Journal of Inorganic Materials ›› 2023, Vol. 38 ›› Issue (2): 113-124.DOI: 10.15541/jim20220400

• REVIEW • Next Articles

LIU Yan1( ), ZHANG Keying1,2, LI Tianyu1,2, ZHOU Bo1,2, LIU Xuejian1, HUANG Zhengren1

), ZHANG Keying1,2, LI Tianyu1,2, ZHOU Bo1,2, LIU Xuejian1, HUANG Zhengren1

Received:2022-07-09

Revised:2022-09-20

Published:2023-02-20

Online:2022-09-22

About author:LIU Yan (1975-), male, PhD, professor. E-mail: stony2000@mail.sic.ac.cn

Supported by:CLC Number:

LIU Yan, ZHANG Keying, LI Tianyu, ZHOU Bo, LIU Xuejian, HUANG Zhengren. Electric-field Assisted Joining Technology for the Ceramics Materials: Current Status and Development Trend[J]. Journal of Inorganic Materials, 2023, 38(2): 113-124.

| Joining method | Electric field type | Electric field | Joining current | Joining temperature | Joining time |

|---|---|---|---|---|---|

| FDB | DC | Small | Small | Low | Long |

| SPS | DC pulse | Small | Large | High | Short |

| FJ | DC/DC pulse | Large | Small | Low | Fast |

Table 1 Comparison of three electric-field assisted joining technologies

| Joining method | Electric field type | Electric field | Joining current | Joining temperature | Joining time |

|---|---|---|---|---|---|

| FDB | DC | Small | Small | Low | Long |

| SPS | DC pulse | Small | Large | High | Short |

| FJ | DC/DC pulse | Large | Small | Low | Fast |

| Joining system | Joining condition | Shear strength/MPa | Main phases at interface | Ref. |

|---|---|---|---|---|

| Al/β-Al2O3 | 500-600 ℃, 500 V, 1-2 h | — | No interlayer | [ |

| Cu/ZrO2 | 800 ℃ 50 V, 1 A, 20 min | — | Cu2O, Cu-Zr | [ |

| Ni/ZrO2 | 1100 ℃, 10 mA, 30 min | 160±15 | Ni-Zr | [ |

| Polycrystal ferrites/single crystalline ferrites | 1200 ℃, 1 A, 24 h | — | No interlayer | [ |

Table 2 FDB of ionic conductive ceramics

| Joining system | Joining condition | Shear strength/MPa | Main phases at interface | Ref. |

|---|---|---|---|---|

| Al/β-Al2O3 | 500-600 ℃, 500 V, 1-2 h | — | No interlayer | [ |

| Cu/ZrO2 | 800 ℃ 50 V, 1 A, 20 min | — | Cu2O, Cu-Zr | [ |

| Ni/ZrO2 | 1100 ℃, 10 mA, 30 min | 160±15 | Ni-Zr | [ |

| Polycrystal ferrites/single crystalline ferrites | 1200 ℃, 1 A, 24 h | — | No interlayer | [ |

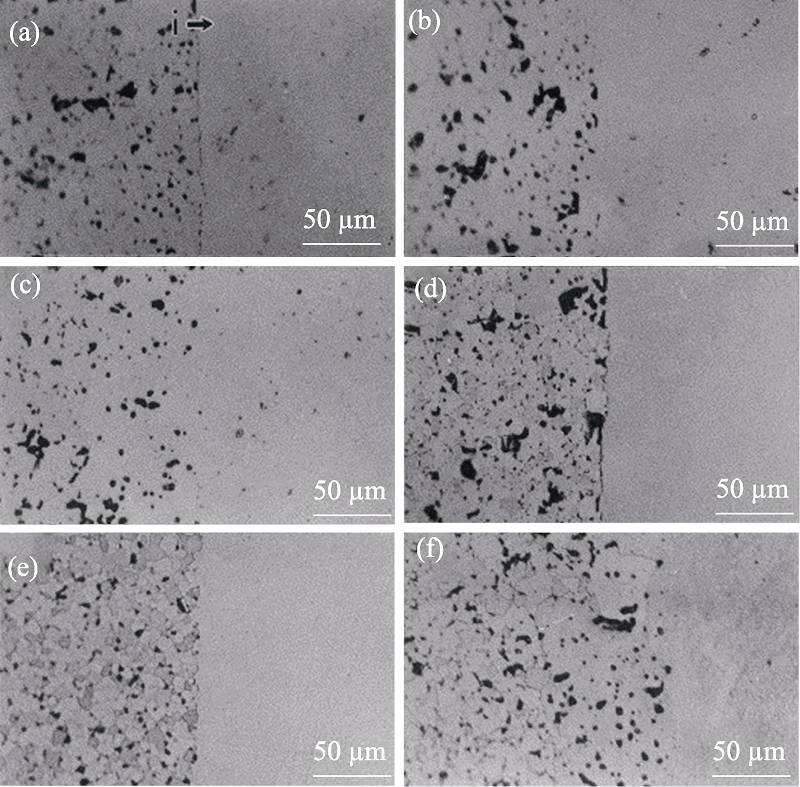

Fig. 3 Interfacial SEM micrographs of manganese-zinc ferrite poly- and single-crystals under different bonding conditions[25] (a) 1000 ℃, 1 h, not etched; (b) 1200 ℃, 1 h, not etched; (c) 1200 ℃, 12 h, not etched; (d) 1000 ℃, 1 h, etched; (e) 1200 ℃, 1 h, etched; (f) 1200 ℃, 12 h, etched. Current for all cases is 1 A

