Journal of Inorganic Materials ›› 2024, Vol. 39 ›› Issue (4): 367-373.DOI: 10.15541/jim20230353

Special Issue: 【能源环境】燃料电池(202506)

• RESEARCH ARTICLE • Previous Articles Next Articles

ZHANG Kun1( ), WANG Yu1, ZHU Tenglong1(

), WANG Yu1, ZHU Tenglong1( ), SUN Kaihua2, HAN Minfang3, ZHONG Qin1

), SUN Kaihua2, HAN Minfang3, ZHONG Qin1

Received:2023-08-03

Revised:2023-09-04

Published:2024-04-20

Online:2023-09-12

Contact:

ZHU Tenglong, associate professor. E-mail: zhutenglong@njust.edu.cnAbout author:ZHANG Kun (1999-), male, Master candidate. E-mail: 2498249631@qq.com

Supported by:CLC Number:

ZHANG Kun, WANG Yu, ZHU Tenglong, SUN Kaihua, HAN Minfang, ZHONG Qin. LaNi0.6Fe0.4O3 Cathode Contact Material: Electrical Conducting Property Manipulation and Its Effect on SOFC Electrochemical Performance[J]. Journal of Inorganic Materials, 2024, 39(4): 367-373.

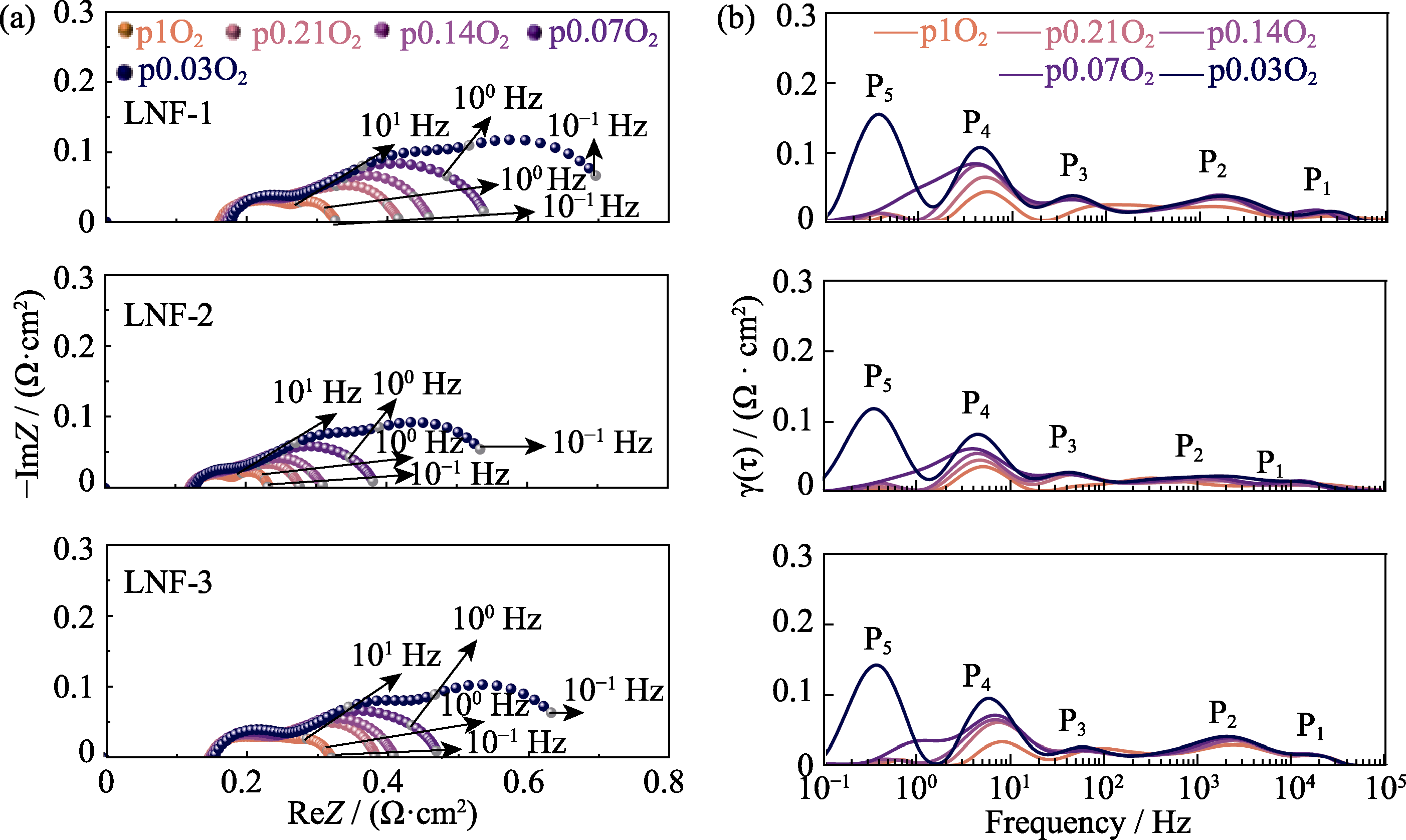

Fig. 4 (a) EIS spectra and (b) DRT fitting plots for single cells tested at 750 ℃ and varied oxygen partial pressures Colorful images are available on website

