Journal of Inorganic Materials ›› 2021, Vol. 36 ›› Issue (4): 386-392.DOI: 10.15541/jim20200479

• RESEARCH PAPER • Previous Articles Next Articles

LÜ Shasha1( ), ZU Yufei2, CHEN Guoqing1(

), ZU Yufei2, CHEN Guoqing1( ), ZHAO Bojun1, FU Xuesong1, ZHOU Wenlong1

), ZHAO Bojun1, FU Xuesong1, ZHOU Wenlong1

Received:2020-08-18

Revised:2020-10-04

Published:2021-04-20

Online:2020-11-05

Contact:

CHEN Guoqing, professor. E-mail: gqchen@dlut.edu.cn

About author:LÜ Shasha(1987-), female, PhD candidate. E-mail: 352445591@qq.com

Supported by:CLC Number:

LÜ Shasha, ZU Yufei, CHEN Guoqing, ZHAO Bojun, FU Xuesong, ZHOU Wenlong. Preparation and Mechanical Property of the Ceramic-reinforced Cr0.5MoNbWTi Refractory High-entropy Alloy Matrix Composites[J]. Journal of Inorganic Materials, 2021, 36(4): 386-392.

| Sample | C/wt% | O/wt% | N/wt% |

|---|---|---|---|

| Mixture before ball milling | 0.044 | 0.448 | 0.046 |

| Mixture after ball milling | 0.482 | 2.181 | 3.920 |

Table 1 Concentrations of C, N, and O in the raw powders and as-milled powders

| Sample | C/wt% | O/wt% | N/wt% |

|---|---|---|---|

| Mixture before ball milling | 0.044 | 0.448 | 0.046 |

| Mixture after ball milling | 0.482 | 2.181 | 3.920 |

| Cr | Mo | Nb | W | Ti | Fe | C | O | N | |

|---|---|---|---|---|---|---|---|---|---|

| BCC | 15.25 | 34.17 | 8.21 | 37.15 | 0.58 | 4.25 | 0.39 | 0 | 0 |

| (Nb,Ti) (N,C) | 1.38 | 0.39 | 31.73 | 0.03 | 18.37 | 0.12 | 9.95 | 4.51 | 33.52 |

| Ti2O3 | 1.18 | 0.81 | 1.32 | 0.71 | 35.14 | 0.21 | 0.96 | 59.66 | 0.01 |

Table 2 Chemical compositions (at%) of the phases in the as-sintered composite

| Cr | Mo | Nb | W | Ti | Fe | C | O | N | |

|---|---|---|---|---|---|---|---|---|---|

| BCC | 15.25 | 34.17 | 8.21 | 37.15 | 0.58 | 4.25 | 0.39 | 0 | 0 |

| (Nb,Ti) (N,C) | 1.38 | 0.39 | 31.73 | 0.03 | 18.37 | 0.12 | 9.95 | 4.51 | 33.52 |

| Ti2O3 | 1.18 | 0.81 | 1.32 | 0.71 | 35.14 | 0.21 | 0.96 | 59.66 | 0.01 |

| Enthalpy of mixing/(kJ·mol-1)/Electronegativity difference | Cr | Mo | Nb | W | Ti |

|---|---|---|---|---|---|

| C* | -61/0.89 | -67/0.39 | -102/0.95 | -60/0.85 | -109/1.01 |

| N* | -107/1.38 | -115/0.88 | -174/1.44 | -103/1.34 | -190/1.50 |

| O** | -205/1.78 | -174/1.28 | -307/1.84 | -164/1.74 | -327/1.90 |

Table 3 Enthalpy of mixing and electronegativity difference between nonmetallic elements and metallic elements

| Enthalpy of mixing/(kJ·mol-1)/Electronegativity difference | Cr | Mo | Nb | W | Ti |

