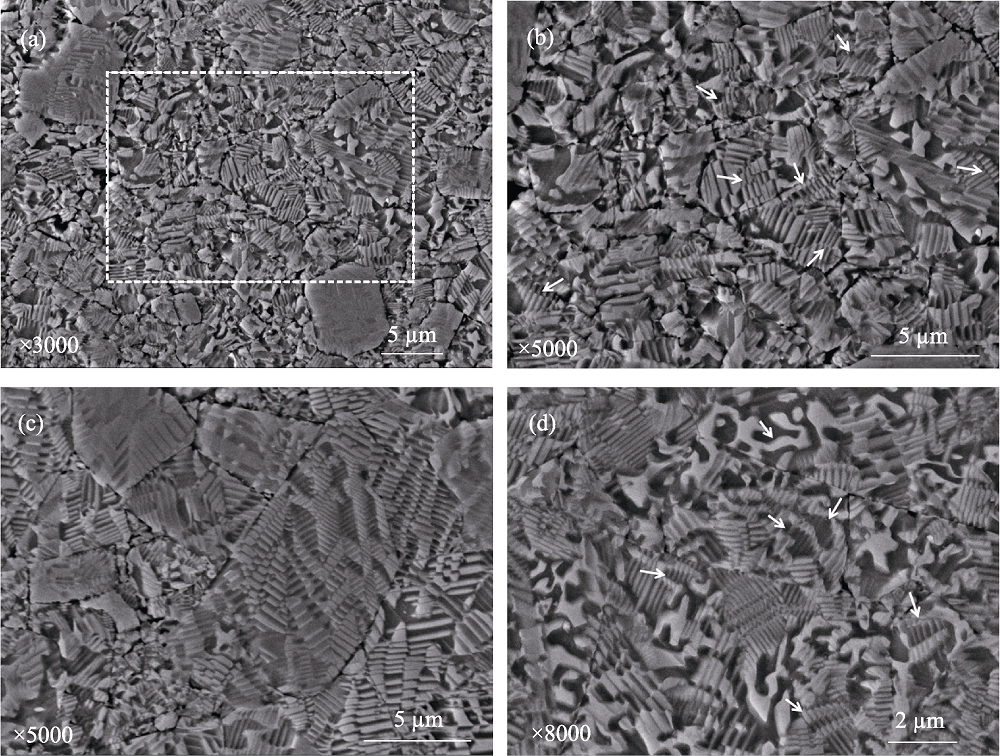

Fig. 3 Typical SEM images of domain patterns observed in the two unpoled representative KNLNST ceramics (a) KNLNST-CS ceramic; (b) Partially enlarged view of (a); (c) and (d) KNLNST-TSS ceramic, corresponding to different locations of the same specimen

