Journal of Inorganic Materials ›› 2017, Vol. 32 ›› Issue (8): 891-896.DOI: 10.15541/jim20160633

• Orginal Article • Previous Articles

GAO Jiao-Jiao, JIANG Long-Kai, SONG Jin-Peng, LIANG Guo-Xing, AN Jing, XIE Jun-Cai, CAO Lei, LV Ming

Received:2016-11-21

Published:2017-08-10

Online:2017-07-19

About author:GAO Jiao-Jiao(1991-), female, candidate of master degree. E-mail: gaojiaojiao1207@163.com

Supported by:CLC Number:

GAO Jiao-Jiao, JIANG Long-Kai, SONG Jin-Peng, LIANG Guo-Xing, AN Jing, XIE Jun-Cai, CAO Lei, LV Ming. Effects of TiC Content on Microstructure and Mechanical Property of WC-TiC-TaC Cemented Carbides[J]. Journal of Inorganic Materials, 2017, 32(8): 891-896.

| Sample | WC/wt% | TiC/wt% | TaC/wt% | Ni/wt% |

|---|---|---|---|---|

| S1 | 78 | 10 | 2 | 10 |

| S2 | 73 | 15 | 2 | 10 |

| S3 | 68 | 20 | 2 | 10 |

| S4 | 63 | 25 | 2 | 10 |

Table1 Compositions of WC-TiC-TaC cemented carbides

| Sample | WC/wt% | TiC/wt% | TaC/wt% | Ni/wt% |

|---|---|---|---|---|

| S1 | 78 | 10 | 2 | 10 |

| S2 | 73 | 15 | 2 | 10 |

| S3 | 68 | 20 | 2 | 10 |

| S4 | 63 | 25 | 2 | 10 |

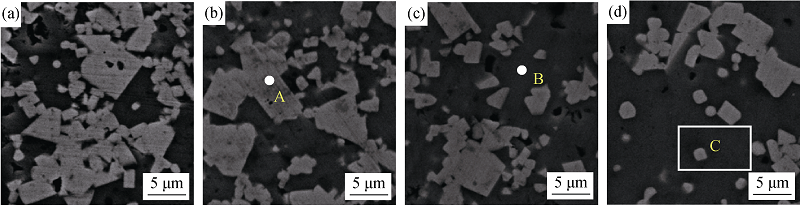

Fig. 2 BSE micrographs of polished surfaces of WC-TiC-TaC cemented carbides(a) WC-10wt%TiC-TaC (S1); (b) WC-15wt%TiC-TaC (S2); (c) WC-20wt%TiC-TaC (S3); (d) WC-25wt%TiC-TaC (S4)

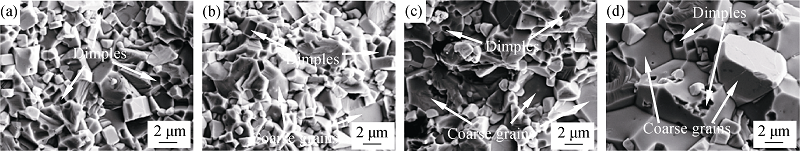

Fig. 5 Fracture morphologies of WC-TiC-TaC cemented carbides(a) WC-10wt%TiC-TaC (S1), (b) WC-15wt%TiC-TaC (S2), (c) WC-20wt%TiC-TaC (S3), (d) WC-25wt%TiC-TaC (S4)

| [1] | UPADHYAYA G S.Materials science of cemented carbides - an overview.Mater. Des., 2001, 22: 483-489. |

| [2] | MOUSTAFA S F, ABDEL-HAMID Z, OSAMA G, et al.Hussien, Synthesis of WC hard materials using coated powders.Adv. Powder Technol., 2011, 22: 596-601. |

| [3] | LIN N, WU C H, HE Y H, et al.Effect of Mo and Co additions on the microstructure and properties of WC-TiC-Ni cemented carbides.Int. J. Refract. Met. Hard Mater., 2012, 30: 107-113. |

| [4] | KIM HWAN-CHEOL, PARK HYUN-KUK, JEONG IN-KYOON, et al.Sintering of binderless WC-Mo2C hard materials by rapid sintering process.Ceram. Int., 2008, 34: 1419-1423. |