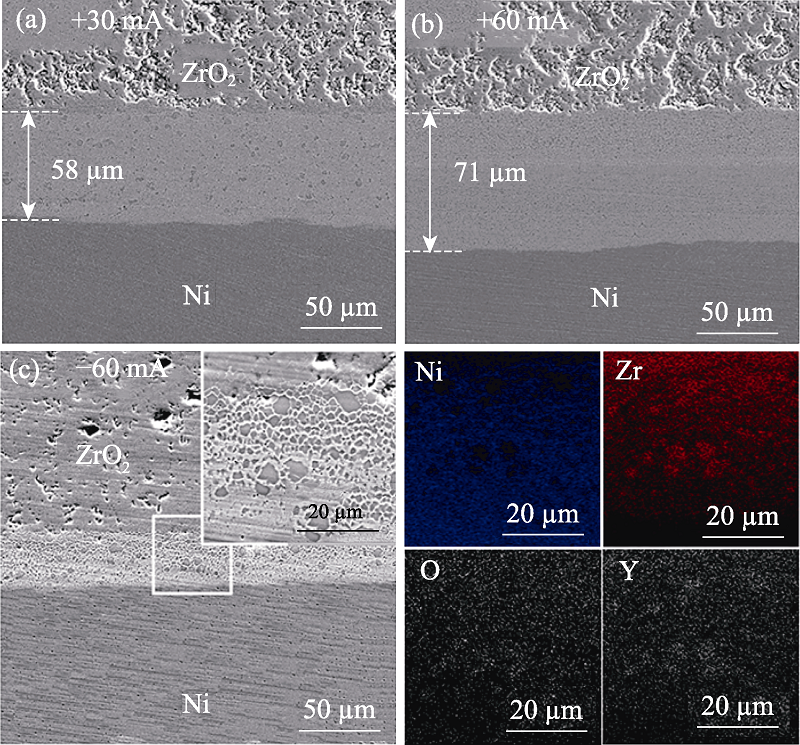

Fig. 4 Cross-sectional microstructures at the Ni/ZrO2 interfaces after joining under different current intensities and polarities[33] (a) +30 mA; (b) +60 mA; (c) −60 mA. The elemental mapping graphs correspond to the magnified frame area in image (c)

Fig. 5 TEM micrographs of the Al2O3/Ti joint bonded at 900 ℃ for 1 h under 700 V DC field [34] (a-c) Morphologies of the reaction layer (a), magnified zone B (b) and magnified zone C (c); (d) Electron diffraction (SAED) patterns of the phases

| Joining system | Joining conditions | Joint strength characterization | Maximum average joint strength/MPa | Ref. |

|---|---|---|---|---|

| SiC/SiC | 1900 ℃, 5 min, 3.5 MPa | Bending strength | 260.24±12.00 | [ |

| LR-SiC/LR-SiC | 1750 ℃, ~500 ℃/min, 800 A, 10 min, 50 MPa | — | — | [ |

| HR-SiC/HR-SiC | 2100 ℃, 100 ℃/min, 2400 A, 10 min, 50 MPa | — | — | [ |

| CVD-SiC/CVD-SiC | 1900 ℃, 50 ℃/min, 5 min, 60 MPa | Bending strength | 436±1 | [ |

| Coated C/SiC/C/SiC | 1700 ℃, 150-200 ℃/min, 3 min, 60 MPa | Shear strength | 24.6 | [ |

| Ti3SiC2/Ti3AlC2 | 1200 ℃, 150 ℃/min, ~1.18 kA, <6 min, 15 MPa | Shear strength | ~50 | [ |

| Ti3SiC2/Ti3SiC2 | 1300 ℃, 150 ℃/min, ~1.30 kA, <6 min, 15 MPa | Shear strength | ~50 | [ |

| Ti3AlC2/Ti3AlC2 | 1300 ℃, 150 ℃/min, ~1.32 kA, <6 min, 15 MPa | Shear strength | ~60 | [ |

| SiCw/Ti3SiC2/SiCw/Ti3SiC2 | 1090 ℃, 100 ℃/min, 586 A·cm-2, 30 s, 30 MPa | Shear strength | 51.8±2.9 | [ |

| STO bicrystal/STO bicrystal | 1200 ℃, 70-80 ℃/min, ~550 A, 15 min, 140 MPa | — | — | [ |

| TaC/HfC | 1850 ℃, 10 min, 60 MPa | — | — | [ |

| α-SiAlON/α-SiAlON | 1650 ℃, 10 min, 20 MPa | Bending strength | ~610 | [ |

Table 3 SPS joining of ceramic material without interlayer

| Joining system | Joining conditions | Joint strength characterization | Maximum average joint strength/MPa | Ref. |

|---|---|---|---|---|

| SiC/SiC | 1900 ℃, 5 min, 3.5 MPa | Bending strength | 260.24±12.00 | [ |

| LR-SiC/LR-SiC | 1750 ℃, ~500 ℃/min, 800 A, 10 min, 50 MPa | — | — | [ |

| HR-SiC/HR-SiC | 2100 ℃, 100 ℃/min, 2400 A, 10 min, 50 MPa | — | — | [ |

| CVD-SiC/CVD-SiC | 1900 ℃, 50 ℃/min, 5 min, 60 MPa | Bending strength | 436±1 | [ |

| Coated C/SiC/C/SiC | 1700 ℃, 150-200 ℃/min, 3 min, 60 MPa | Shear strength | 24.6 | [ |

| Ti3SiC2/Ti3AlC2 | 1200 ℃, 150 ℃/min, ~1.18 kA, <6 min, 15 MPa | Shear strength | ~50 | [ |

| Ti3SiC2/Ti3SiC2 | 1300 ℃, 150 ℃/min, ~1.30 kA, <6 min, 15 MPa | Shear strength | ~50 | [ |

| Ti3AlC2/Ti3AlC2 | 1300 ℃, 150 ℃/min, ~1.32 kA, <6 min, 15 MPa | Shear strength | ~60 | [ |

| SiCw/Ti3SiC2/SiCw/Ti3SiC2 | 1090 ℃, 100 ℃/min, 586 A·cm-2, 30 s, 30 MPa | Shear strength | 51.8±2.9 | [ |

| STO bicrystal/STO bicrystal | 1200 ℃, 70-80 ℃/min, ~550 A, 15 min, 140 MPa | — | — | [ |

