Journal of Inorganic Materials ›› 2023, Vol. 38 ›› Issue (2): 184-192.DOI: 10.15541/jim20220553

Special Issue: 【结构材料】超高温结构陶瓷(202506)

• RESEARCH ARTICLE • Previous Articles Next Articles

SUN Jingwei1( ), WANG Honglei1(

), WANG Honglei1( ), SUN Chuhan1, ZHOU Xingui1, JI Xiaoyu1,2(

), SUN Chuhan1, ZHOU Xingui1, JI Xiaoyu1,2( )

)

Received:2022-09-22

Revised:2022-11-07

Published:2023-02-20

Online:2022-11-16

Contact:

WANG Honglei, associate professor. E-mail: honglei.wang@163.com;About author:SUN Jingwei (2000-), male, Master candidate. E-mail: sunjingwei0120@163.com

Supported by:CLC Number:

SUN Jingwei, WANG Honglei, SUN Chuhan, ZHOU Xingui, JI Xiaoyu. Effects of Carbon Sources on Structure and Properties of TaC Ceramic Powder Prepared by Polymer Derived Ceramics[J]. Journal of Inorganic Materials, 2023, 38(2): 184-192.

Fig. 3 TG curves of different tantalum carbon sources and crosslinked products (a) PTO, PF-3, 2402 Resin, PTC1-25 (220 ℃), PTC2-40(220 ℃); (b) PTC1-25 (1000 ℃); (c) PTC2-40(1000 ℃) Colorful figures are available on website

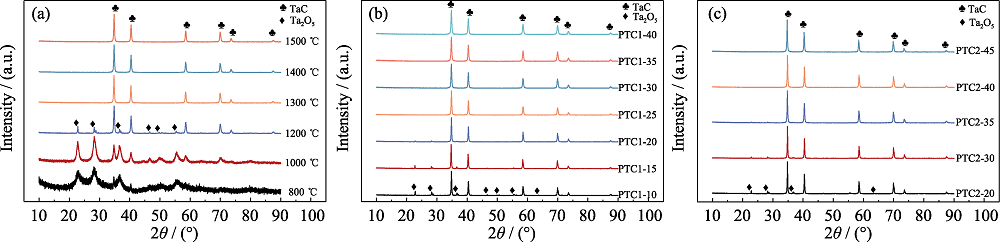

Fig. 4 XRD patterns of ceramic products obtained at different pyrolysis temperatures and tantalum/carbon ratios (a) PTC1-25, 800~1500 ℃; (b) PTC1-(10~40), 1400 ℃, 2 h; (c) PTC2-(20~45), 1400 ℃ 2 h

| Sample | L/nm | Sample | L/nm |

|---|---|---|---|

| PTC1-10 | 62.5 | PTC2-20 | 71.3 |

| PTC1-15 | 73.9 | PTC2-30 | 67.9 |

| PTC1-20 | 67.2 | PTC2-35 | 66.0 |

| PTC1-25 | 47.2 | PTC2-40 | 60.9 |

| PTC1-30 | 45.5 | PTC2-45 | 54.8 |

| PTC1-35 | 39.7 | ||

| PTC1-40 | 37.5 |

Table 1 Average grain size of TaC powder with different carbon source ratios

| Sample | L/nm | Sample | L/nm |

|---|---|---|---|

| PTC1-10 | 62.5 | PTC2-20 | 71.3 |

| PTC1-15 | 73.9 | PTC2-30 | 67.9 |

| PTC1-20 | 67.2 | PTC2-35 | 66.0 |

| PTC1-25 | 47.2 | PTC2-40 | 60.9 |

| PTC1-30 | 45.5 | PTC2-45 | 54.8 |

| PTC1-35 | 39.7 | ||

| PTC1-40 | 37.5 |

| Temperature/℃ | ωD/cm-1 | ωG/cm-1 | |

|---|---|---|---|

| 1200 | 1313 | 1576 | 2.045 |

| 1300 | 1315 | 1579 | 1.641 |

| 1400 | 1313 | 1580 | 1.605 |

Table 2 Center positions of D and G peaks of PTC1-25 products obtained at different pyrolysis temperatures and ratios of ${{I}_{\mathbf{D}}}/{{I}_{\mathbf{G}}}$