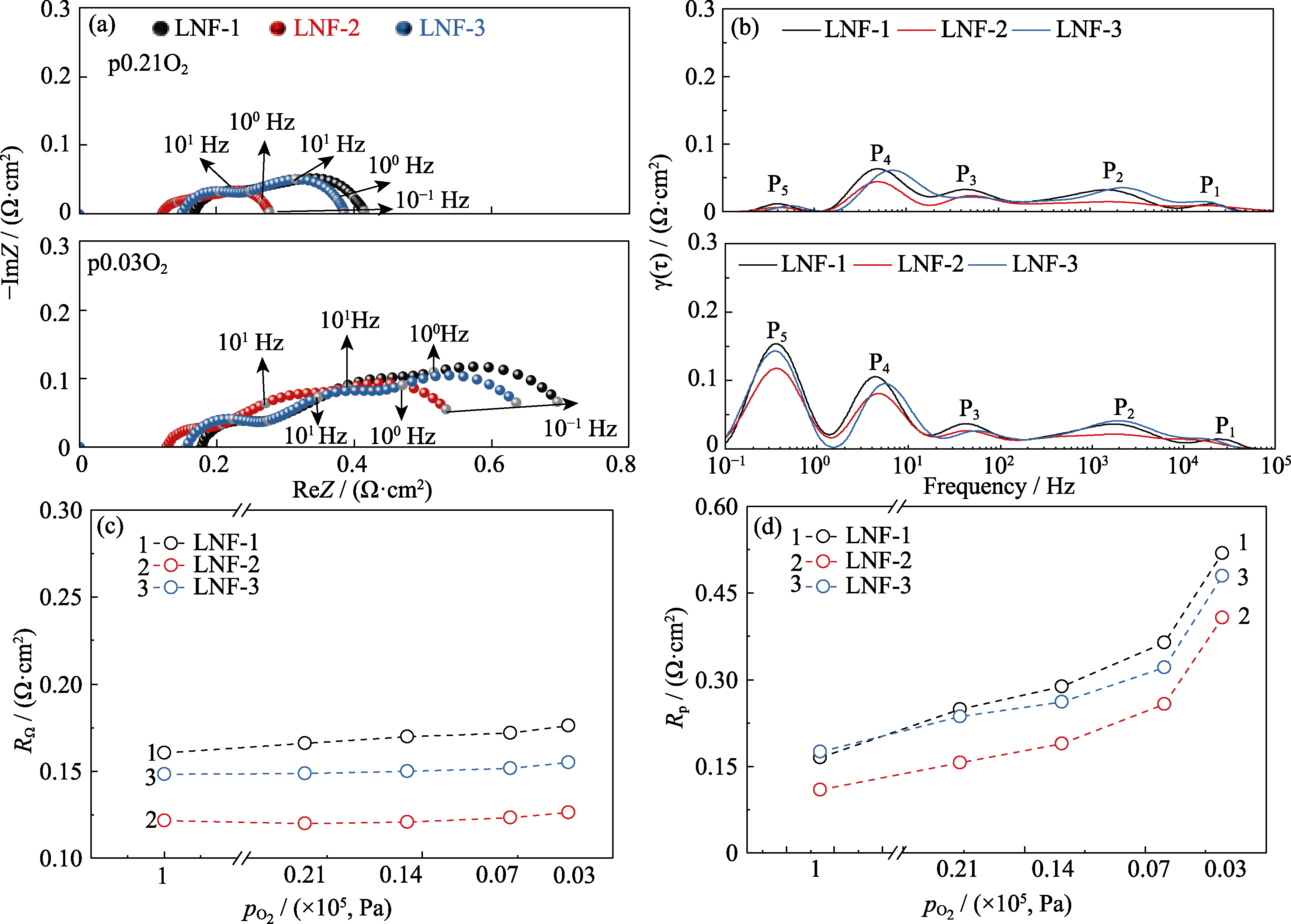

Fig. 5 (a) EIS spectra and (b) DRT fitting plots of single cells under oxygen partial pressure of 2.1×104 and 3×103 Pa, and comparison of corresponding (c) Ohmic resistance and (d) polarization resistance Colorful images are available on website

