Journal of Inorganic Materials ›› 2025, Vol. 40 ›› Issue (10): 1045-1078.DOI: 10.15541/jim20250054

Special Issue: 【结构材料】陶瓷基复合材料(202512)

• JOINT REVIEW • Next Articles

LI Xiaoxuan1( ), FU Qiangang1(

), FU Qiangang1( ), WEN Zihao2, YANG Jinshan3, NI Dewei3, ZHANG Jie4, CHENG Yuan5, LIU Yuxuan5, CHU Yanhui2(

), WEN Zihao2, YANG Jinshan3, NI Dewei3, ZHANG Jie4, CHENG Yuan5, LIU Yuxuan5, CHU Yanhui2( ), CAI Feiyan3(

), CAI Feiyan3( ), WANG Jingyang4(

), WANG Jingyang4( ), ZHANG Xinghong5(

), ZHANG Xinghong5( )

)

Received:2025-02-12

Revised:2025-04-12

Published:2025-10-20

Online:2025-04-16

Contact:

FU Qiangang, professor. Responsible for compiling the entire manuscript and writing about ultra-high temperature ceramic (UHTC) modified carbon/carbon composites. E-mail: fuqiangang@nwpu.edu.cn;About author:LI Xiaoxuan (2000-), female, PhD candidate. E-mail: lixiaoxuan2017@mail.nwpu.edu.cn

Supported by:CLC Number:

LI Xiaoxuan, FU Qiangang, WEN Zihao, YANG Jinshan, NI Dewei, ZHANG Jie, CHENG Yuan, LIU Yuxuan, CHU Yanhui, CAI Feiyan, WANG Jingyang, ZHANG Xinghong. Research Progress on Ultra-high Temperature Ceramic Structural Materials for Extreme Environments[J]. Journal of Inorganic Materials, 2025, 40(10): 1045-1078.

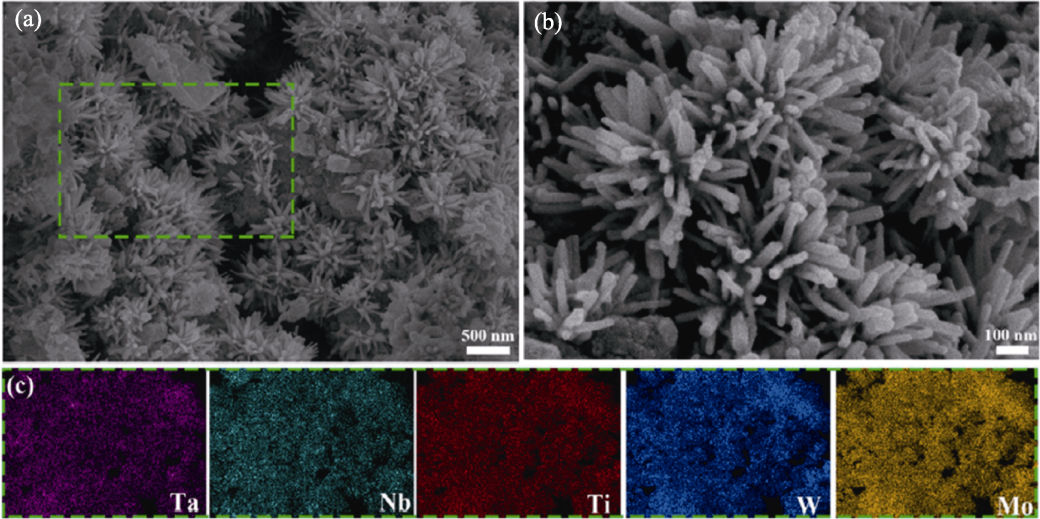

Fig. 1 SEM-EDS analysis of (Ta0.2Nb0.2Ti0.2W0.2Mo0.2)B2 nanoflowers[46] (a) Low magnification SEM image; (b) High magnification SEM image; (c) EDS element distributions

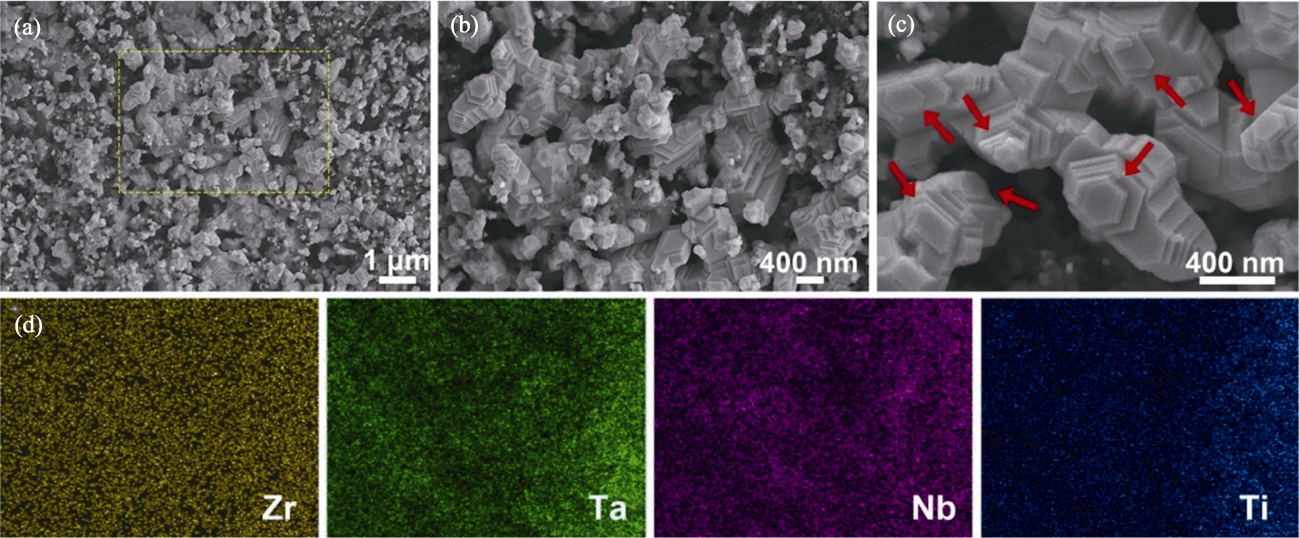

Fig. 2 SEM-EDS analysis of (Zr0.25Ta0.25Nb0.25Ti0.25)C synthesized by carbon thermal reduction method[47] (a) SEM image; (b) High magnification SEM image of the rectangular area in (a); (c) High magnification SEM image of (b); (d) EDS element distributions

| UHTC | Density/ (g·cm-3) | Melting point/ ℃ | Hardness/ GPa | Coefficient of linear expansion/(×10-6, K-1) | Thermal conductivity/ (W·m-1·K-1) |

|---|---|---|---|---|---|

| HfC | 12.76 | 3958 | 26 | 6.6 | 30 (800 ℃) |

| ZrC | 6.56 | 3400 | 27 | 5.2 | 20 (RT) |

| TiC | 4.94 | 3100 | 30 | 7.7 | 21 (RT) |

| TaC | 14.5 | 3768 | 18.2 | 6.3 | 22 (RT) |

| HfB2 | 11.19 | 3380 | 21.2-28.4 | 7.6 | 70 (800 ℃) |

| ZrB2 | 6.1 | 3245 | 28 | 8.3 | 23-25 (RT) |

| TiB2 | 4.52 | 3225 | 33 | 8.6 | 25 (RT) |

| TaB2 | 12.54 | 3040 | 25 | 8.4 | 36.2 (2027 ℃) |

| HfN | 13.8 | 3305 | 17.8 | 6.9 | 21.6 (RT) |

| ZrN | 7.09 | 2960 | 18.6 | 7.86 | 20.9 (RT) |

| TiN | 5.4 | 2950 | 19.6 | 9.4 | 29.1 (RT) |

| TaN | 13.7 | 3090 | 30.6 | 3.2 | 8.3 (RT) |

Table 1 Physical properties of typical UHTC[69-72]

| UHTC | Density/ (g·cm-3) | Melting point/ ℃ | Hardness/ GPa | Coefficient of linear expansion/(×10-6, K-1) | Thermal conductivity/ (W·m-1·K-1) |

