Journal of Inorganic Materials ›› 2017, Vol. 32 ›› Issue (12): 1275-1279.DOI: 10.15541/jim20170056

• Orginal Article • Previous Articles Next Articles

DUAN Yu-Sen1,2, ZHANG Jing-Xian1, LI Xiao-Guang1, HUANG Ming-Ming1,2, SHI Ying2, XIE Jian-Jun2, JIANG Dong-Liang1

Received:2017-01-24

Revised:2017-04-28

Published:2017-12-20

Online:2017-11-21

Supported by:CLC Number:

DUAN Yu-Sen, ZHANG Jing-Xian, LI Xiao-Guang, HUANG Ming-Ming, SHI Ying, XIE Jian-Jun, JIANG Dong-Liang. Rare Earth Oxides on Property of Pressureless Sintered Si3N4 Ceramics[J]. Journal of Inorganic Materials, 2017, 32(12): 1275-1279.

| Sm2O3:TiO2(ST) | Er2O3:TiO2(ET) | Lu2O3:TiO2(LT) | |

|---|---|---|---|

| Mass ratio | 2:1 | 1:1 | 1:1 |

Table 1 The mass ratio of Re2O3 to TiO2

| Sm2O3:TiO2(ST) | Er2O3:TiO2(ET) | Lu2O3:TiO2(LT) | |

|---|---|---|---|

| Mass ratio | 2:1 | 1:1 | 1:1 |

| Element | Sm | Er | Lu |

|---|---|---|---|

| Atomic number | 62 | 68 | 71 |

| Re3+radius/pm | 95.8 | 89.0 | 86.1 |

| Electronegaticity | 1.17 | 1.24 | 1.27 |

| TM of Re2O3/℃ | 2262 | 2387 | 2510 |

Table 2 Ion radius, electronegativity and melting point of rare earth elements

| Element | Sm | Er | Lu |

|---|---|---|---|

| Atomic number | 62 | 68 | 71 |

| Re3+radius/pm | 95.8 | 89.0 | 86.1 |

| Electronegaticity | 1.17 | 1.24 | 1.27 |

| TM of Re2O3/℃ | 2262 | 2387 | 2510 |

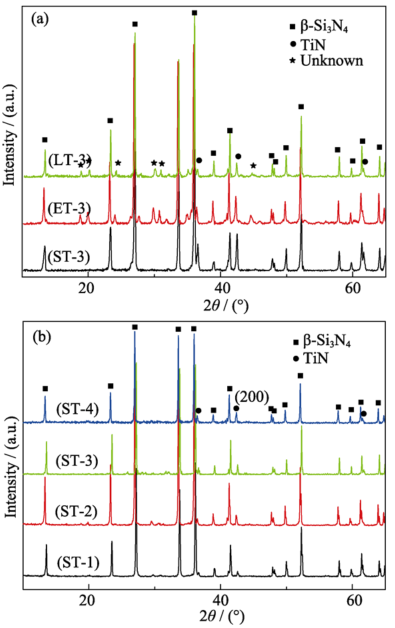

Fig. 2 XRD patterns of Si3N4 ceramics with different sintering additives type (the sintering additives content was 8wt%) (a) and Si3N4 ceramics with different sintering additive contents (the sintering additive was Sm2O3-TiO2)(b)

| ST-1 | ST-2 | ST-3 | ST-4 | |

|---|---|---|---|---|

| Wβ-Si3N4/WTiN | — | 57.8 | 40.6 | 30.2 |

Table 3 Mass ratio of β-Si3N4 to TiN

| ST-1 | ST-2 | ST-3 | ST-4 | |

|---|---|---|---|---|

| Wβ-Si3N4/WTiN | — | 57.8 | 40.6 | 30.2 |

| Sample | Fracture toughness/ (MPa•m1/2) | Hardness/ GPa | Thermal conductivity after annealing/ (W∙m-1∙K-1) |

|---|---|---|---|

| LT-3 | 5.29 | 10.8 | 45.3 |

| ET-3 | 5.46 | 12.2 | 51.8 |

| ST-3 | 5.76 | 11.7 | 40.8 |

Table 4 Mechanical properties of Si3N4 ceramic with different sintering additives and the corresponding thermal conductivity value after annealing at 1600℃ for 8 h

| Sample | Fracture toughness/ (MPa•m1/2) | Hardness/ GPa | Thermal conductivity after annealing/ (W∙m-1∙K-1) |

|---|---|---|---|

| LT-3 | 5.29 | 10.8 | 45.3 |

| ET-3 | 5.46 | 12.2 | 51.8 |

| ST-3 | 5.76 | 11.7 | 40.8 |

| [1] | YOU ZHOU, HIDEKI HYUGA, DAI KUSANO, et al.Development of high-thermal-conductivity silicon nitride ceramics. Journal of Asian Ceramic Society, 2015, 3(3): 221-229. |

