Journal of Inorganic Materials ›› 2023, Vol. 38 ›› Issue (5): 477-488.DOI: 10.15541/jim20220515

Special Issue: 【制备方法】3D打印(202506)

• REVIEW • Next Articles

YUAN Jingkun( ), XIONG Shufeng, CHEN Zhangwei(

), XIONG Shufeng, CHEN Zhangwei( )

)

Received:2022-09-02

Revised:2022-10-10

Published:2022-10-19

Online:2022-10-19

Contact:

CHEN Zhangwei, Professor. E-mail: chen@szu.edu.cnAbout author:YUAN Jingkun (1985-), male, PhD. E-mail: yuanjk@szu.edu.cn

Supported by:CLC Number:

YUAN Jingkun, XIONG Shufeng, CHEN Zhangwei. Research Trends and Challenges of Additive Manufacturing of Polymer-derived Ceramics[J]. Journal of Inorganic Materials, 2023, 38(5): 477-488.

Fig. 2 Additive manufacturing of polymer-derived ceramics[14]. (a) UV-curable preceramic monomers and photoinitiator; (b) SL printing process; (c) As-printed parts; (d) As-pyrolyzed ceramic; (e) Examples of final parts

Fig. 3 Schematic diagram (left) of DLP printing process of four different preceramic polymers, and optical microscopic images and photographs of the printed structures [28] (a, c, e, g) Optical microscopic images of the printed structures; (b, d, f, h) Photographs of the printed structures before and after pyrolysis

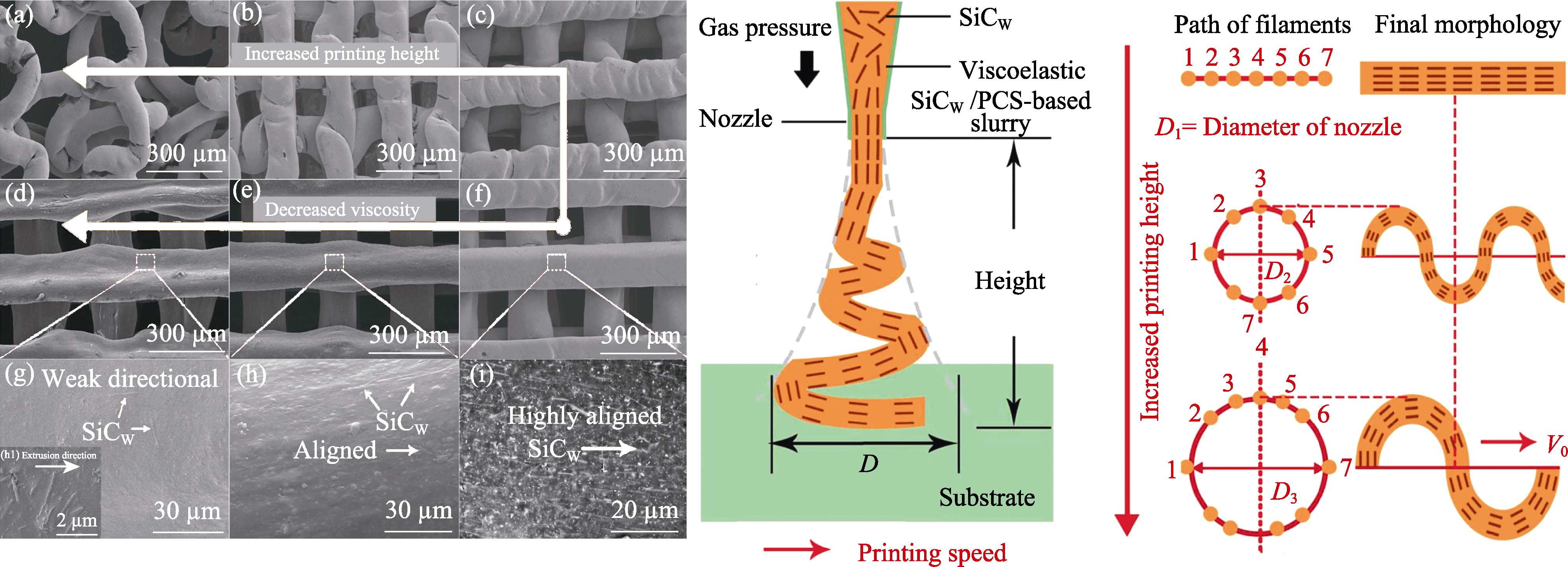

Fig. 4 SEM images of SiCw/SiC lattices under different printing height or using suspensions with different solid loading (left) and schematic illustration of the morphology of extruded filaments with different printing height (right)[19] (a-c) Printed with 62.3% solid loading (in vol.); (d-f) Printed with 57.7%, 59.9% and 62.3% solid loadings (in vol.); (g-i) Enlarged views of the squares in (d-f)

