无机材料学报 ›› 2022, Vol. 37 ›› Issue (9): 983-990.DOI: 10.15541/jim20210659 CSTR: 32189.14.10.15541/jim20210659

收稿日期:2021-10-25

修回日期:2022-12-24

出版日期:2022-09-20

网络出版日期:2022-01-24

通讯作者:

常 江, 研究员. E-mail: jchang@mail.sic.ac.cn作者简介:盛丽丽(1992-), 女, 博士研究生. E-mail: lilissic@163.com

基金资助:

SHENG Lili1,2( ), CHANG Jiang1,2(

), CHANG Jiang1,2( )

)

Received:2021-10-25

Revised:2022-12-24

Published:2022-09-20

Online:2022-01-24

Contact:

CHANG Jiang, professor. E-mail: jchang@mail.sic.ac.cnAbout author:SHENG Lili (1992-), female, PhD candidate. E-mail: lilissic@163.com

Supported by:摘要:

兼具抗菌和组织修复活性的生物材料在再生医学领域具有广阔的应用前景。以光热和磁热为基础的热疗技术都具有抗菌作用, 但光的穿透能力有限, 磁热试剂的热转换效率较低, 限制了其在生物医学领域的应用。本研究合成了Fe2SiO4/Fe3O4双相复合生物陶瓷粉体, 不仅同时具有良好的光热和磁热效应, 还能有效释放活性的铁和硅酸根离子。用陶瓷粉体与明胶/聚己内酯复合制备的电纺丝膜不仅具有良好的细胞相容性, 而且具有光热和磁热效应。复合膜在相对温和的条件下近红外光(808 nm, 0.36 W·cm-2)与交变磁场(506 kHz, 837 A·m-1)同时处理15 min后, 与单独近红外光或磁场热处理相比, 具有更强的细菌抑制活性。因此, 这种集光热、磁热功能于一体且具有细胞相容性的Fe-Si基生物陶瓷及其复合材料在再生医学领域具有潜在的应用前景。

中图分类号:

盛丽丽, 常江. 光/磁热Fe2SiO4/Fe3O4双相生物陶瓷及其复合电纺丝膜制备及抗菌性能研究[J]. 无机材料学报, 2022, 37(9): 983-990.

SHENG Lili, CHANG Jiang. Photo/Magnetic Thermal Fe2SiO4/Fe3O4 Biphasic Bioceramic and Its Composite Electrospun Membrane: Preparation and Antibacterial[J]. Journal of Inorganic Materials, 2022, 37(9): 983-990.

