Journal of Inorganic Materials ›› 2020, Vol. 35 ›› Issue (6): 729-734.DOI: 10.15541/jim20190243

• RESEARCH LETTERS • Previous Articles

DING Jianxiang1,HUANG Peiyan1,ZHA Yuhui1,WANG Dandan2,ZHANG Peigen2,TIAN Wubian2( ),SUN Zhengming2(

),SUN Zhengming2( )

)

Received:2019-05-23

Revised:2019-07-14

Published:2020-06-20

Online:2019-09-12

Supported by:CLC Number:

DING Jianxiang,HUANG Peiyan,ZHA Yuhui,WANG Dandan,ZHANG Peigen,TIAN Wubian,SUN Zhengming. High-purity Ti2AlC Powder: Preparation and Application in Ag-based Electrical Contact Materials[J]. Journal of Inorganic Materials, 2020, 35(6): 729-734.

| Sample | Composition, x | Purity/% |

|---|---|---|

| S1 | 1.05 | 77.5 |

| S2 | 1.10 | 57.9 |

| S3 | 1.15 | 41.4 |

| S4 | 1.20 | 31.5 |

| Sample | Composition, x | Purity/% |

|---|---|---|

| S1 | 1.05 | 77.5 |

| S2 | 1.10 | 57.9 |

| S3 | 1.15 | 41.4 |

| S4 | 1.20 | 31.5 |

| Sample | Composition, x | Purity/% |

|---|---|---|

| S1 | 1.00 | 77.5 |

| S5 | 1.05 | 99.2 |

| S6 | 1.10 | 92.3 |

| S7 | 1.15 | 91.7 |

| Sample | Composition, x | Purity/% |

|---|---|---|

| S1 | 1.00 | 77.5 |

| S5 | 1.05 | 99.2 |

| S6 | 1.10 | 92.3 |

| S7 | 1.15 | 91.7 |

| Sample | Temperature/℃ | Purity/% |

|---|---|---|

| S8 | 1200 | 16.3 |

| S9 | 1300 | 35.7 |

| S10 | 1400 | 99.2 |

| S11 | 1500 | 81.8 |

| Sample | Temperature/℃ | Purity/% |

|---|---|---|

| S8 | 1200 | 16.3 |

| S9 | 1300 | 35.7 |

| S10 | 1400 | 99.2 |

| S11 | 1500 | 81.8 |

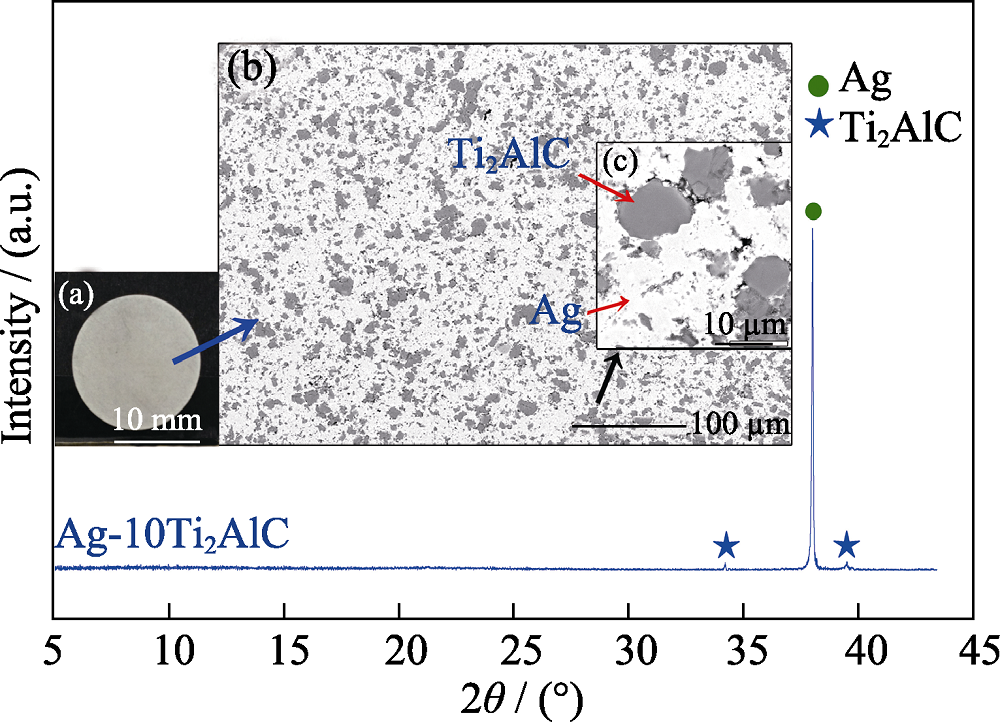

Fig. 6 XRD pattern of Ag/10TAC composite with insets showing (a) picture of the bulk, (b) microstructure of composite, and (c) the magnified SEM image