|---|---|---|---|---|---|

| C* | -61/0.89 | -67/0.39 | -102/0.95 | -60/0.85 | -109/1.01 |

| N* | -107/1.38 | -115/0.88 | -174/1.44 | -103/1.34 | -190/1.50 |

| O** | -205/1.78 | -174/1.28 | -307/1.84 | -164/1.74 | -327/1.90 |

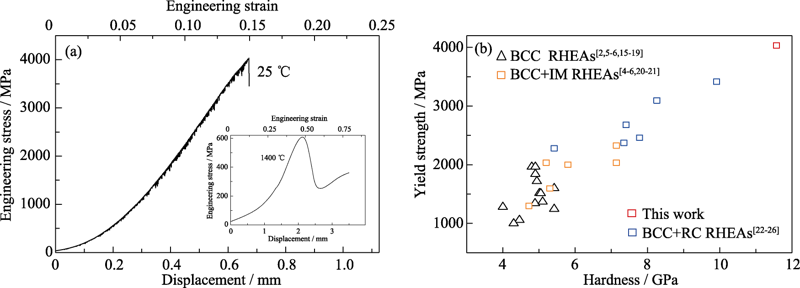

Fig. 6 Engineering stress-strain curves of the composite at room temperature and 1400 ℃ (a); Comparison of mechanical properties of the typical refractory HEAs (b)

| [1] | YEH J W, CHEN S K, LIN S J, et al. Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Advanced Engineering Materials, 2004,6(5):299-303. |

| [2] | SENKOV O N, WILKS G B, SCOTT J M, et al. Mechanical properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 refractory high entropy alloys. Intermetallics, 2011,19(5):698-706. |

| [3] | 吕昭平, 蒋虽合, 何骏阳, 等. 先进金属材料的第二相强化. 金属学报, 2016,52(10):1183-1198. |

| [4] | SENKOV O N, SENKOVA S V, MIRACLE D B, et al. Mechanical properties of low-density, refractory multi-principal element alloys of the Cr-Nb-Ti-V-Zr system. Materials Science and Engineering: A, 2013,565:51-62. |

| [5] |

SENKOV O N, SENKOVA S V, WOODWARD C. Effect of aluminum on the microstructure and properties of two refractory high-entropy alloys. Acta Materialia, 2014,68:214-228.

DOI URL |

| [6] | SENKOV O N, WOODWARD C, MIRACLE D B. Microstructure and properties of aluminum-containing refractory high-entropy alloys. JOM, 2014,66(10):2030-2042. |

| [7] | SENKOV O N, GORSSE S, MIRACLE D B. High temperature strength of refractory complex concentrated alloys. Acta Materialia, 2019,175:394-405. |

| [8] | 童文辉, 张新元, 李为轩, 等. 激光工艺参数对TiC增强钴基合金激光熔覆层组织及性能的影响. 金属学报, 2020,56(9):1265-1274. |

| [9] | 高银, 刘涛, 韩勇, 等. TiC对W-7Cu复合材料组织与性能的影响. 中国有色金属学报, 2020,30(6):1281-1288. |

| [10] | MUNIR Z A, ANSELMI-TAMBURINI U, OHYANAGI M. The effect of electric field and pressure on the synthesis and consolidation of materials: a review of the spark plasma sintering method. Journal of Materials Science, 2006,41(3):763-777. |

| [11] |

YAVARI A R, DESRE P J, BENAMEUR T. Mechanically driven alloying of immiscible elements. Physical Review Letters, 1992,68(14):2235-2238.

URL PMID |

| [12] | 雷智锋. 间隙原子对难熔高熵合金力学和阻尼性能的影响规律及机理研究. 北京: 北京科技大学博士学位论文, 2019. |

| [13] | TAKEUCHI A, INOUE A. Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element. Materials Transactions, 2005,46(12):2817-2829. |

| [14] | 陈伟亮, 张宁, 唐昭辉, 等. Miedema模型在含O和S熔体与合金中的扩展与应用. 材料研究学报, 2014,28(1):31-43. |

| [15] | HAN Z D, CHEN N, ZHAO S F, et al. Effect of Ti additions on mechanical properties of NbMoTaW and VNbMoTaW refractory high entropy alloys. Intermetallics, 2017,84:153-157. |

| [16] |

JUAN C C, TSAI M H, TSAI C W, et al. Enhanced mechanical properties of HfMoTaTiZr and HfMoNbTaTiZr refractory high-entropy alloys. Intermetallics, 2015,62:76-83.

