无机材料学报 ›› 2025, Vol. 40 ›› Issue (10): 1119-1128.DOI: 10.15541/jim20240538 CSTR: 32189.14.jim20240538

曹路涵1,2( ), 孟佳1(

), 孟佳1( ), 薛玉冬3,4, 盛晓晨1, 崔苑苑5, 乐军1, 宋力昕1,2(

), 薛玉冬3,4, 盛晓晨1, 崔苑苑5, 乐军1, 宋力昕1,2( )

)

收稿日期:2024-12-26

修回日期:2025-03-15

出版日期:2025-10-20

网络出版日期:2025-04-02

通讯作者:

孟 佳, 正高级工程师. E-mail: jiameng@mail.sic.ac.cn;作者简介:曹路涵(2000-), 女, 硕士研究生. E-mail: caoluhan22@mails.ucas.ac.cn

CAO Luhan1,2( ), MENG Jia1(

), MENG Jia1( ), XUE Yudong3,4, SHENG Xiaochen1, CUI Yuanyuan5, LE Jun1, SONG Lixin1,2(

), XUE Yudong3,4, SHENG Xiaochen1, CUI Yuanyuan5, LE Jun1, SONG Lixin1,2( )

)

Received:2024-12-26

Revised:2025-03-15

Published:2025-10-20

Online:2025-04-02

Contact:

MENG Jia, professor. E-mail: jiameng@mail.sic.ac.cn;About author:CAO Luhan (2000-), female, Master candidate. E-mail: caoluhan22@mails.ucas.ac.cn

摘要:

SiC/SiC陶瓷基复合材料(SiC/SiC CMCs)以其耐高温、低密度、高强度等优点有望被用于可重复使用空天飞行器的热防护系统。鉴于空天飞行器面临的复杂恶劣使用环境, 为满足可重复使用的要求, 亟需在SiC/SiC CMCs表面制备高温抗氧化封严涂层。由于SiC/SiC CMCs表面粗糙且各向异性, 易诱导涂层开裂失效, 有待进一步研究封严涂层设计和涂层结合性能优化。本工作通过化学气相沉积(Chemical Vapor Deposition, CVD)法在SiC/SiC CMCs表面设计制备了SiC过渡层, 解决了MoSi2掺杂的SiO2-Al2O3-BaO-B2O3(MoSi2-SABB)玻璃陶瓷复合涂层的开裂剥落问题, 使涂层展现出良好的抗热震性能。有限元分析表明SiC过渡层能够有效降低MoSi2-SABB涂层与基材界面的残余应力, 缓解残余应力的各向异性, 显著提升涂层的结合性能。结合第一性原理计算探究了不同晶型、极性SiC过渡层与MoSi2-SABB涂层的结合机制, 揭示了SiC过渡层的晶型与极性是影响涂层结合性能的关键因素。本研究为设计SiC/SiC CMCs表面封严涂层与优化涂层结合性能提供了重要依据。

中图分类号:

曹路涵, 孟佳, 薛玉冬, 盛晓晨, 崔苑苑, 乐军, 宋力昕. SiC过渡层对SiC/SiC陶瓷基复合材料表面MoSi2-SABB涂层结合性能的影响[J]. 无机材料学报, 2025, 40(10): 1119-1128.

CAO Luhan, MENG Jia, XUE Yudong, SHENG Xiaochen, CUI Yuanyuan, LE Jun, SONG Lixin. Effect of SiC Transition Layer on Bonding Properties of MoSi2-SABB Coating on SiC/SiC Ceramic Matrix Composites[J]. Journal of Inorganic Materials, 2025, 40(10): 1119-1128.

| Sample | Temperature, T/℃ | Density, ρ/(kg·m−3) | Elastic modulus/GPa | Poisson’s ratio | Thermal expansion coefficient, α/ (×10−6, K-1) | Thermal conductivity/ (W·m-1·K-1) | Specific heat capacity/ (J·kg-1·K-1) |