| TaC/HfC | 1850 ℃, 10 min, 60 MPa | — | — | [ |

| α-SiAlON/α-SiAlON | 1650 ℃, 10 min, 20 MPa | Bending strength | ~610 | [ |

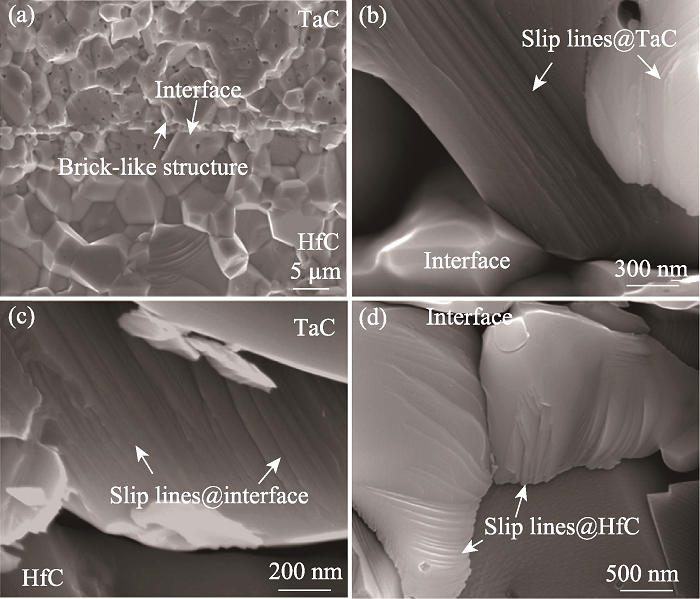

Fig. 7 Fractured micrographs of the TaC-HfC joint [44] (a) Low magnification fractured image; (b-d) High-resolution fractured images of the interface eliciting the presence of slip lines on (b) TaC side, (c) TaC-HfC interface, and (d) HfC side

| Joining system | Interlayer | Joining conditions | Joint strength characterization | Maximum joint strength/MPa | Main phases at interface | Ref. |

|---|---|---|---|---|---|---|

| SiC/SiC | 4.5YSZ | 1700 ℃, 150 ℃/min, 40 MPa | Bending strength | 26.7 | ZrO2 | [ |

| SiC/SiC | 4.5YSZ+ 20% Al2O3 (in mass) | 1800 ℃, 100-200 ℃/min, 40 MPa | Bending strength | 107.3 | ZrO2, mZrO2 | [ |

| SiC/SiC | TSC | 1900 ℃, 5 min, 3.5 MPa | Bending strength | 230.6±19 | TiC, Ti, Al | [ |

| SiC/SiC | TAC | 1900 ℃, 5 min, 3.5 MPa | Bending strength | 230.5±13 | TiC, Al, Ti | [ |

| SiC/SiC | TSC | 1300 ℃, 100-200 ℃/min, 15 min, 50 MPa | Bending strength | 80.4 | TiCx, TixSiy | [ |

| SiC/SiC | TSC | 1400 ℃, 100-200 ℃/min, 30 MPa | Bending strength | 66 | TiSi2, TiC | [ |

| SiC/SiC | TSC | 1600 ℃, 30 min, 20-40 MPa | Bending strength | 110.4 | TSC, TiC | [ |

| CVD-SiC/ CVD-SiC | TSC | 1300 ℃, 100 ℃/min, 5 min, 50 MPa | Bending strength | 220.3±3.2 | TSC | [ |

| Coated SiCf/SiC/ coated SiCf/SiC | TSC | 1300 ℃, 100 ℃/min, 5 min, 50 MPa | Shear strength | 18.3±5.8 | TSC | [ |

| Coated Cf/SiC/ coated Cf/SiC | TSC | 1300 ℃, 100 ℃/min, 5 min, 50 MPa | Shear strength | 31.1±4.0 | TSC | [ |

| Uncoated T300 1K Cf/SiC/uncoated T300 1K Cf/SiC | TSC | 1300 ℃, 100 ℃/min, 5 min, 50 MPa | Shear strength | 19.1±2.0 | TSC, SiC | [ |

| Uncoated M40J 3K Cf/SiC/uncoated M40J 3K Cf/SiC | TSC | 1300 ℃, 100 ℃/min, 5 min, 50 MPa | Shear strength | 5.5±1.8 | TSC, SiC | [ |

| Coated C/SiC/ coated C/SiC | CA | 1480 ℃, 50 ℃/min, 10 min, 0 MPa | Shear strength | ~14.1 | CA | [ |

| Coated C/SiC/ coated C/SiC | SiC+B4C | 1900 ℃, 150-200 ℃/min, 3 min, 60 MPa | Shear strength | 18.2 | — | [ |

| Cf/SiC/Cf/SiC | TSC | 1600 ℃, 30 min, 20-40 MPa | Bending strength | 62.6 | TSC, TiC | [ |

Table 4 SPS joining of ceramic material with inorganic material interlayer

| Joining system | Interlayer | Joining conditions | Joint strength characterization | Maximum joint strength/MPa | Main phases at interface | Ref. |

|---|---|---|---|---|---|---|

| SiC/SiC | 4.5YSZ | 1700 ℃, 150 ℃/min, 40 MPa | Bending strength | 26.7 | ZrO2 | [ |

| SiC/SiC | 4.5YSZ+ 20% Al2O3 (in mass) | 1800 ℃, 100-200 ℃/min, 40 MPa | Bending strength | 107.3 | ZrO2, mZrO2 | [ |

| SiC/SiC | TSC | 1900 ℃, 5 min, 3.5 MPa | Bending strength | 230.6±19 | TiC, Ti, Al | [ |

| SiC/SiC | TAC | 1900 ℃, 5 min, 3.5 MPa | Bending strength | 230.5±13 | TiC, Al, Ti | [ |

| SiC/SiC | TSC | 1300 ℃, 100-200 ℃/min, 15 min, 50 MPa | Bending strength | 80.4 | TiCx, TixSiy | [ |

| SiC/SiC | TSC | 1400 ℃, 100-200 ℃/min, 30 MPa | Bending strength | 66 | TiSi2, TiC | [ |

| SiC/SiC | TSC | 1600 ℃, 30 min, 20-40 MPa | Bending strength | 110.4 | TSC, TiC | [ |

| CVD-SiC/ CVD-SiC | TSC | 1300 ℃, 100 ℃/min, 5 min, 50 MPa | Bending strength | 220.3±3.2 | TSC | [ |

| Coated SiCf/SiC/ coated SiCf/SiC | TSC | 1300 ℃, 100 ℃/min, 5 min, 50 MPa | Shear strength | 18.3±5.8 | TSC | [ |