DOI URL |

| [17] | GUO N N, WANG L, LUO L S, et al. Effect of composing element on microstructure and mechanical properties in Mo-Nb-Hf-Zr-Ti multi-principle component alloys. Intermetallics, 2016,69:13-20. |

| [18] | STEPANOV N D, SHAYSULTANOV D G, SALISHCHEV G A, et al. Structure and mechanical properties of a light-weight AlNbTiV high entropy alloy. Materials Letters, 2015,142:153-155. |

| [19] |

GUO W, LIU B, LIU Y, et al. Microstructures and mechanical properties of ductile NbTaTiV refractory high entropy alloy prepared by powder metallurgy. Journal of Alloys and Compounds, 2018,776(5):428-436.

DOI URL |

| [20] | SENKOV O N, WOODWARD C F. Microstructure and properties of a refractory NbCrMo0.5Ta0.5TiZr alloy. Materials Science and Engineering: A, 2011,529:311-320. |

| [21] | WASEEM O A, LEE J, LEE H M, et al. The effect of Ti on the sintering and mechanical properties of refractory high-entropy alloy TixWTaVCr fabricated via spark plasma sintering for fusion plasma-facing materials. Materials Chemistry and Physics, 2018,210:87-94. |

| [22] | PAN J, DAI T, LU T, et al. Microstructure and mechanical properties of Nb25Mo25Ta25W25 and Ti8Nb23Mo23Ta23W23 high entropy alloys prepared by mechanical alloying and spark plasma sintering. Materials Science and Engineering: A, 2018,738:362-366. |

| [23] | LIU Q, WANG G, SUI X, et al. Microstructure and mechanical properties of ultra-fine grained MoNbTaTiV refractory high-entropy alloy fabricated by spark plasma sintering. Journal of Materials Science & Technology, 2019,35(11):2600-2607. |

| [24] | KANG B, KONG T, RAZA A, et al. Fabrication, microstructure and mechanical property of a novel Nb-rich refractory high-entropy alloy strengthened by in-situ formation of dispersoids. International Journal of Refractory Metals and Hard Materials, 2019,81:15-20. |

| [25] | LÜ S, ZU Y, CHEN G, et al. An ultra-high strength CrMoNbWTi-C high entropy alloy co-strengthened by dispersed refractory IM and UHTC phases. Journal of Alloys and Compounds, 2019,788:1256-1264. |

| [26] | LONG Y, LIANG X, SU K, et al. A fine-grained NbMoTaWVCr refractory high-entropy alloy with ultra-high strength: microstructural evolution and mechanical properties. Journal of Alloys and Compounds, 2019,780:607-617. |

| [27] |

CHEN X J, STRUZHKIN V V, WU Z, et al. Hard superconducting nitrides. Proceedings of the National Academy of Sciences of the United States of America, 2005,102(9):3198-3201.

URL PMID |

| [28] | WAHSH M M S, KHATTAB R M, ZAWEAH M F. Sintering and technological properties of alumina/zirconia/nano-TiO2 ceramic composites. Materials Research Bulletin, 2013,48(4):1411-1414. |

| [29] |

COUZINIÉ J P, SENKOV O N, MIRACLE D B, et al. Comprehensive data compilation on the mechanical properties of refractory high-entropy alloys. Data in Brief, 2018,21:1622-1641.

URL PMID |

| [30] | CHEN H, KAUFFMANN A, GORR B, et al. Microstructure and mechanical properties at elevated temperatures of a new Al-containing refractory high-entropy alloy Nb-Mo-Cr-Ti-Al. Journal of Alloys and Compounds, 2016,661:206-215. |

| [1] | HE Guoqiang, ZHANG Kaiheng, WANG Zhentao, BAO Jian, XI Zhaochen, FANG Zhen, WANG Changhao, WANG Wei, WANG Xin, JIANG Jiapei, LI Xiangkun, ZHOU Di. Ba(Nd1/2Nb1/2)O3: Au Underrated K40 Microwave Dielectric Ceramic [J]. Journal of Inorganic Materials, 2025, 40(6): 639-646. |

| [2] | SUN Yuxuan, WANG Zheng, SHI Xue, SHI Ying, DU Wentong, MAN Zhenyong, ZHENG Liaoying, LI Guorong. Defect Dipole Thermal-stability to the Electro-mechanical Properties of Fe Doped PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 545-551. |

