Journal of Inorganic Materials ›› 2024, Vol. 39 ›› Issue (6): 623-633.DOI: 10.15541/jim20230608

Special Issue: 【结构材料】超高温结构陶瓷(202506); 【结构材料】陶瓷基复合材料(202506)

• REVIEW • Previous Articles Next Articles

Received:2023-12-31

Revised:2024-02-27

Published:2024-06-20

Online:2024-02-26

Contact:

TANG Sufang, professor. E-mail: sftang@imr.ac.cnAbout author:ZHAO Rida (1995-), male, PhD, assistant professor. E-mail: rdzhao16s@imr.ac.cn

Supported by:CLC Number:

ZHAO Rida, TANG Sufang. Research Progress of Ceramic Matrix Composites Prepared by Improved Reactive Melt Infiltration through Ceramization of Porous Carbon Matrix[J]. Journal of Inorganic Materials, 2024, 39(6): 623-633.

| Carbon source | Density of porous carbon/(g·cm-3) | Median pore diameter of porous carbon/nm | Density of ceramic/ (g·cm-3) | Si content/% (in mass) | Ref. |

|---|---|---|---|---|---|

| Furfuryl alcohol | / | 1000 | / | / | [ |

| Furfuryl alcohol | 0.86 | 1300 | / | / | [ |

| Furfuryl | 0.74 | 2580 | 3.04 | 17.6 | [ |

| 0.65 | 1940 | 2.81 | 34.7 | ||

| 0.58 | 670 | 3.01 | / | ||

| 0.90 | 40 | 3.07 | / | ||

| Phenol formaldehyde | 0.79 | 2363 | 2.10 | 13.0 | [ |

| 0.79 | 1552 | 2.81 | 12.0 | ||

| 0.74 | 1226 | 2.88 | 16.0 | ||

| 0.74 | 642 | 2.91 | 14.0 | ||

| 0.73 | 190 | 2.93 | 16.0 | ||

| Phenol formaldehyde | 0.72 | 39.9 | 2.92 | 20.0 | [ |

| 0.72 | 39.9 | 3.07 | 15.4 | ||

| 0.79 | 28.8 | 3.08 | 12.2 | ||

| 0.78 | 38.7 | 2.95 | 3.1 | ||

| Phenol formaldehyde | 0.90 | 20.1 | 2.90 | 3.6 | [ |

Table 1 Carbon sources, densities and median pore diameters of porous carbon, densities and Si content of obtained ceramics

| Carbon source | Density of porous carbon/(g·cm-3) | Median pore diameter of porous carbon/nm | Density of ceramic/ (g·cm-3) | Si content/% (in mass) | Ref. |