Fig. 5 SEM images of Kelvin cell structures pyrolyzed at 1000 ℃[38] (a-c) Kelvin cell structures pyrolyzed at 1000 ℃ on support pillars with increasing height, to reduce shrinkage constraints from the glass substrate during pyrolysis; (d-f) Magnification of the samples shown in the upper row

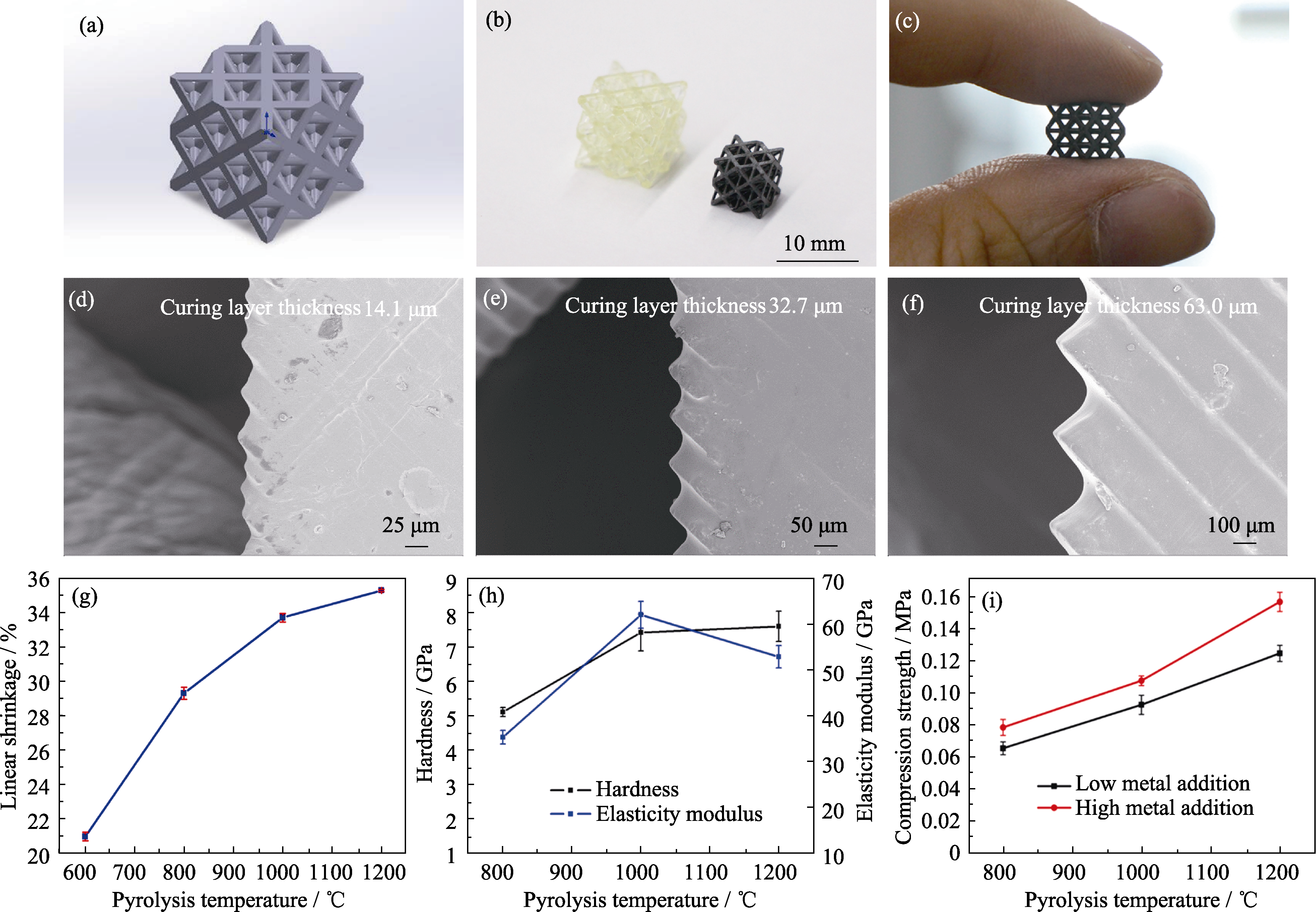

Fig. 6 Pictures and mechanical properties of 3D printing of bimetal-doped precursor[41] (a-c) Lattice CAD model, resin and SiOC ceramics; (d-f) SEM images of different curing layer thickness; (g-i) Mechanical properties