|---|---|---|---|---|---|

| HfC | 12.76 | 3958 | 26 | 6.6 | 30 (800 ℃) |

| ZrC | 6.56 | 3400 | 27 | 5.2 | 20 (RT) |

| TiC | 4.94 | 3100 | 30 | 7.7 | 21 (RT) |

| TaC | 14.5 | 3768 | 18.2 | 6.3 | 22 (RT) |

| HfB2 | 11.19 | 3380 | 21.2-28.4 | 7.6 | 70 (800 ℃) |

| ZrB2 | 6.1 | 3245 | 28 | 8.3 | 23-25 (RT) |

| TiB2 | 4.52 | 3225 | 33 | 8.6 | 25 (RT) |

| TaB2 | 12.54 | 3040 | 25 | 8.4 | 36.2 (2027 ℃) |

| HfN | 13.8 | 3305 | 17.8 | 6.9 | 21.6 (RT) |

| ZrN | 7.09 | 2960 | 18.6 | 7.86 | 20.9 (RT) |

| TiN | 5.4 | 2950 | 19.6 | 9.4 | 29.1 (RT) |

| TaN | 13.7 | 3090 | 30.6 | 3.2 | 8.3 (RT) |

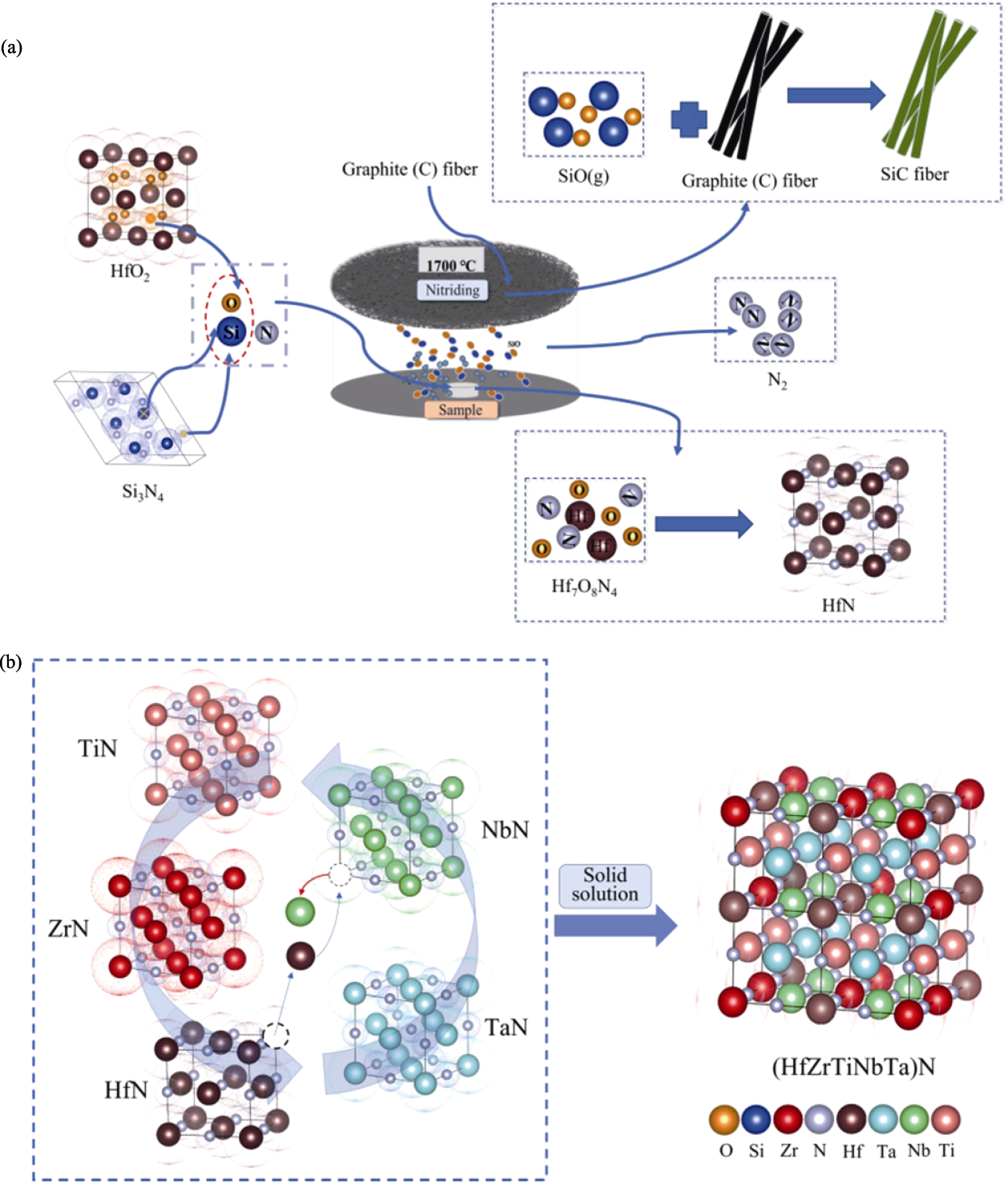

Fig. 5 Schematic diagram of synthesis mechanism of nitride thermal reduction[92] (a) Formation of HfN from HfO2 and Si3N4; (b) Mechanism of mutual solid solutions among metal nitrides

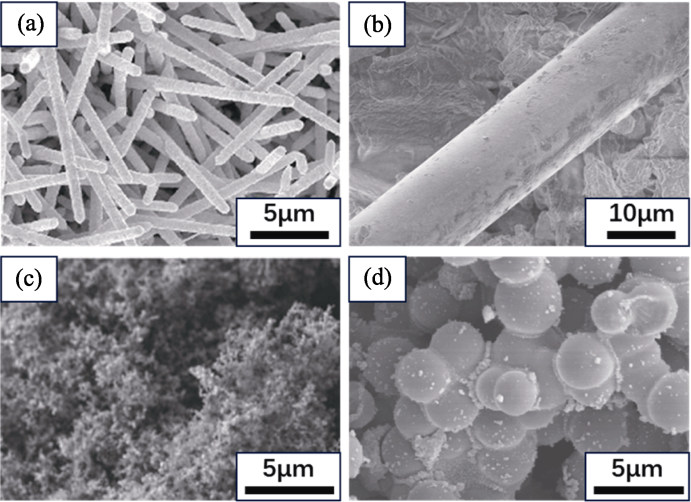

Fig. 6 SEM images of different UHTCs’ structures[108-111] (a) UHTC nanowires[108]; (b) Single UHTC fiber[109]; (c) UHTC aerogel[110]; (d) Porous UHTC[111]

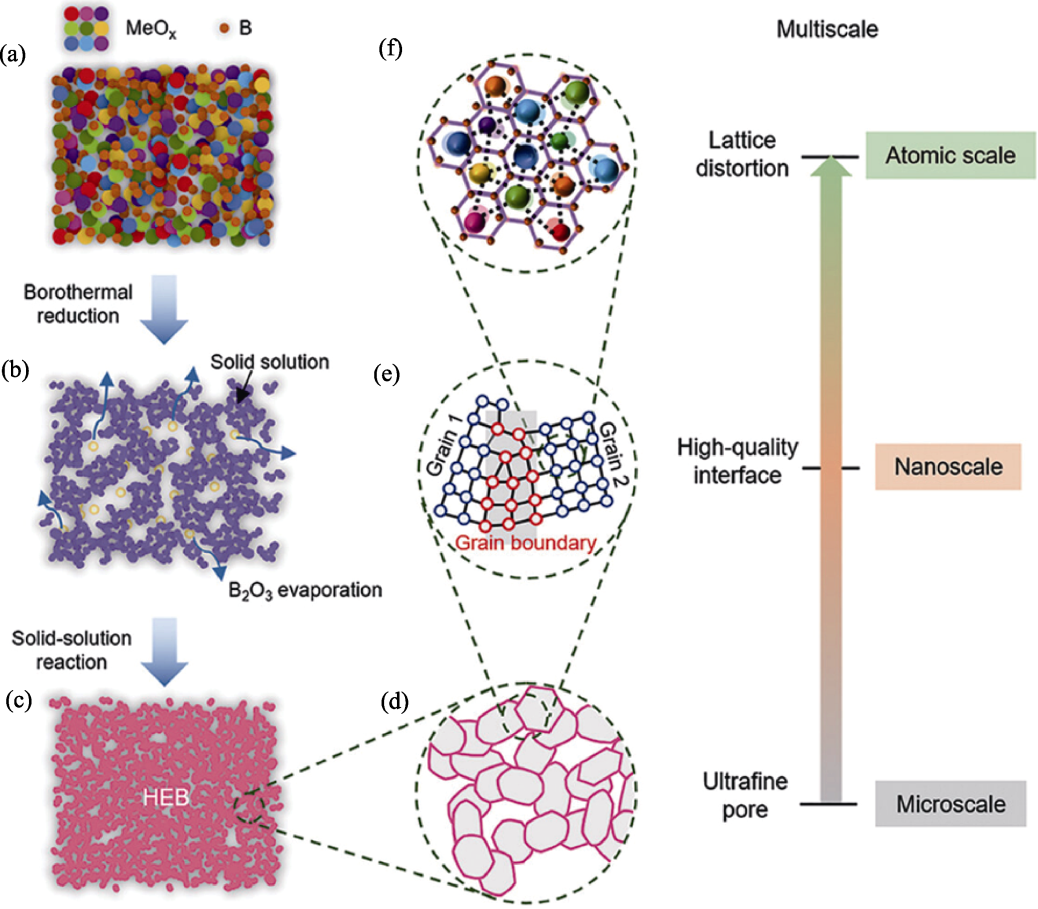

Fig. 8 Schematic diagram of the multiscale design for porous high entropy ceramics[116] (a) Uniform mixture of the original powders; (b) Formation of solid solution using the ultrafast high-temperature synthesis (UHTS) apparatus; (c) Formation of single-phase samples using the UHTS apparatus; (d-f) Multiscale design involving features of (d) ultrafine pore, (e) high-quality interface, and (f) lattice distortion

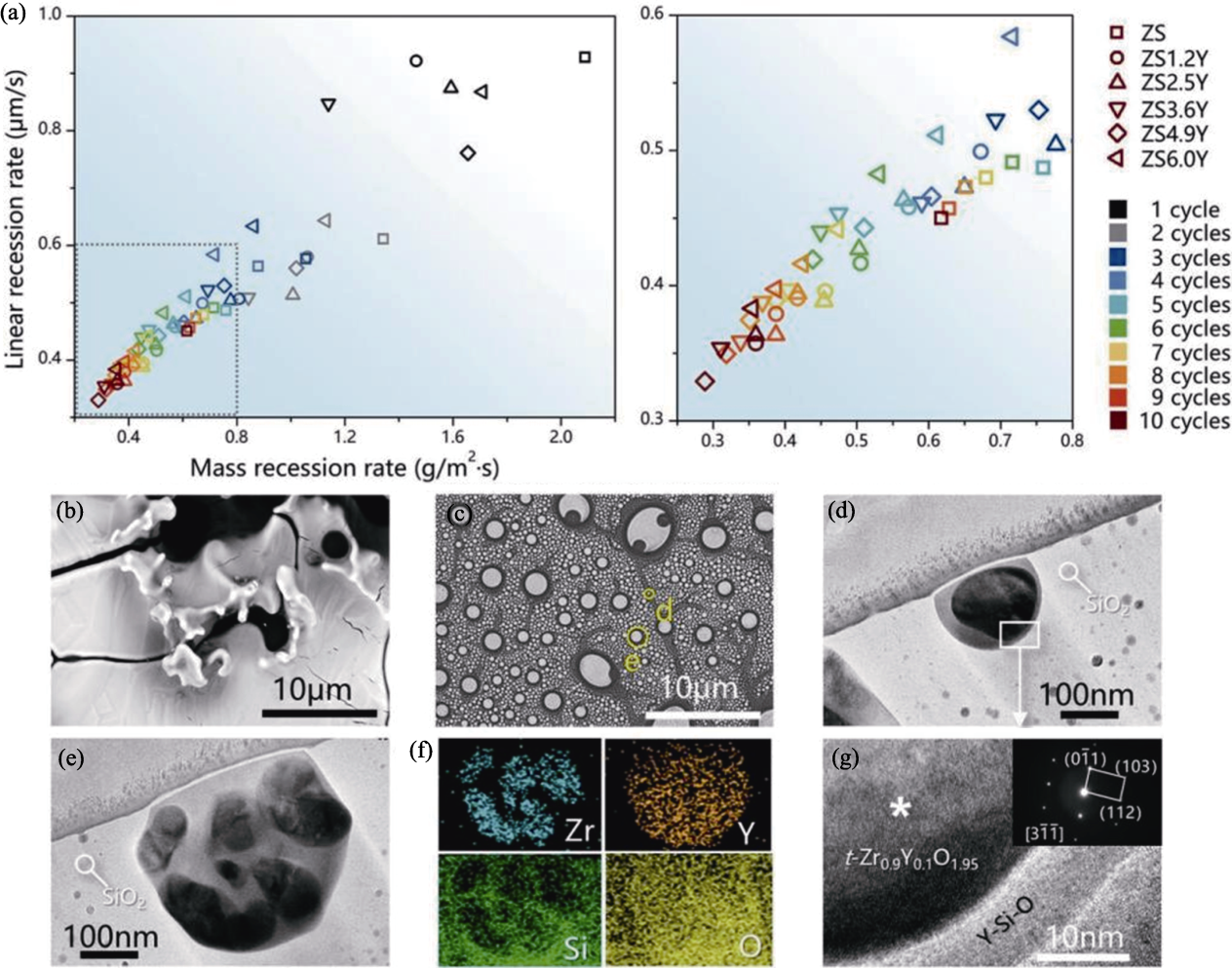

Fig. 10 Multi-cycle ablation behavior and microstructure of the Cf/ZrB2-SiC-Y2O3 composites at 2500 ℃/300 s[152] (a) Ablation recession rates of samples after each ablation cycle; (b) Oxides layer surface of ZS ablated after the 10th cycle; (c) Oxides layer surface of ZS4.9Y ablated after the 10th cycle; (d-g) TEM images of the t-Zr0.9Y0.1O1.95-Y-Si-O core shell and agglomerated particles structure