| [2] | XU PENG, YANG JIAN, QIU TAI, et al.Research progress of β-Si3N4 ceramics with high thermal conductivity. Bulletin of the Chinese Ceramic Society, 2010, 29(2): 384-389. |

| [3] | HAGGERTY J S, LIGHTFOOT A.Opportunities for enhancing the thermal conductivities of SiC and Si3N4 ceramics through improved processing. Ceramic Engineering & Science Proceedings, 1995: 475-487. |

| [4] | KIYOSHI HIRAO, YOU ZHOU, HIDEKI HYUGA, et al.High thermal conductivity silicon nitride ceramics. Journal of the Korean Ceramic Society, 2001, 26(6): 451-455. |

| [5] | ZHOU YOU, HYUGA HIDEKI, KUSANO DAI, et al.A tough silicon nitride ceramic with high thermal conductivity. Advanced Materials, 2011, 23(39): 4563-4567. |

| [6] | ZHU XIN-WEN, SAKKA YOSHIO.Textured silicon nitride: processing and anisotropic properties. Science and Technology of Advanced Materials, 2008, 9(3): 033001. |

| [7] | MIKITO KITAYAMA, KIYOSHI HIRAO, KOJI WATARI, et al.Thermal conductivity of β-Si3N4-III, effect of rare-earth (RE = La, Nd, Gd, Y, Yb, and Sc) oxide additives. Journal of the AmericanCeramic Society, 2001, 84(2): 353-358. |

| [8] | LEE SEA-HOON.Densification, mass loss, and mechanical properties of low-temperature pressureless-sintered Si3N4 with LiYO2 additive: the effects of additive content and annealing. International Journal of Applied Ceramic Technology, 2010, 6(7): 881-888. |

| [9] | MATOVIC B, RIXECKER G, GOLCZEWSKI J, et al.Thermal conductivity of pressureless sintered silicon nitride materials with LiYO2 additive. Science of Sintering, 2004, 36: 3-9. |

| [10] | YANG HAI-TAO, GAO LING, YUAN RUN-ZHAN.Effect of MgO-CeO2 on pressureless sintering of silicon nitridea. Materials Chemistry and Physics, 2001, 69: 281-283. |

| [11] | GAO LING, YANG HAI-TAO, YUAN RUN-ZHANG, et al.Sintering and microstructure of silicon nitride with magnesia and cerium additives. Journal of Materials Processing Technology, 2001, 115: 298-301. |

| [12] | NAOKI KONDO, MIKINORI HOTTA, TATSUKI OHJI.Low-cost silicon nitride from β-silicon nitride powder and by low-temperature sintering. International Journal of Applied Ceramic Technology, 2015, 12(2): 377-382. |

| [13] | GUO WEI-MING., WU LI-XIANG, MA TI, et al.Rapid fabrication of Si3N4 ceramics by reaction-bonding and pressureless sintering. Journal of the European Ceramic Society, 2016, 36: 3919-3924. |

| [14] | ZHU XIN-WEN, ZHOU YOU, HIRAO KIYOSHI, et al.Potential use of only Yb2O3 in producing dense Si3N4 ceramics with high thermal conductivity by gas pressure sintering. Science and Technology of Advanced Materials, 2010, 11(6): 1-12. |

| [15] | WANG ZH, BAI B, NING XS.Effect of rare earth additives on properties of silicon nitride ceramics. Advances in Applied Ceramics, 2014, 133(3): 173-177. |

| [16] | MIKITO KITAYAMA, KIYOSHI HIRAO, SHUZO KANZAKI.Effect of rare earth oxide additives on the phase transformation rates of Si3N4. Journal of the American Ceramic Society, 2006, 89(8): 2612-2618. |

| [17] | ZHANG JIE, NING XIAO-SHAN, LUE XIN, et al.Effect of rare-earth additives on thermal conductivity, mechanical and electrical properties of silicon nitride ceramics. Rare Metal Materials and Engineering, 2008, 37(1): 693-696. |

| [18] | LU XIN, NING XIAO-SHAN, XU WEI, et al.Effect of CeO2, Dy2O3, Yb2O3 and Y2O3 additives on thermal conductivity of silicon nitride ceramics. Rare Metal Materials and Engineering, 2005, 34(24): 1112-1114. |

| [19] | WANG HUI-PING, ZHOU SHU-ZHU.Carbothermic reduction of TiO2 in N2 atmosphere-A study for direct compounding TiCN solid solution. Rare Metals and Cemented Carbides, 1996(127): 25-29. |