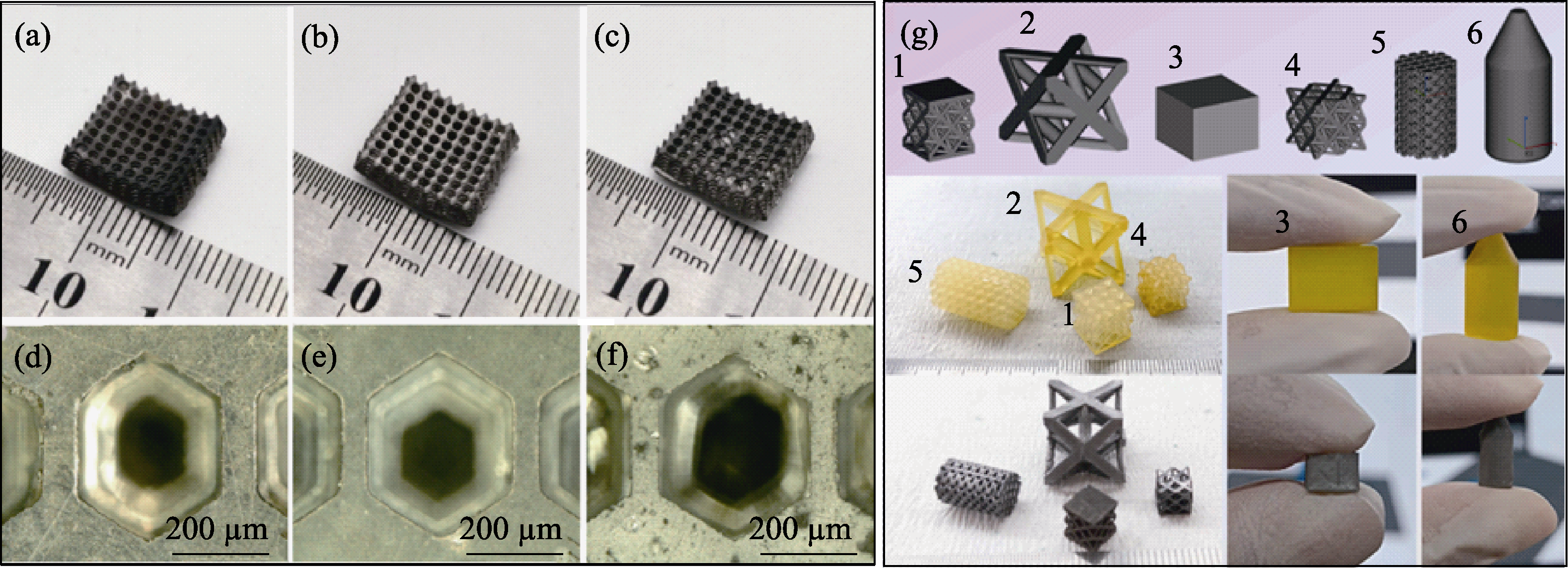

Fig. 7 CAD models and optical images of the samples after printing and pyrolysis (left column), SEM images of the samples’ skeleton surface after pyrolysis (right two columns, (a-d))[44]

Fig. 8 (a-c) Optical images of the SiOC ceramic samples with different proportion of silicone oil additive, (d-f) closer looks of the corresponding samples in (a-c) [46], and (g) CAD models, green and pyrolyzed samples with the addition of phenolic resin additive [47]

Fig. 9 Schematic of 3D printing of polymer-derived ceramics inside a support gel (a), illustration of the printing (b), printed samples (c-e), and pyrolyzed samples (f, g)[53]

Fig. 10 CAD design of the nozzle compared with the final pyrolysed part and SEM images[58] Left: SEM images and AFM images (Col.1, 2 and 4) of ceramic cubes printed with different parameters, with the measured corresponding mean values of the linear shrinkage (Col.3) and the average roughness (Col.5). Upper-right: CAD designs of two different structures and final pyrolysed parts. Lower-right: CAD design of the nozzle compared with the final ceramic part with their SEM images at 0°(I.a and II.a) and 60°(I.b and II.b), and their corresponding X-ray microtomographies from different angles (a-j)