| Coated Cf/SiC/ coated Cf/SiC | TSC | 1300 ℃, 100 ℃/min, 5 min, 50 MPa | Shear strength | 31.1±4.0 | TSC | [ |

| Uncoated T300 1K Cf/SiC/uncoated T300 1K Cf/SiC | TSC | 1300 ℃, 100 ℃/min, 5 min, 50 MPa | Shear strength | 19.1±2.0 | TSC, SiC | [ |

| Uncoated M40J 3K Cf/SiC/uncoated M40J 3K Cf/SiC | TSC | 1300 ℃, 100 ℃/min, 5 min, 50 MPa | Shear strength | 5.5±1.8 | TSC, SiC | [ |

| Coated C/SiC/ coated C/SiC | CA | 1480 ℃, 50 ℃/min, 10 min, 0 MPa | Shear strength | ~14.1 | CA | [ |

| Coated C/SiC/ coated C/SiC | SiC+B4C | 1900 ℃, 150-200 ℃/min, 3 min, 60 MPa | Shear strength | 18.2 | — | [ |

| Cf/SiC/Cf/SiC | TSC | 1600 ℃, 30 min, 20-40 MPa | Bending strength | 62.6 | TSC, TiC | [ |

| Joining system | Interlayer | Joining conditions | Joint strength characterization | Maximum joint strength/MPa | Main phases at interface | Ref. |

|---|---|---|---|---|---|---|

| SiC/SiC | Y | 1900 ℃, 100 ℃/min, 10 min, 50 MPa | Bending strength | 134.8±2.1 | ZrO2 | [ |

| SiC/SiC | Ti | 1000 ℃, 100 ℃/min, 5 min, 30 MPa | Bending strength | 205.7±24 | ZrO2, mZrO2 | [ |

| SiC/SiC | 3Ti/1.2Si/ 2C/0.2Al | 1600 ℃, 100-200 ℃/min, 30 MPa | Bending strength | 133 | TiC, Ti, Al | [ |

| SiC coated C/SiC/ SiC coated C/SiC | Ti/Nb/Ti | 1200 ℃, 100 ℃/min, 5 min, 50 MPa | Shear strength | 61±6 | TiC, Al, Ti | [ |

| CVD-SiC/CVD-SiC | Ti | 1700 ℃, 50 ℃/min, 5 min, 60 MPa | Bending strength | 126±16 | TiCx, TixSiy | [ |

| Coated C/SiC/ coated C/SiC | Ti | 1700 ℃, 150-200 ℃/min, 3 min, 60 MPa | Shear strength | 17.3±7.8 | TiSi2, TiC | [ |

Table 5 SPS joining of ceramic material with metal interlayer

| Joining system | Interlayer | Joining conditions | Joint strength characterization | Maximum joint strength/MPa | Main phases at interface | Ref. |

|---|---|---|---|---|---|---|

| SiC/SiC | Y | 1900 ℃, 100 ℃/min, 10 min, 50 MPa | Bending strength | 134.8±2.1 | ZrO2 | [ |

| SiC/SiC | Ti | 1000 ℃, 100 ℃/min, 5 min, 30 MPa | Bending strength | 205.7±24 | ZrO2, mZrO2 | [ |

| SiC/SiC | 3Ti/1.2Si/ 2C/0.2Al | 1600 ℃, 100-200 ℃/min, 30 MPa | Bending strength | 133 | TiC, Ti, Al | [ |

| SiC coated C/SiC/ SiC coated C/SiC | Ti/Nb/Ti | 1200 ℃, 100 ℃/min, 5 min, 50 MPa | Shear strength | 61±6 | TiC, Al, Ti | [ |

| CVD-SiC/CVD-SiC | Ti | 1700 ℃, 50 ℃/min, 5 min, 60 MPa | Bending strength | 126±16 | TiCx, TixSiy | [ |

| Coated C/SiC/ coated C/SiC | Ti | 1700 ℃, 150-200 ℃/min, 3 min, 60 MPa | Shear strength | 17.3±7.8 | TiSi2, TiC | [ |

Fig. 10 Schematic diagram and performance of flash joining[24] (a) Schematic of the joining apparatus; (b) Changes of the current, voltage and power dissipation with time

Fig. 11 Schematic diagrams of interfacial microstructure evolution of 3YSZ/Ag-CuO/430SS assembly[69] (a) Furnace heating stage; (b) Joule heating, electrochemical reduction of 3YSZ and formation of AgCu4Zr and Zr-rich IMCs

| Joining system | Joining conditions | Joint strength characterization | Maximum average joint strength/MPa | Ref. |

|---|---|---|---|---|

| 3YSZ/3YSZ | 900 ℃, 30 V/cm, 100 mA/mm2, 6 MPa, 1 s | Bending strength | 595 | [ |

| CVD-SiC/Ti/Cf/SiC | 1250 ℃, 2.2 kW, 370 A, 16 MPa, 7 s | Shear strength | 31.4 | [ |

| 3YSZ/3YSZ | 800 ℃, 50 V/cm, 100 mA/mm2, 6 MPa, 18 s | Bending strength | 606±18 | [ |

| MgO-doped Al2O3/MgO-doped Al2O3 | 1300 ℃, 1500 V/cm, 0.1 A, 4 MPa, 30 s | Shear strength | 146 | [ |

| BSCF/BSCF | 1000 ℃, 10 V/cm, 0.45 A/mm2, 10 s | — | — | [ |

| ZrO2/ZA/Al2O3 | 1200 ℃, 1800 V/cm, 0.3 A, 4 MPa, 30 s | Shear strength | 3YSZ/ZA: ~65 ZA/Al2O3: ~30 | [ |