|---|---|---|---|---|---|

| Furfuryl alcohol | / | 1000 | / | / | [ |

| Furfuryl alcohol | 0.86 | 1300 | / | / | [ |

| Furfuryl | 0.74 | 2580 | 3.04 | 17.6 | [ |

| 0.65 | 1940 | 2.81 | 34.7 | ||

| 0.58 | 670 | 3.01 | / | ||

| 0.90 | 40 | 3.07 | / | ||

| Phenol formaldehyde | 0.79 | 2363 | 2.10 | 13.0 | [ |

| 0.79 | 1552 | 2.81 | 12.0 | ||

| 0.74 | 1226 | 2.88 | 16.0 | ||

| 0.74 | 642 | 2.91 | 14.0 | ||

| 0.73 | 190 | 2.93 | 16.0 | ||

| Phenol formaldehyde | 0.72 | 39.9 | 2.92 | 20.0 | [ |

| 0.72 | 39.9 | 3.07 | 15.4 | ||

| 0.79 | 28.8 | 3.08 | 12.2 | ||

| 0.78 | 38.7 | 2.95 | 3.1 | ||

| Phenol formaldehyde | 0.90 | 20.1 | 2.90 | 3.6 | [ |

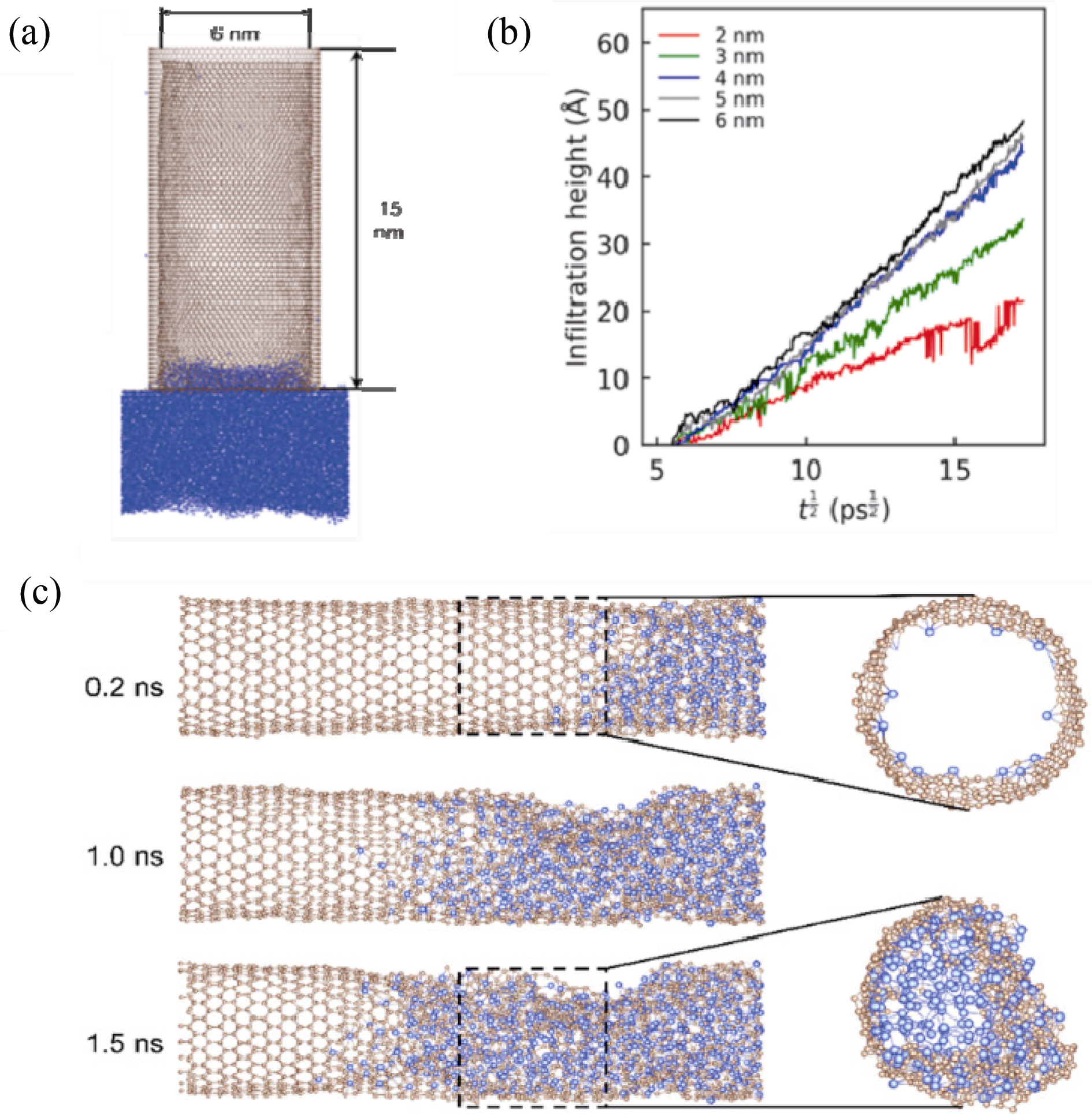

Fig. 6 (a) Schematic illustration of liquid Si infiltration in double-walled carbon nanotubes, (b) relationship between infiltration height (H) and infiltration time (t) for liquid Si infiltration, and (c) capillary infiltration behavior of liquid Si into a double-walled carbon nanotubes with an inner tube diameter of 2 nm[51]