Fig. 11 Origami and 4D printing of PDCs via DIW-morphing-heat treatment method[59] (a) 3D printed elastomeric lattices; (b) Optical image of DIW; (c) Origami of ceramic structures; (d, e) Two 4D printing methods together with heat treatment; (f) Flat and curved cellphone back plate; (g) Top view of flat plate; (h) Curved ceramic honeycomb; Inset indicates the curvature of the honeycomb. Scale bars:1 cm

| Material | AM Tech. | Ceramic yield/% (in mass) | Monolith/ skeleton porosity/% | Density/ (g·cm-3) | Linear shrinkage/ % | Compressive strength/MPa | Tensile strength/ GPa | Hardness/ GPa | Elastic modulus/ GPa | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|

| SiCN | DLP | 80 | 0 | 2.28 | 20 | - | - | 10 | 78 | [ |

| SiCN | DLP | 25.3 | 6.9 | 2.167 | 62.9 | >50 | - | >33 | [ | |

| SiOC | DLP | 44.1 | 1.5 | 2.1 | 35.4 | 0.124-0.156 | - | ~7.61 | - | [ |

| SiOC | DLP | 40.1 | 0 | 2.1 | 51.5 | 10 | 1.9 | - | 3.1 | [ |

| SiOC | DIW | 94 | 0 | - | 8 | 56.4 | - | - | 28.9 | [ |

| SiOC | DIW | - | 0 | - | 55(vol) | ∼3.1 | - | - | - | [ |

| SiOCN | DIW | 77 | 50 | 1.05 | - | 0.3-0.9 | - | - | - | [ |

| SiOC | SLS | 82 | 0 | 2.64 | 3 | 220 | - | - | - | [ |

| SiOC | DIW | 31.3-58.84 | 86.5 | 1.97 | 46.7(vol) | 2.92 | - | - | - | [ |

| SiOC | DLP | 29.63 | 3.64 | 1.60 | 42.01 | 19.08 | - | 5.82 | 46.4 | [ |

| SiOC | BJ3DP | 16.5 | 19 | 1.84 | 22.2 | 20 | - | - | - | [ |

| SiOC | DLP | ~30 | 47 | 1.95 | 30 | 12.9 | - | - | - | [ |

Table 1 Summary of various 3D printing techniques used for different PDC materials and their properties after pyrolysis

| Material | AM Tech. | Ceramic yield/% (in mass) | Monolith/ skeleton porosity/% | Density/ (g·cm-3) | Linear shrinkage/ % | Compressive strength/MPa | Tensile strength/ GPa | Hardness/ GPa | Elastic modulus/ GPa | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|

| SiCN | DLP | 80 | 0 | 2.28 | 20 | - | - | 10 | 78 | [ |

| SiCN | DLP | 25.3 | 6.9 | 2.167 | 62.9 | >50 | - | >33 | [ | |

| SiOC | DLP | 44.1 | 1.5 | 2.1 | 35.4 | 0.124-0.156 | - | ~7.61 | - | [ |

| SiOC | DLP | 40.1 | 0 | 2.1 | 51.5 | 10 | 1.9 | - | 3.1 | [ |

| SiOC | DIW | 94 | 0 | - | 8 | 56.4 | - | - | 28.9 | [ |

| SiOC | DIW | - | 0 | - | 55(vol) | ∼3.1 | - | - | - | [ |

| SiOCN | DIW | 77 | 50 | 1.05 | - | 0.3-0.9 | - | - | - | [ |

| SiOC | SLS | 82 | 0 | 2.64 | 3 | 220 | - | - | - | [ |

| SiOC | DIW | 31.3-58.84 | 86.5 | 1.97 | 46.7(vol) | 2.92 | - | - | - | [ |

| SiOC | DLP | 29.63 | 3.64 | 1.60 | 42.01 | 19.08 | - | 5.82 | 46.4 | [ |

| SiOC | BJ3DP | 16.5 | 19 | 1.84 | 22.2 | 20 | - | - | - | [ |

| SiOC | DLP | ~30 | 47 | 1.95 | 30 | 12.9 | - | - | - | [ |

| [1] |

CHEN Z W, LI Z Y, LI J J, et al. 3D printing of ceramics: a review. Journal of the European Ceramic Society, 2019, 39(4): 661.

DOI |

| [2] | 刘雨, 陈张伟. 陶瓷光固化3D打印技术研究进展. 材料工程, 2020, 48(9): 1. |

| [3] | 陈张伟. 多孔陶瓷的增材制造及构性表征与关系研究. 现代技术陶瓷, 2021, 42(1/2): 43. |

| [4] |

LAKHDAR Y, TUCK C, BINNER J, et al. Additive manufacturing of advanced ceramic materials. Progress in Materials Science, 2021, 116: 100736.