|---|---|---|---|---|---|---|---|

| MoSi2-SABB coating | 25 | 2192 | 33.370 | 0.208 | 3.30 | 1.130 | 716 |

| 100 | - | 33.805 | 0.208 | 3.30 | 1.206 | 789 | |

| 200 | - | 34.125 | 0.208 | 3.51 | 1.277 | 883 | |

| 300 | - | 34.499 | 0.208 | 3.66 | 1.368 | 975 | |

| 400 | - | 34.824 | 0.208 | 3.70 | 1.475 | 1068 | |

| 500 | - | 34.861 | 0.208 | 3.64 | 1.702 | 1159 | |

| 600 | - | 35.246 | 0.208 | 3.59 | 1.849 | 1252 | |

| CMCs | 25 | 2600 | 150 | 0.130 | 2.929 | 4.83 | 759 |

| 200 | - | 150 | 0.130 | 4.128 | / | 706 | |

| 400 | - | 150 | 0.130 | 3.880 | / | 299 | |

| 600 | - | 150 | 0.130 | 3.831 | / | 410 | |

| 800 | - | 150 | 0.130 | 4.124 | 4.68 | 805 | |

| 1000 | - | 150 | 0.130 | 4.157 | 4.57 | 963 | |

| SiC layer[ | 3200 | 340 | 0.142 | 4.0 | 39 | 700 |

表1 相关材料的热物性质

Table 1 Thermophysical properties of the relevant materials

| Sample | Temperature, T/℃ | Density, ρ/(kg·m−3) | Elastic modulus/GPa | Poisson’s ratio | Thermal expansion coefficient, α/ (×10−6, K-1) | Thermal conductivity/ (W·m-1·K-1) | Specific heat capacity/ (J·kg-1·K-1) |

