Journal of Inorganic Materials ›› 2023, Vol. 38 ›› Issue (2): 177-183.DOI: 10.15541/jim20220441

Special Issue: 【结构材料】陶瓷基复合材料(202506)

• RESEARCH ARTICLE • Previous Articles Next Articles

JING Kaikai1( ), GUAN Haoyang1, ZHU Siyu1, ZHANG Chao1,2, LIU Yongsheng1,3, WANG Bo2,4, WANG Jing1,3, LI Mei1, ZHANG Chengyu1,2(

), GUAN Haoyang1, ZHU Siyu1, ZHANG Chao1,2, LIU Yongsheng1,3, WANG Bo2,4, WANG Jing1,3, LI Mei1, ZHANG Chengyu1,2( )

)

Received:2022-07-29

Revised:2022-09-10

Published:2023-02-20

Online:2022-09-15

Contact:

ZHANG Chengyu, professor. E-mail: cyzhang@nwpu.edu.cnAbout author:JING Kaikai (1997-), male, Master candidate. E-mail: 2247436229@qq.com

Supported by:CLC Number:

JING Kaikai, GUAN Haoyang, ZHU Siyu, ZHANG Chao, LIU Yongsheng, WANG Bo, WANG Jing, LI Mei, ZHANG Chengyu. Tensile Creep Behavior of Cansas-II SiCf/SiC Composites at High Temperatures[J]. Journal of Inorganic Materials, 2023, 38(2): 177-183.

| Diameter/ μm | Density/ (g·cm-3) | Tensile strength/GPa | Tensile modulus/GPa |

|---|---|---|---|

| 14 | 2.74 | 2.7 | 270 |

Table 1 Basic properties of domestic second-generation Cansas-II silicon carbide fibers

| Diameter/ μm | Density/ (g·cm-3) | Tensile strength/GPa | Tensile modulus/GPa |