DOI URL |

| [5] | MARCUS H L, BEAMAN J J, BARLOW J W, et al. Solid freeform fabrication-powder processing. American Ceramic Society Bulletin, 1990, 69(6): 1030. |

| [6] |

CHAUDHARY R P, PARAMESWARAN C, IDREES M, et al. Additive manufacturing of polymer-derived ceramics: materials, technologies, properties and potential applications. Progress in Materials Science, 2022, 128: 100969.

DOI URL |

| [7] |

GREIL P. Polymer derived engineering ceramics. Advanced Engineering Materials, 2000, 2(6): 339.

DOI URL |

| [8] |

XIA A, YIN J, CHEN X, et al. Polymer-derived Si-based ceramics: recent developments and perspectives. Crystals, 2020, 10(9): 824.

DOI URL |

| [9] | 骆春佳, 宋燕, 周睿, 等. 高性能陶瓷聚合物前驱体研究新进展. 高分子通报, 2019, 10: 53. |

| [10] | COLOMBO P, MERA G, RIEDEL R, et al. Polymer-derived ceramics: 40 years of research and innovation in advanced ceramics. Journal of the American Ceramic Society, 2010, 93(7): 1805. |

| [11] |

FU S, ZHU M, ZHU Y. Organosilicon polymer-derived ceramics: an overview. Journal of Advanced Ceramics, 2019, 8(4): 457.

DOI |

| [12] |

CAO J W, WANG P, LIU Z Y, et al. Research progress on powder-based laser additive manufacturing technology of ceramics. Journal of Inorganic Materials, 2022, 37(3): 241.

DOI |

| [13] |

熊鼎宇, 屈飘, 朱中琪, 等. 陶瓷挤出和喷射增材制造技术研究进展. 机械工程学报, 2021, 57(17): 253.

DOI |

| [14] |

ECKEL Z C, ZHOU C, MARTIN J H, et al. 3D printing additive manufacturing of polymer-derived ceramics. Science, 2016, 351(6268): 58.

DOI PMID |

| [15] |

吴甲民, 杨源祺, 王操, 等. 陶瓷光固化技术及应用. 机械工程学报, 2020, 56(19): 221.

DOI |

| [16] |

YANG W, YANG D, MEI H, et al. 3D printing of PDC- SiOC@SiC twins with high permittivity and electromagnetic interference shielding effectiveness. Journal of the European Ceramic Society, 2021, 41(11): 5437.

DOI URL |

| [17] |

HUANG K, ELSAYED H, FRANCHIN G, et al. 3D printing of polymer-derived SiOC with hierarchical and tunable porosity. Additive Manufacturing, 2020, 36: 101549.

DOI URL |

| [18] |

XU X, LI P, GE C, et al. 3D printing of complex-type SiOC ceramics derived from liquid photosensitive resin. ChemistrySelect, 2019, 4(23): 6862.

DOI URL |

| [19] |

XIONG H, ZHAO L, CHEN H, et al. 3D SiC containing uniformly dispersed, aligned SiC whiskers: printability, microstructure and mechanical properties. Journal of Alloys and Compounds, 2019, 809: 151824.

DOI URL |

| [20] |

XIONG H, CHEN H, ZHAO L, et al. SiCw/SiCpreinforced 3D-SiC ceramics using direct ink writing of polycarbosilane-based solution: microstructure, composition and mechanical properties. Journal of the European Ceramic Society, 2019, 39(8): 2648.

DOI URL |

| [21] | GYAK K W, VISHWAKARMA N K, HWANG Y H, et al. 3D-printed monolithic SiCN ceramic microreactors from a photocurable preceramic resin for the high temperature ammonia cracking process. Reaction Chemistry & Engineering, 2019, 4(8): 1393 |

| [22] |

JANA P, SANTOLIQUIDO O, ORTONA A, et al. Polymer- derived SiCN cellular structures from replica of 3D printed lattices. Journal of the American Ceramic Society, 2018, 101(7): 2732.

DOI URL |

| [23] |

AZARNOUSH S, LAUBSCHER F, ZOLI L, et al. Additive manufacturing of SiCN ceramic matrix for SiC fiber composites by flash pyrolysis of nanoscale polymer films. Journal of the American Ceramic Society, 2016, 99(6): 1855.

DOI URL |

| [24] |

IVANOVA O, WILLIAMS C, CAMPBELL T. Additive manufacturing (AM) and nanotechnology: promises and challenges. Rapid Prototyping Journal, 2013, 19(5): 353.

DOI URL |

| [25] |

YANG J, YU R, LI X, et al. Silicon carbide whiskers reinforced SiOC ceramics through digital light processing 3D printing technology. Ceramics International, 2021, 47(13): 18314.