|---|---|---|---|---|---|---|---|

| MoSi2-SABB coating | 25 | 2192 | 33.370 | 0.208 | 3.30 | 1.130 | 716 |

| 100 | - | 33.805 | 0.208 | 3.30 | 1.206 | 789 | |

| 200 | - | 34.125 | 0.208 | 3.51 | 1.277 | 883 | |

| 300 | - | 34.499 | 0.208 | 3.66 | 1.368 | 975 | |

| 400 | - | 34.824 | 0.208 | 3.70 | 1.475 | 1068 | |

| 500 | - | 34.861 | 0.208 | 3.64 | 1.702 | 1159 | |

| 600 | - | 35.246 | 0.208 | 3.59 | 1.849 | 1252 | |

| CMCs | 25 | 2600 | 150 | 0.130 | 2.929 | 4.83 | 759 |

| 200 | - | 150 | 0.130 | 4.128 | / | 706 | |

| 400 | - | 150 | 0.130 | 3.880 | / | 299 | |

| 600 | - | 150 | 0.130 | 3.831 | / | 410 | |

| 800 | - | 150 | 0.130 | 4.124 | 4.68 | 805 | |

| 1000 | - | 150 | 0.130 | 4.157 | 4.57 | 963 | |

| SiC layer[ | 3200 | 340 | 0.142 | 4.0 | 39 | 700 |

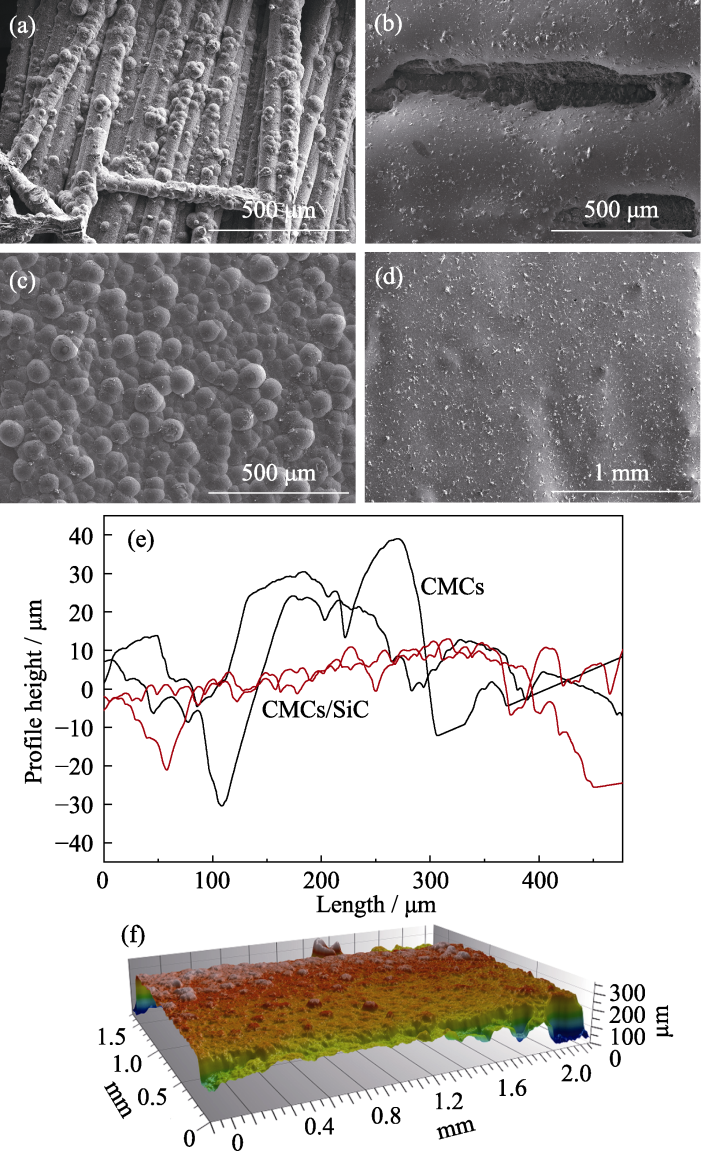

图2 制备SiC过渡层前后CMCs基底的表面形貌结构与在其表面制备的MoSi2-SABB涂层形貌

Fig. 2 Surface morphologies and structures of CMCs substrates before and after preparation of the SiC transition layer, along with morphology of the MoSi2-SABB coating prepared on its surface (a-d) SEM images of (a) CMCs, (b) CMCs/MoSi2-SABB coating, (c) CMCs/SiC, and (d) CMCs/SiC/MoSi2-SABB coating; (e) Surface profile curves of CMCs and CMCs/SiC; (f) Surface 3D profile curves of CMCs/SiC

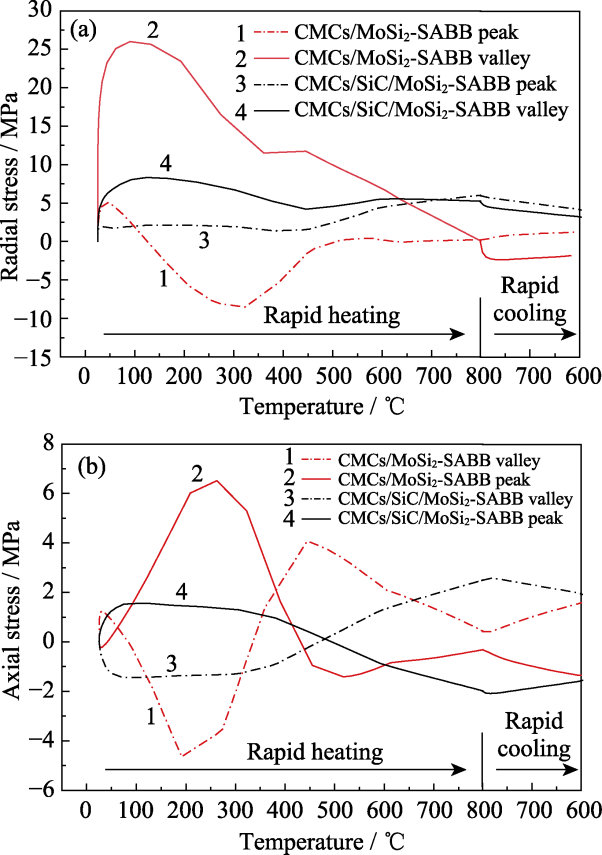

图3 CMCs/MoSi2-SABB与CMCs/SiC/MoSi2-SABB模型中MoSi2-SABB涂层界面在波峰、波谷处的温度与残余应力曲线

Fig. 3 Curves of temperature and residual stress at peaks and valleys of MoSi2-SABB coating interfaces in CMCs/MoSi2- SABB and CMCs/SiC/MoSi2-SABB models (a) Radial stress; (b) Axial stress