| Density/ (g?cm-3) | Relative density/% | Hardness, HV | Resistivity/ (nΩ·m) |

|---|---|---|---|

| 8.692 | 95.7% | 96 | 79.5 |

| Density/ (g?cm-3) | Relative density/% | Hardness, HV | Resistivity/ (nΩ·m) |

|---|---|---|---|

| 8.692 | 95.7% | 96 | 79.5 |

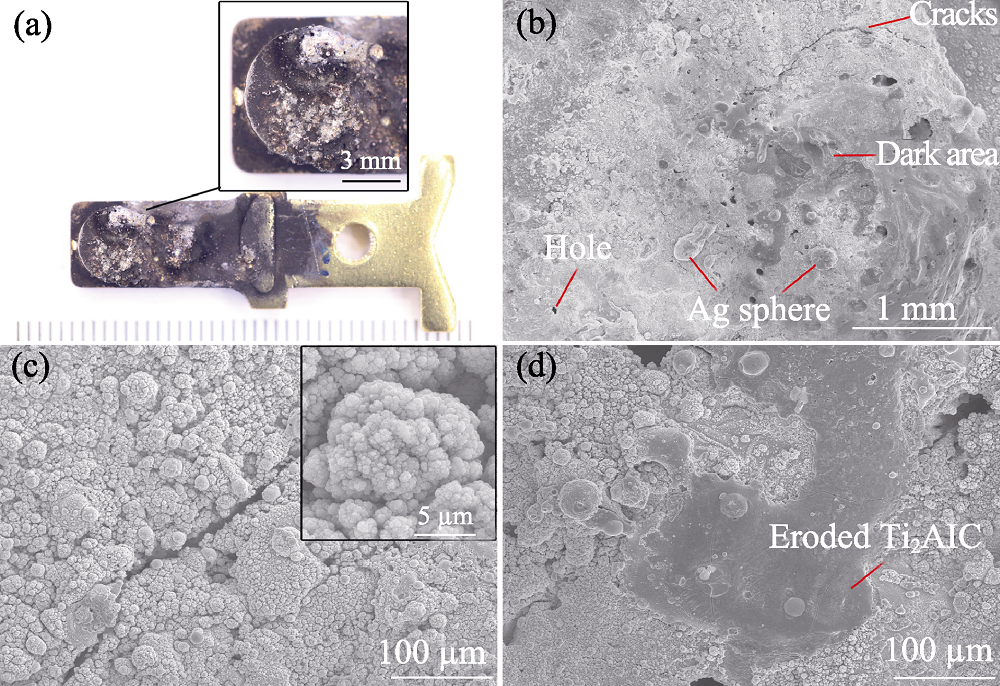

Fig. 7 (a) Optical image of the Ag/10TAC contact after 5610 arc discharging cycles, with magnified SEM image in the inset; (b) SEM image of the contact surface morphology; (c) Morphology of the Ag molten pool, with magnified SEM image of cauliflower-shaped Ag particles in the inset; (d) Magnified SEM image of the aggregated eroded Ti2AlC (dark area in (b))

| [1] | WINDRED G . Electrical contact resistance. Journal of the Franklin Institute, 1941,231(6):547-585. |

| [2] | HOLM R, HOLM E. Electric Contacts Handbook . Berlin: Springer, 1958. |

| [3] | COSOVIC V, COSOVIC A, TALIJAN N , et al. State of the art and challenges in development of electrical contact materials in the light of the RoHS directive. Science of Sintering, 2012,44(2):245-253. |

| [4] | SLADE P G . Effect of high temperature on the release of heavy metals from AgCdO and AgSnO2 contacts. IEEE Transactions on Components, Hybrids, and Manufacturing Technology, 1989,12(1):5-15. |

| [5] | SCHRODER K H . Silver-metal oxides as contact materials. IEEE Transactions on Components, Hybrids, and Manufacturing Technology, 1987,10(1):127-134. |