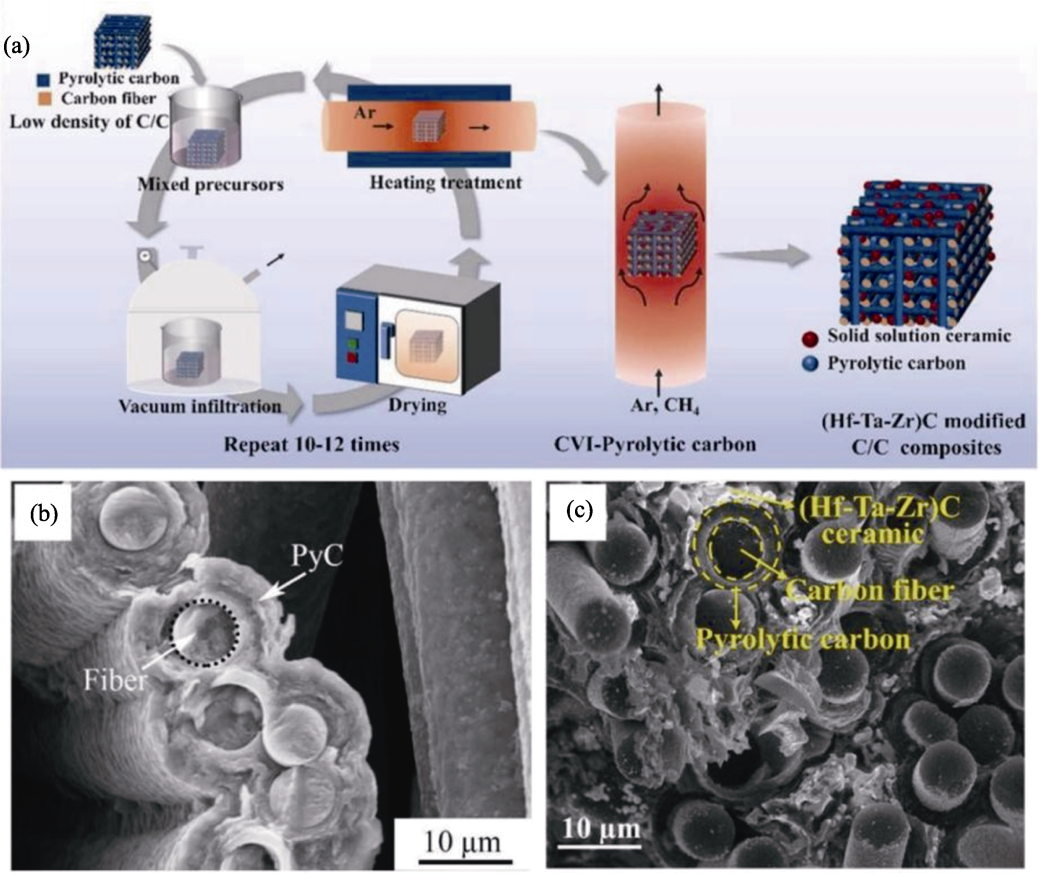

Fig. 11 (a) Schematic diagram of fabrication process of C/C-(Hf-Ta-Zr)C composite[170]; (b, c) Fracture morphologies of (b) C/C composite[171] and (c) C/C-(Hf-Ta-Zr)C composite[170]

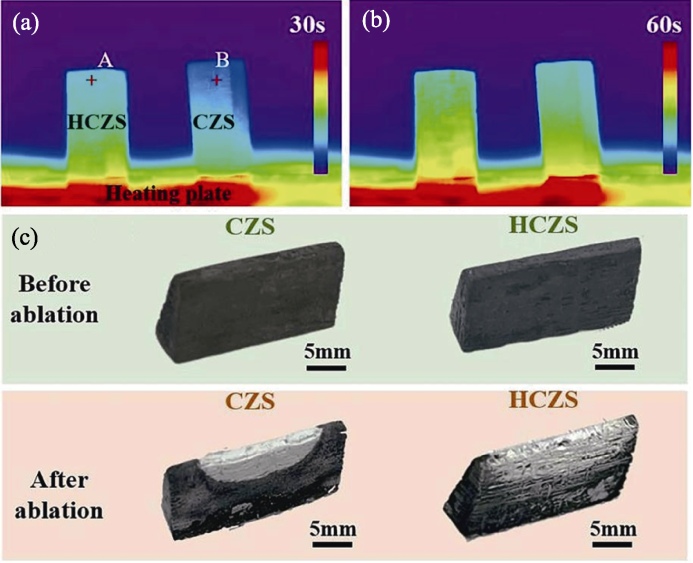

Fig. 13 (a, b) Thermal imaging of C/C-ZrB2-SiC and HTC-C/ C-ZrB2-SiC composites with heat-treatment for (a) 30 and (b) 60 s; (c) Optical images of C/C-ZrB2-SiC and HTC-C/C-ZrB2-SiC composites before and after ablation[178]

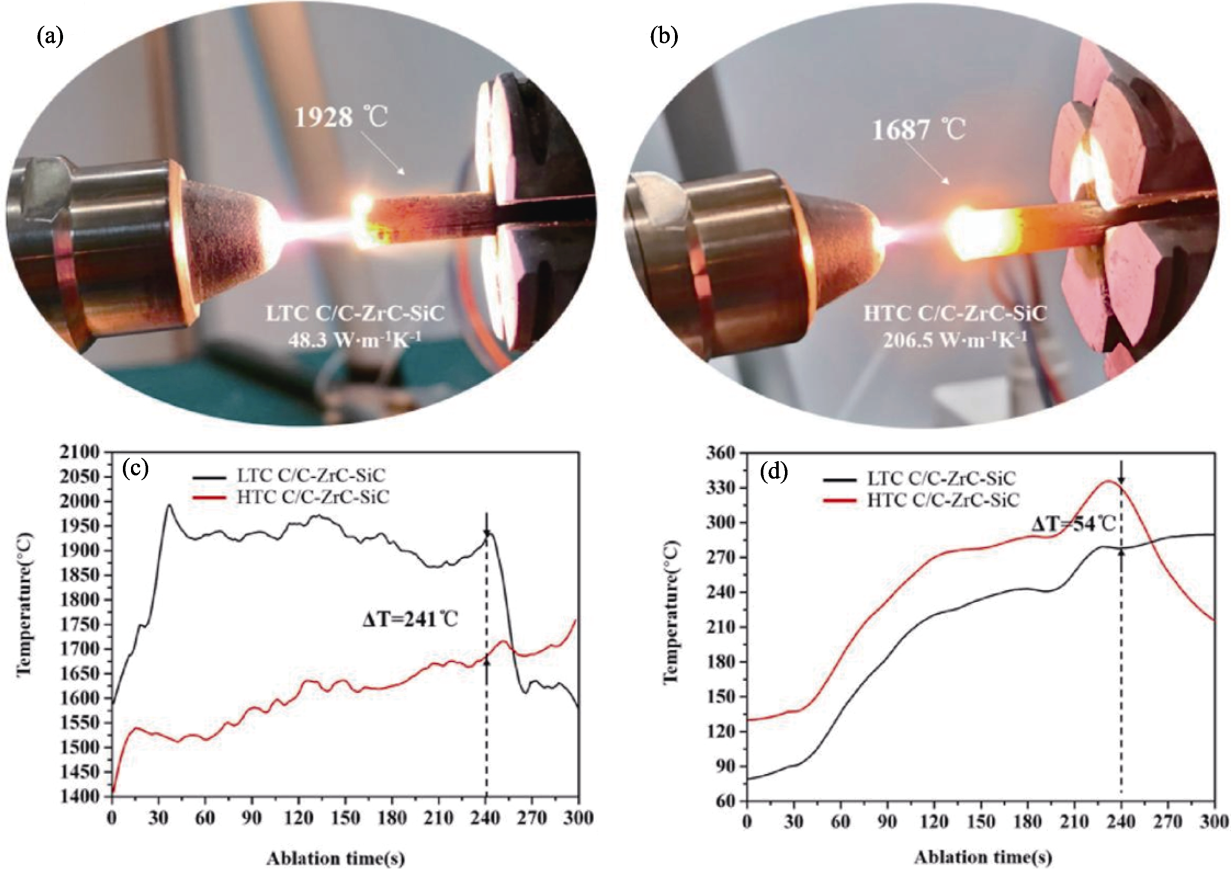

Fig. 16 Images and temperature curves of LTC C/C-ZrC-SiC and HTC C/C-ZrC-SiC composites during ablation test[205] (a) LTC C/C-ZrC-SiC composite; (b) HTC C/C-ZrC-SiC composite; (c) Surface temperature curves; (d) Back temperature curves

| [1] |

PADTURE N P. Advanced structural ceramics in aerospace propulsion. Nature Materials, 2016, 15(8): 804.

DOI PMID |

| [2] | SENGUPTA P, MANNA I. Advanced high-temperature structural materials for aerospace and power sectors: a critical review. Transactions of the Indian Institute of Metals, 2019, 72(8): 2043. |

| [3] | BINNER J, PORTER M, BAKER B, et al. Selection, processing, properties and applications of ultra-high temperature ceramic matrix composites, UHTCMCs-a review. International Materials Reviews, 2020, 65(7): 389. |

| [4] | NI D W, CHENG Y, ZHANG J P, et al. Advances in ultra-high temperature ceramics, composites, and coatings. Journal of Advanced Ceramics, 2022, 11: 1. |

| [5] | ZOLI L, SCITI D, VINCI A, et al. Ultra-high temperature ceramic matrix composites//POMEROY M. Encyclopedia of materials:technical ceramics and glasses. Amsterdam: Elsevier, 2021, 2: 340-352. |

| [6] | FAHRENHOLTZ W G, HILMAS G E. Ultra-high temperature ceramics: materials for extreme environments. Scripta Materialia, 2017, 129: 94. |

| [7] |

PETERS A B, ZHANG D J, CHEN S, et al. Materials design for hypersonics. Nature Communications, 2024, 15: 3328.

