Journal of Inorganic Materials ›› 2026, Vol. 41 ›› Issue (1): 1-11.DOI: 10.15541/jim20250081

• REVIEW • Next Articles

XU Jintao1,2( ), GAO Pan3(

), GAO Pan3( ), HE Weiyi1, JIANG Shengnan1, PAN Xiuhong1, TANG Meibo1, CHEN Kun1, LIU Xuechao1(

), HE Weiyi1, JIANG Shengnan1, PAN Xiuhong1, TANG Meibo1, CHEN Kun1, LIU Xuechao1( )

)

Received:2025-02-24

Revised:2025-03-17

Published:2026-01-20

Online:2025-06-27

Contact:

GAO Pan, professor. E-mail: 32128@sdju.edu.cn;About author:XU Jintao (1999-), male, Master candidate. E-mail: 2781659973@qq.com

Supported by:CLC Number:

XU Jintao, GAO Pan, HE Weiyi, JIANG Shengnan, PAN Xiuhong, TANG Meibo, CHEN Kun, LIU Xuechao. Recent Progress on Preparation of 3C-SiC Single Crystal[J]. Journal of Inorganic Materials, 2026, 41(1): 1-11.

| Property | Si | 3C-SiC | 4H-SiC | 6H-SiC | Ref. |

|---|---|---|---|---|---|

| Stacking sequence | — | ABC | ABCB | ABCACB | [ |

| Crystal structure | Diamond structure | Zinc blende structure | Wurtzite structure | Wurtzite structure | [ |

| Bandgap/eV | 1.12 | 2.36 | 3.26 | 3.02 | [ |

| Lattice constant, a/nm | 0.54310 | 0.43596 | 0.30798 | 0.30805 | [ |

| Lattice constant, c/nm | 0.54310 | 0.43596 | 1.00820 | 1.51151 | [ |

| Density/(g·cm-3) | 2.329 | 3.166 | 3.211 | 3.211 | [ |

| Melting point, Tm/K | 1685 | 3103 | 3103 | 3103 | [ |

| Electrical resistivity (n-type)/(Ω·cm) | 0.4-1.6 | ≤0.0006 | 0.015-0.025 | 0.015-0.025 | [ |

| Electron mobility/(cm2·V-1·s-1) | 1450 | 1000 | 800 (//C axis) 1000 (⊥C axis) | 450 (//C axis) 200 (⊥C axis) | [ |

| Hole mobility/(cm2·V-1·s-1) | 500 | 100 | 120 | 100 | [ |

| Electron saturated drift velocity/ (cm·s-1) | 1×107 | 2×107 | 2.2×107 | 1.9×107 | [ |

| Hole saturated drift velocity/(cm·s-1) | — | 1.3×107 | 1.3×107 | 1.3×107 | [ |

| Relative dielectric constant | 11.9 | 9.72 (//C axis) 9.72 (⊥C axis) | 10.32 (//C axis) 9.76 (⊥C axis) | 10.03 (//C axis) 9.66 (⊥C axis) | [ |

| Thermal conductivity/(W·cm-1·K-1) | 1.56 | 3.3-4.9 | 3.3-4.9 | 3.3-4.9 | [ |

| Coefficient of thermal expansion, α/ (×10-6, K-1) | 2.59 | 3.8 | 4.7 (//C axis) 4.3 (⊥C axis) | 4.7 (//C axis) 4.3 (⊥C axis) | [ |

| Young modulus/GPa | 130-188 | 310-550 | 390-690 | 390-690 | [ |

| Poisson’s ratio | 0.064-0.28 | 0.24 | 0.21 | 0.21 | [ |

Table 1 Comparison of parameters of silicon carbide crystal with silicon[2,7 -10]

| Property | Si | 3C-SiC | 4H-SiC | 6H-SiC | Ref. |

|---|---|---|---|---|---|

| Stacking sequence | — | ABC | ABCB | ABCACB | [ |

| Crystal structure | Diamond structure | Zinc blende structure | Wurtzite structure | Wurtzite structure | [ |