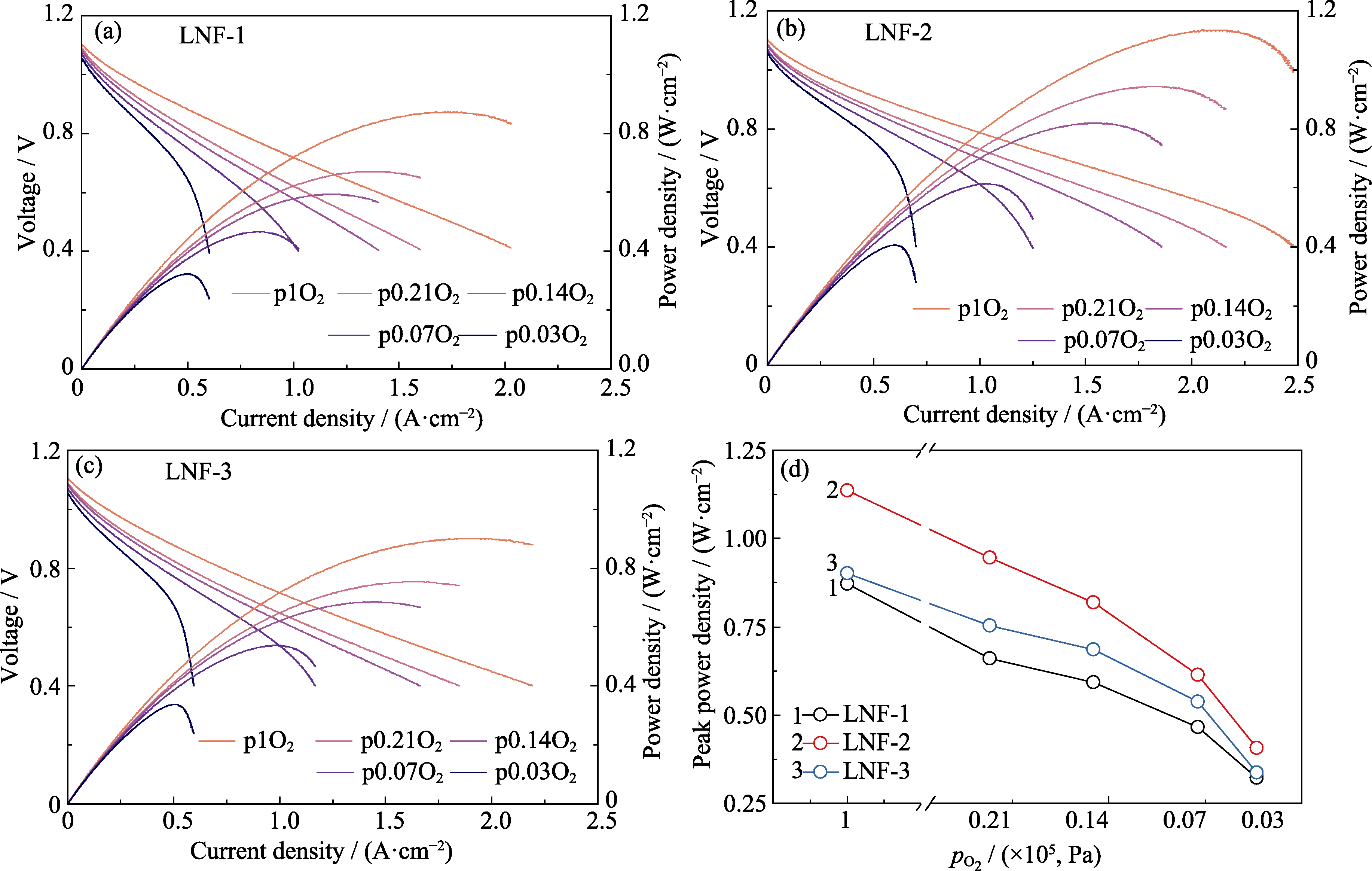

Fig. 6 (a-c) j-V-P curves and (d) peak power density comparison of single cells versus different oxygen partial pressure on cathode sides at 750 ℃ Colorful images are available on website

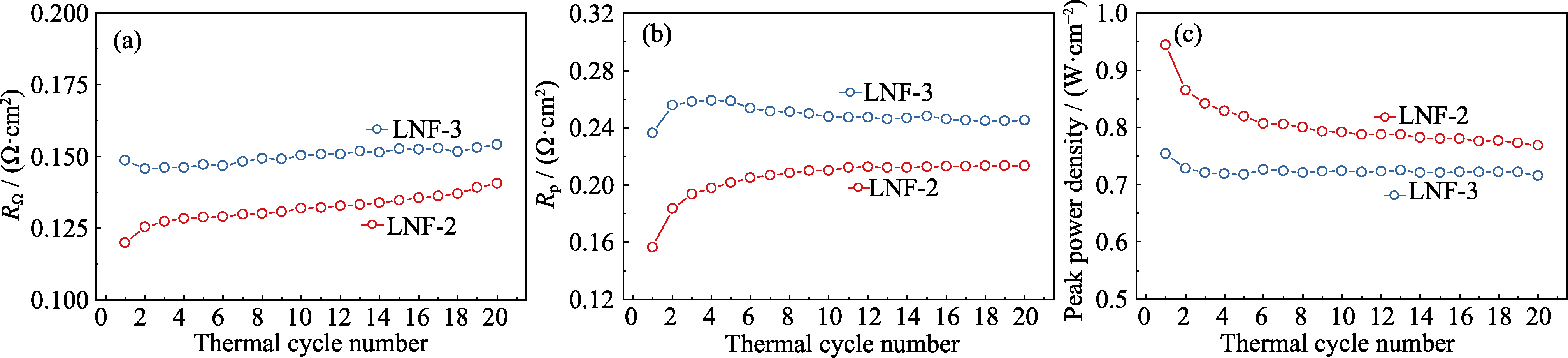

Fig. 7 Evolution of electrochemical performances for single cells under thermal cycling (a) RΩ; (b) Rp; (c) Peak power density Colorful images are available on website

| [1] |

KENNOUCHE D, FANG Q, BLUM L, et al. Analysis of the cathode electrical contact in SOFC stacks. Journal of Electrochemical Society, 2018, 165(9): F677.

DOI URL |

| [2] |

ZHU J H, GHEZEL-AYAGH H. Cathode-side electrical contact and contact materials for solid oxide fuel cell stacking: a review. International Journal of Hydrogen Energy, 2017, 42(38): 24278.

DOI URL |

| [3] |

SHEN M, ZHANG P. Progress and challenges of cathode contact layer for solid oxide fuel cell. International Journal of Hydrogen Energy, 2020, 45(58): 33876.