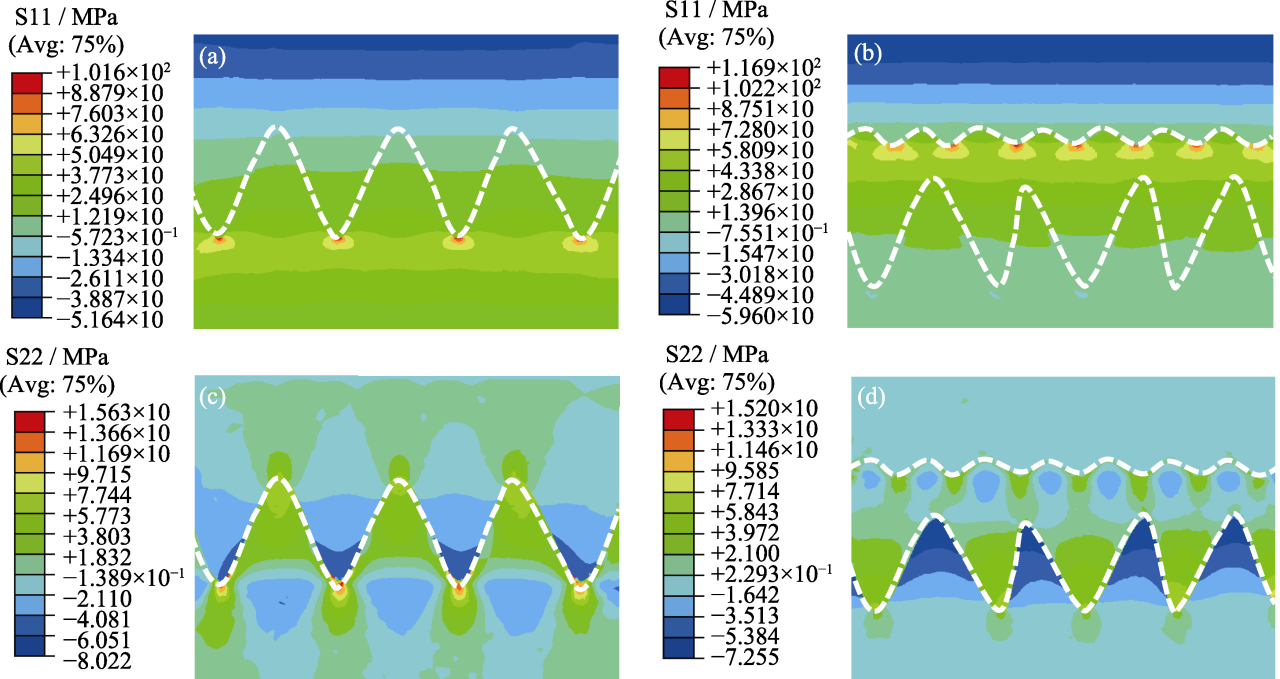

图4 CMCs/MoSi2-SABB(a, c)和CMCs/SiC/MoSi2-SABB(b, d)涂层界面的径向应力(a, b)和轴向应力(c, d)

Fig. 4 Radial stress (a, b) and axial stress (c, d) of coating interface of CMCs/MoSi2-SABB (a, c) and CMCs/SiC/MoSi2-SABB (b, d) S11: radial stress; S22: axial stress. Colorful figures are available on website

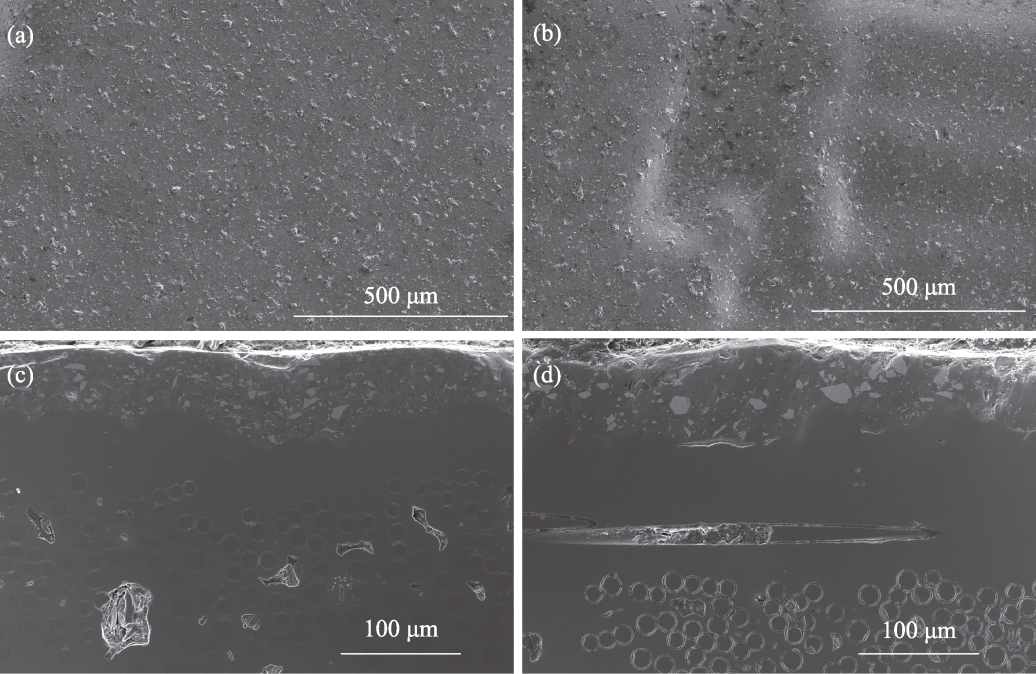

图5 CMCs/SiC/MoSi2-SABB涂层热震循环测试前(a, c)后(b, d)的表面(a, b)和截面(c, d)SEM照片

Fig. 5 (a, b) Surface and (c, d) cross-sectional SEM images of CMCs/SiC/MoSi2-SABB coating before (a, c) and after (b, d) thermal shock cycle