| Temperature/℃ | ωD/cm-1 | ωG/cm-1 | |

|---|---|---|---|

| 1200 | 1313 | 1576 | 2.045 |

| 1300 | 1315 | 1579 | 1.641 |

| 1400 | 1313 | 1580 | 1.605 |

| Sample | Ta/% | C/% | O/% | Cfree/% |

|---|---|---|---|---|

| PTC1-25 | 91.72 | 5.02 | 1.31 | 2.19 |

| PTC2-40 | 92.14 | 6.42 | 0.89 | 1.75 |

Table 3 Elements mass contents of TaC powders obtained at optimal tantalum/carbon ratio

| Sample | Ta/% | C/% | O/% | Cfree/% |

|---|---|---|---|---|

| PTC1-25 | 91.72 | 5.02 | 1.31 | 2.19 |

| PTC2-40 | 92.14 | 6.42 | 0.89 | 1.75 |

| [1] | 周亦人, 沈自才, 齐振一, 等. 中国航天科技发展对高性能材料的需求. 材料工程, 2021, 49(11): 41. |

| [2] |

PEREPEZKO J H. The hotter the engine, the better. Science, 2009, 326(5956): 1068.

DOI URL |

| [3] |

FAHRENHOLTZ W G, HILMAS G E. Ultra-high temperature ceramics: materials for extreme environments. Scripta Materialia, 2017, 129: 94.

DOI URL |

| [4] |

PADTURE N P. Advanced structural ceramics in aerospace propulsion. Nature Materials, 2016, 15 (8): 804.

DOI PMID |

| [5] | JAKUBOWICZ J, ADAMEK G, SOPATA M, et al. Microstructure and electrochemical properties of refractory nanocrystalline tantalum-based alloys. International Journal of Electrochemical Science, 2018, 13(2): 1956. |

| [6] | 王世界, 尹艺程, 邱鑫, 等. 超高温多孔陶瓷的制备、性能及应用研究进展. 材料导报, 2022, 36(12): 57. |

| [7] |

XIAO P, ZHU Y L, WANG S, et al. Research Progress on the Preparation and Characterization of Ultra Refractory TaxHf1-xC solid solution ceramics. Journal of Inorganic Materials, 2021, 36(7): 685.

DOI URL |

| [8] | WANG S L, MA L, MEAD J L, et al. Catalyst-free synthesis and mechanical characterization of TaC nanowires. Science China (Physics, Mechanics & Astronomy), 2021, 64(5): 47. |

| [9] | 爨炳辰. 先驱体转化法制备碳化钽陶瓷研究. 长沙: 国防科技大学硕士学位论文, 2017. |

| [10] | LU Y, CHEN F H, AN P F, et al. Polymer precursor synthesis of TaC-SiC ultrahigh temperature ceramic nanocomposites. Royal Society of Chemistry, 2016, 6(91): 88770. |

| [11] |

PU H, NIU Y R, ZHENG, X B, et al. Ablation of vacuum plasma sprayed TaC-based composite coatings. Ceramics International, 2015, 41(9): 11387.

DOI URL |

| [12] |

NIU Y R, PU H, HUANG L P, et al. Microstructure and ablation property of TaC-SiC composite coatings. In Key Engineering Materials, Trans Tech Publications Ltd, 2016, 697: 535.

DOI URL |

| [13] |

PENG J H, TIKHONOV E. Vacancy on Structures, Mechanical and Electronic Properties of Ternary Hf-Ta-C system: a first-principles study. Journal of Inorganic Materials, 2022, 37(1): 51.

DOI |

| [14] |

WALTER L, FABIO S. Ti(C, N)-based cermets: critical review of achievements and recent developments. Solid State Phenom, 2018, 274: 53.