DOI URL |

| [4] |

WANG Y, WANG L, GAN N, et al. Evaluation of Ni/Y2O3/Al2O3 catalysts for hydrogen production by autothermal reforming of methane. International Journal of Hydrogen Energy, 2014, 39(21): 10971.

DOI URL |

| [5] |

YANG Z, XIA G, SINGH P, et al. Electrical contacts between cathodes and metallic interconnects in solid oxide fuel cells. Journal of Power Sources, 2005, 155(2): 246.

DOI URL |

| [6] |

GUAN W, WANG G, ZHOU X D. Mechanism of the cathode current collector on cell performance in a solid oxide fuel cell stack. Journal of Power Sources, 2017, 351: 169.

DOI URL |

| [7] |

SIMNER S P, ANDERSON M D, PEDERSON L R, et al. Performance variability of La(Sr)FeO3 SOFC cathode with Pt, Ag, and Au current collectors. Journal of the Electrochemical Society, 2005, 152(9): A1851.

DOI URL |

| [8] |

ZHANG W, HUA B, YANG J, et al. Performance evaluation of a new Fe-Cr-Mn alloy in the reducing atmosphere of solid oxide fuel cells. Journal of Alloys and Compounds, 2018, 769: 866.

DOI URL |

| [9] |

WILKINSON L T, ZHU J H. Ag-perovskite composite materials for SOFC cathode-interconnect contact. Journal of the Electrochemical Society, 2009, 156(8): B905.

DOI URL |

| [10] |

GONG Y, QIN C, HUANG K. Can silver be a reliable current collector for electrochemical tests? ECS Electrochemistry Letters, 2012, 2(1): F4.

DOI URL |

| [11] |

YU Y T, LU Y, GUAN C Z, et al. Evaluation of the reactive- sintered (Mn,Co)3O4 spinel layer for SOFC cathode-side contact application. International Journal of Hydrogen Energy, 2022, 47(87): 36964.

DOI URL |

| [12] |

JIANG S P. Development of lanthanum strontium cobalt ferrite perovskite electrodes of solid oxide fuel cells-a review. International Journal of Hydrogen Energy, 2019, 44(14): 7448.

DOI URL |

| [13] |

SUGITA S, YOSHIDA Y, ORUI H, et al. Cathode contact optimization and performance evaluation of intermediate temperature- operating solid oxide fuel cell stacks based on anode-supported planar cells with LaNi0.6Fe0.4O3 cathode. Journal of Power Sources, 2008, 185(2): 932.

DOI URL |

| [14] |

MORÁN-RUIZ A, VIDAL K, LAGUNA-BERCERO M Á, et al. Effects of using (La0.8Sr0.2)0.95Fe0.6Mn0.3Co0.1O3 (LSFMC), LaNi0.6Fe0.4O3-δ (LNF) and LaNi0.6Co0.4O3-δ (LNC) as contact materials on solid oxide fuel cells. Journal of Power Sources, 2014, 248: 1067.

DOI URL |

| [15] |

CHIBA R, YOSHIMURA F, SAKURAI Y. An investigation of LaNi1-xFexO3 as a cathode material for solid oxide fuel cells. Solid State Ionics, 1999, 124(3): 281.

DOI URL |

| [16] |

YANG J, LI Z, YAN D, et al. The investigation of Ag & LaCo0.6Ni0.4O3-δ composites as cathode contact material for intermediate temperature solid oxide fuel cells. International Journal of Hydrogen Energy, 2018, 43(28): 12705.

DOI URL |

| [17] |

ZHOU L, MASON J H, LI W, et al. Comprehensive review of chromium deposition and poisoning of solid oxide fuel cells (SOFCs) cathode materials. Renewable and Sustainable Energy Reviews, 2020, 134: 110320.

DOI URL |

| [18] |

ZHEN Y D, TOK A I Y, JIANG S P, et al. La(Ni,Fe)O3 as a cathode material with high tolerance to chromium poisoning for solid oxide fuel cells. Journal of Power Sources, 2007, 170(1): 61.