DOI PMID |

| [8] | ZAHNG L L, FU Q G, LI H J. Research state and prospect of ultra-high temperature materials. Materials China, 2015, 34: 675. |

| [9] | ZHANG X, GUO L J, LIU H M, et al. Advanced anti-ablation C/C composites: structural design strategies and future perspective. Materials Today, 2024, 80: 710. |

| [10] | FANG D N, LI W G, CHENG T B, et al. Review on mechanics of ultra-high-temperature materials. Acta Mechanica Sinica, 2021, 37(9): 1347. |

| [11] | 郭强强, 冯志海, 周延春. 超高温陶瓷的研究进展. 宇航材料工艺, 2015, 45(5): 1. |

| [12] | ZHANG X H, WANG Y M, CHENG Y, et al. Research progress on ultra-high temperature ceramic composites. Journal of Inorganic Materials, 2024, 39(6): 571. |

| [13] | 沈娟, 李舰. 高超声速飞行器的防热材料与防热结构进展. 飞航导弹, 2013(1): 86. |

| [14] | LI S P, LI K Z, GUO L J, et al. Ablation performances of the HfC modified carbon/carbon composite integrated throat. Journal of Inorganic Materials, 2008, 23(6): 1155. |

| [15] | SMEACETTO F, SALVO M, FERRARIS M. Oxidation protective multilayer coatings for carbon-carbon composites. Carbon, 2002, 40(4): 583. |

| [16] | CHEN S, QIU X C, ZHANG B W, et al. Advances in antioxidation coating materials for carbon/carbon composites. Journal of Alloys and Compounds, 2021, 886: 161143. |

| [17] | REN J C, FENG E R, ZHANG Y L, et al. Microstructure and anti-ablation performance of HfC-TaC and HfC-ZrC coatings synthesized by CVD on C/C composites. Ceramics International, 2020, 46(8): 10147. |

| [18] | 肖元, 李露, 郑瑞晓, 等. 原位SiC纳米线增韧SiC陶瓷的抗热震性能. 复合材料学报, 2022, 39(9): 4366. |

| [19] | 米春虎, 姜勇刚, 石多奇, 等. 陶瓷纤维增强氧化硅气凝胶复合材料力学性能试验. 复合材料学报, 2014, 31(3): 635. |

| [20] | 王力雯, 张琪凯, 侯振华, 等. 陶瓷纤维复合材料的应用研究进展. 化工新型材料, 2024, 52(S1): 90. |

| [21] | 朱小龙, 苏雪筠. 多孔陶瓷材料. 中国陶瓷, 2000, 36(4): 36. |

| [22] | XU Z L, ZHAO K, LI F P, et al. High temperature thermal insulation ceramic aerogels fabricated from ZrC nanofibers welded with carbon nanoparticles. ACS Applied Nano Materials, 2024, 7(9): 10046. |

| [23] | SUN B H, LI C Y, OUYANG H B, et al. Synthesis of HfC nanowires on carbon fibers by a novel catalyst-assisted pyrolysis using HfCl4 as precursor. Ceramics International, 2024, 50(13): 24901. |

| [24] | KIESSLING R. The borides of tantalum. Acta Chemica Scandinavica, 1949, 3: 603. |

| [25] | KIESSLING R. The binary system zirconium-boron. Acta Chemica Scandinavica, 1949, 3: 90. |

| [26] | LIU Z G, GUO J T, YE L L, et al. Formation mechanism of TiC by mechanical alloying. Applied Physics Letters, 1994, 65(21): 2666. |

| [27] | LIU Z G, YE L L, GUO J T, et al. Self-propagating high- temperature synthesis of TiC and NbC by mechanical alloying. Journal of Materials Research, 1995, 10(12): 3129. |

| [28] | CALKA A. Formation of titanium and zirconium nitrides by mechanical alloying. Applied Physics Letters, 1991, 59(13): 1568. |

| [29] | TALLARITA G, LICHERI R, GARRONI S, et al. Novel processing route for the fabrication of bulk high-entropy metal diborides. Scripta Materialia, 2019, 158: 100. |

| [30] | CHICARDI E, GARCÍA-GARRIDO C, GOTOR F J. Low temperature synthesis of an equiatomic (TiZrHfVNb)C5 high entropy carbide by a mechanically-induced carbon diffusion route. Ceramics International, 2019, 45(17): 21858. |

| [31] | CHICARDI E, GARCÍA-GARRIDO C, HERNÁNDEZ-SAZ J, et al. Synthesis of all equiatomic five-transition metals high entropy carbides of the IVB (Ti, Zr, Hf) and VB (V, Nb, Ta) groups by a low temperature route. Ceramics International, 2020, 46(13): 21421. |

| [32] |

MOSKOVSKIKH D, VOROTILO S, BUINEVICH V, et al. Extremely hard and tough high entropy nitride ceramics. Scientific Reports, 2020, 10: 19874.

DOI PMID |

| [33] | PRESCOTT C H J. The equilibrium between zirconium oxide and carbon and their reaction products at incandescent temperatures. Journal of the American Chemical Society, 1926, 48(10): 2534. |

| [34] | HASSINE N A, BINNER J G P, CROSS T E. Synthesis of refractory metal carbide powders via microwave carbothermal reduction. International Journal of Refractory Metals and Hard Materials, 1995, 13(6): 353. |

| [35] | LIU J X, KAN Y M, ZHANG G J. Synthesis of ultra-fine hafnium carbide powder and its pressureless sintering. Journal of the American Ceramic Society, 2010, 93(4): 980. |

| [36] | MOON A, SUH C, KIM J, et al. Fabrication of Ti-Zr-Co composites with refined microstructure using ultrafine Ti-ZrC mixture powders. Journal of Alloys and Compounds, 2018, 740: 82. |

| [37] | HA D, KIM J, HAN J S, et al. Synthesis and properties of (Hf1-xTax)C solid solution carbides. Ceramics International, 2018, 44(16): 19247. |

| [38] | PESHEV P, BLIZNAKOV G, LEYAROVSKA L. On the preparation of some chromium, molybdenum and tungsten borides. Journal of the Less Common Metals, 1967, 13(2): 241. |

| [39] | PESHEV P, BLIZNAKOV G. On the borothermic preparation of titanium, zirconium and hafnium diborides. Journal of the Less Common Metals, 1968, 14(1): 23. |

| [40] | PESHEV P, LEYAROVSKA L, BLIZNAKOV G. On the borothermic preparation of some vanadium, niobium and tantalum borides. Journal of the Less Common Metals, 1968, 15(3): 259. |

| [41] | RAN S L, VAN DER BIEST O, VLEUGELS J. ZrB2 powders synthesis by borothermal reduction. Journal of the American Ceramic Society, 2010, 93(6): 1586. |

| [42] | GUO W M, ZENG L Y, SU G K, et al. Synthesis of TaB2 powders by borothermal reduction. Journal of the American Ceramic Society, 2017, 100(6): 2368. |

| [43] | WHITE G V, MACKENZIE K J D, BROWN I W M, et al. Carbothermal synthesis of titanium nitride. Journal of Materials Science, 1992, 27(16): 4294. |

| [44] | HARRISON R, RAPAUD O, PRADEILLES N, et al. On the fabrication of ZrCxNy from ZrO2 via two-step carbothermic reduction-nitridation. Journal of the European Ceramic Society, 2015, 35(5): 1413. |

| [45] | LIU D, WEN T Q, YE B L, et al. Synthesis of superfine high- entropy metal diboride powders. Scripta Materialia, 2019, 167: 110. |

| [46] | LIU D, LIU H H, NING S S, et al. Chrysanthemum-like high- entropy diboride nanoflowers: a new class of high-entropy nanomaterials. Journal of Advanced Ceramics, 2020, 9(3): 339. |

| [47] |

YE B L, NING S S, LIU D, et al. One-step synthesis of coral-like high-entropy metal carbide powders. Journal of the American Ceramic Society, 2019, 102(10): 6372.

DOI |

| [48] |

FENG L, FAHRENHOLTZ W G, HILMAS G E, et al. Synthesis of single-phase high-entropy carbide powders. Scripta Materialia, 2019, 162: 90.

DOI |

| [49] | MARKOVSKII L Y, VEKSHINA N V, BEZRUK E T, et al. A magnesium-thermic method for the preparation of metal borides. Soviet Powder Metallurgy and Metal Ceramics, 1969, 8(5): 350. |

| [50] | BAO K, WEN Y, KHANGKHAMANO M, et al. Low-temperature preparation of titanium diboride fine powder via magnesiothermic reduction in molten salt. Journal of the American Ceramic Society, 2017, 100(5): 2266. |

| [51] | WON H I, HAYK N, WON C W, et al. Simple synthesis of nano-sized refractory metal carbides by combustion process. Journal of Materials Science, 2011, 46(18): 6000. |

| [52] | YE B L, FAN C, HAN Y J, et al. Synthesis of high-entropy diboride nanopowders via molten salt-mediated magnesiothermic reduction. Journal of the American Ceramic Society, 2020, 103(9): 4738. |

| [53] | CHU Y H, YU R W, HE G, et al. Combustion synthesis of high- entropy carbide nanoparticles for tetracycline degradation via persulfate activation. Science China Materials, 2022, 65(11): 3144. |

| [54] | TING S J, CHU C J, LIMATTA E, et al. The formation of thin films and fibers of TiC from a polymeric titanate precursor. MRS Online Proceedings Library, 1990, 180: 457. |

| [55] | SHAM E L, FARFÁN-TORRES E M, BRUQUE-GÁMEZ S, et al. Synthesis of ZrC/ZrO2 by pyrolysis of modified zirconium alkoxide precursors. Solid State Ionics, 1993, 63: 45. |

| [56] | WEIL K, KUMTA P. Synthesis of transition metal nitride powders and coatings using alkanolamine chelated precursors. Materials & Design, 2001, 22(7): 605. |

| [57] | YANG B Y, LI J P, ZHAO B, et al. Synthesis of hexagonal-prism-like ZrB2 by a Sol-Gel route. Powder Technology, 2014, 256: 522. |

| [58] | WANG T X, WANG Z, HU C G, et al. Dispersant-assisted preparation of ultra-fine HfB2 powder. Applied Surface Science, 2022, 606: 154995. |

| [59] | LIU H H, DU B, CHU Y H. Synthesis of the ternary metal carbide solid-solution ceramics by polymer-derived-ceramic route. Journal of the American Ceramic Society, 2020, 103(5): 2970. |

| [60] | DU B, LIU H H, CHU Y H. Fabrication and characterization of polymer-derived high-entropy carbide ceramic powders. Journal of the American Ceramic Society, 2020, 103(8): 4063. |

| [61] | SUN Y N, CHEN F H, QIU W F, et al. Synthesis of rare earth containing single-phase multicomponent metal carbides via liquid polymer precursor route. Journal of the American Ceramic Society, 2020, 103(11): 6081. |

| [62] | TAIBI A, GIL-GONZÁLEZ E, SÁNCHEZ-JIMÉNEZ P E, et al. Flash joule heating-boro/carbothermal reduction (FJH-BCTR): an approach for the instantaneous synthesis of transition metal diborides. Ceramics International, 2025, 51(5): 5483. |

| [63] |

YAO Y G, HUANG Z N, XIE P F, et al. Carbothermal shock synthesis of high-entropy-alloy nanoparticles. Science, 2018, 359(6383): 1489.