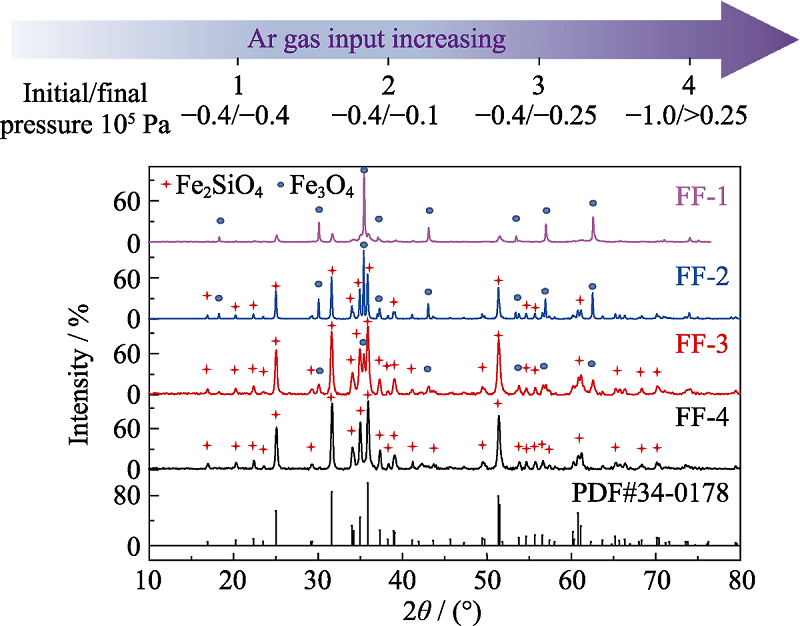

图2 800 ℃不同气氛条件下FF煅烧产物的XRD图谱

Fig. 2 XRD patterns of FF products calcined at 800 ℃ in different atmospheres FF-1: the product obtained by calcining without argon gas; FF-2-FF-4: the product obtained by calcining with argon gas at 10, 25 and >25 kPa in the furnace, respectively.

| Powder | Fe ion/(μg·mL-1) | Silicate ion/(μg·mL-1) |

|---|---|---|

| FF-1 | 43.96 | 70.12 |

| FF-2 | 28.37 | 40.23 |

| FF-3 | 13.62 | 27.16 |

| FF-4 | 5.76 | 12.68 |

表1 不同条件下粉体产物在ECM中24 h的离子释放量

Table 1 Ion release of powders prepared under different conditions after 24 h being submersed in cell culture medium ECM

| Powder | Fe ion/(μg·mL-1) | Silicate ion/(μg·mL-1) |

|---|---|---|

| FF-1 | 43.96 | 70.12 |

| FF-2 | 28.37 | 40.23 |

| FF-3 | 13.62 | 27.16 |

| FF-4 | 5.76 | 12.68 |

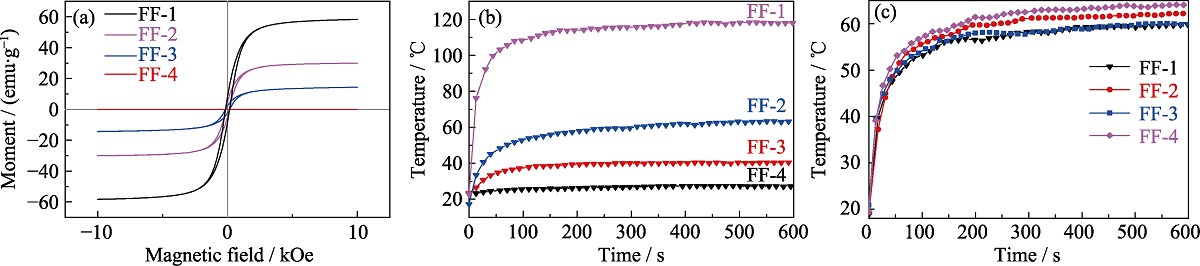

图3 不同煅烧条件制备的粉体产物的磁热和光热性能

Fig. 3 Magnetothermal and photothermal properties of powder products after being calcined under different conditions (a) Magnetic analysis results; (b) Results of thermal performance of different powders under alternating magnetic field intensity of 506 kHz at 837 A·m-1; (c) Photothermal performance of different powders under 808 nm near-infrared light irradiation at a density of 0.36 W·cm-2. FF-1: the product obtained by calcining without argon gas; FF-2-FF-4: the product obtained by calcining with argon gas at 10, 25 and >25 kPa in the furnace, respectively. 1 emu=103 A·m-1, 1 Oe=1000/4π A/m Colorful figures are available on website

图5 FF-2粉体的SEM和TEM照片。

Fig. 5 SEM and TEM images of FF-2 powders (a, b) SEM images at low (a) and high (b) magnification; (c) TEM high-resolution image of the powder with inset showing electron diffraction pattern of the powder