Table 6 Flash joining between ceramics

| Joining system | Joining conditions | Joint strength characterization | Maximum average joint strength/MPa | Ref. |

|---|---|---|---|---|

| 3YSZ/3YSZ | 900 ℃, 30 V/cm, 100 mA/mm2, 6 MPa, 1 s | Bending strength | 595 | [ |

| CVD-SiC/Ti/Cf/SiC | 1250 ℃, 2.2 kW, 370 A, 16 MPa, 7 s | Shear strength | 31.4 | [ |

| 3YSZ/3YSZ | 800 ℃, 50 V/cm, 100 mA/mm2, 6 MPa, 18 s | Bending strength | 606±18 | [ |

| MgO-doped Al2O3/MgO-doped Al2O3 | 1300 ℃, 1500 V/cm, 0.1 A, 4 MPa, 30 s | Shear strength | 146 | [ |

| BSCF/BSCF | 1000 ℃, 10 V/cm, 0.45 A/mm2, 10 s | — | — | [ |

| ZrO2/ZA/Al2O3 | 1200 ℃, 1800 V/cm, 0.3 A, 4 MPa, 30 s | Shear strength | 3YSZ/ZA: ~65 ZA/Al2O3: ~30 | [ |

| Joining system | Joining conditions | Joint strength characterization | Maximum joint strength/MPa | Main phases at interface | Ref. |

|---|---|---|---|---|---|

| ZrO2/Ti-alloy | 700 ℃, 100 V/cm, 70 mA/mm2, 30 s,10 MPa | Shear strength | 67±9 | Ti, Zr | [ |

| ZrO2/Ni-alloy | 800 ℃, 100 V/cm, 100 mA/mm2, 1 s, 5 MPa | Shear strength | 133 | Ni, Zr | [ |

| 3YSZ/Ag-CuO/430SS | 950 ℃, 80 V/cm, 40 mA/mm2, 30 s, 0.7 MPa | Shear strength | 158±9 | AgCu4Zr | [ |

| 3YSZ/Cu/304SS | 1200 ℃, 50 V/cm, 100 mA/mm2, 30 s, 6 MPa | Shear strength | 21±4 | Cu-Zr | [ |

| 3YSZ/Cu/GH3128 | 1000 ℃, 30 mA/mm2, 30 s, 0.1 MPa | Shear strength | 250±15 | Cu-Zr | [ |

Table 7 Flash joining between ceramics and metals

| Joining system | Joining conditions | Joint strength characterization | Maximum joint strength/MPa | Main phases at interface | Ref. |

|---|---|---|---|---|---|

| ZrO2/Ti-alloy | 700 ℃, 100 V/cm, 70 mA/mm2, 30 s,10 MPa | Shear strength | 67±9 | Ti, Zr | [ |

| ZrO2/Ni-alloy | 800 ℃, 100 V/cm, 100 mA/mm2, 1 s, 5 MPa | Shear strength | 133 | Ni, Zr | [ |

| 3YSZ/Ag-CuO/430SS | 950 ℃, 80 V/cm, 40 mA/mm2, 30 s, 0.7 MPa | Shear strength | 158±9 | AgCu4Zr | [ |

| 3YSZ/Cu/304SS | 1200 ℃, 50 V/cm, 100 mA/mm2, 30 s, 6 MPa | Shear strength | 21±4 | Cu-Zr | [ |

| 3YSZ/Cu/GH3128 | 1000 ℃, 30 mA/mm2, 30 s, 0.1 MPa | Shear strength | 250±15 | Cu-Zr | [ |

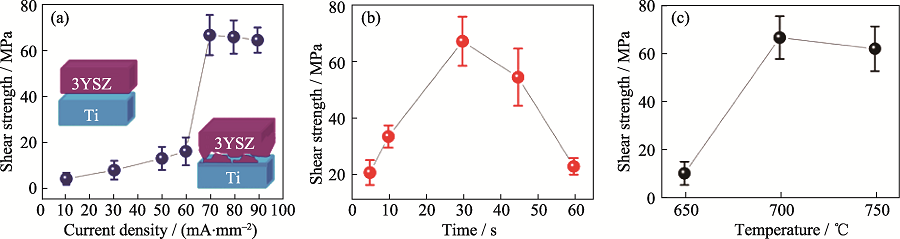

Fig. 13 Shear strength of the 3YSZ/Ti-alloy joint under different conditions[74] (a) 700 ℃ and 30 s at different current densities; (b) 700 ℃ at current density of 70 mA/mm2 for different time; (c) Current density of 70 mA/mm2 for 30 s at different temperatures

| [1] | LI Z R, GU W, FENG J C. Research status of ceramic and metal joining. Welding, 2008(3): 55. |

| [2] | SHI K Q, LI M, ZHU D D, et al. Research progress of brazing between ceramic and metal. Thermal processing, 2021, 50(13): 7. |

| [3] | JIAO R B, RONG S F, LI H B, et al. Current situation and prospect of advanced ceramics and metal connections. Foshan Ceramics, 2018, 28(3): 6. |

| [4] | CONG S S. State-of-the-art bonding methods for ceramics and metals. Bonding, 1983(3): 21. |

| [5] | FU W, SONG X G, ZHAO Y X, et al. Indirect brazing of Al2O3 ceramics and copper. Journal of Welding, 2015, 36(6): 27. |

| [6] | LIU H J, LI Z R, FENG J C, et al. Vacuum brazing of SiC ceramics and TiAl alloys. Welding, 1999(3): 7. |

| [7] |

WANG Q, CHEN G Q, WANG K, et al. Microstructural evolution and growth kinetics of interfacial compounds in TiAl/Ti3SiC2 diffusion bonding joints. Materials Science and Engineering A-Structural Materials Properties Microstructure and Processing, 2019, 756: 149.

DOI URL |

| [8] |

ZHANG C G, QIAO G J, JIN Z H. Active brazing of pure alumina to Kovar alloy based on the partial transient liquid phase (PTLP) technique with Ni-Ti interlayer. Journal of the European Ceramic Society, 2002, 22(13): 2181.

DOI URL |

| [9] |

LI S J, ZHOU Y, DUAN H P, et al. Joining of SiC ceramic to Ni-based superalloy with functionally gradient material fillers and a tungsten intermediate layer. Journal of Materials Science, 2003, 38(19): 4065.

DOI URL |

| [10] |

ESSA A A, BAHRANI A S. The friction joining of ceramics to metals. Journal of Materials Processing Technology, 1991, 26(2): 133.