| [5] | RAJABI A, GHAZALI M J, DAUD A R.Chemical composition, microstructure and sintering temperature modifications on mechanical properties of TiC-based cermet - a review.Mater. Des., 2015, 67: 95-106. |

| [6] | MILL B.Recent developments in cutting tool materials.J. Mater. Process Technol., 1996, 56: 16-23. |

| [7] | YANG XUEFENG, WANG SHOUREN, YANG LIYING, et al.Research on the wear behaviors of WC-8Co and Al2O3-TiC conical dies.J. Inorg. Mater., 2012, 27(8): 876-882. |

| [8] | YAN KE, WANG YATAI, ZHU YONGSHENG, et al.Investigation on heat dissipation characteristic of ball bearing cage and inside cavity at ultra high rotation speed.Tribol. Int., 2016, 93: 470-481. |

| [9] | XIONG JI, GUO ZHIXING, YANG MEI, et al.Tool life and wear of WC-TiC-Co ultrafine cemented carbide during dry cutting of AISI H13 steel.Ceram. Int., 2013, 39: 337-346. |

| [10] | ZHAO JUN, YUAN XUNLIANG, ZHOU YONGHUI.Cutting performance and failure mechanisms of an Al2O3/WC/TiC micro- nano-composite ceramic tool.Int. J. Refract. Met. Hard Mater., 2010, 28: 330-337. |

| [11] | MAHMOODAN M, ALIAKBARZADEH H, GHOLAMIPOUR R.Sintering of WC-10% Co nano powders containing TaC and VC grain growth inhibitors.Trans. Nonferrous Metals Soc. China, 2011, 21: 1080-1084. |

| [12] | OUYANG CHENXIN, ZHU SHIGEN, QU HAIXIA.VC and Cr3C2 doped WC-MgO compacts prepared by hot-pressing sintering.Mater. Des., 2012, 40: 550-555. |

| [13] | GENGA R M, CORNISH L A, AKDOGAN G.Effect of Mo2C additions on the properties of SPS manufactured WC-TiC-Ni cemented carbides.Int. J. Refract. Met. Hard Mater., 2013, 41: 12-21. |

| [14] | XIONG JI, GUO ZHIXING, SHEN BAOLUO, et al.The effect of WC, Mo2C, TaC content on the microstructure and properties of ultra-fine TiC0.7N0.3 cermet.Mater. Des., 2007, 28: 1689-1694. |

| [15] | WU PENG, ZHENG YONG, ZHAO YONGLE, et al.Effect of TaC addition on the microstructures and mechanical properties of Ti(C, N)-based cermets.Mater. Des., 2010, 31: 3537-3541. |

| [16] | GENGA R M, AKDOGAN G, WESTRAADT J E, et al.Microstructure and material properties of PECS manufactured WC-NbC-Co and WC-TiC-Ni cemented carbides.Int. J. Refract. Met. Hard Mater., 2015, 49: 240-248. |

| [17] | PIRSO J, VILJUS M, LETUNOVITŠ S.Friction and dry sliding wear behavior of cermets. Wear, 2006, 260: 815-824. |

| [18] | ZOU BIN, HUANG CHUANZHEN, SONG JINPENG, et al.Effects of sintering processes on mechanical properties and microstructure of TiB2-TiC + 8wt% nano-Ni composite ceramic cutting tool material.Mater. Sci. Eng. A, 2012, 540: 235-244. |

| [19] | SUN PEIQIU, ZHU DEGUI, JIANG XIAOSONG, et al.Research on microstructures and properties of in-situ synthesis of TiB2-TiC0.8-SiC multiphase ceramics.J. Inorg. Mater., 2013, 28(4): 363-368. |

| [20] | LIN NAN, HE YUEHUI, WU CHONGHU, et al.Influence of TiC additions on the corrosion behaviour of WC-Co hardmetals in alkaline solution.Int. J. Refract. Met. Hard Mater., 2014, 46: 52-57. |

| [21] | YU YINHU, WANG TAO, ZHANG HONGMIN, et al.Low temperature combustion synthesis of TiC powder induced by PTFE.J. Inorg. Mater., 2015, 30(3): 272-276. |