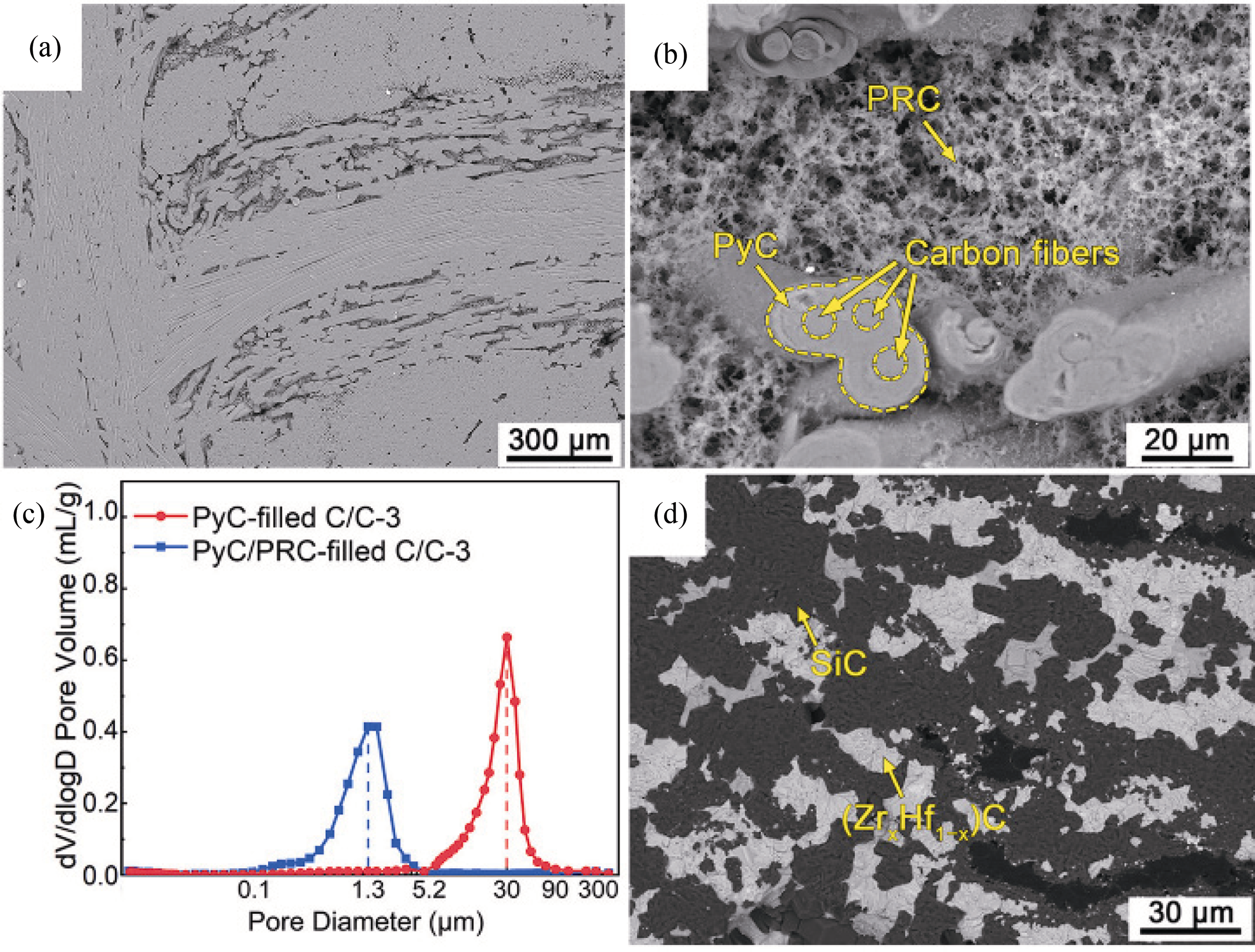

Fig. 8 (a, b) Microstructures and (c) pore size distribution curves of the porous C/C, and (d) cross-sectional micrograph of the C/C-SiC-(ZrxHf1-x)C[35]