DOI URL |

| [11] |

DOEHLER F, ZSCHECKEL T, KASCH S, et al. A glass in the CaO/MgO/Al2O3/SiO2 system for the rapid laser sealing of alumina. Ceramics International, 2017, 43(5): 4302.

DOI URL |

| [12] |

RABIN B H. Joining of silicon carbide/silicon carbide composites and dense silicon carbide using combustion reactions in the titanium-carbon-nickel system. Journal of the American Ceramic Society, 1992, 75(1): 131.

DOI URL |

| [13] |

FERNIE J A, DREW R A L, KNOWLES K M. Joining of engineering ceramics. International Materials Reviews, 2009, 54(5): 283.

DOI URL |

| [14] | JING W, ZHANG H. Influence of packaging technology on performance of power semiconductor modules. Power Electronics Technology, 2018, 52(8): 1. |

| [15] | LIU F J, DU Z L, CHEN S P, et al. Effect of electric field on the structure and mechanical properties of AZ31B/Al diffusion bonding interface. Weapon Materials Science and Engineering, 2009, 32(5): 18. |

| [16] |

WALLIS G, POMERANTZ D I. Field assisted glass-metal sealing. Journal of Applied Physics, 1969, 40(10): 3946.

DOI URL |

| [17] |

BYEON S C, HONG K S. Electric field assisted bonding of ceramics. Materials Science and Engineering A-Structural Materials Properties Microstructure and Processing, 2000, 287(2): 159.

DOI URL |

| [18] |

MUNIR Z A, ANSELMI-TAMBURINI U, OHYANAGI M. The effect of electric field and pressure on the synthesis and consolidation of materials: a review of the spark plasma sintering method. Journal of Materials Science, 2006, 41(3): 763.

DOI URL |

| [19] |

DONG H, LI S, TENG Y, et al. Joining of SiC ceramic-based materials with ternary carbide Ti3SiC2. Materials Science and Engineering: B, 2011, 176(1): 60.

DOI URL |

| [20] |

FITRIANI P, SEPTIADI A, HYUK J D, et al. Joining of SiC monoliths using a thin MAX phase tape and the elimination of joining layer by solid-state diffusion. Journal of the European Ceramic Society, 2018, 38(10): 3433.

DOI URL |

| [21] |

TATARKO P, CASALEGNO V, HU C, et al. Joining of CVD-SiC coated and uncoated fibre reinforced ceramic matrix composites with pre-sintered Ti3SiC2 MAX phase using Spark Plasma Sintering. Journal of the European Ceramic Society, 2016, 36(16): 3957.

DOI URL |

| [22] |

GRASSO S, TATARKO P, RIZZO S, et al. Joining of β-SiC by spark plasma sintering. Journal of the European Ceramic Society, 2014, 34(7): 1681.

DOI URL |

| [23] |

ZHOU X, HAN Y H, SHEN X, et al. Fast joining SiC ceramics with Ti3SiC2 tape film by electric field-assisted sintering technology. Journal of Nuclear Materials, 2015, 466: 322

DOI URL |

| [24] |

XIA J, REN K, WANG Y. One-second flash joining of zirconia ceramic by an electric field at low temperatures. Scripta Materialia, 2019, 165: 34.

DOI URL |

| [25] |

KNOWLES K M, VAN HELVOORT A T J. Anodic bonding. International Materials Reviews, 2006, 51(5): 273.

DOI URL |

| [26] | PAN R. Study on technology and mechanism of electric-assisted diffusion bonding of alumina ceramic to Ti. Harbin: Master Thesis of Harbin Institute of Technology, 2013. |

| [27] |

DUNN B. Field-assisted bonding of beta-alumina to metals. Journal of the American Ceramic Society, 1979, 62(11/12): 545.

DOI URL |

| [28] |

BYEON S C, BYUN T Y, HONG K S. Bonding between single- crystal manganese-zinc ferrites using electric field. Journal of Materials Research, 1998, 13(11): 3191.

DOI URL |

| [29] |

BYEON S C, JE H J, HONG K S. Direct current-induced bonding between single- and polycrystalline manganese-zinc ferrites. IEEE Transactions on Magnetics, 2000, 36(1): 371.

DOI URL |

| [30] |

LU F H, DIECKMANN R. Point defects and cation tracer diffusion in (Co, Fe, Mn)3-δO4 spinels: I. Mixed spinels (CoxFe2yMny)3-δO4. Solid State Ionics, 1992, 53-56: 290.

DOI URL |

| [31] |

LU F H, DIECKMANN R. Point defects and cation tracer diffusion in (Co, Fe, Mn)3-δO4 spinels: II. Mixed spinels (CoxFezMn2z)3-δO4. Solid State Ionics, 1993, 59(1): 71.

DOI URL |

| [32] | ARATA Y, OHMORI A, SANO A. Interfacial phenomena during field assisted bonding of zirconia to metals. Transactions of JWRI, 1986, 15(2): 387. |

| [33] |

YANG B, SHEN P, YU L T, et al. Electrochemically-driven direct joining of Ni and ZrO2. Scripta Materialia, 2017, 141: 41.

DOI URL |

| [34] |

PAN R, WANG Q, SUN D, et al. Effects of electric field on interfacial microstructure and shear strength of diffusion bonded α-Al2O3/Ti joints. Journal of the European Ceramic Society, 2015, 35(1): 219.

DOI URL |

| [35] |

DONG P, WANG Z, WANG W, et al. Understanding the spark plasma sintering from the view of materials joining. Scripta Materialia, 2016, 123: 118.

DOI URL |

| [36] |

MAMEDOV V. Spark plasma sintering as advanced PM sintering method. Powder Metallurgy, 2002, 45(4): 322.

DOI URL |

| [37] |

SHEN Z, JOHNSSON M, ZHAO Z, et al. Spark plasma sintering of alumina. Journal of the American Ceramic Society, 2002, 85(8): 1921.

DOI URL |

| [38] |

GUILLON O, GONZALEZ-JULIAN J, DARGATZ B, et al. Field-assisted sintering technology/Spark plasma sintering: mechanisms, materials, and technology developments. Advanced Engineering Materials, 2014, 16(7): 830.

DOI URL |

| [39] |

LI H, KOYANAGI T, ANG C, et al. Electric current-assisted direct joining of silicon carbide. Journal of the European Ceramic Society, 2021, 41(5): 3072.