DOI URL |

| [15] |

LI Z J, ZHU C L, CAI B J, et al. Effect of TiB2 content on the microstructure and mechanical properties of Ti(C, N)-TiB2-FeCoCrNiAl high-entropy alloys composite cermets. Journal of the Ceramic Society of Japan, 2020, 128: 66.

DOI URL |

| [16] |

SHANKAR E, PRABU S B, K. Effect of nano-TiB2 addition on the microstructure, mechanical properties and machining performance of TiCN cermet. Journal of the Australian Ceramic Society, 2018, 54: 565.

DOI URL |

| [17] |

PAN R Q, CHEN G Q, YU X M, et al. Densification, microstructure and mechanical properties of Ta4HfC5-based ceramics obtained from synthesized nanoscale powder. Journal of the European Ceramic Society, 2021, 41(4): 2247.

DOI URL |

| [18] |

XU X Y, ZHENG Y, ZHAO Y J, et al. Influence of TaC content on microstructure and mechanical performance of Ti(C,N)-based cermets fabricated by mechanical activation and subsequent in situ carbothermal reduction. Ceramics International, 2022, 48(3): 3826.

DOI URL |

| [19] |

ZHANG J, WANG S, LI W, et al. Understanding the oxidation behavior of Ta-Hf-C ternary ceramics at high temperature. Corrosion Science, 2020, 164: 108348.

DOI URL |

| [20] |

FANG C Q, HUANG B Y, YANG X, et al. Effects of LaB6 on composition, microstructure and ablation property of the HfC- TaC-SiC doped C/C composites prepared by precursor infiltration and pyrolysis. Corrosion Science, 2021, 184: 109347.

DOI URL |

| [21] |

WANG B Z, LI D X, YANG Z H, et al. Study on oxidation resistance and oxidative damage mechanism of SiBCN-Ta4HfC5 composite ceramics. Corrosion Science, 2022, 197: 110049.

DOI URL |

| [22] |

LU Y, ZHU S Y, WANG X Y, et al. High temperature tribological behavior of polymer-derived Ta4HfC5 nanoceramics. Tribology International, 2021, 156: 106859.

DOI URL |

| [23] |

ZHAO X R, ZHANG M X, ZUO D W, et al. Ti(C, N)-based cermet with different TaC/(TaC+WC) weight ratio by in-situ reactive hot pressing: microstructure and mechanical properties. Materials Today Communications, 2020, 25: 101661.

DOI URL |

| [24] | COLOMBO P, MERA G, RIEDEL R, et al. Polymer-derived ceramics: 40 years of research and innovation in advanced ceramics. Journal of the American Ceramic Society, 2010, 93(7): 1805. |

| [25] |

CAI T, QIU W F, ZHAO T, et al. Polymer precursor-derived HfCSiC ultrahigh-temperature ceramic nanocomposites. Journal of the American Ceramic Society, 2018, 101(1): 20.

DOI URL |

| [26] |

Li F, Lu Y, Wang X G, et al. Liquid precursor-derived high- entropy carbide nanopowders. Ceramics International, 2019, 45(17): 22437.

DOI URL |

| [27] |

SUN Y N, YE L, ZHAO W Y, et al. Synthesis of high entropy carbide nano powders via liquid polymer precursor route. Journal of Inorganic Materials, 2021, 36(4): 393.

DOI URL |

| [28] |

CHENG J, DONG Z J, ZHU H, et al. Synthesis and ceramisation of organometallic precursors for Ta4HfC5 and TaHfC2 ultra-fine powders through a facile one-pot reaction. Journal of Alloys and Compounds, 2022, 898: 162989.

DOI URL |

| [29] |

LU Y, SUN Y A, ZHANG T Z, et al. Polymer-derived Ta4HfC5 nanoscale ultrahigh-temperature ceramics: synthesis, microstructure and properties. Journal of the European Ceramic Society, 2019, 39(2/3): 205.