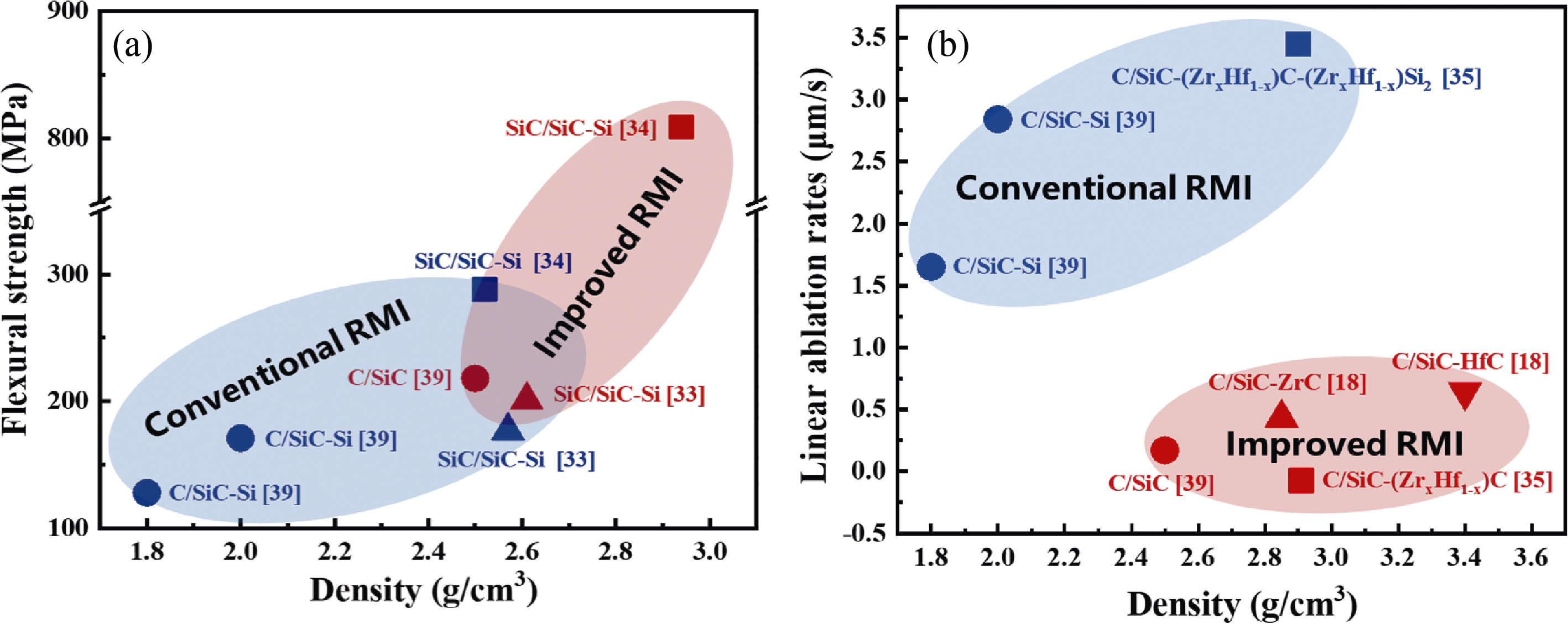

Fig. 10 Comparison of (a) flexural strength and (b) 2200 ℃ linear ablation rates of ceramic matrix composites obtained by conventional RMI and improved RMI through ceramization of porous carbon matrix[18,33⇓-35,39]

| Preform | Preparation method of porous matrix | Median pore diameter/nm | Predominant pore size range/nm | Ceramic matrix composites | Flexural strength/MPa | Ref. |

|---|---|---|---|---|---|---|

| C/SiC-C | Phase separation | 1800 | 500-10000 | C/SiC-Si | / | [ |

| SiC/BNx/SiNx/C | Phase separation | / | 1000-4500 | SiC/BNx/SiNx/SiC-Si | / | [ |

| C/B4C-C | Sol-Gel | 39800 | 25000-75000 | C/ZrB2-SiC-ZrC | 231 | [ |

| C/B4C-Al2O3-C | Sol-Gel | / | 10-10000 | C/B4C-Al2O3-SiC-Si | 300 | [ |

| C/ZrC-C | Carbothermal reduction | / | 4-130000 | C/ZrC-SiC-ZrSi2 | 380 | [ |

| C/C | Phase separation | 41.6 | 10-80 | C/SiC | 218 | [ |

| SiC/SiC-C | Phase separation | / | 100-5000 | SiC/SiC-Si | 201 | [ |

| C/C | Phase separation | 1300 | 100-5200 | C/C-SiC-(ZrxHf1−x)C | / | [ |

| SiC/SiC-C | Sol-Gel | / | 500-10000 | SiC/SiC-Si | 809 | [ |

| C/C | Phase separation | / | 10-130 | C/SiC-ZrC | 288 | [ |

| C/SiC-HfC | 251 |

Table 2 Preparation methods of porous matrix in preform, median pore diameters and predominant pore size ranges of preform, and flexural strength of the obtained ceramic matrix composites

| Preform | Preparation method of porous matrix | Median pore diameter/nm | Predominant pore size range/nm | Ceramic matrix composites | Flexural strength/MPa | Ref. |

|---|---|---|---|---|---|---|

| C/SiC-C | Phase separation | 1800 | 500-10000 | C/SiC-Si | / | [ |

| SiC/BNx/SiNx/C | Phase separation | / | 1000-4500 | SiC/BNx/SiNx/SiC-Si | / | [ |