| [22] | YANG SHIE, LU ZHANLING, FAN ZHIQIN, et al.Highly adherent diamond film deposited onto WC-Co cemented.J. Inorg. Mater., 2005, 20(1): 235-238. |

| [23] | FANG Z Z, WANG X, RYU T, et al.Synthesis, sintering, and mechanical properties of nanocrystalline cemented tungsten carbide-a review. Int. J. Refract. Met. Hard Mater., 2009, 27: 288-299. |

| [24] | KONG D H, HE BS, LIN L H.Effect of chromium content on structure and properties of WC-based cemented carbide.Shanghai Nonfer. Metal, 2005, 26: 53-57. |

| [25] | SHI KAI-HUA, ZHOU KE-CHAO, LI ZHI-YOU, et al.Effect of adding method of Cr on microstructure and properties of WC-9Ni-2Cr cemented carbides.Int. J. Refract. Met. Hard Mater., 2013, 38: 1-6. |

| [26] | LINDAHL P, GUATAFSON P, ROLANDER U, et al.Microstructure of model cermets with high Mo or W content.Int. J. Refract. Met. Hard Mater., 1999, 17: 411-421. |

| [27] | LIU N, XU Y D, LI Z H, et al.Influence of molybdenum addition on the microstructure and mechanical properties of TiC-based cermets with nano-TiN modification.Ceram. Int., 2003, 29: 919-925. |

| [28] | KWON HANJUNG, SUH CHANG-YUL, KIM WONBAEK.Microstructure and mechanical properties of (Ti,W)C-Ni cermet prepared using a nano-sized TiC-WC powder mixture. J. Alloy. Compd., 2015, 639: 21-26. |

| [29] | CHENG ZHANG, JINPENG SONG, LONGKAI JIANG, et al.Fabrication and tribological properties of WC-TiB2 composite cutting tool materials under dry sliding condition.Tribol. Int., 2017, 109: 97-103. |

| [30] | SHON I J, JEONG I K, KO I Y, et al.Sintering behaviour and mechanical properties of WC-10Co, WC-10Ni and WC-10Fe hardmaterials produced by high frequency induction heated sintering.Ceram. Int., 2009, 35: 339-344. |

| [31] | LI YUXIN, BAI PEIKANG, WANG YAOMIN, et al.Effect of TiC content on Ni/TiC composites by direct laser fabrication.Mater. Des., 2009, 30: 1409-1412. |

| [32] | EE KYONG H, CHA SEUNG I, KIM BYUNG K, et al.Effect of WC/TiC grain size ratio on microstructure and mechanical properties of WC-TiC-Co cemented carbides.Int. J. Refract. Met. Hard Mater., 2006, 24: 109-114. |

| [33] | LI ANHAI, ZHAO JUN, WANG DONG, et al.Three-point bending fatigue behavior of WC-Co cemented carbides.Mater. Des., 2013, 45: 271-278. |

| [34] | WANG JUN, LIU YING, ZHANG PING, et al.Effect of VC and nano-TiC addition on the microstructure and properties of micrometer grade Ti(CN)-based cermets.Mater. Des., 2009, 30: 2222-2226. |

| [35] | NIELS HANSEN.Hall-Petch relation and boundary strengthening.Scripta Mater., 2004, 51: 801-806. |

| [36] | SONG JINPENG, HUANG CHUANZHEN, ZOU BIN, et al.Microstructure and mechanical properties of TiB2-TiC-WC composite ceramic tool materials.Mater. Des., 2012, 36: 69-74. |

| [1] | MU Haojie, ZHANG Yuanjiang, YU Bin, FU Xiumei, ZHOU Shibin, LI Xiaodong. Preparation and Properties of ZrO2 Doped Y2O3-MgO Nanocomposite Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 281-289. |

| [2] | FAN Wugang, CAO Xiong, ZHOU Xiang, LI Ling, ZHAO Guannan, ZHANG Zhaoquan. Anticorrosion Performance of 8YSZ Ceramics in Simulated Aqueous Environment of Pressurized Water Reactor [J]. Journal of Inorganic Materials, 2024, 39(7): 803-809. |