DOI URL |

| [30] |

JIANG J M, WANG S, LI W. Preparation and characterization of ultrahigh-temperature ternary ceramics Ta4HfC5. Journal of the American Ceramic Society, 2016, 99(10): 3198.

DOI URL |

| [31] |

ZHANG J, WANG S, LI W. Nano-scale 1TaC-3HfC solid solution powder synthesized using a solvothermal method and its densification. Ceramics International, 2019, 45(1): 1455.

DOI URL |

| [32] |

SUN Y A, YANG C M, LU Y, et al. Transformation of metallic polymer precursor into nanosized HfTaC2 ceramics. Ceramics International, 2020, 46(5): 6022.

DOI URL |

| [33] |

PIMENTA M A, DRESSELHAUS G, DRESSELHAUS M S, et al. Studying disorder in graphite-based systems by Raman spectroscopy. Physical Chemistry Chemical Physics, 2007, 9: 1276.

PMID |

| [34] |

FERREIRA MARTINS E H, MOUTINHO V O, STAVALE F, et al. Evolution of the Raman spectra from single-, few-, and many- layer graphene with increasing disorder. Physical Review B, 2010, 82: 125429.

DOI URL |

| [35] | 郭伟. 超细碳化钽粉末的制备方法. 中国: CN102134073B. 2012-11-14. |

| [36] |

GHAFFARI S, FAGHIHI-SANI M, GOLESTANI-FARD F, et al. Pressureless sintering of Ta0.8Hf0.2C UHTC in the presence of MoSi2. Ceramics International, 2013, 39: 1985.

DOI URL |

| [37] |

OMAR C, SALVATORE G, NASR IN A, et al. Sintering behaviour, solid solution formation and characterization of TaC, HfC and TaC-HfC fabricated by spark plasma sintering. Journal of the European Ceramic Society, 2016, 36: 1539.

DOI URL |

| [38] | 张德尧. 采用废钽料制备细颗粒TaC粉. 稀有金属快报, 2000, 8: 13. |

| [39] |

PATSERA E I, KURBATKINA V V, LEVASHOV E A, et al. Research into the possibility of producing single-phase tantalum- hafnium carbide by SHS. Russian Journal of Non-Ferrous Metals, 2018, 59(5): 576.

DOI URL |

| [40] |

KURBATKINA V, PATSERA E, LEVASHOV E, et al. Self- propagating high-temperature synthesis of single-phase binary tantalum-hafnium carbide (Ta, Hf)C and its consolidation by hot pressing and spark plasma sintering. Ceramics International, 2018, 44(4): 4320.

DOI URL |

| [1] | ZHANG Kun, WANG Yu, ZHU Tenglong, SUN Kaihua, HAN Minfang, ZHONG Qin. LaNi0.6Fe0.4O3 Cathode Contact Material: Electrical Conducting Property Manipulation and Its Effect on SOFC Electrochemical Performance [J]. Journal of Inorganic Materials, 2024, 39(4): 367-373. |

| [2] | CHEN Xinli, LI Yan, WANG Weisheng, SHI Zhiwen, ZHU Liqiang. Gelatin/Carboxylated Chitosan Gated Oxide Neuromorphic Transistor [J]. Journal of Inorganic Materials, 2023, 38(4): 421-428. |

| [3] | WANG Jingyu, WAN Changjin, WAN Qing. Dual-gate IGZO-based Neuromorphic Transistors with Stacked Al2O3/Chitosan Gate Dielectrics [J]. Journal of Inorganic Materials, 2023, 38(4): 445-451. |

| [4] | HUA Siheng, YANG Dongwang, TANG Hao, YUAN Xiong, ZHAN Ruoyu, XU Zhuoming, LYU Jianan, XIAO Yani, YAN Yonggao, TANG Xinfeng. Effect of Surface Treatment of n-type Bi2Te3-based Materials on the Properties of Thermoelectric Units [J]. Journal of Inorganic Materials, 2023, 38(2): 163-169. |