| C/B4C-C | Sol-Gel | 39800 | 25000-75000 | C/ZrB2-SiC-ZrC | 231 | [ |

| C/B4C-Al2O3-C | Sol-Gel | / | 10-10000 | C/B4C-Al2O3-SiC-Si | 300 | [ |

| C/ZrC-C | Carbothermal reduction | / | 4-130000 | C/ZrC-SiC-ZrSi2 | 380 | [ |

| C/C | Phase separation | 41.6 | 10-80 | C/SiC | 218 | [ |

| SiC/SiC-C | Phase separation | / | 100-5000 | SiC/SiC-Si | 201 | [ |

| C/C | Phase separation | 1300 | 100-5200 | C/C-SiC-(ZrxHf1−x)C | / | [ |

| SiC/SiC-C | Sol-Gel | / | 500-10000 | SiC/SiC-Si | 809 | [ |

| C/C | Phase separation | / | 10-130 | C/SiC-ZrC | 288 | [ |

| C/SiC-HfC | 251 |

| [1] | 张俊敏, 蔡飞燕, 靳喜海, 等. 连续纤维增强陶瓷基复合材料研究与应用进展. 陶瓷学报, 2023, 44(2):195. |

| [2] | 赵日达.纳米多孔碳均匀陶瓷化制备超高温陶瓷基复合材料及其性能研究. 沈阳: 中国科学技术大学博士学位论文, 2022. |

| [3] | JIANG Y, HU C L, LIANG B, et al. Cyclic ablation resistance at 2300 ℃ of (Hf0.4Zr0.4Ta0.2)B2-SiC-Si coating for C/SiC composites prepared by SiC-assisted reactive infiltration of silicon. Surface & Coatings Technology, 2022, 451: 129072. |

| [4] | TANG P J, HU C L, PANG S Y, et al. Self-densifcation behavior, interfacial bonding and cyclic ablation resistance of HfSi2-ZrSi2 modified SiC/ZrB2-SiC/SiC coating for Cf/SiC composite. Corrosion Science, 2023, 219: 111223. |

| [5] | TANG P J, HU C L, PANG S Y, et al. Interfacial modification and cyclic ablation behaviors of a SiC/ZrB2-SiC/SiC triple-layer coating for C/SiC composites at above 2000 ℃. Corrosion Science, 2020, 169: 108604. |

| [6] |

OUYANG Q, WANG Y F, XU J, et al. Research progre.ss of SiC fiber reinforced SiC composites for nuclear application. Journal of Inorganic Materials, 2022, 37(8):821.

DOI |

| [7] |

CHEN Q, BAI S X, YE Y. Highly thermal conductive silicon carbide ceramics matrix composites for thermal management: a review. Journal of Inorganic Materials, 2023, 38(6):634.

DOI |

| [8] |

ZHANG B Y, WANG L, WANG X M, et al. Effect of precursors on impregnation behaviors of C/SiC composites. Journal of Inorganic Materials, 2020, 35(9):1017.

DOI |

| [9] | SHEN X Y, MA Q, XUE Y D, et al. Effects of multilayered interfaces on mechanical damage of SiCf/SiC composites. Journal of Inorganic Materials, 2023, 38(8):917. |

| [10] | JI S Y, LIANG B, YANG B, et al. Long-term oxidation behaviors and strength retention properties of self-healing SiCf/SiC-SiBCN composites. Journal of the European Ceramic Society, 2023, 43(5): 1843. |

| [11] | YAO J J, PANG S Y, HU C L, et al. Mechanical, oxidation and ablation properties of C/(C-SiC)CVI-(ZrC-SiC)PIP composites. Corrosion Science, 2020, 162: 108200. |

| [12] |

JU Y C, LIU X Y, WANG Q, et al. Ablation behavior of ultra-high temperature composite ceramic matrix composites. Journal of Inorganic Materials, 2022, 37(1):86.

DOI |

| [13] |

LIU Y F, FENG X, WANG J M, et al. Preparation and properties of high-performance needled C/C composites. Journal of Inorganic Materials, 2020, 35(10):1105.

DOI |

| [14] | PANG S Y, WANG P Y, HU C L, et al. Carbon fiber preform's structure on mechanical property of C/C composites and bolts. Journal of Inorganic Materials, 2019, 34(12):1272. |

| [15] |

PAN B C, REN P H, ZHOU T J, et al. Microstructure and property of thermal insulation coating on the carbon fiber reinforced epoxy resin composites. Journal of Inorganic Materials, 2020, 35(8):947.

DOI |

| [16] | 宋若康, 张梦珊, 戴珍, 等. 烧蚀型防热/吸波多功能一体化复合材料的制备及性能. 复合材料学报, 2023, 41(1):252. |

| [17] | SCITI D, ZOLI L, REIMER T, et al. A systematic approach for horizontal and vertical scale up of sintered ultra-high temperature ceramic matrix composites for aerospace-advances and perspectives. Composites Part B: Engineering, 2022, 234: 109709. |

| [18] | ZHAO R D, PANG S Y, LIANG B, et al. Comparative ablation behaviors of C/SiC-ZrC and C/SiC-HfC composites prepared by ceramization of carbon aerogel preforms. Corrosion Science, 2023, 225: 111623. |

| [19] | 孙倩, 张会丰, 黄传兵, 等. 碳纤维增强超高温陶瓷基复合材料的多相反应制备与抗烧蚀性能. 过程工程学报, 2023, 23(2):10. |