DOI URL |

| [26] |

HE C, MA C, LI X, et al. Polymer-derived SiOC ceramic lattice with thick struts prepared by digital light processing. Additive Manufacturing, 2020, 35: 101366.

DOI URL |

| [27] |

WANG X, SCHMIDT F, HANAOR D, et al. Additive manufacturing of ceramics from preceramic polymers: a versatile stereolithographic approach assisted by thiolene click chemistry. Additive Manufacturing, 2019, 27: 80.

DOI URL |

| [28] |

MA C, HE C, WANG W, et al. Metal-doped polymer-derived SiOC composites with inorganic metal salt as the metal source by digital light processing 3D printing. Virtual and Physical Prototyping, 2020, 15(3): 294.

DOI URL |

| [29] |

HE C, LIU X, MA C, et al. Digital light processing fabrication of mullite component derived from preceramic precursor using photosensitive hydroxysiloxane as the matrix and alumina nanoparticles as the filler. Journal of the European Ceramic Society, 2021, 41(11): 5570.

DOI URL |

| [30] |

KULKARNI A, SORARU G D, PEARCE J M. Polymer-derived SiOC replica of material extrusion-based 3-D printed plastics. Additive Manufacturing, 2020, 32: 100988.

DOI URL |

| [31] |

XIAO J, LIU D, CHENG H, et al. Carbon nanotubes as light absorbers in digital light processing three-dimensional printing of SiCN ceramics from preceramic polysilazane. Ceramics International, 2020, 46(11): 19393.

DOI URL |

| [32] |

WANG M, XIE C, HE R, et al. Polymer-derived silicon nitride ceramics by digital light processing based additive manufacturing. Journal of the American Ceramic Society, 2019, 102(9): 5117.

DOI URL |

| [33] | 何汝杰, 周妮平, 张可强, 等. SiC陶瓷材料增材制造研究进展与挑战. 现代技术陶瓷, 2021, 42(1/2): 1. |

| [34] |

PIERIN G, GROTTA C, COLOMBO P, et al. Direct ink writing of micrometric SiOC ceramic structures using a preceramic polymer. Journal of the European Ceramic Society, 2016, 36(7): 1589.

DOI URL |

| [35] |

SCHMIDT J, COLOMBO P. Digital light processing of ceramic components from polysiloxanes. Journal of the European Ceramic Society, 2018, 38(1): 57.

DOI URL |

| [36] |

PELANCONI M, COLOMBO P, ORTONA A. Additive manufacturing of silicon carbide by selective laser sintering of PA12 powders and polymer infiltration and pyrolysis. Journal of the European Ceramic Society, 2021, 41(10): 5056.

DOI URL |

| [37] |

ZOCCA A, COLOMBO P, GOMES C M, et al. Additive manufacturing of ceramics: issues, potentialities, and opportunities. Journal of the American Ceramic Society, 2015, 98(7): 1983.

DOI URL |

| [38] |

BRIGO L, SCHMIDT J E M, GANDIN A, et al. 3D nanofabrication of SiOC ceramic structures. Advanced Science, 2018, 5(12): 1800937.

DOI URL |

| [39] |

ZANCHETTA E, CATTALDO M, FRANCHIN G, et al. Stereolithography of SiOC ceramic microcomponents. Advanced Materials, 2016, 28(2): 370.

DOI URL |

| [40] |

SCHMIDT J, BRIGO L, GANDIN A, et al. Multiscale ceramic components from preceramic polymers by hybridization of vat polymerization-based technologies. Additive Manufacturing, 2019, 30: 100913.

DOI URL |

| [41] |

FU Y, XU G, CHEN Z, et al. Multiple metals doped polymer- derived SiOC ceramics for 3D printing. Ceramics International, 2018, 44(10): 11030.

DOI URL |

| [42] |

CHEN Z W, LI Z Y, LI J J, et al. 3D printing of ceramics: a review. Journal of the European Ceramic Society, 2019, 39(4): 661.

DOI |

| [43] |

RASAKI S A, XIONG D, XIONG S, et al. Photopolymerization-based additive manufacturing of ceramics: a systematic review. Journal of Advanced Ceramics, 2021, 10(3): 442.

DOI |

| [44] |

LI Z, CHEN Z, LIU J, et al. Additive manufacturing of lightweight and high-strength polymer-derived SiOC ceramics. Virtual and Physical Prototyping, 2020, 15(2): 163.

DOI URL |

| [45] |

FU Y, CHEN Z, XU G, et al. Preparation and stereo lithography 3D printing of ultralight and ultrastrong ZrOC porous ceramics. Journal of Alloys and Compounds, 2019, 789: 867.