DOI URL |

| [19] | SHAUR A, REHMAN S U, KIM H S, et al. Hybrid electrochemical deposition route for the facile nanofabrication of a Cr-poisoning- tolerant La(Ni,Fe)O3-δ cathode for solid oxide fuel cells. ACS Applied Materials & Interfaces, 2020, 12(5): 5730. |

| [20] |

SOLOVYEV A A, SHIPILOVA A V, RABOTKIN S V, et al. Study of the efficiency of composite LaNi0.6Fe0.4O3-based cathodes in intermediate-temperature anode-supported SOFCs. International Journal of Hydrogen Energy, 2023, 48(59): 22594.

DOI URL |

| [21] |

WANG G, GUAN W, MIAO F, et al. Factors of cathode current- collecting layer affecting cell performance inside solid oxide fuel cell stacks. International Journal of Hydrogen Energy, 2014, 39(31): 17836.

DOI URL |

| [22] |

KARRI N K, KOEPPEL B J, NGUYEN B N, et al. Structural reliability of cathode cpontact materials in planar SOFCs. ECS Transactions, 2017, 78(1): 1701.

DOI URL |

| [23] |

LIN C K, CHEN T T, CHYOU Y P. Thermal stress analysis of a planar SOFC stack. Journal of Power Sources, 2007, 164(1): 238.

DOI URL |

| [24] |

WANG Y, LYU Q, ZHU T L, et al. Electrical and electrochemical performances evaluation of LaNi0.6Fe0.4O3 cathode contact and current collecting layer in SOFCs. Journal of the Electrochemical Society, 2022, 169(4): 044531.

DOI |

| [25] |

LYU Q, WANG Y, ZHU T L, et al. Conducting property and performance evaluation of LNF as cathode current contact layer in solid oxide fuel cell. ECS Transactions, 2021, 103(1): 1461.

DOI |

| [26] |

CHIBA R, TABATA Y, KOMATSU T, et al. Property change of a LaNi0.6Fe0.4O3 cathode in the initial current loading process and the influence of a ceria interlayer. Solid State Ionics, 2008, 178(31): 1701.

DOI URL |

| [27] |

WAN T H, SACCOCCIO M, CHEN C, et al. Influence of the discretization methods on the distribution of relaxation times deconvolution: implementing radial basis functions with DRTtools. Electrochimica Acta, 2015, 184: 483.

DOI URL |

| [28] |

SHI W, JIA C, ZHANG Y, et al. Differentiation and decomposition of solid oxide fuel cell electrochemical impedance spectra. Acta Physico-Chimica Sinica, 2019, 35(5): 509.

DOI URL |

| [29] |

XIA J, WANG C, WANG X, et al. A perspective on DRT applications for the analysis of solid oxide cell electrodes. Electrochimica Acta, 2020, 349: 136328.

DOI URL |

| [30] |

ZHANG J, LEI L, LI H, et al. Experimental investigations of cell resistances to characterize the concentration polarization behavior of 10×10 cm2 solid oxide fuel cells. Journal of Power Sources, 2021, 516: 230678.

DOI URL |

| [1] | WEI Hailang, CAO Xueqiang, DENG Longhui, JIANG Jianing. Thermodynamic Properties and Thermal Cycling Lifetimes of LaMeAl11O19/YSZ Thermal Barrier Coatings [J]. Journal of Inorganic Materials, 2022, 37(12): 1259-1266. |

| [2] | CHENG Liang, LUO Ling-Hong, SHI Ji-Jun, SUN Liang-Liang, XU Xu, WU Ye-Fan, HU Jia-Xing. Ni/YSZ Anode Impregnated La2O3 on Anti-carbon Deposition of SOFC Cell [J]. Journal of Inorganic Materials, 2017, 32(3): 241-246. |

| [3] | MA Wen,GUO Hong-Bo,GONG Sheng-Kai,DONG Hong-Ying. Lanthanum-cerium Oxide Thermal Barrier Coatings Prepared by Atmospheric Plasma Spraying [J]. Journal of Inorganic Materials, 2009, 24(5): 983-988. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||