DOI PMID |

| [64] | TANG Z Y, WEN Z H, LIU Y W, et al. Rapid experimental screening of high-entropy diborides for superior oxidation resistance. Advanced Functional Materials, 2024, 34(12): 2312239. |

| [65] | MENG H, LIU Y W, YU H L, et al. Machine-learning-potential- driven prediction of high-entropy ceramics with ultra-high melting points. Cell Reports Physical Science, 2025, 6(2): 102449. |

| [66] | LIU Q, XU L, ZOU J, et al. Dense nine elemental high entropy diboride ceramics with unique high temperature mechanical and physical properties. Composites Part B: Engineering, 2024, 287: 111868. |

| [67] | MENG H, YU R W, TANG Z Y, et al. Formation ability descriptors for high-entropy carbides established through high- throughput methods and machine learning. Cell Reports Physical Science, 2023, 4(8): 101512. |

| [68] | WEN Z H, TANG Z Y, MENG H, et al. Ultrafast synthesis of high-entropy carbides up to 3,273 K for superior oxidation resistance. Cell Reports Physical Science, 2024, 5(2): 101821. |

| [69] | OPEKA M M, TALMY I G, WUCHINA E J, et al. Mechanical, thermal, and oxidation properties of refractory hafnium and zirconium compounds. Journal of the European Ceramic Society, 1999, 19(13/14): 2405. |

| [70] | KURBATKINA V V, PATSERA E I, SMIRNOV D V, et al. Part 2. Structure, mechanical and thermophysical properties of consolidated ceramics based on (Hf, Ta)B2. Ceramics International, 2019, 45(3): 4076. |

| [71] | 徐怡, 李日升, 苏继楷, 等. 二硼化钛(TiB2)的性能及其应用. 中国搪瓷, 1998, 19(5): 40. |

| [72] | 陈红梅, 蒋进明. 碳化钽耐超高温陶瓷的研究进展. 中国陶瓷, 2018, 54(11): 9. |

| [73] | 于多, 殷杰, 张步豪, 等. 碳化物超高温陶瓷材料研究进展. 航空制造技术, 2019, 62(19): 53. |

| [74] | 马宝霞, 郭二军, 王丽萍. ZrC超高温陶瓷复合材料的研究进展. 材料导报, 2013, 27(3): 49. |

| [75] | 宋瑞颖, 刘宁, 张红芹, 等. ZrC陶瓷的性能、制备及应用. 硬质合金, 2009, 26(2): 134. |

| [76] | FENG L, FAHRENHOLTZ W G, HILMAS G E, et al. Densification, microstructure, and mechanical properties of ZrC-SiC ceramics. Journal of the American Ceramic Society, 2019, 102(10): 5786. |

| [77] | 李辉, 孙国栋, 邓娟利, 等. 碳化铪氧化的热力学研究. 材料导报, 2015, 29(18): 136. |

| [78] | KIM K S, LEE S H, NGUYEN V Q, et al. Ablation characteristics of rocket nozzle using HfC-SiC refractory ceramic composite. Acta Astronautica, 2020, 173: 31. |

| [79] | WEN Q B, RIEDEL R, IONESCU E. Significant improvement of the short-term high-temperature oxidation resistance of dense monolithic HfC/SiC ceramic nanocomposites upon incorporation of Ta. Corrosion Science, 2018, 145: 191. |

| [80] | GOLLA B R, MUKHOPADHYAY A, BASU B, et al. Review on ultra-high temperature boride ceramics. Progress in Materials Science, 2020, 111: 100651. |

| [81] | 贾坤乐, 张鑫, 张思源, 等. 硼化铪粉末制备研究. 热喷涂技术, 2020, 12(2): 30. |

| [82] | BAI Y S, SHEN W X, FANG C, et al. Preparation and properties of HfB2-HfC and HfB2-HfC-MoB composites by reactive spark plasma sintering. Journal of Asian Ceramic Societies, 2023, 11(2): 270. |

| [83] | ZHANG Y T, CHEN G H, SHI X H, et al. Atomic simulations and experimental of the effect of transition metal on the high-temperature oxidation behavior of ZrB2. Corrosion Science, 2024, 236: 112218. |

| [84] | 严春雷, 袁蓓, 查柏林. 超高温陶瓷材料研究进展. 硅酸盐通报, 2017, 36(11): 3703. |

| [85] | SUVOROVA V S, NEPAPUSHEV A A, VOLODKO S S, et al. Oxidation behavior of novel ultra-high temperature hafnium- zirconium carbonitrides: effect of nitrogen and metal ratios. Ceramics International, 2024, 50(1): 1898. |

| [86] | PENG Z, SUN W, XIONG X, et al. Novel nitrogen-doped hafnium carbides for advanced ablation resistance up to 3273 K. Corrosion Science, 2021, 189: 109623. |

| [87] |

CASTLE E, CSANÁDI T, GRASSO S, et al. Processing and properties of high-entropy ultra-high temperature carbides. Scientific Reports, 2018, 8: 8609.

DOI PMID |

| [88] | DENG X C, ZHANG G H. Preparation of high-performance (ZrHfTaNbTiMo)C-10Co ceramic by SPS using self-synthesized fine high-entropy carbide powders. Ceramics International, 2024, 50(12): 21050. |

| [89] |

GILD J, ZHANG Y Y, HARRINGTON T, et al. High-entropy metal diborides: a new class of high-entropy materials and a new type of ultrahigh temperature ceramics. Scientific Reports, 2016, 6: 37946.

DOI PMID |

| [90] | GUO R R, LI Z J, LI L, et al. Oxidation behavior of high-entropy (Zr0.2Hf0.2Ta0.2Nb0.2Ti0.2)B2 ceramic with 20% SiC addition. Journal of the European Ceramic Society, 2024, 44(8): 5181. |

| [91] | 颜邓伊, 许文举, 吉利, 等. 高熵陶瓷材料的研究进展. 材料保护, 2023, 56(8): 35. |

| [92] | LIU X, LU Y J, XU Q, et al. Synthesis of (HfZrTiNbTa)N powders via nitride thermal reduction with soft mechano-chemical assistance. Journal of Advanced Ceramics, 2023, 12(3): 565. |

| [93] | 刘倩, 刘含莲, 黄传真, 等. 高熵碳氮化物陶瓷的研究现状及应用展望. 工具技术, 2023, 57(9): 16. |

| [94] | PENG Z, SUN W, XIONG X, et al. Novel refractory high-entropy ceramics: transition metal carbonitrides with superior ablation resistance. Corrosion Science, 2021, 184: 109359. |

| [95] | 李县辉, 孙永安, 张永乾. 陶瓷材料的烧结方法. 陶瓷学报, 2003, 24(2): 120. |

| [96] | 何金懋, 赵国梁, 刘天伟, 等. 先进烧结技术制备高熵陶瓷的研究进展. 陶瓷学报, 2024, 45(1): 32. |

| [97] | GAO J J, SONG J P, LV M, et al. Microstructure and mechanical properties of TiC0.7N0.3-HfC cermet tool materials. Ceramics International, 2018, 44(15): 17895. |

| [98] | 王松, 谢明, 张吉明, 等. 放电等离子烧结技术进展. 贵金属, 2012, 33(3): 73. |

| [99] | 王秀芬, 周曦亚. 放电等离子烧结技术. 中国陶瓷, 2006, 42(7): 14. |

| [100] | SUN W Z, TIAN Y, XU S D, et al. Powder synthesis, densification, microstructure, and mechanical properties of HfB2-HfC ceramic composites. International Journal of Applied Ceramic Technology, 2024, 21(1): 195. |

| [101] |

LIU J L, LIU D G, REN K, et al. Research progress on the flash sintering mechanism of oxide ceramics and its application. Journal of Inorganic Materials, 2022, 37(5): 473.

DOI |

| [102] | 李健, 关丽丽, 王松宪, 等. 陶瓷材料闪烧制备技术研究进展. 中国陶瓷工业, 2018, 25(6): 20. |

| [103] | FOROUGHI P, DURYGIN A, SUN S C, et al. Flash sintering of tantalum-hafnium diboride solid solution powder. Journal of Materials Research, 2022, 37(13): 2150. |

| [104] | 李辰冉, 谢志鹏, 赵林. 碳化硅陶瓷材料烧结技术的研究与应用进展. 陶瓷学报, 2020, 41(2): 137. |

| [105] | NAM M S, CHOI J H, JUNG I H, et al. In-situ fabrication and characterization of W-ZrC composites via pressureless reaction sintering. International Journal of Refractory Metals and Hard Materials, 2024, 120: 106573. |

| [106] | 陈玉峰, 洪长青, 胡成龙, 等. 空天飞行器用热防护陶瓷材料. 现代技术陶瓷, 2017, 38(5): 311. |

| [107] | ZHANG W, CHEN L, XU C G, et al. Grain growth kinetics and densification mechanism of (TiZrHfVNbTa)C high-entropy ceramic under pressureless sintering. Journal of Materials Science & Technology, 2022, 110: 57. |

| [108] | FU Y Q, ZHANG Y L, CHEN H, et al. Ultra-high temperature resistance of one-dimensional hafnium carbide wrapped with pyrolytic carbon up to 2450 ℃. Corrosion Science, 2022, 195: 110015. |

| [109] | CHENG J, WANG X Z, WANG J, et al. Synthesis of a novel single-source precursor for HfC ceramics and its feasibility for the preparation of Hf-based ceramic fibres. Ceramics International, 2018, 44(6): 7305. |

| [110] |

CAHILL J T, TURNER S, YE J C, et al. Ultrahigh-temperature ceramic aerogels. Chemistry of Materials, 2019, 31(10): 3700.