| [20] | 姜毅, 李国栋, 于士杰, 等. 浆料注射法制备Cf/SiC-ZrC复合材料的力学和抗氧化性能. 粉末冶金材料科学与工程, 2022, 27(2):151. |

| [21] | YAO J J, LIANG B, HU C L, et al. Pitch resin addition induced evolution of composition, microstructure and mechanical property of C/C-SiC-ZrC composites. Journal of the European Ceramic Society, 2022, 42(14):6412. |

| [22] |

ZHANG S, FU Q Q, ZHANG P, et al. Influence of high temperature treatment of C/C porous preform on friction and wear behavior of C/C-SiC composites. Journal of Inorganic Materials, 2023, 38(5):561.

DOI |

| [23] | WANG Y X, TAN S H, JIANG D L. Research and development of reaction sintered silicon carbide. Journal of Inorganic Materials, 2004, 19(3):456. |

| [24] | MESSNER R P, CHIANG Y M. Liquid-phase reaction-bonding of silicon carbide using alloyed silicon-molybdenum melts. Journal of the American Ceramic Society, 1990, 73(5):1193. |

| [25] | CHIANG Y M, MESSNER R P, TERWILLIGER C D, et al. Reaction-formed silicon carbide. Materials Science and Engineering: A, 1991, 144(1/2):63. |

| [26] | SINGH M, DICKERSON R M. Microstructure and mechanical properties of reaction-formed silicon carbide (RFSC) ceramics. Materials Science and Engineering: A, 1994, 187(2):183. |

| [27] | XU S J, QIAO G J, LI D C, et al. Reaction forming of silicon carbide ceramic using phenolic resin derived porous carbon preform. Journal of the European Ceramic Society, 2009, 29(11):2395. |

| [28] | SINGH M, DICKERSON R M. Characterization of SiC fiber (SCS-6) reinforced-reaction formed silicon carbide matrix composites. Journal of Materials Research, 1996, 11(3):746. |

| [29] | SINGH M, DICKERSON R M, OLMSTEAD F A, et al. SiC (SCS-6) fiber reinforced-reaction formed SiC matrix composites: microstructure and interfacial properties. Journal of Materials Research, 1997, 12(3):706. |

| [30] | MAINZER B, RODER K, WÖCKEL L, et al. Development of wound SiCBNx/SiNx/SiC with near stoichiometric SiC matrix via LSI process. Journal of the European Ceramic Society, 2016, 36(7):1571. |

| [31] | ZHONG Q, ZHANG X Y, DONG S M, et al. Reactive melt infiltrated Cf/SiC composites with robust matrix derived from novel engineered pyrolytic carbon structure. Ceramics International, 2017, 43(7):5832. |

| [32] | 董绍明, 钟强, 张翔宇, 等.一种高致密的碳化硅陶瓷基复合材料及其制备方法: CN106588060A. 2017-04-26. |

| [33] | ZHANG J M, CHEN XW, LIAO C J, et al. Optimizing microstructure and properties of SiCf/SiC composites prepared by reactive melt infiltration. Journal of Inorganic Materials, 2021, 36(10):1103. |

| [34] | GUO G D, YE F, CHENG L F, et al. A novel porous carbon synthesized to serve in the preparation of highly dense and high-strength SiC/SiC by reactive melt infiltration. Composites Part A: Applied Science and Manufacturing, 2024, 176: 107839. |

| [35] | LIU Z D, WANG Y L, XIONG X, et al. Structural optimization and air-plasma ablation behaviors of C/C-SiC-(ZrxHf1-x)C composites prepared by reactive melt infiltration method. Corrosion Science, 2023, 222: 111408. |

| [36] | 冯志海, 刘宇峰, 张中伟, 等. 一种基于熔融渗硅工艺的复合材料、碳/碳多孔体及其制备方法: CN108794040A. 2018-11-13. |

| [37] | 杨良伟, 王鹏, 宋环君, 等.一种碳/碳化硅-碳化锆陶瓷基复合材料的制备方法: CN112321315A. 2021-02-05. |

| [38] | 汤素芳, 赵日达, 庞生洋, 等.一种多孔碳均匀陶瓷化制备碳化硅基复合材料的方法: CN115557800A. 2023-01-03. |

| [39] | ZHAO R D, PANG S Y, HU C L, et al. Fabrication of C/SiC composites by siliconizing carbon fiber reinforced nanoporous carbon matrix preforms and their properties. Journal of the European Ceramic Society, 2023, 43(2):273. |