图6 不同FF-2粉体含量的复合电纺丝膜的形貌

Fig. 6 Morphologies of composite electrospun membranes with different FF-2 powder compositing amounts (a) Optical photos; (b) SEM images. 0, 10, 20, 30, and 40 in the figures represent composite membranes with powder contents of 0, 10%, 20%, 30%, and 40%, respectively

| Powder content/% | Fe ion/(μg·mL-1) | Silicate ion/(μg·mL-1) |

|---|---|---|

| 0 | 0 | 0 |

| 10 | 0.05 | 0.27 |

| 20 | 0.13 | 1.45 |

| 30 | 0.32 | 2.76 |

| 40 | 0.61 | 5.98 |

表2 不同粉体含量的复合电纺丝膜的离子释放性能

Table 2 Ion release properties of composite electrospun films with different powder contents in cell culture medium ECM

| Powder content/% | Fe ion/(μg·mL-1) | Silicate ion/(μg·mL-1) |

|---|---|---|

| 0 | 0 | 0 |

| 10 | 0.05 | 0.27 |

| 20 | 0.13 | 1.45 |

| 30 | 0.32 | 2.76 |

| 40 | 0.61 | 5.98 |

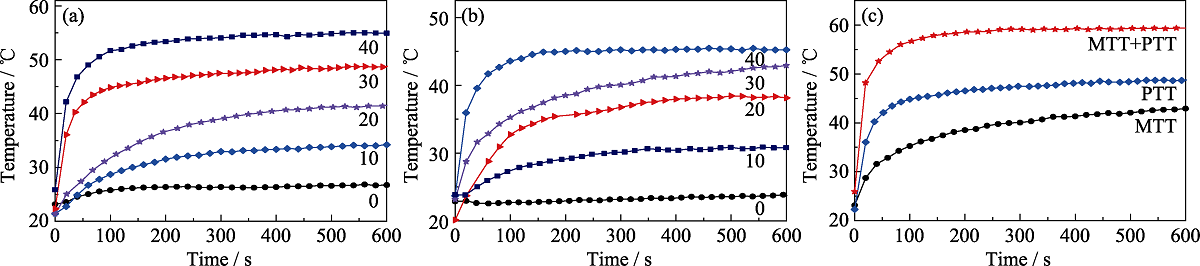

图7 不同粉体含量的复合膜的光热和磁热性能

Fig. 7 Photothermal and magnetothermal properties of composite membranes with different powder contents (a) Under NIR light (0.36 W·cm-2) irradiation at a wavelength of 808 nm; (b) In an alternating magnetic field (506 kHz, 837A·m-1); (c) Composite film with 30% powder content under laser, alternating magnetic field and laser in combination with alternating magnetic field, respectively. 0, 10, 20, 30, and 40 in the figures represent composite membranes with powder contents of 0, 10%, 20%, 30%, and 40%, respectively. MTT: magnetothermal; PTT: photothermal; MTT+PTT: combined photothermal and magnetothermal

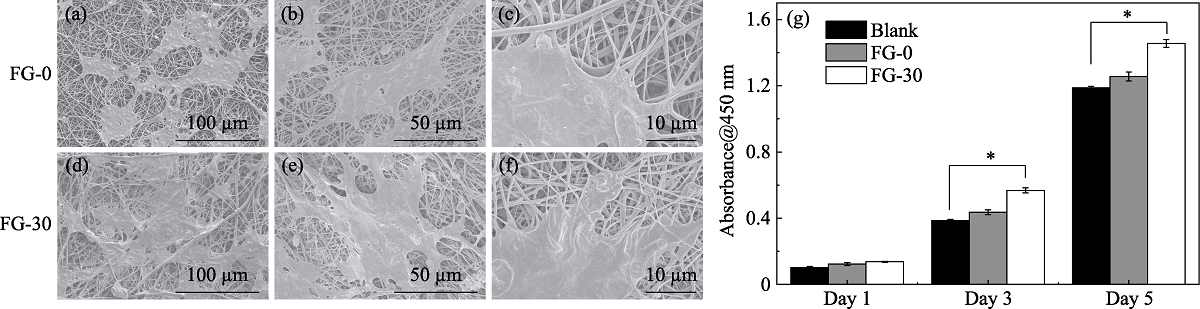

图8 FG-30复合电纺丝膜的细胞相容性

Fig. 8 Cytocompatibility of FG-30 composite electrospun membranes (a-f) SEM images of cell adhesion on FG-0 membrane (a-c) and FG-30 composite membrane (d-f) after 24 h of HUVEC culture, respectively; (g) Effect of composite membrane on HUVECs proliferation. Blank, FG-0, and FG-30 in the figures indicate blank control group, FG-0 electrospun membrane group, and FG-30 composite electrospun membrane group, respectively. * indicates p<0.05 which means significant difference between groups