DOI URL |

| [40] |

RIZZO S, GRASSO S, SALVO M, et al. Joining of C/SiC composites by spark plasma sintering technique. Journal of the European Ceramic Society, 2014, 34(4): 903.

DOI URL |

| [41] |

SHEN L, XUE J M, BARSOUM M W, et al. Rapid bonding of Ti3SiC2 and Ti3AlC2 by pulsed electrical current heating. Journal of the American Ceramic Society, 2014, 97(12): 3721.

DOI URL |

| [42] |

ZHOU X, SHI L-K, ZOU S, et al. Fast seamless joining of SiCw/Ti3SiC2 composite using electric field-assisted sintering technique. International Journal of Applied Ceramic Technology, 2021, 18(5): 1670.

DOI URL |

| [43] | HUGHES L A, VAN BENTHEM K. Spark plasma sintering apparatus used for the formation of strontium titanate bicrystals. Journal of Visualized Experiments, 2017, 120: 1. |

| [44] |

NISAR A, DOLMETSCH T, PAUL T, et al. Electric field assisted solid-state interfacial joining of TaC-HfC ceramics without filler. Journal of the American Ceramic Society, 2021, 104(6): 2483.

DOI URL |

| [45] |

LIU L, YE F, ZHOU Y, et al. Fast bonding α-SiAlON ceramics by spark plasma sintering. Journal of the European Ceramic Society, 2010, 30(12): 2683.

DOI URL |

| [46] |

TATARKO P, CHLUP Z, MAHAJAN A, et al. High temperature properties of the monolithic CVD beta-SiC materials joined with a pre-sintered MAX phase Ti3SiC2 interlayer via solid-state diffusion bonding. Journal of the European Ceramic Society, 2017, 37(4): 1205.

DOI URL |

| [47] |

YU Y, DONG H, MA B, et al. Effect of different filler materials on the microstructure and mechanical properties of SiC-SiC joints joined by spark plasma sintering. Journal of Alloys and Compounds, 2017, 708: 373.

DOI URL |

| [48] |

DONG H, YU Y, JIN X, et al. Microstructure and mechanical properties of SiC-SiC joints joined by spark plasma sintering. Ceramics International, 2016, 42(13): 14463.

DOI URL |

| [49] |

ZHAO X, DUAN L, WANG Y. Fast interdiffusion and Kirkendall effects of SiC-coated C/SiC composites joined by a Ti-Nb-Ti interlayer via spark plasma sintering. Journal of the European Ceramic Society, 2019, 39(5): 1757.

DOI URL |

| [50] |

ZHOU X, LIU J, ZOU S, et al. Almost seamless joining of SiC using an in-situ reaction transition phase of Y3Si2C2. Journal of the European Ceramic Society, 2020, 40(2): 259.

DOI URL |

| [51] |

YANG H, ZHOU X, SHI W, et al. Thickness-dependent phase evolution and bonding strength of SiC ceramics joints with active Ti interlayer. Journal of the European Ceramic Society, 2017, 37(4): 1233.

DOI URL |

| [52] | AKDOGAN E K, SAVKLIYILDIZ I, BICER H, et al. Anomalous lattice expansion in yttria stabilized zirconia under simultaneous applied electric and thermal fields: a time-resolved in situ energy dispersive X-ray diffractometry study with an ultrahigh energy synchrotron probe. Journal of Applied Physics, 2013, 113(23): 3503. |

| [53] |

GRIMLEY C A, PRETTE A L G, DICKEY E C. Effect of boundary conditions on reduction during early stage flash sintering of YSZ. Acta Materialia, 2019, 174: 271.

DOI URL |

| [54] |

TODD R I, ZAPATA-SOLVAS E, BONILLA R S, et al. Electrical characteristics of flash sintering: thermal runaway of Joule heating. Journal of the European Ceramic Society, 2015, 35(6): 1865.

DOI URL |

| [55] |

ZHANG Y Y, NIE J Y, LUO J. Flash sintering activated by bulk phase and grain boundary complexion transformations. Acta Materialia, 2019, 181: 544.

DOI URL |

| [56] |

NAIK K S, SGLAVO V M, RAJ R. Flash sintering as a nucleation phenomenon and a model thereof. Journal of the European Ceramic Society, 2014, 34(15): 4063.

DOI URL |

| [57] |

RAJ R, COLOGNA M, FRANCIS J S C. Influence of externally imposed and internally generated electrical fields on grain growth, diffusional creep, sintering and related phenomena in ceramics. Journal of the American Ceramic Society, 2011, 94(7): 1941.

DOI URL |

| [58] |

CHAIM R. Liquid film capillary mechanism for densification of ceramic powders during flash sintering. Materials, 2016, 9(4): 280.

DOI URL |

| [59] |

CHAIM R, AMOUYAL Y. Liquid-film assisted mechanism of reactive flash sintering in oxide systems. Materials, 2019, 12(9): 1494.

DOI URL |

| [60] |

DONG Y H, CHEN I W. Predicting the onset of flash sintering. Journal of the American Ceramic Society, 2015, 98(8): 2333.

DOI URL |

| [61] |

YU M, GRASSO S, MCKINNON R, et al. Review of flash sintering: materials, mechanisms and modelling. Advances in Applied Ceramics, 2017, 116(1): 24.

DOI URL |

| [62] |

JI W, PARKER B, FALCO S, et al. Ultra-fast firing: effect of heating rate on sintering of 3YSZ, with and without an electric field. Journal of the European Ceramic Society, 2017, 37(6): 2547.

DOI URL |

| [63] |

ZHANG Y Y, JUNG J I, LUO J. Thermal runaway, flash sintering and asymmetrical microstructural development of ZnO and ZnO-Bi2O3 under direct currents. Acta Materialia, 2015, 94: 87.

DOI URL |

| [64] |

MISHRA T P, AVILA V, NETO R R I, et al. On the role of debye temperature in the onset of flash in three oxides. Scripta Materialia, 2019, 170: 81.