| [40] | WU Y, ZHAO R D, LIANG B, et al. Construction of C/SiC-Cu3Si-Cu interpenetrating composites for long-duration thermal protection at 2500 ℃ by cooperative active-passive cooling. Composites Part B: Engineering, 2023, 266: 111015. |

| [41] | SINGH M, DICKERSON R M. Reactive melt infiltration of silicon-molybdenum alloys into microporous carbon preforms. Materials Science and Engineering: A, 1995, 194(2):193. |

| [42] | SINGH M. Joining of sintered silicon carbide ceramics for high-temperature applications. Journal of materials science letters, 1998, 17(6):459. |

| [43] | WANG Y X, TAN S H, JIANG D L. The effect of porous carbon preform and the infiltration process on the properties of reaction-formed SiC. Carbon, 2004, 42(8/9): 1833. |

| [44] | WANG Y X, TAN S H, JIANG D L. The fabrication of reaction- formed silicon carbide with controlled microstructure by infiltrating a pure carbon preform with molten Si. Ceramics International, 2004, 30(3):435. |

| [45] | XU S J, QIAO G J, WANG H J, et al. Preparation of mesoporous carbon by phenol resin polymerization-dependent phase separation and pyrolysis. Journal of Inorganic Materials, 2008, 23(5):971. |

| [46] | 徐顺建, 乔冠军. 复杂形状 SiC 陶瓷的模板法成型研究进展. 材料导报, 2009, 23(21):59. |

| [47] | XU S J, QIAO G J, WANG H J, et al. Microstructure evolution and reaction mechanism of microporous carbon derived SiC ceramic. Journal of Inorganic Materials, 2009, 24(2):291. |

| [48] | 袁志勇.树脂碳源反应烧结碳化硅陶瓷凝胶注模成型机理研究. 哈尔滨: 哈尔滨工业大学博士学位论文, 2014. |

| [49] | 吴西士.Cf/SiC复合材料陶瓷连接层的设计、 制备与连接性能研究. 上海: 中国科学院上海硅酸盐研究所博士学位论文, 2019. |

| [50] | WU X S, ZHU Y Z, HUANG Q, et al. Effect of pore structure of organic resin-based porous carbon on joining properties of Cf/SiC composites. Journal of Inorganic Materials, 2022, 37(12):1275. |

| [51] | ZHANG K Y, ZHAO R D, YANG Y Q, et al. Capillary infiltration of liquid silicon in carbon nanotubes: a molecular dynamics simulation. Journal of Materials Science & Technology, 2023, 144: 219. |

| [52] | ZHAO R D, HU C L, WANG Y H, et al. Construction of sandwich-structured C/C-SiC and C/C-SiC-ZrC composites with good mechanical and anti-ablation properties. Journal of the European Ceramic Society, 2022, 42(4):1219. |

| [53] | WANG D K, DONG S M, ZHOU H J, et al. Fabrication and microstructure of 3D Cf/ZrC-SiC composites: through RMI method with ZrO2 powders as pore-making agent. Ceramics International, 2016, 42(6):6720. |

| [54] | NI D W, WANG J X, DONG S M, et al. Fabrication and properties of Cf/ZrC-SiC-based composites by an improved reactive melt infiltration. Journal of the American Ceramic Society, 2018, 101(8):3253. |

| [55] | 陈小武, 董绍明, 倪德伟, 等. 碳纤维增强超高温陶瓷基复合材料研究进展. 中国材料进展, 2019, 38(9):842. |

| [56] | CHEN X W, NI D W, KAN Y M, et al. Reaction mechanism and microstructure development of ZrSi2 melt-infiltrated Cf/SiC-ZrC- ZrB2 composites: the influence of preform pore structures. Journal of Materiomics, 2018, 4(3):266. |

| [57] | MAGNANT J, MAILLÉ L, PAILLER R, et al. Carbon fiber/reaction-bonded carbide matrix for composite materials- manufacture and characterization. Journal of the European Ceramic Society, 2012, 32(16):4497. |

| [58] | GAO Y Q, LIU Y S, WANG J, et al. Formation mechanism of Si-Y-C ceramic matrix by reactive melt infiltration using Si-Y alloy and properties of C/Si-Y-C composites. Ceramics International, 2020, 46(11):18976. |

| [59] | 史扬帆, 潘勇, 高扬, 等. 超高温陶瓷及其复合材料的稀土改性研究进展. 硅酸盐通报, 2023, 42(2):682. |

| [60] | GUO W J, HU J, FANG W, et al. A novel strategy for rapid fabrication of continuous carbon fiber reinforced (TiZrHfNbTa)C high-entropy ceramic composites: high-entropy alloy in-situ reactive melt infiltration. Journal of the European Ceramic Society, 2023, 43(6):2295. |