| [3] | CHEN Qian, SU Haijun, JIANG Hao, SHEN Zhonglin, YU Minghui, ZHANG Zhuo. Progress of Ultra-high Temperature Oxide Ceramics: Laser Additive Manufacturing and Microstructure Evolution [J]. Journal of Inorganic Materials, 2024, 39(7): 741-753. |

| [4] | JIANG Lingyi, PANG Shengyang, YANG Chao, ZHANG Yue, HU Chenglong, TANG Sufang. Preparation and Oxidation Behaviors of C/SiC-BN Composites [J]. Journal of Inorganic Materials, 2024, 39(7): 779-786. |

| [5] | ZHENG Yawen, ZHANG Cuiping, ZHANG Ruijie, XIA Qian, RU Hongqiang. Fabrication of Boron Carbide Ceramic Composites by Boronic Acid Carbothermal Reduction and Silicon Infiltration Reaction Sintering [J]. Journal of Inorganic Materials, 2024, 39(6): 707-714. |

| [6] | XUE Yifan, LI Weijie, ZHANG Zhongwei, PANG Xu, LIU Yu. Process Control of PyC Interphases Microstructure and Uniformity in Carbon Fiber Cloth [J]. Journal of Inorganic Materials, 2024, 39(4): 399-408. |

| [7] | SUN Chuan, HE Pengfei, HU Zhenfeng, WANG Rong, XING Yue, ZHANG Zhibin, LI Jinglong, WAN Chunlei, LIANG Xiubing. SiC-based Ceramic Materials Incorporating GNPs Array: Preparation and Mechanical Characterization [J]. Journal of Inorganic Materials, 2024, 39(3): 267-273. |

| [8] | ZHENG Jiaqian, LU Xiao, LU Yajie, WANG Yingjun, WANG Zhen, LU Jianxi. Functional Bioadaptability in Medical Bioceramics: Biological Mechanism and Application [J]. Journal of Inorganic Materials, 2024, 39(1): 1-16. |

| [9] | HE Danqi, WEI Mingxu, LIU Ruizhi, TANG Zhixin, ZHAI Pengcheng, ZHAO Wenyu. Heavy-Fermion YbAl3 Materials: One-step Synthesis and Enhanced Thermoelectric Performance [J]. Journal of Inorganic Materials, 2023, 38(5): 577-582. |

| [10] | WU Shuang, GOU Yanzi, WANG Yongshou, SONG Quzhi, ZHANG Qingyu, WANG Yingde. Effect of Heat Treatment on Composition, Microstructure and Mechanical Property of Domestic KD-SA SiC Fibers [J]. Journal of Inorganic Materials, 2023, 38(5): 569-576. |

| [11] | XIE Jiaye, LI Liwen, ZHU Qiang. Contrastive Study on in Vitro Antibacterial Property and Biocompatibility of Three Clinical Pulp Capping Agents [J]. Journal of Inorganic Materials, 2023, 38(12): 1449-1456. |

| [12] | LI Jianbo, TIAN Zhen, JIANG Quanwei, YU Lifeng, KANG Huijun, CAO Zhiqiang, WANG Tongmin. Effects of Different Element Doping on Microstructure and Thermoelectric Properties of CaTiO3 [J]. Journal of Inorganic Materials, 2023, 38(12): 1396-1404. |

| [13] | WU Dongjiang, ZHAO Ziyuan, YU Xuexin, MA Guangyi, YOU Zhulin, REN Guanhui, NIU Fangyong. Direct Additive Manufacturing of Al2O3-TiCp Composite Ceramics by Laser Directed Energy Deposition [J]. Journal of Inorganic Materials, 2023, 38(10): 1183-1192. |

| [14] | ZHANG Ye, ZENG Yuping. Progress of Porous Silicon Nitride Ceramics Prepared via Self-propagating High Temperature Synthesis [J]. Journal of Inorganic Materials, 2022, 37(8): 853-864. |

| [15] | XIA Qian, SUN Shihao, ZHAO Yiliang, ZHANG Cuiping, RU Hongqiang, WANG Wei, YUE Xinyan. Effect of Boron Carbide Particle Size Distribution on the Microstructure and Properties of Reaction Bonded Boron Carbide Ceramic Composites by Silicon Infiltration [J]. Journal of Inorganic Materials, 2022, 37(6): 636-642. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||