|---|---|---|---|

| 14 | 2.74 | 2.7 | 270 |

| Temperature/℃ | E/GPa | σPLS/MPa | σUTS/MPa | ε/% |

|---|---|---|---|---|

| RT | 273 | 115 | 282 | 0.57 |

| 1200 | 259 | 110 | 249 | 0.74 |

| 1300 | 223 | 92 | 229 | 0.60 |

Table 2 Tensile properties of 2D-SiCf/SiC composites

| Temperature/℃ | E/GPa | σPLS/MPa | σUTS/MPa | ε/% |

|---|---|---|---|---|

| RT | 273 | 115 | 282 | 0.57 |

| 1200 | 259 | 110 | 249 | 0.74 |

| 1300 | 223 | 92 | 229 | 0.60 |

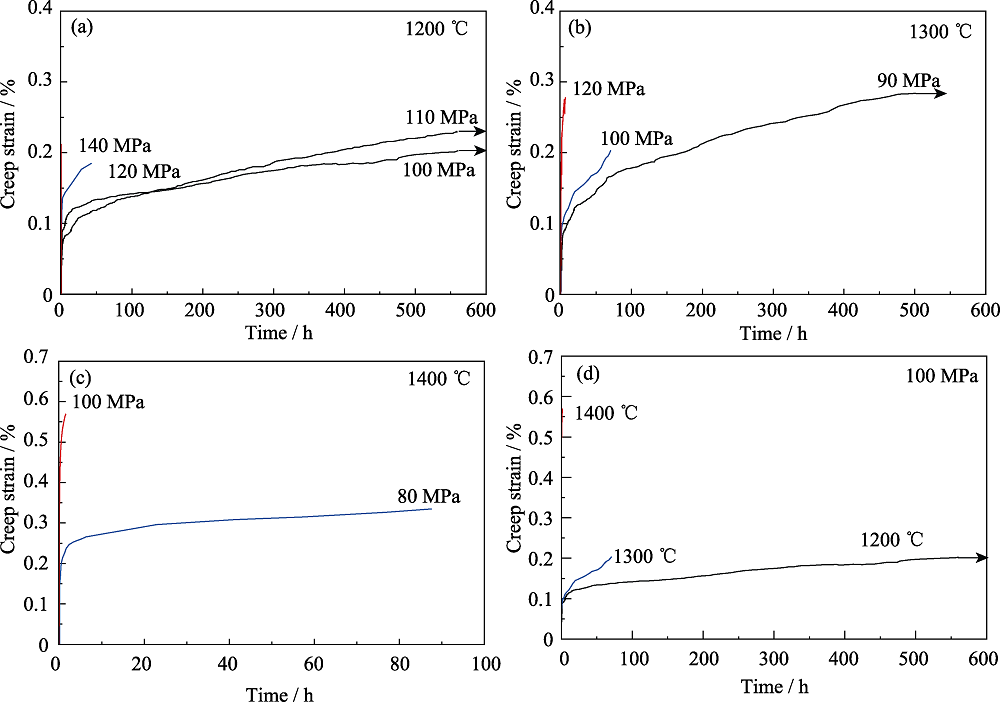

Fig. 2 Tensile creep curves of 2D-SiCf/SiC at high temperatures (a) 1200 ℃, different stress; (b) 1300 ℃, different stress; (c) 1400 ℃, different stress; (d) Different temperatures, 100 MPa

| Specimen | Tempera- ture/℃ | Stress/ MPa | Steady-state creep strain rate/s-1 | Creep rupture time/h | Creep strain/% |

|---|---|---|---|---|---|

| 2D-SiCf/SiC | 1200 | 100 | 1.86×10-10 | >560 | 0.20 |

| 1200 | 110 | 4.95×10-10 | >560 | 0.23 | |

| 1200 | 120 | 2.16×10-9 | 42 | 0.18 | |

| 1200 | 140 | 8.45×10-7 | 0.1 | 0.21 | |

| 1300 | 90 | 5.62×10-10 | >500 | 0.28 | |

| 1300 | 100 | 1.73×10-9 | 70 | 0.20 | |

| 1300 | 120 | 1.86×10-8 | 6 | 0.28 | |

| 1400 | 80 | 1.32×10-9 | 88 | 0.33 | |

| 1400 | 100 | 1.46×10-8 | 1.6 | 0.57 | |

| CVI-SiCf/SiC[ | 1300 | 75 | 2.3×10-9 | 111.1 | — |

| 1300 | 90 | 6.2×10-8 | 33.4 | — | |

| 1300 | 120 | 3.6×10-7 | 0.83 | — | |

| 1300 | 150 | 3.0×10-6 | 0.14 | — | |

| MI-SiCf/SiC[ | 1204 | 125 | 3.0×10-11 | >1000 | 0.25 |

| 1204 | 140 | 2.3×10-10 | >1000 | 0.31 | |

| 1204 | 150 | — | 82.1 | 0.29 |

Table 3 Tensile creep properties of 2D-SiCf/SiC composites in air at high temperatures

| Specimen | Tempera- ture/℃ | Stress/ MPa | Steady-state creep strain rate/s-1 | Creep rupture time/h | Creep strain/% |