| [61] | HE H R, TANG J G, GUO W J, et al. Microstructures and formation mechanism of continuous carbon fiber-reinforced (TiZrHfNbTa)C high-entropy ceramic composites fabricated via high-entropy alloy reactive melt infiltration. Ceramics International, 2023, 49(22):36997. |

| [62] | GUO W J, BAI S X, YE Y C. Controllable fabrication and mechanical properties of C/C-SiC composites based on an electromagnetic induction heating reactive melt infiltration. Journal of the European Ceramic Society, 2021, 41(4):2347. |

| [63] | ZOU X G, NI D, CHEN B W, et al. Fabrication and properties of Cf/Ta4HfC5-SiC composite via precursor infiltration and pyrolysis. Journal of the American Ceramic Society, 2021, 104(12):6601. |

| [64] | CAI F Y, NI D W, BAO W C, et al. Ablation behavior and mechanisms of Cf/(Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2) C-SiC high-entropy ceramic matrix composites. Composites Part B: Engineering, 2022, 243: 110177. |

| [1] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [2] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [3] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [4] | ZHANG Bihui, LIU Xiaoqiang, CHEN Xiangming. Recent Progress of Hybrid Improper Ferroelectrics with Ruddlesden-Popper Structure [J]. Journal of Inorganic Materials, 2025, 40(6): 587-608. |

| [5] | WU Jie, YANG Shuai, WANG Mingwen, LI Jinglei, LI Chunchun, LI Fei. Textured PT-based Piezoelectric Ceramics: Development, Status and Challenge [J]. Journal of Inorganic Materials, 2025, 40(6): 575-586. |

| [6] | JIANG Kun, LI Letian, ZHENG Mupeng, HU Yongming, PAN Qinxue, WU Chaofeng, WANG Ke. Research Progress on Low-temperature Sintering of PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 627-638. |

| [7] | TIAN Ruizhi, LAN Zhengyi, YIN Jie, HAO Nanjing, CHEN Hangrong, MA Ming. Microfluidic Technology Based Synthesis of Inorganic Nano-biomaterials: Principles and Progress [J]. Journal of Inorganic Materials, 2025, 40(4): 337-347. |

| [8] | ZHANG Jiguo, WU Tian, ZHAO Xu, YANG Fan, XIA Tian, SUN Shien. Improvement of Cycling Stability of Cathode Materials and Industrialization Process for Sodium-ion Batteries [J]. Journal of Inorganic Materials, 2025, 40(4): 348-362. |

| [9] | YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 245-255. |

| [10] | CHEN Guangchang, DUAN Xiaoming, ZHU Jinrong, GONG Qing, CAI Delong, LI Yuhang, YANG Donglei, CHEN Biao, LI Xinmin, DENG Xudong, YU Jin, LIU Boya, HE Peigang, JIA Dechang, ZHOU Yu. Advanced Ceramic Materials in Helicopter Special Structures: Research Progress and Application Prospect [J]. Journal of Inorganic Materials, 2025, 40(3): 225-244. |

| [11] | FAN Xiaobo, ZU Mei, YANG Xiangfei, SONG Ce, CHEN Chen, WANG Zi, LUO Wenhua, CHENG Haifeng. Research Progress on Proton-regulated Electrochemical Ionic Synapses [J]. Journal of Inorganic Materials, 2025, 40(3): 256-270. |

| [12] | HAIREGU Tuxun, GUO Le, DING Jiayi, ZHOU Jiaqi, ZHANG Xueliang, NUERNISHA Alifu. Research Progress of Optical Bioimaging Technology Assisted by Upconversion Fluorescence Probes in Tumor Imaging [J]. Journal of Inorganic Materials, 2025, 40(2): 145-158. |

| [13] | SUN Shujuan, ZHENG Nannan, PAN Haokun, MA Meng, CHEN Jun, HUANG Xiubing. Research Progress on Preparation Methods of Single-atom Catalysts [J]. Journal of Inorganic Materials, 2025, 40(2): 113-127. |

| [14] | TAO Guilong, ZHI Guowei, LUO Tianyou, OUYANG Peidong, YI Xinyan, LI Guoqiang. Progress on Key Technologies of Cavity-structured Thin Film Bulk Acoustic Wave Filter [J]. Journal of Inorganic Materials, 2025, 40(2): 128-144. |

| [15] | ZHOU Fan, TIAN Zhilin, LI Bin. Research Progress on Carbide Ultra-high Temperature Ceramic Anti-ablation Coatings for Thermal Protection System [J]. Journal of Inorganic Materials, 2025, 40(1): 1-16. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||