Journal of Inorganic Materials ›› 2025, Vol. 40 ›› Issue (3): 323-328.DOI: 10.15541/jim20240148

• RESEARCH LETTER • Previous Articles Next Articles

MU Shuang1,2( ), MA Qin1,2, ZHANG Yu1,2, SHEN Xu1,2, YANG Jinshan1,2(

), MA Qin1,2, ZHANG Yu1,2, SHEN Xu1,2, YANG Jinshan1,2( ), DONG Shaoming1,2(

), DONG Shaoming1,2( )

)

Received:2024-03-27

Revised:2024-05-13

Published:2025-03-20

Online:2024-05-16

Contact:

YANG Jinshan, professor. E-mail: jyang@mail.sic.ac.cn;About author:MU Shuang (1995-), female, PhD candidate. E-mail: 2285489162@qq.com

Supported by:CLC Number:

MU Shuang, MA Qin, ZHANG Yu, SHEN Xu, YANG Jinshan, DONG Shaoming. Oxidation Behavior of Yb2Si2O7 Modified SiC/SiC Mini-composites[J]. Journal of Inorganic Materials, 2025, 40(3): 323-328.

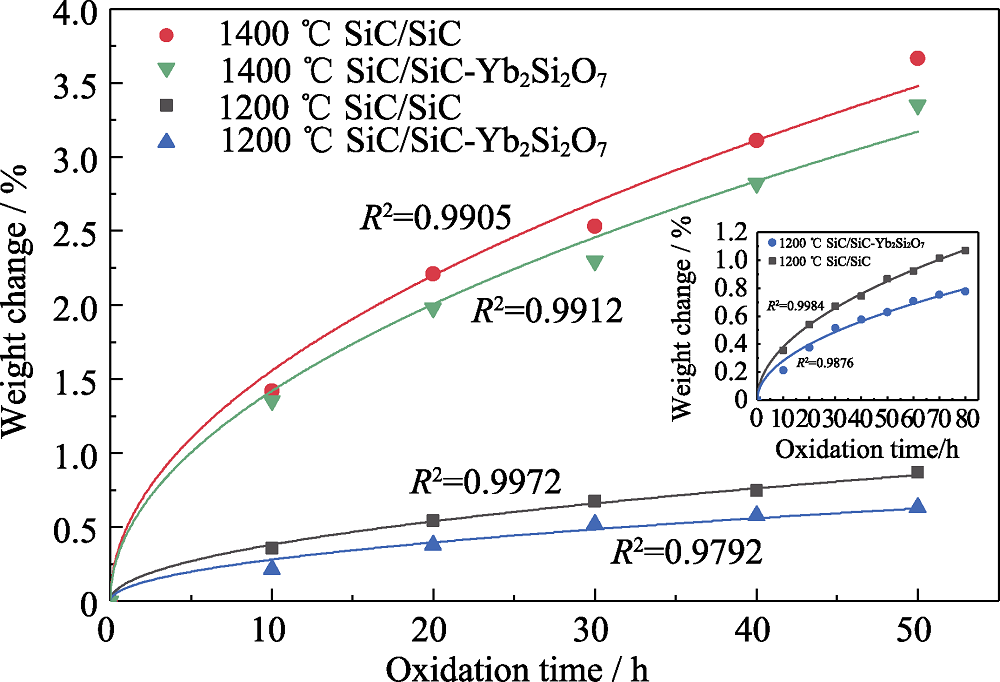

Fig. 5 Weight change of SiC/SiC and SiC/SiC-Yb2Si2O7 mini-composites during oxidation at 1200 and 1400 ℃ for 50 h with inset showing the weight change during oxidation at 1200 ℃ for 80 h