|---|---|---|---|---|---|

| 2D-SiCf/SiC | 1200 | 100 | 1.86×10-10 | >560 | 0.20 |

| 1200 | 110 | 4.95×10-10 | >560 | 0.23 | |

| 1200 | 120 | 2.16×10-9 | 42 | 0.18 | |

| 1200 | 140 | 8.45×10-7 | 0.1 | 0.21 | |

| 1300 | 90 | 5.62×10-10 | >500 | 0.28 | |

| 1300 | 100 | 1.73×10-9 | 70 | 0.20 | |

| 1300 | 120 | 1.86×10-8 | 6 | 0.28 | |

| 1400 | 80 | 1.32×10-9 | 88 | 0.33 | |

| 1400 | 100 | 1.46×10-8 | 1.6 | 0.57 | |

| CVI-SiCf/SiC[ | 1300 | 75 | 2.3×10-9 | 111.1 | — |

| 1300 | 90 | 6.2×10-8 | 33.4 | — | |

| 1300 | 120 | 3.6×10-7 | 0.83 | — | |

| 1300 | 150 | 3.0×10-6 | 0.14 | — | |

| MI-SiCf/SiC[ | 1204 | 125 | 3.0×10-11 | >1000 | 0.25 |

| 1204 | 140 | 2.3×10-10 | >1000 | 0.31 | |

| 1204 | 150 | — | 82.1 | 0.29 |

| σUTS/MPa | E/GPa | σPLS/MPa | ε/% | ||

|---|---|---|---|---|---|

| As-received | 282 | 273 | 115 | 0.57 | |

| Crept | 1200 ℃/100 MPa | 211 | — | — | — |

| 1200 ℃/110 MPa | 173 | 209 | 89 | 0.25 | |

| 1300 ℃/90 MPa | 138 | 157 | 55 | 0.17 | |

Table 4 Residual tensile properties of 2D-SiCf/SiC after creeping

| σUTS/MPa | E/GPa | σPLS/MPa | ε/% | ||

|---|---|---|---|---|---|

| As-received | 282 | 273 | 115 | 0.57 | |

| Crept | 1200 ℃/100 MPa | 211 | — | — | — |

| 1200 ℃/110 MPa | 173 | 209 | 89 | 0.25 | |

| 1300 ℃/90 MPa | 138 | 157 | 55 | 0.17 | |

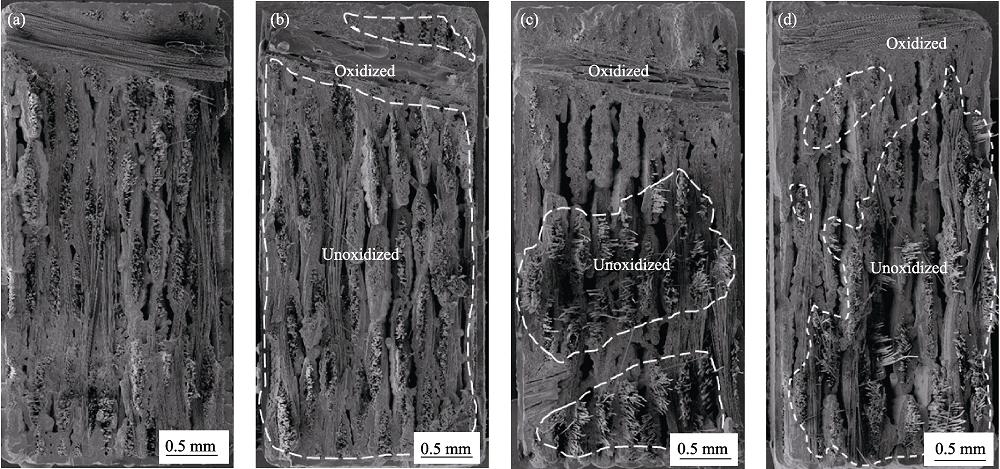

Fig. 4 Macroscopic morphologies of fractures of 2D-SiCf/SiC under different conditions (a) As-received; (b) Crept at 1200 ℃/110 MPa for 560 h; (c) Crept at 1200 ℃/120 MPa; (d) Crept at 1200 ℃/140 MPa