| [6] | WU C P, YI D Q, LI J , et al. Investigation on microstructure and performance of Ag/ZnO contact material. Journal of Alloys and Compounds, 2008,457(1/2):565-570. |

| [7] | ZHOU X L, CAO J C, CHEN J C , et al. Micro-superplastic behavior of copper oxide in AgCuO composites. Rare Metal Materials and Engineering, 2013,42(11):2242-2244. |

| [8] | WOJCIK-GRZYBEK D, FRYDMAN K, BORKOWSKI P . The influence of the microstructure on the switching properties of Ag C, Ag-WC-C and Ag-WC contact materials. Archives of Metallurgy and Materials, 2013,58(4):1059-1065. |

| [9] | WU C P, YI D Q, WENG W , et al. Arc erosion behavior of Ag/Ni electrical contact materials. Materials & Design, 2015,85:511-519. |

| [10] | BARSOUM M W . The M N+1AXN phases: a new class of solids; thermodynamically stable nanolaminates. Progress in Solid State Chemistry, 2000,28(1-4):201-281. |

| [11] | SUN Z M . Progress in research and development on MAX phases: a family of layered ternary compounds. International Materials Reviews, 2011,56(3):143-166. |

| [12] | ZHANG M, TIAN W B, ZHANG P G , et al. Microstructure and properties of Ag-Ti3SiC2 contact materials prepared by pressureless sintering. International Journal of Minerals, Metallurgy, and Materials, 2018,25(7):810-816. |

| [13] | DING J X, TIAN W B, ZHANG P G , et al. Arc erosion behavior of Ag/Ti3AlC2 electrical contact materials. Journal of Alloys and Compounds, 2018,740:669-676. |

| [14] | DING J X, TIAN W B, WANG D D , et al. Corrosion and degradation mechanism of Ag/Ti3AlC2 composites under dynamic electric arc discharging. Corrosion Science, 2019,156:147-160. |

| [15] | WANG D D, TIAN W B, MA A B , et al. Anisotropic properties of Ag/Ti3AlC2 electrical contact materials prepared by equal channel angular pressing. Journal of Alloys and Compounds, 2019,784:431-438. |

| [16] | LIU M M, CHEN J L, CUI H , et al. Ag/Ti3AlC2 composites with high hardness, high strength and high conductivity. Materials Letters, 2018,213:269-273. |

| [17] | DING J X, TIAN W B, ZHANG P G , et al. Preparation and arc erosion properties of Ag/Ti2SnC composites under electric arc discharging. Journal of Advanced Ceramics, 2019,8(1):90-101. |

| [18] | DING J X, TIAN W B, WANG D D , et al. Microstructure evolution, oxidation behavior and corrosion mechanism of Ag/Ti2SnC composite during dynamic electric arc discharging. Journal of Alloys and Compounds, 2019,785:1086-1096. |

| [19] | ZHU J F, GAO J Q, YANG J F , et al. Synthesis and microstructure of layered-ternary Ti2AlC ceramic by high energy milling and hot pressing. Materials Science and Engineering A, 2008,490(1/2):62-65. |

| [20] | BAI Y L, ZHANG H X, HE X D , et al. Growth morphology and microstructural characterization of nonstoichiometric Ti2AlC bulk synthesized by self-propagating high temperature combustion synthesis with pseudo hot isostatic pressing. International Journal of Refractory Metals and Hard Materials, 2014,45:58-63. |

| [21] | ZHOU W B, MEI B C, ZHU J Q , et al. Rapid synthesis of Ti2AlC by spark plasma sintering technique. Materials Letters, 2005,59(1):131-134. |

| [22] | LIANG B Y, WANG M Z, LI X P , et al. Synthesis of Ti2AlC by laser- induced self-propagating high-temperature sintering. Journal of Alloys and Compounds, 2010,501(1):L1-L3. |

| [23] | LIU W, BO T Z, XIE Z P , et al. Fabrication of injection moulded translucent alumina ceramics via pressureless sintering. Advances in Applied Ceramics, 2011,110(4):251-254. |

| [24] | YEH C L, SHEN Y G . Combustion synthesis of Ti3AlC2 from Ti/Al/C/TiC powder compacts. Journal of Alloys and Compounds, 2008,466:308-313. |

| [1] | ZHANG Jinghui, LU Xiaotong, MAO Haiyan, TIAN Yazhou, ZHANG Shanlin. Effect of Sintering Additives on Sintering Behavior and Conductivity of BaZr0.1Ce0.7Y0.2O3-δ Electrolytes [J]. Journal of Inorganic Materials, 2025, 40(1): 84-90. |