DOI |

| [111] | LI C Y, GAO R N, OUYANG H B, et al. Hierarchical porous (Ta0.2Nb0.2Ti0.2Zr0.2Hf0.2)C high-entropy ceramics prepared by a self-foaming method for thermal insulation. Journal of Advanced Ceramics, 2024, 13(7): 956. |

| [112] | 张丛, 李志鹏, 高晓菊, 等. 耐超高温陶瓷纤维制备研究综述. 陶瓷, 2016(7): 9. |

| [113] | WANG W, WU Z W, SONG S C, et al. Facile preparation of a novel HfC aerogel with low thermal conductivity and excellent mechanical properties. Gels, 2023, 9(10): 839. |

| [114] | 李飞, 刘吉轩, 黄晓, 等. 多孔超高温陶瓷: 制备、结构及性能. 硅酸盐学报, 2018, 46(12): 1669. |

| [115] | 鞠银燕, 宋士华, 陈晓峰. 多孔陶瓷的制备、应用及其研究进展. 硅酸盐通报, 2007, 26(5): 969. |

| [116] | WEN Z H, TANG Z Y, LIU Y W, et al. Ultrastrong and high thermal insulating porous high-entropy ceramics up to 2000 ℃. Advanced Materials, 2024, 36(14): 2311870. |

| [117] | QIU S H, ZOU J, LIU J J, et al. Achieving superhardness and enhanced toughness in high-entropy boride-based composites by tailoring their multi-scale microstructures. Small, 2025, 21(8): 2404632. |

| [118] | LI Q G, DONG S M, WANG Z, et al. Fabrication and properties of 3-D Cf/SiC-ZrC composites, using ZrC precursor and polycarbosilane. Journal of the American Ceramic Society, 2012, 95(4): 1216. |

| [119] | ZHANG M Y, LI K Z, SHI X H, et al. Effects of SiC interphase on the mechanical and ablation properties of C/C-ZrC-ZrB2-SiC composites prepared by precursor infiltration and pyrolysis. Materials & Design, 2017, 122: 322. |

| [120] | JIANG Y L, NI D W, DING Q, et al. Synthesis and characterization of nano-crystalized HfC based on an aqueous solution-derived precursor. RSC Advances, 2018, 8(69): 39284. |

| [121] | IONESCU E, BERNARD S, LUCAS R, et al. Polymer-derived ultra-high temperature ceramics (UHTCs) and related materials. Advanced Engineering Materials, 2019, 21(8): 1900269. |

| [122] | ZOU X G, NI D W, CHEN B W, et al. Fabrication and properties of Cf/Ta4HfC5-SiC composite via precursor infiltration and pyrolysis. Journal of the American Ceramic Society, 2021, 104(12): 6601. |

| [123] | RUBIO V, RAMANUJAM P, BINNER J. Ultra-high temperature ceramic composite. Advances in Applied Ceramics, 2018, 117(sup1): s56. |

| [124] | LIU Q M, ZHANG L T, LIU J, et al. The oxidation behavior of SiC-ZrC-SiC-coated C/SiC minicomposites at ultrahigh temperatures. Journal of the American Ceramic Society, 2010, 93(12): 3990. |

| [125] | CAI F Y, NI D W, CHEN B W, et al. Fabrication and properties of Cf/(Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)C-SiC high-entropy ceramic matrix composites via precursor infiltration and pyrolysis. Journal of the European Ceramic Society, 2021, 41(12): 5863. |

| [126] | CHEN X W, DONG S M, KAN Y M, et al. Microstructure and mechanical properties of three dimensional Cf/SiC-ZrC-ZrB2 composites prepared by reactive melt infiltration method. Journal of the European Ceramic Society, 2016, 36(16): 3969. |

| [127] | CHEN X W, FENG Q, ZHOU H J, et al. Ablation behavior of three-dimensional Cf/SiC-ZrC-ZrB2 composites prepared by a joint process of Sol-Gel and reactive melt infiltration. Corrosion Science, 2018, 134: 49. |

| [128] | ZHAO Z G, LI K Z, LI W, et al. Ablation behavior of C/C-ZrC-SiC composites prepared by reactive melt infiltration under oxyacetylene torch at two heat fluxes. Ceramics International, 2018, 44(14): 17345. |

| [129] | CHEN X W, FENG Q, GAO L, et al. Interphase degradation of three-dimensional Cf/SiC-ZrC-ZrB2 composites fabricated via reactive melt infiltration. Journal of the American Ceramic Society, 2017, 100(10): 4816. |

| [130] | NI D W, WANG J X, DONG S M, et al. Fabrication and properties of Cf/ZrC-SiC-based composites by an improved reactive melt infiltration. Journal of the American Ceramic Society, 2018, 101(8): 3253. |

| [131] | CHEN B W, NI D W, LU J, et al. Multi-cycle and long-term ablation behavior of Cf/ZrB2-SiC composites at 2500 ℃. Corrosion Science, 2021, 184: 109385. |

| [132] | HU P, ZHANG D Y, DONG S, et al. A novel vibration-assisted slurry impregnation to fabricate Cf/ZrB2-SiC composite with enhanced mechanical properties. Journal of the European Ceramic Society, 2019, 39(4): 798. |

| [133] | CHEN B W, NI D W, WANG J X, et al. Ablation behavior of Cf/ZrC-SiC-based composites fabricated by an improved reactive melt infiltration. Journal of the European Ceramic Society, 2019, 39(15): 4617. |

| [134] | CHEN B W, NI D W, LU J, et al. Microstructure and mechanical behaviors of 2D-Cf/ZrB2-SiC composites at elevated temperatures. Journal of the European Ceramic Society, 2022, 42(13): 5410. |

| [135] | VINCI A, ZOLI L, SCITI D, et al. Mechanical behaviour of carbon fibre reinforced TaC/SiC and ZrC/SiC composites up to 2100 ℃. Journal of the European Ceramic Society, 2019, 39(4): 780. |

| [136] | HU P, CHENG Y, GUO X, et al. Architectural engineering inspired method of preparing Cf/ZrC-SiC with graceful mechanical responses. Journal of the American Ceramic Society, 2019, 102(1): 70. |

| [137] | RUBIO V, BINNER J, COUSINET S, et al. Materials characterisation and mechanical properties of Cf-UHTC powder composites. Journal of the European Ceramic Society, 2019, 39(4): 813. |

| [138] | BAKER B, RUBIO V, RAMANUJAM P, et al. Development of a slurry injection technique for continuous fibre ultra-high temperature ceramic matrix composites. Journal of the European Ceramic Society, 2019, 39(14): 3927. |

| [139] | ZHAO Y Q, ZHU J Z, HE W Y, et al. 3D printing of unsupported multi-scale and large-span ceramic via near-infrared assisted direct ink writing. Nature Communications, 2023, 14: 2381. |

| [140] | LU J, NI D W, LIAO C J, et al. Fabrication and microstructure evolution of Csf/ZrB2-SiC composites via direct ink writing and reactive melt infiltration. Journal of Advanced Ceramics, 2021, 10(6): 1371. |

| [141] | LU J, NI D W, CHEN B W, et al. Ablation behaviour of Csf/ZrB2-SiC composites fabricated by direct ink writing and reactive melt infiltration. Journal of the European Ceramic Society, 2023, 43(8): 3034. |

| [142] |

MEI H, YAN Y K, FENG L P, et al. First printing of continuous fibers into ceramics. Journal of the American Ceramic Society, 2019, 102(6): 3244.

DOI |

| [143] | CHEN S A, ZHANG C R, ZHANG Y D, et al. Effects of polymer derived SiC interphase on the properties of C/ZrC composites. Materials & Design, 2014, 58: 102. |

| [144] | GUO S Q, KAGAWA Y, NISHIMURA T, et al. Thermal and electric properties in hot-pressed ZrB2-MoSi2-SiC composites. Journal of the American Ceramic Society, 2007, 90(7): 2255. |

| [145] | TANG S F, DENG J Y, WANG S J, et al. Fabrication and characterization of an ultra-high-temperature carbon fiber-reinforced ZrB2-SiC matrix composite. Journal of the American Ceramic Society, 2007, 90(10): 3320. |

| [146] | VINCI A, ZOLI L, LANDI E, et al. Oxidation behaviour of a continuous carbon fibre reinforced ZrB2-SiC composite. Corrosion Science, 2017, 123: 129. |

| [147] | WYATT B C, NEMANI S K, HILMAS G E, et al. Ultra-high temperature ceramics for extreme environments. Nature Reviews Materials, 2024, 9: 773. |

| [148] | CAI F Y, NI D W, ZHOU Z Y, et al. Ablation mechanism of Cf/(Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)C-SiC composite during plasma ablation above 2000 ℃. Journal of Materials Science & Technology, 2025, 213: 109. |

| [149] | PAUL A, VENUGOPAL S, BINNER J G P, et al. UHTC-carbon fibre composites: preparation, oxyacetylene torch testing and characterisation. Journal of the European Ceramic Society, 2013, 33(2): 423. |

| [150] | TANG S F, DENG J Y, WANG S J, et al. Ablation behaviors of ultra-high temperature ceramic composites. Materials Science and Engineering: A, 2007, 465(1/2): 1. |

| [151] | LUO L, LIU J P, DUAN L Y, et al. Multiple ablation resistance of La2O3/Y2O3-doped C/SiC-ZrC composites. Ceramics International, 2015, 41(10): 12878. |

| [152] | CHEN B W, NI D W, BAO W C, et al. Engineering Cf/ZrB2-SiC-Y2O3 for thermal structures of hypersonic vehicles with excellent long-term ultrahigh temperature ablation resistance. Advanced Science, 2023, 10(34): 2304254. |

| [153] | ZENG Y, WANG D N, XIONG X, et al. Ultra-high-temperature ablation behavior of SiC-ZrC-TiC modified carbon/carbon composites fabricated via reactive melt infiltration. Journal of the European Ceramic Society, 2020, 40(3): 651. |

| [154] | BACKMAN L, OPILA E J. Thermodynamic assessment of the group IV, V and VI oxides for the design of oxidation resistant multi-principal component materials. Journal of the European Ceramic Society, 2019, 39(5): 1796. |

| [155] |

ROST C M, SACHET E, BORMAN T, et al. Entropy-stabilized oxides. Nature Communications, 2015, 6: 8485.

DOI PMID |

| [156] | 胡逗. 等离子喷涂Zr基陶瓷涂层成分结构优化与烧蚀防护机理研究. 西安: 西北工业大学博士学位论文, 2024. |

| [157] | 王雅雷. 化学气相渗透TaC、SiC/TaC改性C/C复合材料的制备及其力学性能. 长沙: 中南大学硕士学位论文, 2008. |

| [158] | 王雅雷. C/C复合材料HfC抗烧蚀涂层的制备、结构及性能研究. 长沙: 中南大学博士学位论文, 2012. |

| [159] | 熊翔, 王雅雷, 李国栋, 等. CVI-SiC/TaC改性C/C复合材料的力学性能及其断裂行为. 复合材料学报, 2008, 25(5): 91. |

| [160] | LIU L, LI H J, FENG W, et al. Effect of surface ablation products on the ablation resistance of C/C-SiC composites under oxyacetylene torch. Corrosion Science, 2013, 67: 60. |

| [161] | HE Q C, LU J H, WANG Y W, et al. Effects of joint processes of CLVD and PIP on the microstructure and mechanical properties of C/C-ZrC composites. Ceramics International, 2016, 42(15): 17429. |

| [162] | YAN C L, LIU R J, ZHA B L, et al. Fabrication and properties of 3-dimensional 4-directional Cf/HfC-SiC composites by precursor impregnation and pyrolysis process. Journal of Alloys and Compounds, 2018, 739: 955. |

| [163] | ZOU X G, NI D W, CHEN B W, et al. Ablation behavior and mechanisms of 3D-Cf/Ta0.8Hf0.2C-SiC composite at temperatures up to 2500 ℃. Journal of the European Ceramic Society, 2023, 43(4): 1284. |

| [164] | ZHAO D, ZHANG C R, HU H F, et al. Preparation and characterization of three-dimensional carbon fiber reinforced zirconium carbide composite by precursor infiltration and pyrolysis process. Ceramics International, 2011, 37(7): 2089. |