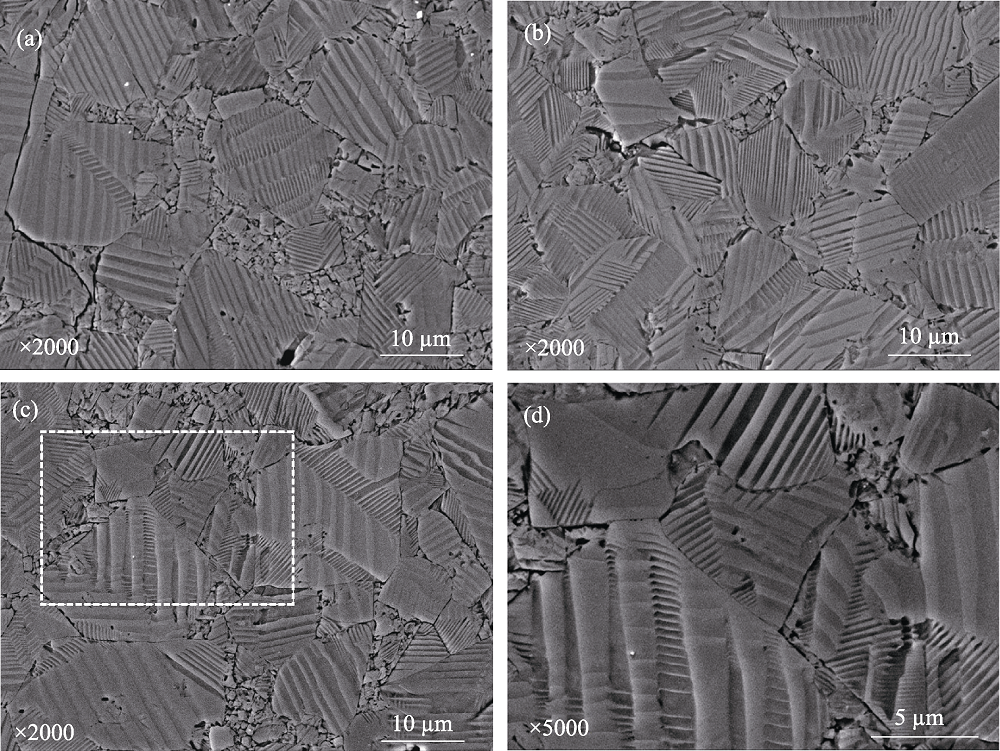

Fig. 5 Typical SEM images of microstructure and domain patterns observed in a poled KNLNST-TSS ceramic. (a-c) Correspond to different positions of the same sample; (d) A partial enlarged image in (c)

| [1] | GAO Y, ZHANG J L, ZONG X J , et al. Extremely temperature- stable piezoelectric properties of orthorhombic phase in (K,Na) NbO3- based ceramics. J. Appl. Phys., 2010, 107(7): 074101-1-5. |

| [2] |

SAITO Y, TAKAO H, TANI T , et al. Lead-free piezoceramics. Nature, 2004,432(4):84-87.

DOI |

| [3] |

GUO Y P, KAKIMOTO K, OHSATO H . Phase transitional behavior and piezoelectric properties of (Na0.5K0.5)NbO3-LiNbO3 ceramics. Appl. Phys. Lett., 2004,85(18):4121-4123.

DOI URL |

| [4] |

GUO Y P, KAKIMOTO K, OHSATO H .( Na0.5K0.5)NbO3-LiTaO3 lead-free piezoelectric ceramics. Mater. Lett., 2005. 59(2/3):241-244.

DOI URL |

| [5] | FU J, ZUO R Z, WANG X H , et al. Polymorphic phase transition and enhanced piezoelectric properties of LiTaO3-modified (Na0.52K0.48)(Nb0.93Sb0.07)O3 lead-free ceramics. J. Phys. D: Appl. Phys., 2009, 42(1): 012006-1-4. |

| [6] |

GAO Y, ZHANG J L, QIN Y L , et al. Remarkably strong piezoelectricity of lead-free (K0.45Na0.55)0.98Li0.02(Nb0.77Ta0.18Sb0.05)O3 ceramic. J. Am. Ceram. Soc., 2011,94(9):2968-2973.

DOI URL |

| [7] |

ZHANG B Y, WU J G, CHENG X J , et al. Lead-free piezoelectrics based on potassium-sodium niobate with giant d33. ACS Appl. Mater. Interfaces, 2013,5(16):7718-7725.

DOI URL |

| [8] |

WANG X P, WU J G, XIAO D Q , et al. Giant piezoelectricity in potassium-sodium niobate lead-free ceramics.[J]. Am. Chem. Soc., 2014,136(7):2905-2910.

DOI URL |

| [9] |

ZHENG T, WU J G, CHEN Q , et al. Composition-driven phase boundary and piezoelectricity in potassium-sodium niobate-based ceramics. ACS Appl. Mater. Interfaces, 2015,7(36):20332-20341.

DOI URL |

| [10] |

WU B, WU H J, WU J G , et al. Giant piezoelectricity and high Curie temperature in nanostructured alkali niobate lead-free piezoceramics through phase coexistence.[J]. Am. Chem. Soc., 2016,138(47):15459-15464.

DOI URL |

| [11] |

XU K, LI J, LÜ X , et al. Superior piezoelectric properties in potassium- sodium niobate lead-free ceramics. Adv. Mater., 2016,28(38):8519-8523.