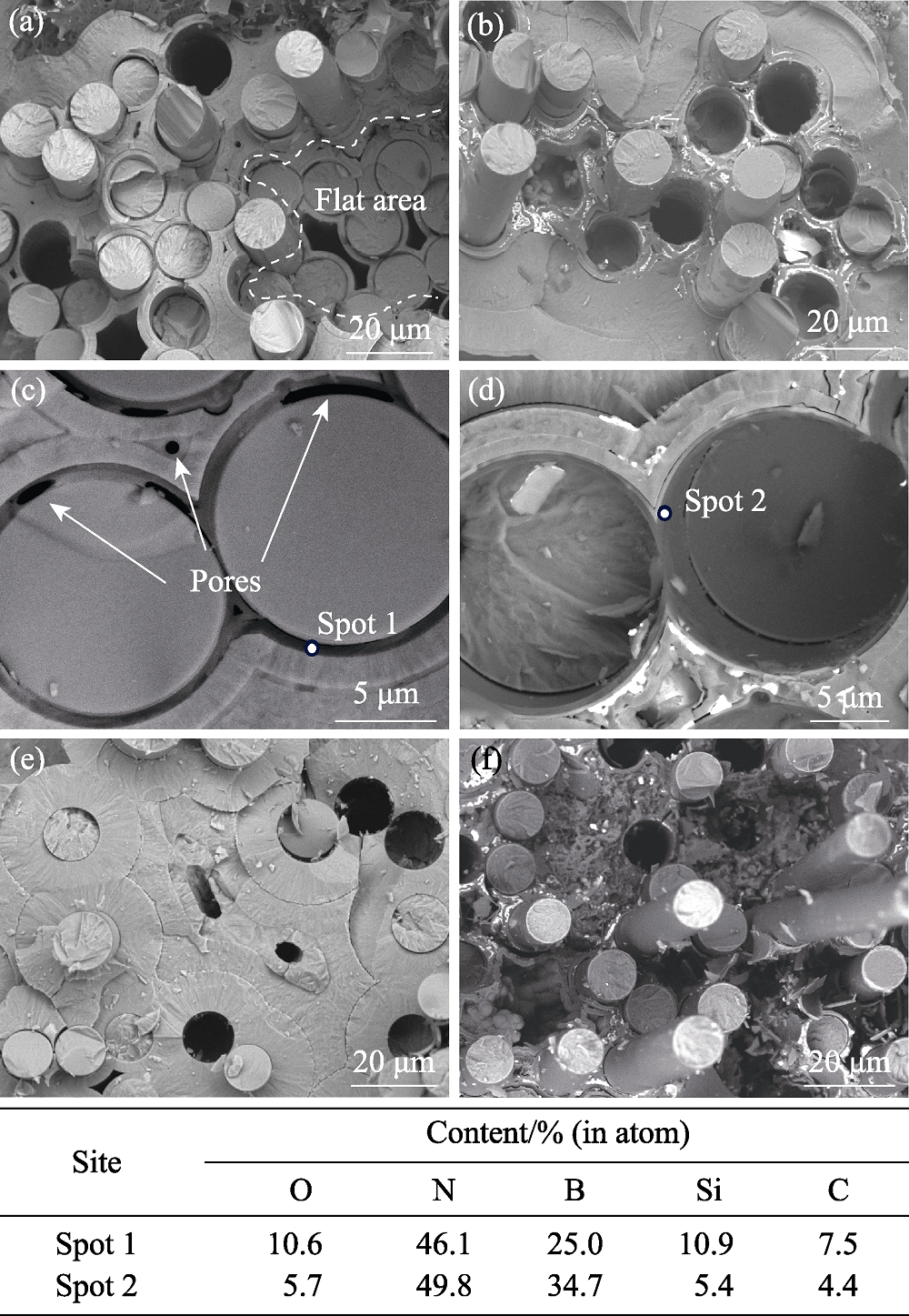

Fig. 6 Tensile fracture morphologies of (a, c, e) SiC/SiC, and (b, d, f) SiC/SiC-Yb2Si2O7 mini-composites after oxidation at (a-d) 1200 ℃ with EDS results (table at the bottom), and (e, f) at 1400 ℃, respectively

| Material | Tensile strength/MPa | ||

|---|---|---|---|

| As-prepared | Oxidation at 1200 ℃ | Oxidation at 1400 ℃ | |

| SiC/SiC | 506±56 | 391±69 | 351±56 |

| SiC/SiC-Yb2Si2O7 | 484±83 | 425±21 | 374±33 |

Tensile properties of mini-composites

| Material | Tensile strength/MPa | ||

|---|---|---|---|

| As-prepared | Oxidation at 1200 ℃ | Oxidation at 1400 ℃ | |

| SiC/SiC | 506±56 | 391±69 | 351±56 |

| SiC/SiC-Yb2Si2O7 | 484±83 | 425±21 | 374±33 |

| [1] | HE F, CAO Y, LIU Y, et al. Self-healing and failure behavior of yttrium silicate coated SiCf/SiC composites in air at elevated temperatures. Ceramics International, 2023, 49(3): 5335. |