| [165] | SUN Y N, YE L, ZHANG Y Q, et al. Synthesis of high entropy carbide ceramics via polymer precursor route. Ceramics International, 2022, 48(11): 15939. |

| [166] | WANG H, CHEN X B, GAO B, et al. Synthesis and characterization of a novel precursor-derived ZrC/ZrB2 ultra- high-temperature ceramic composite. Applied Organometallic Chemistry, 2013, 27(2): 79. |

| [167] | YANG Y, JAYARAMAN S, KIM D Y, et al. CVD growth kinetics of HfB2 thin films from the single-source precursor Hf(BH4)4. Chemistry of Materials, 2006, 18(21): 5088. |

| [168] | LU Y, CHEN F H, AN P F, et al. Polymer precursor synthesis of TaC-SiC ultrahigh temperature ceramic nanocomposites. RSC Advances, 2016, 6(91): 88770. |

| [169] | NISAR A, ZHANG C, BOESL B, et al. A perspective on challenges and opportunities in developing high entropy-ultra high temperature ceramics. Ceramics International, 2020, 46(16): 25845. |

| [170] | MIAO Q, FU Y Q, CHEN H, et al. Simultaneous enhancement of mechanical and ablation properties of C/C composites modified by (Hf-Ta-Zr)C solid solution ceramics. Journal of the European Ceramic Society, 2023, 43(8): 3182. |

| [171] | 刘跃. 反应熔渗法制备超高温陶瓷改性C/C复合材料的研究. 西安: 西北工业大学博士学位论文, 2018. |

| [172] | MAKURUNJE P, MIDDLEBURGH S C, LEE W E. Addressing high processing temperatures in reactive melt infiltration for multiphase ceramic composites. Journal of the European Ceramic Society, 2023, 43(2): 183. |

| [173] | FITZER E, GADOW R. Fiber-reinforced silicon carbide. American Ceramic Society Bulletin, 1986, 65(2): 326. |

| [174] | KRENKEL W. Cost effective processing of CMC composites by melt infiltration (LSI-process). 25th Annual Conference on Composites, Advanced Ceramics, Materials and Structures, Florida, 2001: 443. |

| [175] | WANG Y G, ZHU X J, ZHANG L T, et al. C/C-SiC-ZrC composites fabricated by reactive melt infiltration with Si0.87Zr0.13 alloy. Ceramics International, 2012, 38(5): 4337. |

| [176] | LIU Z Q, FU Q G, SHI H L, et al. Comparative study of microstructure and ablation behaviour of C/C-HfC-SiC composites prepared under two different conditions. Materials Characterization, 2022, 194: 112467. |

| [177] | 李鑫港. 真空抽滤结合RMI制备C/C-ZrB2-ZrC-SiC复合材料研究. 西安: 西北工业大学硕士学位论文, 2022. |

| [178] | 雷新英. ZrB2-SiC改性高导热C/C复合材料的制备及性能研究. 西安: 西北工业大学硕士学位论文, 2024. |

| [179] | 付前刚, 董智杰, 胡逗, 等. 一种超高温陶瓷选区改性回转体C/C复合材料的真空抽滤装置: CN220989977U. 2024-05-24. |

| [180] | 张雨雷, 赵俊浩, 付艳芹, 等. 一种梯度分布高熵陶瓷-SiC改性C/C复合材料及制备方法: CN117142870A. 2023-12-01. |

| [181] | MONTEVERDE F, SAVINO R, DE STEFANO FUMO M, et al. Plasma wind tunnel testing of ultra-high temperature ZrB2-SiC composites under hypersonic re-entry conditions. Journal of the European Ceramic Society, 2010, 30(11): 2313. |

| [182] | 庄磊. ZrC-SiC改性C/C复合材料及其表面硅基陶瓷涂层的研究. 西安: 西北工业大学博士学位论文, 2020. |

| [183] | SAVINO R, DE STEFANO FUMO M, SILVESTRONI L, et al. Arc-jet testing on HfB2 and HfC-based ultra-high temperature ceramic materials. Journal of the European Ceramic Society, 2008, 28(9): 1899. |

| [184] | SHEN Q L, WANG T Y, SONG Q, et al. Unraveling of the laser drilling of carbon/carbon composites: ablation mechanisms, shape evolution, and damage evaluation. International Journal of Machine Tools and Manufacture, 2023, 184: 103978. |

| [185] | TANG S F, HU C L. Design, preparation and properties of carbon fiber reinforced ultra-high temperature ceramic composites for aerospace applications: a review. Journal of Materials Science & Technology, 2017, 33(2): 117. |

| [186] | LIU Y, FU Q G, WANG B B, et al. Ablation behavior of C/C-SiC-ZrB2 composites in simulated solid rocket motor plumes. Journal of Alloys and Compounds, 2017, 727: 135. |

| [187] | LI Z Q, LI H J, ZHANG S Y, et al. Effect of reaction melt infiltration temperature on the ablation properties of 2D C/C-SiC-ZrC composites. Corrosion Science, 2012, 58: 12. |

| [188] | CHEN S A, ZHANG C R, ZHANG Y D, et al. Mechanism of ablation of 3D C/ZrC-SiC composite under an oxyacetylene flame. Corrosion Science, 2013, 68: 168. |

| [189] | FENG B, LI H J, ZHANG Y L, et al. Effect of SiC/ZrC ratio on the mechanical and ablation properties of C/C-SiC-ZrC composites. Corrosion Science, 2014, 82: 27. |

| [190] | LI K Z, XIE J, FU Q G, et al. Effects of porous C/C density on the densification behavior and ablation property of C/C-ZrC-SiC composites. Carbon, 2013, 57: 161. |

| [191] | 赵志刚. ZrC基陶瓷掺杂碳/碳复合材料的烧蚀行为研究. 西安: 西北工业大学博士学位论文, 2019. |

| [192] | WALKER L S, CORRAL E L. Self-generating high-temperature oxidation-resistant glass-ceramic coatings for C-C composites using UHTCs. Journal of the American Ceramic Society, 2014, 97(9): 3004. |

| [193] | YAN M, LI H J, FU Q G, et al. Ablative property of C/C-SiC-HfC composites prepared via precursor infiltration and pyrolysis under 3000 ℃ oxyacetylene torch. Acta Metallurgica Sinica: English Letters, 2014, 27(6): 981. |

| [194] | LU J H, HAO K, LIU L, et al. Ablation resistance of SiC-HfC-ZrC multiphase modified carbon/carbon composites. Corrosion Science, 2016, 103: 1. |

| [195] | LI W, LV J S, LI J T, et al. Superior ablation resistance of C/C-HfC-SiC composite sharp leading edges above 2500 ℃ prepared by precursor infiltration and pyrolysis. Journal of Materiomics, 2025, 11(2): 100879. |

| [196] | CHEN Y T, SUN W, XIONG X, et al. Microstructure, thermophysical properties, and ablation resistance of C/HfC-ZrC-SiC composites. Ceramics International, 2019, 45(4): 4685. |

| [197] | 张佳平. C/C复合材料与涂层的镶嵌界面设计及基体掺杂HfB2-SiC改性研究. 西安: 西北工业大学博士学位论文, 2019. |

| [198] | LIU Z Q, JIA Y J, HOU J Q, et al. C/C-HfC-SiC composites with simultaneous the resistance to ultra-high temperature airflow erosion and high temperature oxidation. Journal of Materiomics, 2025, 11(1): 100846. |

| [199] | DONG Z J, YU H Z, ZHANG Y, et al. C/C-HfC-ZrC composites with excellent long-term ablation performance prepared by combining PIP and RMI. Ceramics International, 2024, 50(8): 13912. |

| [200] | LI J C, ZHANG Y L, ZHAO Y X, et al. A novel (Hf1/3Zr1/3Ti1/3)C medium-entropy carbide coating with excellent long-life ablation resistance applied above 2100 ℃. Composites Part B: Engineering, 2023, 251: 110467. |

| [201] | YE B L, WEN T Q, NGUYEN M C, et al. First-principles study, fabrication and characterization of (Zr0.25Nb0.25Ti0.25V0.25)C high-entropy ceramics. Acta Materialia, 2019, 170: 15. |

| [202] | YAN X L, CONSTANTIN L, LU Y F, et al. (Hf0.2Zr0.2Ta0.2Nb0.2Ti0.2)C high-entropy ceramics with low thermal conductivity. Journal of the American Ceramic Society, 2018, 101(10): 4486. |

| [203] | WANG Y C, REECE M J. Oxidation resistance of (Hf-Ta-Zr-Nb)C high entropy carbide powders compared with the component monocarbides and binary carbide powders. Scripta Materialia, 2021, 193: 86. |

| [204] | FU Y Q, ZHANG Y L, LI T, et al. Effect of SiC on the anti-ablation resistance and flexural strength of (Hf-Ta-Zr)C-C/C composites. Journal of the European Ceramic Society, 2024, 44(1): 107. |

| [205] | HUANG D, LIU Q L, ZHANG Y F, et al. Ablation behavior and thermal conduction mechanism of 3D ZrC-SiC-modified carbon/carbon composite having high thermal conductivity using mesophase-pitch-based carbon fibers and pyrocarbon as heat transfer channels. Composites Part B: Engineering, 2021, 224: 109201. |

| [206] | LIU L, LI H J, SHI X H, et al. Effect of Cu particles on the ablation properties of C/C composites. Solid State Sciences, 2013, 25: 78. |

| [207] | 薛朋飞, 张光喜, 崔红, 等. C/C-ZrC-Cu复合材料的微观结构与抗烧蚀性能. 固体火箭技术, 2021, 44(1): 96. |

| [208] | ZHANG Y, LIU B, HU D, et al. ZrC modified carbon/carbon composites using ZrSi2 and Zr-Cu alloys as reactive infiltrating materials: a comparative investigation. Journal of Alloys and Compounds, 2024, 1003: 175515. |

| [209] | 黄剑锋, 李贺军, 熊信柏, 等. 炭/炭复合材料高温抗氧化涂层的研究进展. 新型炭材料, 2005, 20(4): 373. |

| [210] |

汤素芳, 杨嘉, 唐鹏举, 等. Cf/SiC复合材料表面抗氧化涂层研究进展. 材料工程, 2023, 51(3): 17.

DOI |

| [211] |

付前刚, 石慧伦. C/C复合材料表面耐高温抗氧化硅基陶瓷涂层研究进展. 航空材料学报, 2021, 41(3): 1.