图9 FG-30复合膜对金黄色葡萄球菌的光/磁热联合抑制作用

Fig. 9 Combined photo/magneto-thermal inhibition of S.aureus by FG-30 composite membrane (a) Optical photographs of colony coated plates; (b) Statistical results of inhibition rate. Blank, FG-0, FG-30, FG-30 (MTT), FG-30 (PTT), and FG-30 (MTT+PTT) denote blank control, FG-0 membrane, FG-30 membrane, FG-30 membrane with magnetothermal, FG-30 membrane with photothermal, FG-30 membrane with combined photothermal and magnetothermal, respectively. * indicates p<0.05 which means significant difference between groups

| [1] |

BELKAID Y, TAMOUTOUNOUR S. The influence of skin microorganisms on cutaneous immunity. Nature Reviews Immunology, 2016, 16(6): 353-366.

DOI URL |

| [2] |

FALANGA V. Wound healing and its impairment in the diabetic foot. Lancet, 2005, 366(9498): 1736-1743.

DOI URL |

| [3] |

ROBSON M. Wound infection - a failure of wound healing caused by an imbalance of bacteria. Surgical Clinics of North America, 1997, 77(3): 637-650.

DOI URL |

| [4] |

LI P L, HAN F X, CAO W W, et al. Carbon quantum dots derived from lysine and arginine simultaneously scavenge bacteria and promote tissue repair. Applied Materials Today, 2020, 19(1): 100601.

DOI URL |

| [5] |

XIE X, WU J R, CAI X J, et al. Photothermal/pH response B-CuS-DOX nanodrugs for chemo-photothermal synergistic therapy of tumor. Journal of Inorganic Materials, 2020, 36(1): 81-87.

DOI URL |

| [6] |

ZENG Y L, CHEN J J, TIAN Z F, et al. Preparation of mesoporous organosilica-based nanosystem for in vitro synergistic chemo-and photothermal therapy. Journal of Inorganic Materials, 2020, 35(12): 1365-1372.

DOI URL |

| [7] |

ZHAO L Y, LIU Y M, XING R R, et al. Supramolecular photothermal effects: a promising mechanism for efficient thermal conversion. Angewandte Chemie International Edition, 2020, 59(10): 3793-3801.

DOI URL |

| [8] |

WU G Z, WU Z Y, LIU L, et al. NIR light responsive MoS2 nanomaterials for rapid sterilization: optimum photothermal effect via sulfur vacancy modulation. Chemical Engineering Journal, 2022, 427(1): 132007.

DOI URL |

| [9] |

CHEN R, ROMERO G, CHRISTIANSEN M G, et al. Wireless magnetothermal deep brain stimulation. Science, 2015, 347(6229): 1477-1480.

DOI URL |

| [10] |

LI W, WEI W Y, WU X P, et al. The antibacterial and antibiofilm activities of mesoporous hollow Fe3O4 nanoparticles in an alternating magnetic field. Biomaterials Science, 2020, 8(16): 4492-4507.

DOI URL |

| [11] |

ZHUANG H, LIN R C, LIU Y Q, et al. 3D-printed bioceramic scaffolds with osteogenic activity for simultaneous photo-magnetothermal therapy of bone tumor. ACS Biomaterials Science and Engineering, 2019, 5(12): 6725-6734.