| [2] | YANG H, YANG Y, CAO X, et al. Thermal shock resistance and bonding strength of tri-layer Yb2SiO5/mullite/Si coating on SiCf/SiC composites. Ceramics International, 2020, 46(17): 27292. |

| [3] | DETWILER K N, OPILA E J. Oxidation of SiC/BN/SiC ceramic matrix composites in dry and wet oxygen at intermediate temperatures. Journal of the European Ceramic Society, 2022, 42(10): 4110. |

| [4] | XU X, LUAN X, ZHANG J, et al. Single-source-precursor derived SiHfBCN enhancing oxidation resistance of SiC/SiC composites in wet oxygen. Corrosion Science, 2022, 208: 110602. |

| [5] | HE F, LIU Y, LI J, et al. Effect of heat treatment on the microstructure and strength of yttrium silicate matrix-modified SiCf/SiC composites. Journal of the European Ceramic Society, 2021, 41(16): 93. |

| [6] | KITAHARA T, MITANI K, SAITO H, et al. Improvement in the self-healing property of plasma-sprayed environmental barrier coatings by SiC addition. Journal of Thermal Spray Technology, 2022, 31(8): 2314. |

| [7] | ZHANG Q, XIA X, CHEN P, et al. Current research art of rare earth compound modified SiC-CMCs for enhanced wet-oxygen corrosion resistance. Ceramics International, 2022, 48(17): 24131. |

| [8] | LUO Y, SUN L, WANG J, et al. Phase formation capability and compositional design of β-phase multiple rare-earth principal component disilicates. Nature Communications, 2023, 14: 1275. |

| [9] | BOAKYE E E, MOGILEVSKY P, PARTHASARATHY T A, et al. Processing and testing of RE2Si2O7 fiber-matrix interphases for SiC-SiC composites. Journal of the American Ceramic Society, 2016, 99(2): 415. |

| [10] | BOAKYE E E, MOGILEVSKY P, KEY T S, et al.In situ Y2Si2O7 coatings on hi-Nicalon-S SiC fibers: phase formation and fiber strength. Journal of the American Ceramic Society, 2019, 102(10): 5725. |

| [11] | BOAKYE E E, MOGILEVSKY P, HAY R S, et al. Rare-earth disilicates as oxidation-resistant fiber coatings for silicon carbide ceramic-matrix composites. Journal of the American Ceramic Society, 2011, 94(6): 1716. |

| [12] | BOAKYE E E, KEY T S, PARTHASARATHY T A, et al. Evaluation of SiC/SiC minicomposites with yttrium disilicate fiber coating. Journal of the American Ceramic Society, 2018, 101(1): 91. |

| [13] | BOAKYE E E, KEY T S, MOGILEVSKY P, et al. SiC/SiC mini-composites with yttrium disilicate fiber coatings: oxidation in steam. Journal of the European Ceramic Society, 2021, 41(5): 3132. |

| [14] | WANG P, WANG Q L, ZHANG X Y, et al. Oxidation behavior of SiCf/SiC composites modified by layered-Y2Si2O7 in wet oxygen environment. Journal of Inorganic Materials, 2019, 34(8): 904. |

| [15] | ZHAO C, WANG F, SUN Y, et al. Synthesis and characterization of β-Yb2Si2O7 powders. Ceramics International, 2013, 39(5): 5805. |

| [16] | NASIRI N A, PATRA N, NI N, et al. Oxidation behaviour of SiC/SiC ceramic matrix composites in air. Journal of the European Ceramic Society, 2016, 36(14): 3293. |

| [17] | YANG H, LU Z, BIE B, et al. Microstructure and damage evolution of SiCf/PyC/SiC and SiCf/BN/SiC mini-composites: a synchrotron X-ray computed microtomography study. Ceramics International, 2019, 45(9): 11395. |