DOI |

| [212] | 张曦挚, 崔红, 胡杨, 等. 利用等离子喷涂制备C/C复合材料表面耐烧蚀抗氧化涂层的研究进展. 材料导报, 2023, 37(6): 84. |

| [213] | ZHU Y, CHENG L F, MA B S, et al. Effect of CVD ZrB2 coating thickness on anti-ablation performance of C/SiC composites. Ceramics International, 2018, 44(7): 8166. |

| [214] | CHEN M M, LI H J, YAO X Y, et al. High temperature oxidation resistance of La2O3-modified ZrB2-SiC coating for SiC-coated carbon/carbon composites. Journal of Alloys and Compounds, 2018, 765: 37. |

| [215] | YAO X Y, LI H J, ZHANG Y L, et al. A SiC/ZrB2-SiC/SiC oxidation resistance multilayer coating for carbon/carbon composites. Corrosion Science, 2012, 57: 148. |

| [216] | NIU Y R, WANG H Y, LI H, et al. Dense ZrB2-MoSi2 composite coating fabricated by low pressure plasma spray (LPPS). Ceramics International, 2013, 39(8): 9773. |

| [217] | BARTULI C, VALENTE T, TULUI M. Plasma spray deposition and high temperature characterization of ZrB2-SiC protective coatings. Surface and Coatings Technology, 2002, 155(2/3): 260. |

| [218] | WANG R Q, WANG N, ZHU S Z, et al. Study on the mechanism of ultra-high temperature ablation of ZrB2-SiC-TaSi2 coatings by low-pressure plasma spraying on the C/C composites. Ceramics International, 2023, 49(7): 11344. |

| [219] | LIU T, ZHENG L L, ZHANG H. Effect of solid shield on coating properties in atmospheric plasma spray process. Journal of Thermal Spray Technology, 2016, 25(8): 1502. |

| [220] | TULUI M, MARINO G, VALENTE T. Plasma spray deposition of ultra high temperature ceramics. Surface and Coatings Technology, 2006, 201(5): 2103. |

| [221] | SHUAI K, ZHANG Y L, FU Y Q, et al. MoSi2-HfC/TaC-HfC multi-phase coatings synthesized by supersonic atmospheric plasma spraying for C/C composites against ablation. Corrosion Science, 2021, 193: 109884. |

| [222] | FAHRENHOLTZ W G, HILMAS G E, TALMY I G, et al. Refractory diborides of zirconium and hafnium. Journal of the American Ceramic Society, 2007, 90(5): 1347. |

| [223] | PARTHASARATHY T A, RAPP R A, OPEKA M, et al. A model for the oxidation of ZrB2, HfB2 and TiB2. Acta Materialia, 2007, 55(17): 5999. |

| [224] | ZOU X, FU Q G, LIU L, et al. ZrB2-SiC coating to protect carbon/carbon composites against ablation. Surface and Coatings Technology, 2013, 226: 17. |

| [225] | SILVESTRONI L, MERIGGI G, SCITI D. Oxidation behavior of ZrB2 composites doped with various transition metal silicides. Corrosion Science, 2014, 83: 281. |

| [226] | LI B, LI H J, YAO X Y, et al. Ablation behavior of sharp leading edge parts made of rare earth La-compound modified ZrB2 coated C/C composites. Corrosion Science, 2020, 175: 108895. |

| [227] | LIU X Z, HAN W, WEN K, et al. Bimodal microstructure ZrB2-MoSi2 coating prepared by atmospheric plasma spraying for carbon/carbon composites against long-term ablation. Ceramics International, 2017, 43(18): 16659. |

| [228] | JAYASEELAN D D, ZAPATA-SOLVAS E, BROWN P, et al. In situ formation of oxidation resistant refractory coatings on SiC-reinforced ZrB2 ultra high temperature ceramics. Journal of the American Ceramic Society, 2012, 95(4): 1247. |

| [229] | QIAN D Y, CHEN Y X, REN X R, et al. Effect of La2O3 content on the oxygen barrier ability of the HfB2-SiC coating at 1973 K. Journal of the American Ceramic Society, 2023, 106(3): 2155. |

| [230] | BARGERON C B, BENSON R C, JETTE A N, et al. Oxidation of hafnium carbide in the temperature range 1400 to 2060 ℃. Journal of the American Ceramic Society, 1993, 76(4): 1040. |

| [231] | WANG S L, LI K Z, LI H J, et al. Ablation behavior of CVD-ZrC coating under oxyacetylene torch environment with different heat fluxes. International Journal of Refractory Metals and Hard Materials, 2015, 48: 108. |

| [232] | FENG G H, LI H J, YAO X Y, et al. Ablation resistance of TaC-modified HfC coating prepared by supersonic plasma spraying for SiC-coated carbon/carbon composites. Ceramics International, 2019, 45(14): 17936. |

| [233] | REN J C, ZHANG Y L, FU Y Q, et al. Effects of the second phase on the microstructure and ablation resistance of HfC coating on C/C composites. Surface and Coatings Technology, 2018, 344: 250. |

| [234] | JIA Y J, LI H J, YAO X Y, et al. Long-time ablation protection of carbon/carbon composites with different-La2O3-content modified ZrC coating. Journal of the European Ceramic Society, 2018, 38(4): 1046. |

| [235] | FU Q G, ZHANG P, ZHUANG L, et al. Micro/nano multiscale reinforcing strategies toward extreme high-temperature applications: take carbon/carbon composites and their coatings as the examples. Journal of Materials Science & Technology, 2022, 96: 31. |

| [236] | LIU B, SUN J, GUO L X, et al. Materials design of silicon based ceramic coatings for high temperature oxidation protection. Materials Science and Engineering: R: Reports, 2025, 163: 100936. |

| [237] | WANG Y J, LI H J, FU Q G, et al. SiC/HfC/SiC ablation resistant coating for carbon/carbon composites. Surface and Coatings Technology, 2012, 206(19/20): 3883. |

| [238] | CHEN Z K, XIONG X, LI G D, et al. Ablation behaviors of carbon/carbon composites with C-SiC-TaC multi-interlayers. Applied Surface Science, 2009, 255(22): 9217. |

| [239] | LOEHMAN R E, CORRAL E L. Multilayer ultra-high-temperature ceramic coatings: US20090366028. 2012-03-20. |

| [240] | HU D, FU Q G, LIU T Y, et al. Structural design and ablation performance of ZrB2/MoSi2 laminated coating for SiC coated carbon/carbon composites. Journal of the European Ceramic Society, 2020, 40(2): 212. |

| [241] | WANG Y J, LI H J, FU Q G, et al. Ablation behaviour of a TaC coating on SiC coated C/C composites at different temperatures. Ceramics International, 2013, 39(1): 359. |

| [242] | 任俊杰, 姚西媛, 李克智, 等. 超音速等离子喷涂制备ZrB2-SiC基涂层C/C复合材料的氧化烧蚀性能研究. 中国材料进展, 2017, 36(1): 75. |

| [243] | ZHOU L, ZHANG J P, HU D, et al. Investigation on the oxidation and ablation behaviors of HfB2-SiC-Si/SiC-Si coatings for carbon/carbon composites. Corrosion Science, 2021, 190: 109638. |

| [244] | LIU T, NIU Y R, LI C, et al. Ablation resistance of ZrC-MoSi2/ ZrC-SiC double-layered coating in a plasma flame. Corrosion Science, 2018, 145: 239. |

| [245] | LI J H, ZHANG Y L, WANG H H, et al. Long-life ablation resistance ZrB2-SiC-TiSi2 ceramic coating for SiC coated C/C composites under oxidizing environments up to 2200 K. Journal of Alloys and Compounds, 2020, 824: 153934. |

| [246] | ZHANG P, FU Q G, CHENG C Y, et al. Comparing oxidation behaviors at 1773 K and 1973 K of HfB2-MoSi2/SiC-Si coating prepared by a combination method of pack cementation, slurry painting and in situ synthesis. Surface and Coatings Technology, 2020, 403: 126418. |

| [1] | YU Shengyang, SU Haijun, JIANG Hao, YU Minghui, YAO Jiatong, YANG Peixin. A Review of Pore Defects in Ultra-high Temperature Oxide Ceramics by Laser Additive Manufacturing: Formation and Suppression [J]. Journal of Inorganic Materials, 2025, 40(9): 944-956. |

| [2] | CHEN Bin, REN Ke, WANG Yiguang. Evolution of Mechanical Properties of Mini-SiCf/SiC Composites at High Temperatures over a Long Period of Time [J]. Journal of Inorganic Materials, 2025, 40(9): 971-980. |

| [3] | LIU Jiangping, GUAN Xin, TANG Zhenjie, ZHU Wenjie, LUO Yongming. Research Progress on Catalytic Oxidation of Nitrogen-containing Volatile Organic Compounds [J]. Journal of Inorganic Materials, 2025, 40(9): 933-943. |

| [4] | XIAO Xiaolin, WANG Yuxiang, GU Peiyang, ZHU Zhenrong, SUN Yong. Advances in Regulation of Damaged Skin Regeneration by Two-dimensional Inorganic Materials [J]. Journal of Inorganic Materials, 2025, 40(8): 860-870. |

| [5] | MA Jingge, WU Chengtie. Application of Inorganic Bioceramics in Promoting Hair Follicle Regeneration and Hair Growth [J]. Journal of Inorganic Materials, 2025, 40(8): 901-910. |

| [6] | ZHANG Hongjian, ZHAO Ziyi, WU Chengtie. Inorganic Biomaterials on Regulating Neural Cell Function and Innervated Tissue Regeneration: A Review [J]. Journal of Inorganic Materials, 2025, 40(8): 849-859. |

| [7] | AI Minhui, LEI Bo. Micro-nanoscale Bioactive Glass: Functionalized Design and Angiogenic Skin Regeneration [J]. Journal of Inorganic Materials, 2025, 40(8): 921-932. |

| [8] | WANG Yutong, CHANG Jiang, XU He, WU Chengtie. Advances in Silicate Bioceramic/Bioglass for Wound Healing: Effects, Mechanisms and Application Ways [J]. Journal of Inorganic Materials, 2025, 40(8): 911-920. |

| [9] | MA Wenping, HAN Yahui, WU Chengtie, LÜ Hongxu. Application of Inorganic Bioactive Materials in Organoid Research [J]. Journal of Inorganic Materials, 2025, 40(8): 888-900. |

| [10] | LUO Xiaomin, QIAO Zhilong, LIU Ying, YANG Chen, CHANG Jiang. Inorganic Bioactive Materials Regulating Myocardial Regeneration [J]. Journal of Inorganic Materials, 2025, 40(8): 871-887. |

| [11] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [12] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [13] | HE Guoqiang, ZHANG Kaiheng, WANG Zhentao, BAO Jian, XI Zhaochen, FANG Zhen, WANG Changhao, WANG Wei, WANG Xin, JIANG Jiapei, LI Xiangkun, ZHOU Di. Ba(Nd1/2Nb1/2)O3: Au Underrated K40 Microwave Dielectric Ceramic [J]. Journal of Inorganic Materials, 2025, 40(6): 639-646. |

| [14] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [15] | ZHANG Bihui, LIU Xiaoqiang, CHEN Xiangming. Recent Progress of Hybrid Improper Ferroelectrics with Ruddlesden-Popper Structure [J]. Journal of Inorganic Materials, 2025, 40(6): 587-608. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||