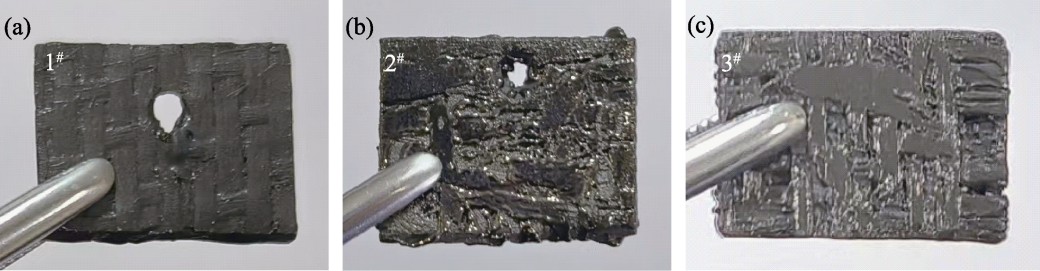

图6 不同CVD工艺制备的三种SiC过渡层表面的MoSi2-SABB涂层宏观形貌

Fig. 6 Macroscopic morphologies of MoSi2-SABB coatings on the surface of three SiC transition layers prepared by different CVD processes (a) 1# sample; (b) 2# sample; (c) 3# sample

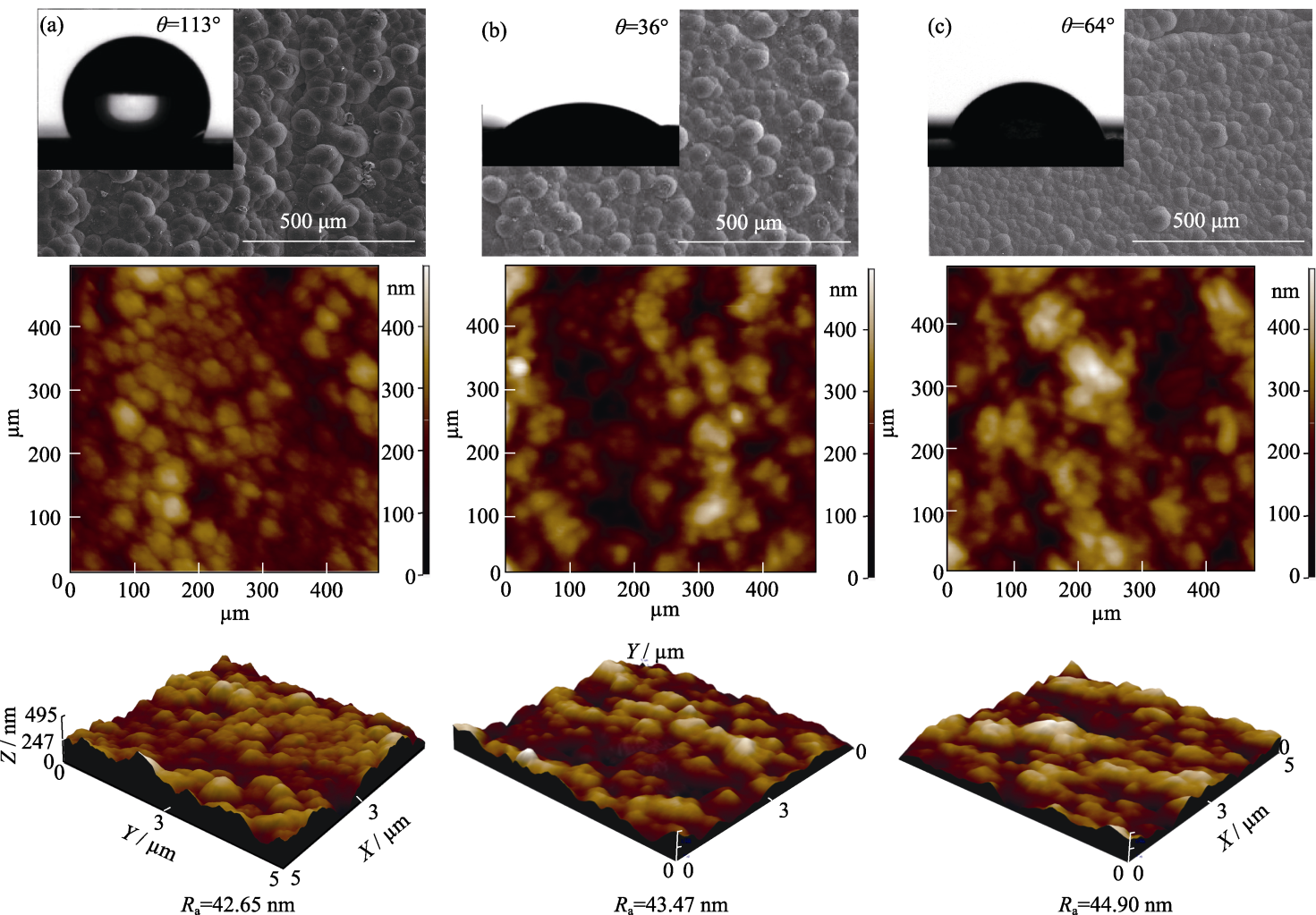

图7 1#~3# CMCs/SiC基底表面SEM照片、AFM图像与水接触角示意图

Fig. 7 SEM, AFM and water contact angle images of the surface of 1#-3# CMCs/SiC substrates (a) 1# CMCs/SiC; (b) 2# CMCs/SiC; (c) 3# CMCs/SiC