DOI URL |

| [12] |

ZHANG M H, WANG K, DU Y J , et al. High and temperature- insensitive piezoelectric strain in alkali niobate lead-free perovskite.[J]. Am. Chem. Soc., 2017,139(10):3889-3895.

DOI URL |

| [13] |

JAEGER E, EGERTON L . Hot pressing of potassium-sodium niobates.[J]. Am. Ceram. Soc., 1962,45(5):209-213.

DOI URL |

| [14] |

ZHANG S J, LEE H J, MA C , et al. Sintering effect on microstructure and properties of (K, Na)NbO3 ceramics. J. Am. Ceram. Soc., 2011,94(11):3659-3665.

DOI URL |

| [15] |

LI J F, WANG K, ZHANG B P , et al. Ferroelectric and piezoelectric properties of fine-grained Na0.5K0.5NbO3 lead-free piezoelectric ceramics prepared by spark plasma sintering.[J]. Am. Ceram. Soc., 2006,89(2):706-709.

DOI URL |

| [16] |

ERIKSON M, YAN H X, VIOLA G , et al. Ferroelectric domain structures and electrical properties of fine-grained lead-free sodium potassium niobate ceramics.[J]. Am. Ceram. Soc., 2011,94(10):3391-3396.

DOI URL |

| [17] |

CHEN I W, WANG H X . Sintering dense nanocrystalline ceramics without final-stage grain growth. Nature, 2000,404(9):168-71.

DOI |

| [18] |

WANG X H, CHEN P L, CHEN I W . Two-step sintering of ceramics with constant grain-size.[J]. Am. Ceram. Soc., 2006,89(2):431-437.

DOI URL |

| [19] |

WANG X H, DENG X Y, BAI H L , et al. Two-step sintering of ceramics with constant grain-size, II: BaTiO3 and Ni-Cu-Zn ferrite.[J]. Am. Ceram. Soc., 2006,89(2):438-443.

DOI URL |

| [20] |

FANG J, WANG X H, TIAN Z B , et al. Two-step sintering: an approach to broaden the sintering temperature range of alkaline niobate-based lead-free piezoceramics.[J]. Am. Ceram. Soc., 2010,93(11):3552-3555.

DOI URL |

| [21] |

PANG X M, QIU J H, ZHU K J , et al. ( K,Na)NbO3-based lead-free piezoelectric ceramics manufactured by two-step sintering. Ceram. Int., 2012,38(3):2521-2527.

DOI URL |

| [22] |

WU J G, WANG Y M . Two-step sintering of new potassium sodium niobate ceramics: a high d33 and wide sintering temperature range. Dalton Trans., 2014,43(34):12836-12841.

DOI URL |

| [23] |

ZHANG J L, QIN Y L, GAO Y , et al. Improvement of physical properties for KNN-based ceramics by modified two-step sintering.[J]. Am. Ceram. Soc., 2014,97(3):759-764.

DOI URL |

| [24] |

ARLT G, SASKO P . Domain configuration and equilibrium size of domains in BaTiO3 ceramics.[J]. Appl. Phys., 1980,51(9):4956-496.

DOI URL |

| [25] |

JUAREZ R L, PERALTA O N, GARCÍA F G , et al. Ferroelectric domain structure of lead-free potassium-sodium niobate ceramics.[J]. Eur. Ceram. Soc., 2011,31(9):1861-1864.

DOI URL |

| [1] | CHEN Xiangjie, LI Ling, LEI Tianfu, WANG Jiajia, WANG Yaojin. Enhanced Piezoelectric Properties of (1-x)(0.8PZT-0.2PZN)-xBZT Ceramics via Phase Boundary and Domain Engineering [J]. Journal of Inorganic Materials, 2025, 40(6): 729-734. |

| [2] | MU Haojie, ZHANG Yuanjiang, YU Bin, FU Xiumei, ZHOU Shibin, LI Xiaodong. Preparation and Properties of ZrO2 Doped Y2O3-MgO Nanocomposite Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 281-289. |