DOI URL |

| [46] |

LIU J, XIONG S F, MEI H, et al. 3D printing of complex-shaped polymer-derived ceramics with enhanced structural retention. Materials and Manufacturing Processes, 2022, 37(11): 1267.

DOI URL |

| [47] | XIONG S F, LIU J, CAO J W, et al. 3D printing of crack-free dense polymer-derived ceramic monoliths and lattice skeletons with improved thickness and mechanical performance. Additive Manufacturing, 2022, 57: 102924. |

| [48] |

TUMBLESTON J R, SHIRVANYANTS D, ERMOSHKIN N, et al. Continuous liquid interface production of 3D objects. Science, 2015, 347: 1349.

DOI URL |

| [49] | DE BEER M P, VAN DER LAAN H L, COLE M A, et al. Rapid, continuous additive manufacturing by volumetric polymerization inhibition patterning. Science Advances, 2019, 5(1): eaau8723. |

| [50] | KRUNER B, ODENWALD C, TOLOSA A, et al. Carbide-derived carbon beads with tunable nanopores from continuously produced polysilsesquioxanes for supercapacitor electrodes. Sustainable Energy & Fuels, 2017, 1(7): 1588. |

| [51] |

JANUSZIEWICZ R, TUMBLESTON J R, QUINTANILLA A L, et al. Layerless fabrication with continuous liquid interface production. Proceedings of the National Academy of Sciences of the United States of America, 2016, 113(42): 11703.

PMID |

| [52] | JOHNSON A R, CAUDILL C L, TUMBLESTON J R, et al. Single- step fabrication of computationally designed microneedles by continuous liquid interface production. PLOS ONE, 2016, 11(9): e0162518. |

| [53] | MAHMOUDI M, WANG C, MORENO S, et al. Three-dimensional printing of ceramics through "carving" a gel and "filling in" the precursor polymer. ACS Applied Materials & Interfaces, 2020, 12(28): 31984. |

| [54] | MINARY M, MAHMOUDI M. 3D printing polymer-derived ceramics using a thixotropic support bath. American Ceramic Society Bulletin, 2021, 100(3): 32. |

| [55] | 兰洪波, 李涤尘, 卢秉恒. 微纳尺度3D打印. 中国科学, 2015, 45(9): 919. |

| [56] |

VAEZI M, SEITZ H, YANG S. A review on 3D micro-additive manufacturing technologies. International Journal of Advanced Manufacturing Technology, 2013, 67(5): 1721.

DOI URL |

| [57] | KIM W S, HOUBERTZ R, LEE T H, et al. Effect of photoinitiator on photopolymerization of inorganic-organic hybrid polymers (ORMOCER (R)). Journal of Polymer Science, 2004, 42(10): 1979. |

| [58] |

KONSTANTINOU G, KAKKAVA E, HAGELUEKEN L, et al. Additive micro-manufacturing of crack-free PDCs by two-photon polymerization of a single, low-shrinkage preceramic resin. Additive Manufacturing, 2020, 35: 101343.

DOI URL |

| [59] | LIU G, ZHAO Y, WU G, et al. Origami and 4D printing of elastomer-derived ceramic structures. Science Advances, 2018, 4(8): eaat0641. |

| [60] | GYAK K W, VISHWAKARMA N K, HWANG Y H, et al. 3D-printed monolithic SiCN ceramic microreactors from a photocurable preceramic resin for the high temperature ammonia cracking process. Reaction Chemistry & Engineering, 2019, 4(8): 1393. |

| [61] |

BRODNIK N R, SCHMIDT J, COLOMBO P, et al. Analysis of multi-scale mechanical properties of ceramic trusses prepared from preceramic polymers (Revision prepared for additive manufacturing). Additive Manufacturing, 2020, 31: 100957.

DOI URL |

| [62] |

KEMP J W, HMEIDAT N S, COMPTON B G. Boron nitride- reinforced polysilazane-derived ceramic composites via direct-ink writing. Journal of the American Ceramic Society, 2020, 103(8): 4043.

DOI URL |

| [63] |

ROMAN-MANSO B, MOYANO J J, PEREZ-COLL D, et al. Polymer-derived ceramic/graphene oxide architected composite with high electrical conductivity and enhanced thermal resistance. Journal of the European Ceramic Society, 2018, 38(5): 2265.

DOI URL |

| [64] |

FRIEDEL T, TRAVITZKY N, NIEBLING F, et al. Fabrication of polymer derived ceramic parts by selective laser curing. Journal of the European Ceramic Society, 2005, 25(3): 193.