| Wsep/(J·m-2) | 6H-SiC/ MoSi2 | 6H-SiC/ SiO2 | 3C-SiC/ MoSi2 | 3C-SiC/ SiO2 |

|---|---|---|---|---|

| Si termination | 3.64 | 6.67 | 2.91 | 4.79 |

| C termination | 4.80 | 1.60 | 7.41 | 0.49 |

表2 6H-SiC、3C-SiC与MoSi2、SiO2界面的黏附强度

Table 2 Adhesion strength of 6H-SiC, 3C-SiC and MoSi2, SiO2 interfaces

| Wsep/(J·m-2) | 6H-SiC/ MoSi2 | 6H-SiC/ SiO2 | 3C-SiC/ MoSi2 | 3C-SiC/ SiO2 |

|---|---|---|---|---|

| Si termination | 3.64 | 6.67 | 2.91 | 4.79 |

| C termination | 4.80 | 1.60 | 7.41 | 0.49 |

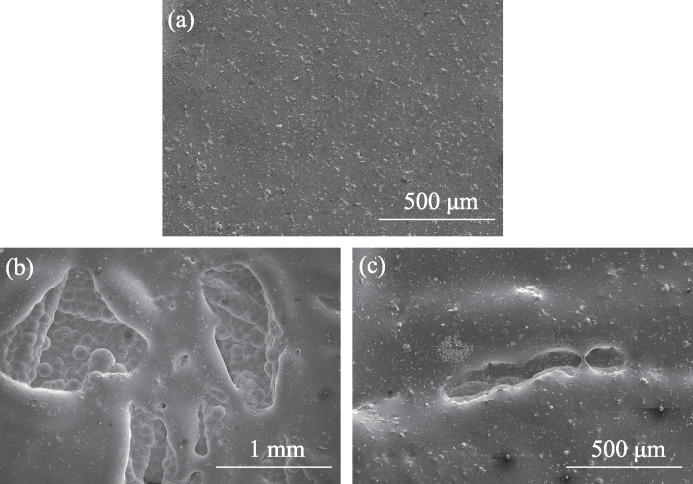

图9 1#~3# CMCs/SiC表面MoSi2-SABB涂层的SEM照片

Fig. 9 SEM images of MoSi2-SABB coatings on the surfaces of 1#-3# CMCs/SiC (a) 1# CMCs/SiC; (b) 2# CMCs/SiC; (c) 3# CMCs/SiC

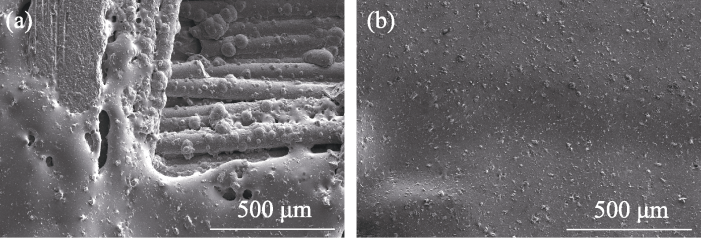

图11 2# CMCs/SiC表面玻璃改性前(a)后(b)的MoSi2-SABB涂层的SEM照片

Fig. 11 SEM images of MoSi2-SABB coating on 2# CMCs/SiC substrate before (a) and after (b) modification of glass

| [1] | WANG X, GAO X, ZHANG Z, et al. Advances in modifications and high-temperature applications of silicon carbide ceramic matrix composites in aerospace: a focused review. Journal of the European Ceramic Society, 2021, 41(9): 4671. |

| [2] | KÖNIG T, GALETZ M, ALBERT B. Application of the pack cementation process on SiC/SiC ceramic matrix composites. Journal of the European Ceramic Society, 2021, 41(16): 101. |

| [3] | KARADIMAS G, SALONITIS K. Ceramic matrix composites for aero engine applications—a review. Applied Sciences, 2023, 13(5): 3017. |

| [4] | MAZLAN N, SAPUAN S, ILYAS R A. Advanced composites in aerospace engineering applications. New York: Springer, 2022: 367. |

| [5] |

ZOK F W, MAXWELL P T, KAWANISHI K, et al. Degradation of a SiC-SiC composite in water vapor environments. Journal of the American Ceramic Society, 2020, 103(3): 1927.