| [18] | DAI J, HE L, XU Z, et al. Oxidation behavior of SiCf/SiC minicomposites with multilayered (BN/SiC)n interfacial coatings under humid environment. Journal of Materials Engineering and Performance, 2022, 31(12): 10343. |

| [1] | WANG Wenting, XU Jingjun, MA Ke, LI Meishuan, LI Xingchao, LI Tongqi. Oxidation Behavior at 1000-1300 ℃ in air of Ti2AlC-20TiB2 Synthesized by in-situ Reaction/Hot Pressing [J]. Journal of Inorganic Materials, 2025, 40(1): 31-38. |

| [2] | TAN Min, CHEN Xiaowu, YANG Jinshan, ZHANG Xiangyu, KAN Yanmei, ZHOU Haijun, XUE Yudong, DONG Shaoming. Microstructure and Oxidation Behavior of ZrB2-SiC Ceramics Fabricated by Tape Casting and Reactive Melt Infiltration [J]. Journal of Inorganic Materials, 2024, 39(8): 955-964. |

| [3] | JIANG Lingyi, PANG Shengyang, YANG Chao, ZHANG Yue, HU Chenglong, TANG Sufang. Preparation and Oxidation Behaviors of C/SiC-BN Composites [J]. Journal of Inorganic Materials, 2024, 39(7): 779-786. |

| [4] | Shu-Guang ZHOU, Yi-Jun GUO, Xiao LIU. Simulation of ZrB2 Oxidation Behavior at Constant Temperature Ambient [J]. Journal of Inorganic Materials, 2019, 34(6): 660-666. |

| [5] | LI Si-Wei, ZHANG Li-Tong, LIU Yong-Sheng, CHENG Lai-Fei, FENG Zu-De, LUAN Xin-Gang, ZHANG Wei-Hua, YANG Wen-Bin. Self-healing Behavior of 2D C/SiC Modified by Partial Boron Carbide Matrix after Annealing at Low Temperature in Wet Oxygen [J]. Journal of Inorganic Materials, 2010, 25(11): 1199-1203. |

| [6] |

WANG Ni-Na,HUANG Jian-Feng,CAO Li-Yun,WU Jian-Peng.

Influence of Temperature on Oxidation Resistance of Carbon/Carbon Composites Modified by a Hydrothermal Treatment [J]. Journal of Inorganic Materials, 2009, 24(5): 948-952. |

| [7] |

OUYANG Hai-Bo,LI He-Jun,QI Le-Hua,LI Zheng-Jia,WEI Jian-Feng.

Microstructure and Oxidation Behavior of the SiC/PyC Multilayer Coated Carbon Fibers [J]. Journal of Inorganic Materials, 2009, 24(1): 103-106. |

| [8] | ZHANG Wei-Hua,CHENG Lai-Fei,ZHANG Li-Tong,YANG Wen-Bin,LIU Yong-Sheng,XU Yong-Dong. Preparation and Anti-oxidation Behavior of Si-C-B Self-healing Coating on C/SiC Composite [J]. Journal of Inorganic Materials, 2008, 23(4): 774-778. |

| [9] | XU Xin-Rui,YAN Wei-Lin,ZHUANG Han-Rui,LI Wen-Lan,XU Su-Ying. Oxidation Behavior of Aluminium Nitride [J]. Journal of Inorganic Materials, 2003, 18(2): 337-342. |

| [10] | ZHANG Jun-Hong,WANG Pei-Ling,ZHANG Jiong,JIA Ying-Xin. Oxidation Behavior of Multi-Canon a-Sialons Containing Rare Earth [J]. Journal of Inorganic Materials, 1999, 14(5): 806-812. |

| [11] | ZHANG Jiong,ZHANG Jun-Hong,WANG Pei-Ling. Oxidation Behavior of Dy-melilite Solid Solutions [J]. Journal of Inorganic Materials, 1999, 14(3): 449-455. |

| [12] | ZHANG Jun-Hong,WANG Pei-Ling,JIA Ying-Xin,ZHANG Jiong. Formation and Oxidation Behavior of β-Sialon-Melilite Solid Solution Ceramics [J]. Journal of Inorganic Materials, 1998, 13(6): 853-858. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||