DOI |

| [65] |

TATARKO P, GRASSO S, SAUNDERS T G, et al. Flash joining of CVD-SiC coated Cf/SiC composites with a Ti interlayer. Journal of the European Ceramic Society, 2017, 37(13): 3841.

DOI URL |

| [66] |

XIA J B, REN K, WANG Y G. One-second flash joining of zirconia ceramic by an electric field at low temperatures. Scripta Materialia, 2019, 165: 34.

DOI URL |

| [67] |

FRANCIS J S C, RAJ R. Flash-sinter-forging of nanograin zirconia: field assisted sintering and super-plasticity. Journal of the American Ceramic Society, 2012, 95(1): 138.

DOI URL |

| [68] |

FRANCIS J S C, RAJ R. Influence of the field and the current limit on flash sintering at isothermal furnace temperatures. Journal of the American Ceramic Society, 2013, 96(9): 2754.

DOI URL |

| [69] |

CAO Y, XU G C, SHEN P. Flash joining of 3YSZ and 430 SS using Ag-CuO filler. Ceramics International, 2022, 48(3): 4005.

DOI URL |

| [70] |

XIA J B, REN K, LIU W, et al. Ultrafast joining of zirconia ceramics using electric field at low temperatures. Journal of the European Ceramic Society, 2019, 39(10): 3173.

DOI URL |

| [71] |

XIA J, REN K, WANG Y. Flash joining of alumina ceramics under a small current density. Journal of the European Ceramic Society, 2021, 41(4): 2782.

DOI URL |

| [72] | SHI D. Research on the process and mechanism of BSCF ceramics’ flash sintering and flash joining. Harbin: Master Thesis of Harbin Institute of Technology, 2020. |

| [73] |

XIA J, REN K, WANG Y. Rapid joining of heterogeneous ceramics with a composite interlayer under the action of an electric field. Journal of the European Ceramic Society, 2021, 41(14): 7164.

DOI URL |

| [74] |

XIA J B, REN K, WANG Y G. Reversible joining of zirconia to titanium alloy. Ceramics International, 2019, 45(2): 2509.

DOI |

| [75] |

XIA J B, REN K, WANG Y G, et al. Reversible flash-bonding of zirconia and nickel alloys. Scripta Materialia, 2018, 153: 31.

DOI URL |

| [76] | CAO Y, XU G C, LI L, et al. Flash sintering of 3YSZ and in-situ joining with 304 stainless steel using copper as an interlayer. Scripta Materialia, 2021, 194: 5. |

| [77] |

LI L, LIANG Y Z, CHEN S M, et al. Ultrafast and robust joining of 3YSZ and GH3128 superalloy using Cu interlayer under an electric field. Journal of Alloys and Compounds, 2022, 890: 161893.

DOI URL |

| [1] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [2] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [3] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [4] | ZHANG Bihui, LIU Xiaoqiang, CHEN Xiangming. Recent Progress of Hybrid Improper Ferroelectrics with Ruddlesden-Popper Structure [J]. Journal of Inorganic Materials, 2025, 40(6): 587-608. |

| [5] | WU Jie, YANG Shuai, WANG Mingwen, LI Jinglei, LI Chunchun, LI Fei. Textured PT-based Piezoelectric Ceramics: Development, Status and Challenge [J]. Journal of Inorganic Materials, 2025, 40(6): 575-586. |

| [6] | JIANG Kun, LI Letian, ZHENG Mupeng, HU Yongming, PAN Qinxue, WU Chaofeng, WANG Ke. Research Progress on Low-temperature Sintering of PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 627-638. |

| [7] | TIAN Ruizhi, LAN Zhengyi, YIN Jie, HAO Nanjing, CHEN Hangrong, MA Ming. Microfluidic Technology Based Synthesis of Inorganic Nano-biomaterials: Principles and Progress [J]. Journal of Inorganic Materials, 2025, 40(4): 337-347. |

| [8] | ZHANG Jiguo, WU Tian, ZHAO Xu, YANG Fan, XIA Tian, SUN Shien. Improvement of Cycling Stability of Cathode Materials and Industrialization Process for Sodium-ion Batteries [J]. Journal of Inorganic Materials, 2025, 40(4): 348-362. |

| [9] | YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 245-255. |

| [10] | CHEN Guangchang, DUAN Xiaoming, ZHU Jinrong, GONG Qing, CAI Delong, LI Yuhang, YANG Donglei, CHEN Biao, LI Xinmin, DENG Xudong, YU Jin, LIU Boya, HE Peigang, JIA Dechang, ZHOU Yu. Advanced Ceramic Materials in Helicopter Special Structures: Research Progress and Application Prospect [J]. Journal of Inorganic Materials, 2025, 40(3): 225-244. |

| [11] | FAN Xiaobo, ZU Mei, YANG Xiangfei, SONG Ce, CHEN Chen, WANG Zi, LUO Wenhua, CHENG Haifeng. Research Progress on Proton-regulated Electrochemical Ionic Synapses [J]. Journal of Inorganic Materials, 2025, 40(3): 256-270. |

| [12] | HAIREGU Tuxun, GUO Le, DING Jiayi, ZHOU Jiaqi, ZHANG Xueliang, NUERNISHA Alifu. Research Progress of Optical Bioimaging Technology Assisted by Upconversion Fluorescence Probes in Tumor Imaging [J]. Journal of Inorganic Materials, 2025, 40(2): 145-158. |

| [13] | SUN Shujuan, ZHENG Nannan, PAN Haokun, MA Meng, CHEN Jun, HUANG Xiubing. Research Progress on Preparation Methods of Single-atom Catalysts [J]. Journal of Inorganic Materials, 2025, 40(2): 113-127. |

| [14] | TAO Guilong, ZHI Guowei, LUO Tianyou, OUYANG Peidong, YI Xinyan, LI Guoqiang. Progress on Key Technologies of Cavity-structured Thin Film Bulk Acoustic Wave Filter [J]. Journal of Inorganic Materials, 2025, 40(2): 128-144. |

| [15] | ZHOU Fan, TIAN Zhilin, LI Bin. Research Progress on Carbide Ultra-high Temperature Ceramic Anti-ablation Coatings for Thermal Protection System [J]. Journal of Inorganic Materials, 2025, 40(1): 1-16. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||