DOI |

| [6] | HU C, TANG S, PANG S, et al. Long-term oxidation behaviors of C/SiC composites with a SiC/UHTC/SiC three-layer coating in a wide temperature range. Corrosion Science, 2019, 147: 1. |

| [7] | RUGGLES-WRENN M B, WILLIAMS T M. Fatigue of a SiC/SiC ceramic composite with an ytterbium-disilicate environmental barrier coating at elevated temperature. International Journal of Applied Ceramic Technology, 2020, 17(5): 2074. |

| [8] | XU Y, CHENG L, ZHANG L, et al. Oxidation behavior and mechanical properties of C/SiC composites with Si-MoSi2 oxidation protection coating. Journal of Materials Science, 1999, 34: 6009. |

| [9] | CAO X, LUAN X, WANG Y, et al. Oxidation and corrosion behavior of 2D laminated SiC/SiC with Si/mullite/BSAS EBC in dry oxygen/water vapor at 1200 ℃. Corrosion Science, 2023, 219: 111237. |

| [10] | ABDUL-AZIZ A, BHATT R T. Modeling of thermal residual stress in environmental barrier coated fiber reinforced ceramic matrix composites. Journal of Composite Materials, 2012, 46(10): 1211. |

| [11] | ZHAO K, DONG S, LÜ K, et al. Feasibility research of Yb3Al5O12 garnet as environmental barrier coating materials. Ceramics International, 2023, 49(10): 15413. |

| [12] | LEE K N. Yb2Si2O7 environmental barrier coatings with reduced bond coat oxidation rates via chemical modifications for long life. Journal of the American Ceramic Society, 2019, 102(3): 1507. |

| [13] | LEE K N, ZHU D, LIMA R S. Perspectives on environmental barrier coatings (EBCs) manufactured via air plasma spray (APS) on ceramic matrix composites (CMCs): a tutorial paper. Journal of Thermal Spray Technology, 2021, 30: 40. |

| [14] | TEJERO-MARTIN D, BENNETT C, HUSSAIN T. A review on environmental barrier coatings: history, current state of the art and future developments. Journal of the European Ceramic Society, 2021, 41(3): 1747. |

| [15] | WANG Z, ZENG F, LI Y, et al. Self-healing effect and oxidation resistance of ZrSiO4-glass coating for C/C composites at 1173 K- 1573 K. Journal of Alloys and Compounds, 2019, 792: 496. |

| [16] | FENG T, LI H J, WANG S L, et al. Boron modified multi-layer MoSi2-CrSi2-SiC-Si oxidation protective coating for carbon/carbon composites. Ceramics International, 2014, 40(9): 15167. |

| [17] | YANG X, ZOU Y, HUANG Q, et al. Influence of preparation technology on the structure and phase composition of MoSi2-Mo5Si3/SiC multi-coating for carbon/carbon composites. Journal of Materials Science & Technology, 2010, 26(2): 106. |

| [18] | FANG G, REN J, SHI J, et al. Thermal stress analysis of environmental barrier coatings considering interfacial roughness. Coatings, 2020, 10(10): 947. |

| [19] | FANG G, ZHENG M, CHEN M, et al. Stochastic simulation of thermal residual stress in environmental barrier coated 2.5D woven ceramic matrix composites. Journal of Materials Engineering and Performance, 2024, 33(8): 4114. |

| [20] | WANG B, LI G, LI J, et al. Interfacial modification and oxidation resistance behavior of a CVD-SiC coating for C/SiC composites. Ceramics International, 2023, 49(22): 36816. |

| [21] | KIM J G, PARK S J, PARK J Y, et al. The effect of temperature on the growth and properties of chemical vapor deposited ZrC films on SiC-coated graphite substrates. Ceramics International, 2015, 41(1): 211. |

| [22] | HU D, FU Q, LIU T, et al. Structural design and ablation performance of ZrB2/MoSi2 laminated coating for SiC coated carbon/carbon composites. Journal of the European Ceramic Society, 2020, 40(2): 212. |

| [23] | HU D, FU Q, LIU B, et al. Multi-layered structural designs of MoSi2/mullite anti-oxidation coating for SiC-coated C/C composites. Surface and Coatings Technology, 2021, 409: 126901. |

| [24] | LOMBARD C, VAN SITTERT C, MUGO J, et al. Computational investigation of α-SiO2 surfaces as a support for Pd. Physical Chemistry Chemical Physics, 2023, 25(8): 6121. |

| [25] | JIANG D, CARTER E A. Prediction of strong adhesion at the MoSi2/Fe interface. Acta Materialia, 2005, 53(17): 4489. |