DOI URL |

| [12] |

FU D P, LIU J L, REN Q L, et al. Magnetic iron sulfide nanoparticles as thrombolytic agents for magnetocaloric therapy and photothermal therapy of thrombosis. Frontiers in Materials, 2019, 6(1): 316.

DOI URL |

| [13] |

LIU J C, GUO X, ZHAO Z, et al. Fe3S4 nanoparticles for arterial inflammation therapy: integration of magnetic hyperthermia and photothermal treatment. Applied Materials Today, 2020, 18(1): 100457.

DOI URL |

| [14] |

LI H Y, CHANG J. Stimulation of proangiogenesis by calcium silicate bioactive ceramic. Acta Biomaterialia, 2013, 9(2): 5379-5389.

DOI URL |

| [15] |

ZHAI W Y, LU H X, CHEN L, et al. Silicate bioceramics induce angiogenesis during bone regeneration. Acta Biomaterialia, 2012, 8(1): 341-349.

DOI URL |

| [16] |

YU Q Q, CHANG J, WU C. Silicate bioceramics: from soft tissue regeneration to tumor therapy. Journal of Material Chemistry B, 2019, 7(36): 5449-5460.

DOI URL |

| [17] |

MAO L X, XIA L G, CHANG J, et al. The synergistic effects of Sr and Si bioactive ions on osteogenesis, osteoclastogenesis and angiogenesis for osteoporotic bone regeneration. Acta Biomaterialia, 2017, 61(1): 217-232.

DOI URL |

| [18] | GAO L, ZhOU Y L, PENG J L, et al. A novel dual-adhesive and bioactive hydrogel activated by bioglass for wound healing. NPG Asia Materials, 2019, 11: 66. |

| [19] | WEINTRAUB L R, GORAL A, GRASSO J, et al. Collagen biosynthesis in iron overload. Annals of the New York Academy of Sciences, 1988, 526(1): 179-184. |

| [20] |

SHENG L, ZHANG Z, ZHANG Y, et al. A novel “hot spring”-mimetic hydrogel with excellent angiogenic properties for chronic wound healing. Biomaterials, 2020, 264(1): 120414.

DOI URL |

| [21] |

XING M, HUAN Z G, LI Q, et al. Containerless processing of Ca-Sr-Si system bioactive materials: thermophysical properties and ion release behaviors. Ceramics International, 2017, 43(6): 5156-5163.

DOI URL |

| [22] |

LI H Y, CHANG J. Bioactive silicate materials stimulate angiogenesis in fibroblast and endothelial cell co-culture system through paracrine effect. Acta Biomaterialia, 2013, 9(6): 6981-6991.

DOI URL |

| [23] |

XING M, WANG X Y, WANG E D, et al. Bone tissue engineering strategy based on the synergistic effects of silicon and strontium ions. Acta Biomaterialia, 2018, 72(1): 381-395.

DOI URL |

| [24] |

ZHANG J, SHI H S, LIU J Q, et al. Good hydration and cell-biological performances of superparamagnetic calcium phosphate cement with concentration-dependent osteogenesis and angiogenesis induced by ferric iron. Journal of Materials Chemistry B, 2015, 3(45): 8782-8795.

DOI URL |

| [25] |

WU M, DEOKAR A R, LIAO J, et al. Graphene-based photothermal agent for rapid and effective killing of bacteria. ACS Nano, 2013, 7(2): 1281-1290.

DOI URL |

| [26] |

IBELLI T, TEMPLETON S, LEVI-POLYACHENKO N. Progress on utilizing hyperthermia for mitigating bacterial infections. International Journal of Hyperthermia, 2018, 34(2): 144-156.