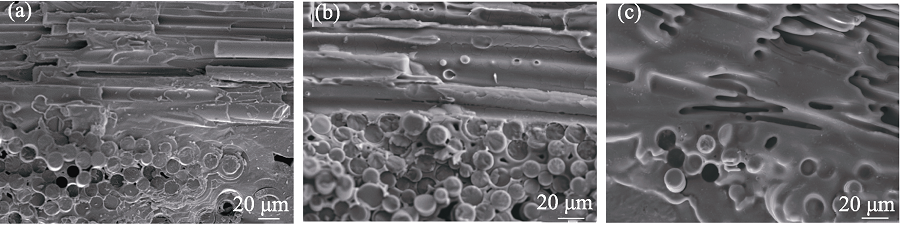

Fig. 5 Morphologies of fracture oxidation zone of 2D-SiCf/SiC under different creep rupture conditions (a) 1200 ℃/120 MPa; (b) 1300 ℃/100 MPa; (c) 1400 ℃/80 MPa

| [1] | ALMANSOUR A. Characterizing ceramic-matrix composites to improve durability. American Ceramic Society Bulletin, 2016, 95(5): 35. |

| [2] |

YUAN Q, SONG Y C. Research and development of continuous SiC fibers and SiCf/SiC composites. Journal of Inorganic Materials, 2016, 31(11): 1157.

DOI |

| [3] |

ZHAO S, YANG Z C, ZHOU X G. Fracture behavior of SiC/SiC composites with different interfaces. Journal of Inorganic Materials, 2016, 31(1): 58.

DOI |

| [4] |

WANG X, SONG Z L, CHENG Z, et al. Tensile creep properties and damage mechanisms of 2D-SiCf/SiC composites reinforced with low-oxygen high-carbon type SiC fiber. Journal of the European Ceramic Society, 2020, 40(14): 4872.

DOI URL |

| [5] |

ALMANSOUR A, MAILET E, RAMASAMY S, et al. Effect of fiber content on single tow SiC minicomposite mechanical and damage properties using acoustic emission. Journal of the European Ceramic Society, 2015, 35(13): 3389.

DOI URL |

| [6] |

PRYCE A W, SMITH P A. Matrix cracking in crossply ceramic matrix composites under quasi-static and cyclic loading. Acta Metallurgica Et Materialia, 1993, 42(3): 861.

DOI URL |

| [7] | CAO J, MIZUNO M, NAGANO Y. The stress dependence damage mechanism during tensile creep and fatigue in a SiC/SiC composite at 1400 ℃. 22nd Annual Conference on Composites, Advanced Ceramics, Materials, and Structures: A. Florida, 1998: 251. |

| [8] |

FARIZY G, CHERMANT J L, VICENS J, et al. Understanding of the behaviour and the influence of oxidation during creep of SiCf-SiBC composites in air. Advanced Engineering Materials, 2005, 7(6): 529.

DOI URL |

| [9] |

BHATT R T, KISER J D. Creep behavior and failure mechanisms of CVI and PIP SiC/SiC composites at temperatures to 1650 ℃ in air. Journal of the European Ceramic Society, 2021, 41(13): 6196.

DOI URL |

| [10] |

WANG X, WANG K J, BAI H, et al. Creep properties and damage mechanisms of 2D-SiCf/SiC compositer prepared by CVI. Journal of Inorganic Materials, 2020, 35(7): 817.

DOI |

| [11] |

MORSCHER G N. Tensile creep and rupture of 2D-woven SiC/SiC composites for high temperature applications. Journal of the European Ceramic Society, 2010, 30(11): 2209.

DOI URL |

| [12] |

ZHU S, MIZUNO M, KAGAWA Y, et al. Creep and fatigue behavior in Hi-NicalonTM-fiber-reinforced silicon carbide composites at high temperatures. Journal of the American Ceramic Society, 1999, 82(1): 117.

DOI URL |

| [13] |

ZHU S, MIZUNO M, KAGAWA Y, et al. Monotonic tension, fatigue and creep behavior of SiC-fiber-reinforced SiC-matrix composites: a review. Composites Science and Technology, 1999, 59(6): 833.

DOI URL |

| [14] |

ZHU S, MIZUNO M, NAGANO Y, et al. Tensile creep behavior of a SiC-fiber/SiC composite at elevated temperatures. Composites Science and Technology, 1998, 57(12): 1629.