DOI URL |

| [65] |

HUANG K, ELSAYED H, FRANCHIN G, et al. 3D printing of polymer-derived SiOC with hierarchical and tunable porosity. Additive Manufacturing, 2020, 36: 101549.

DOI URL |

| [66] |

ZOCCA A, GOMES C M, STAUDE A, et al. SiOC ceramics with ordered porosity by 3D-printing of a preceramic polymer. Journal of Materials Research, 2013, 28(17): 2243.

DOI URL |

| [67] |

FENG Y R, GUO X, HUANG K, et al. Enhanced electromagnetic microwave absorption of SiOC ceramics targeting the integration of structure and function. Journal of the European Ceramic Society, 2021, 41(13): 6393.

DOI URL |

| [68] |

NGO T D, KASHANI A, IMBALZANO G, et al. Additive manufacturing (3D printing): a review of materials, methods, applications and challenges. Composites Part B-Engineering, 2018, 143: 172.

DOI URL |

| [69] |

SINGH S, RAMAKRISHNA S, SINGH R. Material issues in additive manufacturing: a review. Journal of Manufacturing Processes, 2017, 25: 185.

DOI URL |

| [1] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [2] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [3] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [4] | ZHANG Bihui, LIU Xiaoqiang, CHEN Xiangming. Recent Progress of Hybrid Improper Ferroelectrics with Ruddlesden-Popper Structure [J]. Journal of Inorganic Materials, 2025, 40(6): 587-608. |

| [5] | WU Jie, YANG Shuai, WANG Mingwen, LI Jinglei, LI Chunchun, LI Fei. Textured PT-based Piezoelectric Ceramics: Development, Status and Challenge [J]. Journal of Inorganic Materials, 2025, 40(6): 575-586. |

| [6] | JIANG Kun, LI Letian, ZHENG Mupeng, HU Yongming, PAN Qinxue, WU Chaofeng, WANG Ke. Research Progress on Low-temperature Sintering of PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 627-638. |

| [7] | TIAN Ruizhi, LAN Zhengyi, YIN Jie, HAO Nanjing, CHEN Hangrong, MA Ming. Microfluidic Technology Based Synthesis of Inorganic Nano-biomaterials: Principles and Progress [J]. Journal of Inorganic Materials, 2025, 40(4): 337-347. |

| [8] | ZHANG Jiguo, WU Tian, ZHAO Xu, YANG Fan, XIA Tian, SUN Shien. Improvement of Cycling Stability of Cathode Materials and Industrialization Process for Sodium-ion Batteries [J]. Journal of Inorganic Materials, 2025, 40(4): 348-362. |

| [9] | YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 245-255. |

| [10] | CHEN Guangchang, DUAN Xiaoming, ZHU Jinrong, GONG Qing, CAI Delong, LI Yuhang, YANG Donglei, CHEN Biao, LI Xinmin, DENG Xudong, YU Jin, LIU Boya, HE Peigang, JIA Dechang, ZHOU Yu. Advanced Ceramic Materials in Helicopter Special Structures: Research Progress and Application Prospect [J]. Journal of Inorganic Materials, 2025, 40(3): 225-244. |

| [11] | FAN Xiaobo, ZU Mei, YANG Xiangfei, SONG Ce, CHEN Chen, WANG Zi, LUO Wenhua, CHENG Haifeng. Research Progress on Proton-regulated Electrochemical Ionic Synapses [J]. Journal of Inorganic Materials, 2025, 40(3): 256-270. |

| [12] | HAIREGU Tuxun, GUO Le, DING Jiayi, ZHOU Jiaqi, ZHANG Xueliang, NUERNISHA Alifu. Research Progress of Optical Bioimaging Technology Assisted by Upconversion Fluorescence Probes in Tumor Imaging [J]. Journal of Inorganic Materials, 2025, 40(2): 145-158. |

| [13] | SUN Shujuan, ZHENG Nannan, PAN Haokun, MA Meng, CHEN Jun, HUANG Xiubing. Research Progress on Preparation Methods of Single-atom Catalysts [J]. Journal of Inorganic Materials, 2025, 40(2): 113-127. |

| [14] | TAO Guilong, ZHI Guowei, LUO Tianyou, OUYANG Peidong, YI Xinyan, LI Guoqiang. Progress on Key Technologies of Cavity-structured Thin Film Bulk Acoustic Wave Filter [J]. Journal of Inorganic Materials, 2025, 40(2): 128-144. |

| [15] | ZHOU Fan, TIAN Zhilin, LI Bin. Research Progress on Carbide Ultra-high Temperature Ceramic Anti-ablation Coatings for Thermal Protection System [J]. Journal of Inorganic Materials, 2025, 40(1): 1-16. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||