| [1] | FAN Wenkai, YANG Xiao, LI Honghua, LI Yong, LI Jiangtao. Pressureless Sintering of (Y0.2Gd0.2Er0.2Yb0.2Lu0.2)2Zr2O7 High-entropy Ceramic and Its High Temperature CMAS Corrosion Resistance [J]. Journal of Inorganic Materials, 2025, 40(2): 159-167. |

| [2] | WANG Weiming, WANG Weide, SU Yi, MA Qingsong, YAO Dongxu, ZENG Yuping. Research Progress of High Thermal Conductivity Silicon Nitride Ceramics Prepared by Non-oxide Sintering Additives [J]. Journal of Inorganic Materials, 2024, 39(6): 634-646. |

| [3] | ZHENG Bin, KANG Kai, ZHANG Qing, YE Fang, XIE Jing, JIA Yan, SUN Guodong, CHENG Laifei. Preparation and Thermal Stability of Ti3SiC2 Ceramics by Polymer Derived Ceramics Method [J]. Journal of Inorganic Materials, 2024, 39(6): 733-740. |

| [4] | JIN Min, MA Yupeng, WEI Tianran, LIN Siqi, BAI Xudong, SHI Xun, LIU Xuechao. Growth and Characterization of Large-size InSe Crystal from Non-stoichiometric Solution via a Zone Melting Method [J]. Journal of Inorganic Materials, 2024, 39(5): 554-560. |

| [5] | WANG Shuling, JIANG Meng, WANG Lianjun, JIANG Wan. n-Type Pb-free AgBiSe2 Based Thermoelectric Materials with Stable Cubic Phase Structure [J]. Journal of Inorganic Materials, 2023, 38(7): 807-814. |

| [6] | CHEN Qiang, BAI Shuxin, YE Yicong. Highly Thermal Conductive Silicon Carbide Ceramics Matrix Composites for Thermal Management: a Review [J]. Journal of Inorganic Materials, 2023, 38(6): 634-646. |

| [7] | ZHANG Shuo, FU Qiangang, ZHANG Pei, FEI Jie, LI Wei. Influence of High Temperature Treatment of C/C Porous Preform on Friction and Wear Behavior of C/C-SiC Composites [J]. Journal of Inorganic Materials, 2023, 38(5): 561-568. |

| [8] | JIN Xihai, DONG Manjiang, KAN Yanmei, LIANG Bo, DONG Shaoming. Fabrication of Transparent AlON by Gel Casting and Pressureless Sintering [J]. Journal of Inorganic Materials, 2023, 38(2): 193-198. |

| [9] | FU Shi, YANG Zengchao, LI Jiangtao. Progress of High Strength and High Thermal Conductivity Si3N4 Ceramics for Power Module Packaging [J]. Journal of Inorganic Materials, 2023, 38(10): 1117-1132. |

| [10] | LI Honghua, DONG Wanru, WANG Liang, YANG Zengchao, LI Jiangtao. Consistency of Silicon Nitride Powders Produced by Combustion Synthesis: Evaluation and Application [J]. Journal of Inorganic Materials, 2023, 38(10): 1169-1175. |

| [11] | SUN Xiaofan, CHEN Xiaowu, JIN Xihai, KAN Yanmei, HU Jianbao, DONG Shaoming. Fabrication and Properties of AlN-SiC Multiphase Ceramics via Low Temperature Reactive Melt Infiltration [J]. Journal of Inorganic Materials, 2023, 38(10): 1223-1229. |

| [12] | FU Shi, YANG Zengchao, LI Honghua, WANG Liang, LI Jiangtao. Mechanical Properties and Thermal Conductivity of Si3N4 Ceramics with Composite Sintering Additives [J]. Journal of Inorganic Materials, 2022, 37(9): 947-953. |

| [13] | HU Jiajun, WANG Kai, HOU Xinguang, YANG Ting, XIA Hongyan. Boron Phosphide with High Thermal Conductivity: Synthesis by Molten Salt Method and Thermal Management Performance [J]. Journal of Inorganic Materials, 2022, 37(9): 933-940. |

| [14] | ZHANG Ye, ZENG Yuping. Progress of Porous Silicon Nitride Ceramics Prepared via Self-propagating High Temperature Synthesis [J]. Journal of Inorganic Materials, 2022, 37(8): 853-864. |

| [15] | WANG Pengjiang, KANG Huijun, YANG Xiong, LIU Ying, CHENG Cheng, WANG Tongmin. Inhibition of Lattice Thermal Conductivity of ZrNiSn-based Half-Heusler Thermoelectric Materials by Entropy Adjustment [J]. Journal of Inorganic Materials, 2022, 37(7): 717-723. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||