| [2] | WANG Wenting, XU Jingjun, MA Ke, LI Meishuan, LI Xingchao, LI Tongqi. Oxidation Behavior at 1000-1300 ℃ in air of Ti2AlC-20TiB2 Synthesized by in-situ Reaction/Hot Pressing [J]. Journal of Inorganic Materials, 2025, 40(1): 31-38. |

| [3] | WANG Weiming, WANG Weide, SU Yi, MA Qingsong, YAO Dongxu, ZENG Yuping. Research Progress of High Thermal Conductivity Silicon Nitride Ceramics Prepared by Non-oxide Sintering Additives [J]. Journal of Inorganic Materials, 2024, 39(6): 634-646. |

| [4] | JIN Min, MA Yupeng, WEI Tianran, LIN Siqi, BAI Xudong, SHI Xun, LIU Xuechao. Growth and Characterization of Large-size InSe Crystal from Non-stoichiometric Solution via a Zone Melting Method [J]. Journal of Inorganic Materials, 2024, 39(5): 554-560. |

| [5] | FAN Jiashun, XIA Donglin, LIU Baoshun. Temperature Dependent Transient Photoconductive Response of CsPbBr3 NCs [J]. Journal of Inorganic Materials, 2023, 38(8): 893-900. |

| [6] | WANG Shuling, JIANG Meng, WANG Lianjun, JIANG Wan. n-Type Pb-free AgBiSe2 Based Thermoelectric Materials with Stable Cubic Phase Structure [J]. Journal of Inorganic Materials, 2023, 38(7): 807-814. |

| [7] | CHEN Qiang, BAI Shuxin, YE Yicong. Highly Thermal Conductive Silicon Carbide Ceramics Matrix Composites for Thermal Management: a Review [J]. Journal of Inorganic Materials, 2023, 38(6): 634-646. |

| [8] | ZHANG Shuo, FU Qiangang, ZHANG Pei, FEI Jie, LI Wei. Influence of High Temperature Treatment of C/C Porous Preform on Friction and Wear Behavior of C/C-SiC Composites [J]. Journal of Inorganic Materials, 2023, 38(5): 561-568. |

| [9] | SHANGGUAN Li, NIE Xiaoshuang, YE Kuicai, CUI Yuanyuan, QIAO Yuqin. Effects of Surface Wettability of Titanium Oxide Coatings on Osteoimmunomodulatory Properties [J]. Journal of Inorganic Materials, 2023, 38(12): 1457-1565. |

| [10] | JIANG Runlu, WU Xin, GUO Haocheng, ZHENG Qi, WANG Lianjun, JIANG Wan. UiO-67 Based Conductive Composites: Preparation and Thermoelectric Performance [J]. Journal of Inorganic Materials, 2023, 38(11): 1338-1344. |

| [11] | FU Shi, YANG Zengchao, LI Jiangtao. Progress of High Strength and High Thermal Conductivity Si3N4 Ceramics for Power Module Packaging [J]. Journal of Inorganic Materials, 2023, 38(10): 1117-1132. |

| [12] | SUN Xiaofan, CHEN Xiaowu, JIN Xihai, KAN Yanmei, HU Jianbao, DONG Shaoming. Fabrication and Properties of AlN-SiC Multiphase Ceramics via Low Temperature Reactive Melt Infiltration [J]. Journal of Inorganic Materials, 2023, 38(10): 1223-1229. |

| [13] | FU Shi, YANG Zengchao, LI Honghua, WANG Liang, LI Jiangtao. Mechanical Properties and Thermal Conductivity of Si3N4 Ceramics with Composite Sintering Additives [J]. Journal of Inorganic Materials, 2022, 37(9): 947-953. |

| [14] | HU Jiajun, WANG Kai, HOU Xinguang, YANG Ting, XIA Hongyan. Boron Phosphide with High Thermal Conductivity: Synthesis by Molten Salt Method and Thermal Management Performance [J]. Journal of Inorganic Materials, 2022, 37(9): 933-940. |

| [15] | WANG Pengjiang, KANG Huijun, YANG Xiong, LIU Ying, CHENG Cheng, WANG Tongmin. Inhibition of Lattice Thermal Conductivity of ZrNiSn-based Half-Heusler Thermoelectric Materials by Entropy Adjustment [J]. Journal of Inorganic Materials, 2022, 37(7): 717-723. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||