DOI URL |

| [15] | GREGORY S C, KRISHAN L L. GE Global Research. Melt Infiltrated Ceramic Composites (Hipercomp®) For Gas Turbine Engine Applications. Continuous Fiber Ceramic Composites Program Phase II Final Report, 2006: 153. |

| [16] |

MORSCHER G N, CAWLEY J D. Intermediate temperature strength degradation in SiC/SiC composites. Journal of the European Ceramic Society, 2002, 22(14/15): 2777.

DOI URL |

| [17] |

LU Z L, YUE J, FU Z Y, et al. Microstructure and mechanical performance of SiCf/BN/SiC mini-composites oxidized at elevated temperature from ambient temperature to 1500 ℃ in air. Journal of the European Ceramic Society, 2020, 40(8): 2821.

DOI URL |

| [18] | MORSCHER G N, Stress-environmental effects on fiber reinforced SiC-based composites. The American Ceramic Society. Ceramic Matrix Composites: Materials, Modeling and Technology. Hoboken, New Jersey: John Wiley & Sons, Inc., 2014: 334. |

| [19] |

OGBUJI L U J T, OPILA E J, et al. A comparison of the oxidation kinetics of SiC and SiN. Journal of the Electrochemical Society, 1995, 142: 925.

DOI URL |

| [20] |

DICARLO J A. Creep of chemically vapor-deposited SiC fibers. Journal of Materials Science. 1986, 21(1): 217.

DOI URL |

| [1] | ZHANG Li, GUAN Haoyang, ZHENG Qining, HONG Zhiliang, WANG Jiaxuan, XING Ning, LI Mei, LIU Yongsheng, ZHANG Chengyu. Creep Properties and Damage Mechanisms of SiCf/SiC-SiYBC Prepared by Melt Infiltration [J]. Journal of Inorganic Materials, 2025, 40(1): 23-30. |

| [2] | WANG Xi,WANG Kejie,BAI Hui,SONG Zhuolin,WANG Bo,ZHANG Chengyu. Creep Properties and Damage Mechanisms of 2D-SiCf/SiC Composites Prepared by CVI [J]. Journal of Inorganic Materials, 2020, 35(7): 817-821. |

| [3] |

CHEN Gang,ZHAI Peng-Cheng,ZHANG Qing-Jie.

Theory and Experiment Research on MSP Evaluation Method for Si3N4 Ceramic Creep Properties [J]. Journal of Inorganic Materials, 2009, 24(5): 924-928. |

| [4] | LIU Xiao-Ying,ZHANG Jun,ZHANG Li-Tong,XU Yong-Dong,LUAN Xin-Gang. Failure Mechanism of C/SiC Composites under Stress in Oxidizing Environments [J]. Journal of Inorganic Materials, 2006, 21(5): 1191-1196. |

| [5] | WANG Gang,JIANG Wan,ZHAO Shi-Ke. Effect of Na2O on Mechanical Properties of MoSi2/Oxide Composites for Heating Elements [J]. Journal of Inorganic Materials, 2003, 18(1): 103-108. |

| [6] | LIN Ming-Tong,JIANG Dan-Yu,WANG Lin,RUAN Mei-Ling,SHI Jian-Lin. Microstructure and Creep Behavior of a Y-α-β Sialon Composite [J]. Journal of Inorganic Materials, 2001, 16(6): 1113-1120. |

| [7] | LU Qing-Mei,WANG Hao-Jing,DONG Wen-Sheng,WANG Xin-Kui. Progress of Research on Preparation and Properties of Yttrium Aluminium Garnet Fibers [J]. Journal of Inorganic Materials, 2001, 16(4): 595-600. |

| [8] | YE Jiandong,CHEN Kai,Arturo Dominguez-Rodriguez. Compressive Plastic Deformation of Superplastic Y-TZP [J]. Journal of Inorganic Materials, 1997, 12(2): 181-186. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||