| Bandgap/eV | 1.12 | 2.36 | 3.26 | 3.02 | [ |

| Lattice constant, a/nm | 0.54310 | 0.43596 | 0.30798 | 0.30805 | [ |

| Lattice constant, c/nm | 0.54310 | 0.43596 | 1.00820 | 1.51151 | [ |

| Density/(g·cm-3) | 2.329 | 3.166 | 3.211 | 3.211 | [ |

| Melting point, Tm/K | 1685 | 3103 | 3103 | 3103 | [ |

| Electrical resistivity (n-type)/(Ω·cm) | 0.4-1.6 | ≤0.0006 | 0.015-0.025 | 0.015-0.025 | [ |

| Electron mobility/(cm2·V-1·s-1) | 1450 | 1000 | 800 (//C axis) 1000 (⊥C axis) | 450 (//C axis) 200 (⊥C axis) | [ |

| Hole mobility/(cm2·V-1·s-1) | 500 | 100 | 120 | 100 | [ |

| Electron saturated drift velocity/ (cm·s-1) | 1×107 | 2×107 | 2.2×107 | 1.9×107 | [ |

| Hole saturated drift velocity/(cm·s-1) | — | 1.3×107 | 1.3×107 | 1.3×107 | [ |

| Relative dielectric constant | 11.9 | 9.72 (//C axis) 9.72 (⊥C axis) | 10.32 (//C axis) 9.76 (⊥C axis) | 10.03 (//C axis) 9.66 (⊥C axis) | [ |

| Thermal conductivity/(W·cm-1·K-1) | 1.56 | 3.3-4.9 | 3.3-4.9 | 3.3-4.9 | [ |

| Coefficient of thermal expansion, α/ (×10-6, K-1) | 2.59 | 3.8 | 4.7 (//C axis) 4.3 (⊥C axis) | 4.7 (//C axis) 4.3 (⊥C axis) | [ |

| Young modulus/GPa | 130-188 | 310-550 | 390-690 | 390-690 | [ |

| Poisson’s ratio | 0.064-0.28 | 0.24 | 0.21 | 0.21 | [ |

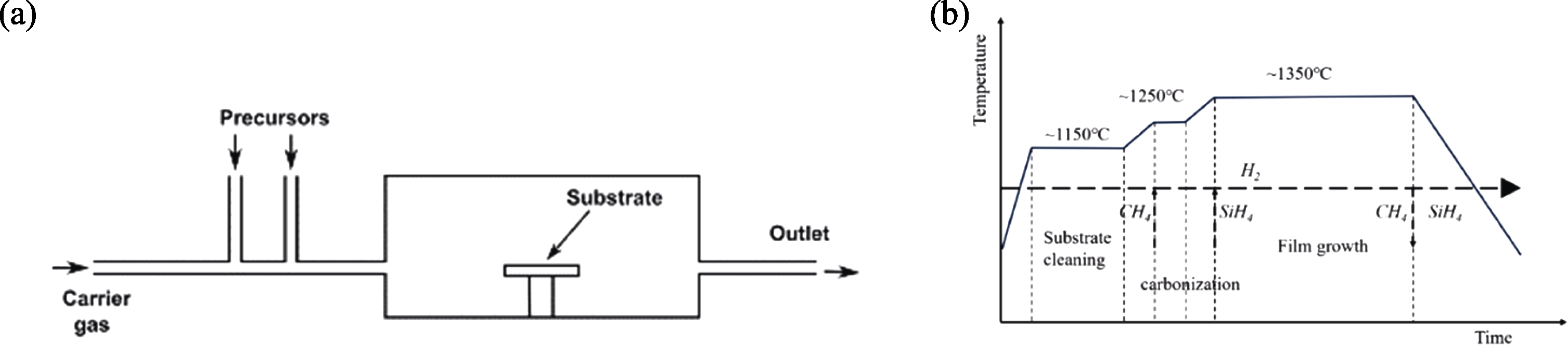

Fig. 3 Preparation of 3C-SiC thin films by CVD process[39] (a) Principle configuration of CVD reactor; (b) Flow diagram of epitaxial growth of 3C-SiC film by CVD