| [3] | CHEN Yi, QIU Haipeng, CHEN Mingwei, XU Hao, CUI Heng. SiC/SiC Composite: Matrix Boron Modification and Mechanical Properties [J]. Journal of Inorganic Materials, 2025, 40(5): 504-510. |

| [4] | CUI Ning, ZHANG Yuxin, WANG Lujie, LI Tongyang, YU Yuan, TANG Huaguo, QIAO Zhuhui. Single-phase Formation Process and Carbon Vacancy Regulation of (TiVNbMoW)Cx High-entropy Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 511-520. |

| [5] | LI Jianjun, CHEN Fangming, ZHANG Lili, WANG Lei, ZHANG Liting, CHEN Huiwen, XUE Changguo, XU Liangji. Peroxymonosulfate Activation by CoFe2O4/MgAl-LDH Catalyst for the Boosted Degradation of Antibiotic [J]. Journal of Inorganic Materials, 2025, 40(4): 440-448. |

| [6] | MU Shuang, MA Qin, ZHANG Yu, SHEN Xu, YANG Jinshan, DONG Shaoming. Oxidation Behavior of Yb2Si2O7 Modified SiC/SiC Mini-composites [J]. Journal of Inorganic Materials, 2025, 40(3): 323-328. |

| [7] | YANG Shuqi, YANG Cunguo, NIU Huizhu, SHI Weiyi, SHU Kewei. GeP3/Ketjen Black Composite: Preparation via Ball Milling and Performance as Anode Material for Sodium-ion Batteries [J]. Journal of Inorganic Materials, 2025, 40(3): 329-336. |

| [8] | LI Ziwei, GONG Weilu, CUI Haifeng, YE Li, HAN Weijian, ZHAO Tong. (Zr, Hf, Nb, Ta, W)C-SiC Composite Ceramics: Preparation via Precursor Route and Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 271-280. |

| [9] | GAO Chenguang, SUN Xiaoliang, CHEN Jun, LI Daxin, CHEN Qingqing, JIA Dechang, ZHOU Yu. SiBCN-rGO Ceramic Fibers Based on Wet Spinning Technology: Microstructure, Mechanical and Microwave-absorbing Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 290-296. |

| [10] | CHEN Guangchang, DUAN Xiaoming, ZHU Jinrong, GONG Qing, CAI Delong, LI Yuhang, YANG Donglei, CHEN Biao, LI Xinmin, DENG Xudong, YU Jin, LIU Boya, HE Peigang, JIA Dechang, ZHOU Yu. Advanced Ceramic Materials in Helicopter Special Structures: Research Progress and Application Prospect [J]. Journal of Inorganic Materials, 2025, 40(3): 225-244. |

| [11] | MU Haojie, ZHANG Yuanjiang, YU Bin, FU Xiumei, ZHOU Shibin, LI Xiaodong. Preparation and Properties of ZrO2 Doped Y2O3-MgO Nanocomposite Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 281-289. |

| [12] | WANG Yue, WANG Xin, YU Xianli. Room-temperature Ferromagnetic All-carbon Films Based on Reduced Graphene Oxide [J]. Journal of Inorganic Materials, 2025, 40(3): 305-313. |

| [13] | LUAN Xingang, HE Dianwei, TU Jianyong, CHENG Laifei. 2D Plain and 3D Needle-punched C/SiC Composites: Low-velocity Impact Damage Behavior and Failure Mechanism [J]. Journal of Inorganic Materials, 2025, 40(2): 205-214. |

| [14] | WANG Yueyue, HUANG Jiahui, KONG Hongxing, LI Huaizhu, YAO Xiaohong. Silver Loaded Radial Mesoporous Silica: Preparation and Application in Dental Resins [J]. Journal of Inorganic Materials, 2025, 40(1): 77-83. |

| [15] | WANG Wenting, XU Jingjun, MA Ke, LI Meishuan, LI Xingchao, LI Tongqi. Oxidation Behavior at 1000-1300 ℃ in air of Ti2AlC-20TiB2 Synthesized by in-situ Reaction/Hot Pressing [J]. Journal of Inorganic Materials, 2025, 40(1): 31-38. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||