| [26] | GUO D, XU B, JIA X, et al. Bonding strength and thermal conductivity of novel nanostructured Lu2Si2O7/Lu2SiO5 environmental barrier coating. Surface and Coatings Technology, 2024, 480: 130600. |

| [27] | YANG H, YANG Y, CAO X, et al. Thermal shock resistance and bonding strength of tri-layer Yb2SiO5/mullite/Si coating on SiCf/SiC composites. Ceramics International, 2020, 46(17): 27292. |

| [28] | HUANG J, LIU R, HU Q, et al. High temperature abradable sealing coating for SiCf/SiC ceramic matrix composites. Ceramics International, 2023, 49(2): 1779. |

| [29] | KIM J G, YOO W S, PARK J Y, et al. Quantitative analysis of contact angle of water on SiC: polytype and polarity dependence. ECS Journal of Solid State Science and Technology, 2020, 9(12): 123006. |

| [30] | OWENS D K, WENDT R. Estimation of the surface free energy of polymers. Journal of Applied Polymer Science, 1969, 13(8): 1741. |

| [1] | 凌意瀚, 郭胜, 曹志强, 田云峰, 刘方升, 金芳军, 高源. 固体氧化物电池直孔电极结构的制备技术与性能研究进展[J]. 无机材料学报, 2025, 40(12): 1311-1323. |

| [2] | 吴明轩, 李珺杰, 陈硕, 鄢永高, 苏贤礼, 张清杰, 唐新峰. 区熔n型Bi1.96Sb0.04Te2.70Se0.30热电材料均匀性研究[J]. 无机材料学报, 2025, 40(11): 1252-1260. |

| [3] | 张海丰, 蒋蒙, 孙婷婷, 王连军, 江莞. 稳定立方相p型GeMnTe2基热电材料制备[J]. 无机材料学报, 2025, 40(11): 1245-1251. |

| [4] | 李成明, 周闯, 刘鹏, 郑礼平, 赖泳机, 陈良贤, 刘金龙, 魏俊俊. CVD金刚石膜应力的产生、抑制、应用及测量[J]. 无机材料学报, 2025, 40(11): 1188-1200. |

| [5] | 袁龙, 贾如, 袁梦, 张健, 段羽, 孟祥东. X射线诱导光致变色材料的机理与应用[J]. 无机材料学报, 2025, 40(10): 1097-1110. |

| [6] | 艾伊昭彤, 任九龙, 强林芽, 张小珍, 杨凯, 高彦峰. 高承载下Al2O3-GdAlO3(GAP)非晶陶瓷涂层的摩擦磨损性能[J]. 无机材料学报, 2025, 40(10): 1111-1118. |

| [7] | 宛心怡, 王文奇, 李加诚, 赵俊亮, 马董云, 王金敏. 基于WO3·xH2O与可逆金属电沉积的无色/黑色转换电致变色器件[J]. 无机材料学报, 2025, 40(10): 1163-1174. |

| [8] | 赵丽华, 王言帅, 尹昕妩, 毛叶琼, 牛德超. 负载硫化铋纳米簇的硅基杂化胶束的制备及其光热抗菌性能[J]. 无机材料学报, 2025, 40(10): 1129-1136. |

| [9] | 吴华鑫, 张骐昊, YAN Haixue, 王连军, 江莞. 纳米复合MgAgSb基合金的热电输运性能优化[J]. 无机材料学报, 2025, 40(9): 997-1004. |

| [10] | 王亮君, 欧阳玉昭, 赵俊亮, 杨长. Cu-Mn-I固溶体薄膜制备及其p型透明导电性质调控[J]. 无机材料学报, 2025, 40(9): 1022-1028. |

| [11] | 余升阳, 苏海军, 姜浩, 余明辉, 姚佳彤, 杨培鑫. 激光增材制造超高温氧化物陶瓷孔隙缺陷形成及抑制研究进展[J]. 无机材料学报, 2025, 40(9): 944-956. |

| [12] | 李廷松, 王文丽, 刘强, 王雁斌, 周真真, 胡辰, 李江. Cr3+掺杂浓度对YAGG:Ce3+,Cr3+发光陶瓷余辉性能的影响[J]. 无机材料学报, 2025, 40(9): 1037-1044. |

| [13] | 马景阁, 吴成铁. 无机生物材料用于毛囊和毛发再生的研究[J]. 无机材料学报, 2025, 40(8): 901-910. |

| [14] | 张洪健, 赵梓壹, 吴成铁. 无机生物材料调控神经细胞功能及神经化组织再生的研究进展[J]. 无机材料学报, 2025, 40(8): 849-859. |

| [15] | 马文平, 韩雅卉, 吴成铁, 吕宏旭. 无机活性材料在类器官研究领域的应用[J]. 无机材料学报, 2025, 40(8): 888-900. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||