DOI URL |

| [1] | 潘雨舟, 何法鉴, 徐路路, 戴世勋. 980 nm LD泵浦下Dy3+/Yb3+共掺碲酸盐玻璃3 μm波段中红外宽带发光特性[J]. 无机材料学报, 2025, 40(5): 521-528. |

| [2] | 李建军, 陈芳明, 张梨梨, 王磊, 张丽亭, 陈慧雯, 薛长国, 徐良骥. CoFe2O4/MgAl-LDH催化剂活化过氧一硫酸盐促进抗生素降解[J]. 无机材料学报, 2025, 40(4): 440-448. |

| [3] | 薛柯, 蔡长焜, 谢满意, 李舒婷, 安胜利. 固体氧化物燃料电池Pr1+xBa1-xFe2O5+δ阴极材料的制备及电化学性能研究[J]. 无机材料学报, 2025, 40(4): 363-371. |

| [4] | 刘会来, 李志豪, 孔德峰, 陈星. 酞菁铁/MXene复合阴极的制备及电芬顿降解磺胺间二甲氧嘧啶[J]. 无机材料学报, 2025, 40(1): 61-69. |

| [5] | 王月月, 黄佳慧, 孔红星, 李怀珠, 姚晓红. 载银放射状介孔二氧化硅的制备及其在牙科树脂中的应用[J]. 无机材料学报, 2025, 40(1): 77-83. |

| [6] | 程俊, 张家伟, 仇鹏飞, 陈立东, 史迅. P掺杂β-FeSi2材料的制备与热电输运性能[J]. 无机材料学报, 2024, 39(8): 895-902. |

| [7] | 何思哲, 王俊舟, 张勇, 费嘉维, 吴爱民, 陈意峰, 李强, 周晟, 黄昊. 高频低损耗的Fe/亚微米FeNi软磁复合材料[J]. 无机材料学报, 2024, 39(8): 871-878. |

| [8] | 李刘媛, 黄开明, 赵秀艺, 刘会超, 王超. RE-Si-Al-O玻璃相对高熵稀土双硅酸盐微结构及耐CMAS腐蚀性能的影响[J]. 无机材料学报, 2024, 39(7): 793-802. |

| [9] | 张琨, 王宇, 朱腾龙, 孙凯华, 韩敏芳, 钟秦. LaNi0.6Fe0.4O3阴极接触材料导电特性调控及其对SOFC电化学性能的影响[J]. 无机材料学报, 2024, 39(4): 367-373. |

| [10] | 岳仔豪, 杨小兔, 张正亮, 邓瑞翔, 张涛, 宋力昕. Pb2+对掺杂硼硅酸盐玻璃中CsPbBr3钙钛矿量子点发光性能的影响[J]. 无机材料学报, 2024, 39(4): 449-456. |

| [11] | 陈正鹏, 金芳军, 李明飞, 董江波, 许仁辞, 徐韩昭, 熊凯, 饶睦敏, 陈创庭, 李晓伟, 凌意瀚. 双钙钛矿Sr2CoFeO5+δ阴极材料的制备及其中温固体氧化物燃料电池性能研究[J]. 无机材料学报, 2024, 39(3): 337-344. |

| [12] | 陈梦杰, 王倩倩, 吴成铁, 黄健. 基于DFT的描述符预测生物陶瓷的降解性[J]. 无机材料学报, 2024, 39(10): 1175-1181. |

| [13] | 蔡梦宇, 李杨虹淼, 杨彩云, 周雨婷, 吴昊. 基于活性污泥焚灰的类Fenton催化剂的制备及其对亚甲基蓝的降解性能[J]. 无机材料学报, 2024, 39(10): 1135-1142. |

| [14] | 李光兰, 王天宇, 刘一辰, 路中发. 片状NiFeCo-LDH-Ti6C3.75复合催化剂的制备及电催化析氧性能[J]. 无机材料学报, 2023, 38(7): 823-829. |

| [15] | 吴锐, 张敏慧, 金成韵, 林健, 王德平. 光热核壳TiN@硼硅酸盐生物玻璃纳米颗粒的降解和矿化性能[J]. 无机材料学报, 2023, 38(6): 708-716. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||