| [5] | WANG Ye, JIAO Yinan, GUO Junxia, LIU Huan, LI Rui, SHANG Zixuan, ZHANG Shidong, WANG Yonghao, GENG Haichuan, HOU Denglu, ZHAO Jinjin. Optimization of Interfacial Engineering of Perovskite Solar Cells [J]. Journal of Inorganic Materials, 2023, 38(11): 1323-1330. |

| [6] | DING Jianxiang, ZHANG Kaige, LIU Dongming, ZHENG Wei, ZHANG Peigen, SUN Zhengming. Ag-based Electrical Contact Material Reinforced by Ti3AlC2 Ceramic and Its Derivative Ti3C2Tx [J]. Journal of Inorganic Materials, 2022, 37(5): 567-573. |

| [7] | XIAO Peng, ZHU Yulin, WANG Song, YU Yiping, LI Hao. Research Progress on the Preparation and Characterization of Ultra Refractory TaxHf1-xC Solid Solution Ceramics [J]. Journal of Inorganic Materials, 2021, 36(7): 685-694. |

| [8] | DING Jianxiang,HUANG Peiyan,ZHA Yuhui,WANG Dandan,ZHANG Peigen,TIAN Wubian,SUN Zhengming. High-purity Ti2AlC Powder: Preparation and Application in Ag-based Electrical Contact Materials [J]. Journal of Inorganic Materials, 2020, 35(6): 729-734. |

| [9] | GUO Yu, PENG Tong-Hua, LIU Chun-Jun, YANG Zhan-Wei, CAI Zhen-Li. Correlation between Stacking Faults in Epitaxial Layers of 4H-SiC and Defects in 4H-SiC Substrate [J]. Journal of Inorganic Materials, 2019, 34(7): 748-754. |

| [10] | Wei WANG, Li-Li YUAN, Qian-Yuan QIU, Ming-Yang ZHOU, Mei-Lin LIU, Jiang LIU. A Direct Carbon Solid Oxide Fuel Cell Stack Based on a Single Electrolyte Plate Fabricated by Tape Casting Technique [J]. Journal of Inorganic Materials, 2019, 34(5): 509-514. |

| [11] | HU Xiao-Kai, ZHANG Shuang-Meng, ZHAO Fu, LIU Yong, LIU Wei-Shu. Thermoelectric Device: Contact Interface and Interface Materials [J]. Journal of Inorganic Materials, 2019, 34(3): 269-278. |

| [12] | WU Qing-Qing, WANG Zhen, DING Qi, NI De-Wei, KAN Yan-Mei, DONG Shao-Ming. C/SiOC Composites by a Modified PIP Using Solid Polysiloxane: Fabrication, Microstructure and Mechanical Properties [J]. Journal of Inorganic Materials, 2019, 34(12): 1349-1356. |

| [13] | ZHANG Qi-Hao, LIAO Jin-Cheng, TANG Yun-Shan, GU Ming, LIU Rui-Heng, BAI Sheng-Qiang, CHEN Li-Dong. Interface Stability of Skutterudite Thermoelectric Materials/Ti88Al12 [J]. Journal of Inorganic Materials, 2018, 33(8): 889-894. |

| [14] | LIU Ding, YU Yang, MI Le, YU Yun, SONG Li-Xin. Preparation of Room Temperature Curable Organic-inorganic Hybrid Thermal Control Coatings [J]. Journal of Inorganic Materials, 2018, 33(8): 914-918. |

| [15] | LI Tian, CHEN Xiu-Fang, YANG Xiang-Long, XIE Xue-Jian, ZHANG Fu-Sheng, XIAO Long-Fei, WANG Rong-Kun, XU Xian-Gang, HU Xiao-Bo, WANG Rui-Qi, YU Peng. Characterization and Electrical Property of Impurity Concentration in Ge-N Codoped SiC Crystals [J]. Journal of Inorganic Materials, 2018, 33(5): 535-539. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||