| [3] | GAO Tianyu, LIU Dong, ZHAO Sixue, DENG Wei, ZHANG Boping, ZHU Lifeng. K0.5Na0.5NbO3-based Piezoelectric Ceramics: Excellent Temperature Stability and Application in Type 1-3 Transducer [J]. Journal of Inorganic Materials, 2025, 40(3): 297-304. |

| [4] | HUANG Jianfeng, LIANG Ruihong, ZHOU Zhiyong. Effects of W/Cr Co-doping on the Crystal Structure and Electric Properties of CaBi2Nb2O9 Piezoceramics [J]. Journal of Inorganic Materials, 2024, 39(8): 887-894. |

| [5] | FAN Wugang, CAO Xiong, ZHOU Xiang, LI Ling, ZHAO Guannan, ZHANG Zhaoquan. Anticorrosion Performance of 8YSZ Ceramics in Simulated Aqueous Environment of Pressurized Water Reactor [J]. Journal of Inorganic Materials, 2024, 39(7): 803-809. |

| [6] | CHEN Qian, SU Haijun, JIANG Hao, SHEN Zhonglin, YU Minghui, ZHANG Zhuo. Progress of Ultra-high Temperature Oxide Ceramics: Laser Additive Manufacturing and Microstructure Evolution [J]. Journal of Inorganic Materials, 2024, 39(7): 741-753. |

| [7] | JIANG Lingyi, PANG Shengyang, YANG Chao, ZHANG Yue, HU Chenglong, TANG Sufang. Preparation and Oxidation Behaviors of C/SiC-BN Composites [J]. Journal of Inorganic Materials, 2024, 39(7): 779-786. |

| [8] | ZHENG Yawen, ZHANG Cuiping, ZHANG Ruijie, XIA Qian, RU Hongqiang. Fabrication of Boron Carbide Ceramic Composites by Boronic Acid Carbothermal Reduction and Silicon Infiltration Reaction Sintering [J]. Journal of Inorganic Materials, 2024, 39(6): 707-714. |

| [9] | XUE Yifan, LI Weijie, ZHANG Zhongwei, PANG Xu, LIU Yu. Process Control of PyC Interphases Microstructure and Uniformity in Carbon Fiber Cloth [J]. Journal of Inorganic Materials, 2024, 39(4): 399-408. |

| [10] | SUN Chuan, HE Pengfei, HU Zhenfeng, WANG Rong, XING Yue, ZHANG Zhibin, LI Jinglong, WAN Chunlei, LIANG Xiubing. SiC-based Ceramic Materials Incorporating GNPs Array: Preparation and Mechanical Characterization [J]. Journal of Inorganic Materials, 2024, 39(3): 267-273. |

| [11] | PENG Ping, TAN Litao. Structure and Piezoelectric Properties of CuO-doped (Ba,Ca)(Ti,Sn)O3 Ceramics [J]. Journal of Inorganic Materials, 2024, 39(10): 1100-1106. |

| [12] | ZHENG Jiaqian, LU Xiao, LU Yajie, WANG Yingjun, WANG Zhen, LU Jianxi. Functional Bioadaptability in Medical Bioceramics: Biological Mechanism and Application [J]. Journal of Inorganic Materials, 2024, 39(1): 1-16. |

| [13] | HE Danqi, WEI Mingxu, LIU Ruizhi, TANG Zhixin, ZHAI Pengcheng, ZHAO Wenyu. Heavy-Fermion YbAl3 Materials: One-step Synthesis and Enhanced Thermoelectric Performance [J]. Journal of Inorganic Materials, 2023, 38(5): 577-582. |

| [14] | WU Shuang, GOU Yanzi, WANG Yongshou, SONG Quzhi, ZHANG Qingyu, WANG Yingde. Effect of Heat Treatment on Composition, Microstructure and Mechanical Property of Domestic KD-SA SiC Fibers [J]. Journal of Inorganic Materials, 2023, 38(5): 569-576. |

| [15] | XIE Jiaye, LI Liwen, ZHU Qiang. Contrastive Study on in Vitro Antibacterial Property and Biocompatibility of Three Clinical Pulp Capping Agents [J]. Journal of Inorganic Materials, 2023, 38(12): 1449-1456. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||