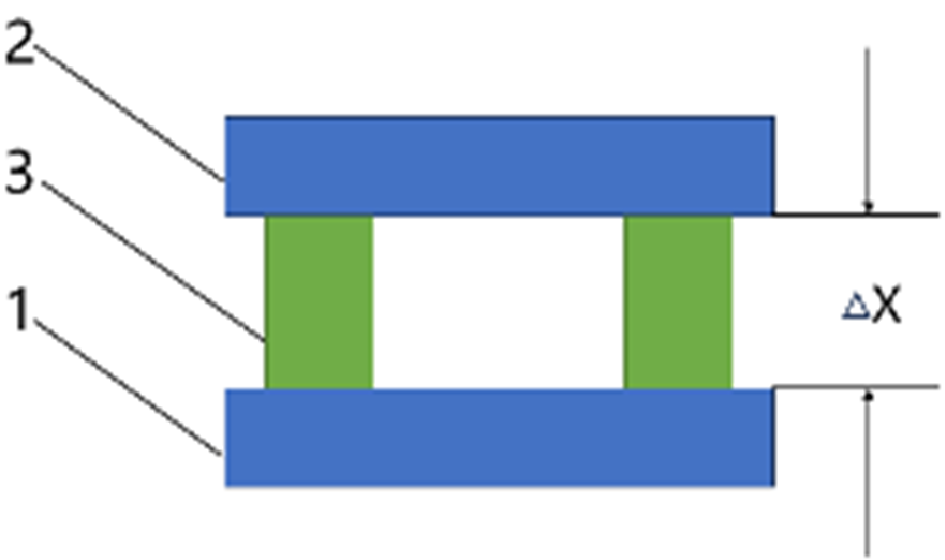

Fig. 7 Schematic diagram of SiC single crystal grown by sublimation epitaxy sandwich method 1. SiC single-crystal vapour source; 2. SiC single-crystal substrate; 3. Graphite platelets fixing the clearance ΔX between crystals

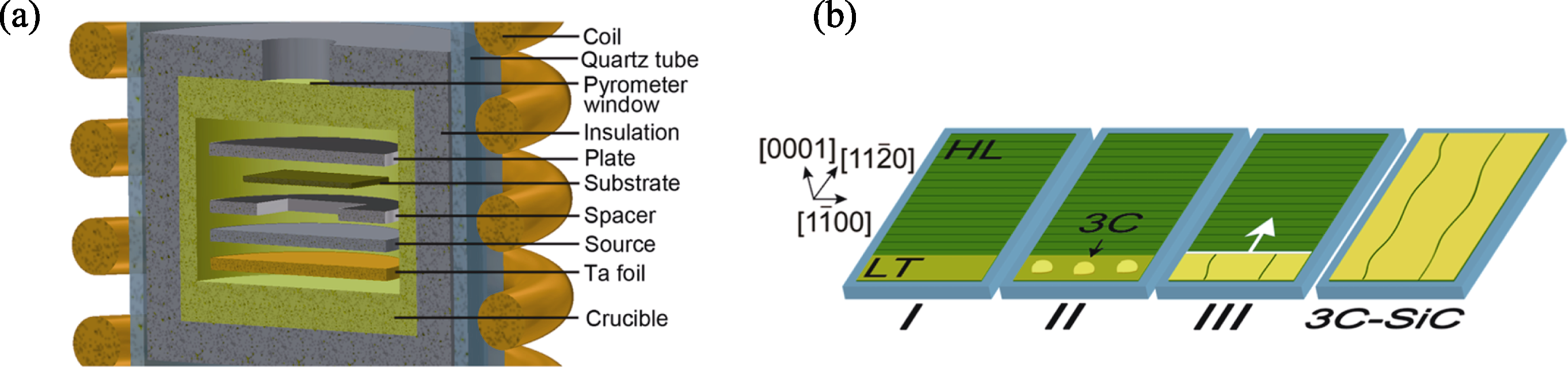

Fig. 8 3C-SiC crystal growth mechanism proposed by Jokubaviciu’s team[66] (a) Sublimation epitaxial growth arrangement; (b) 3C-SiC formation stages on off-oriented hexagonal SiC substrate HL: homoepitaxial layer; LT: large terrace

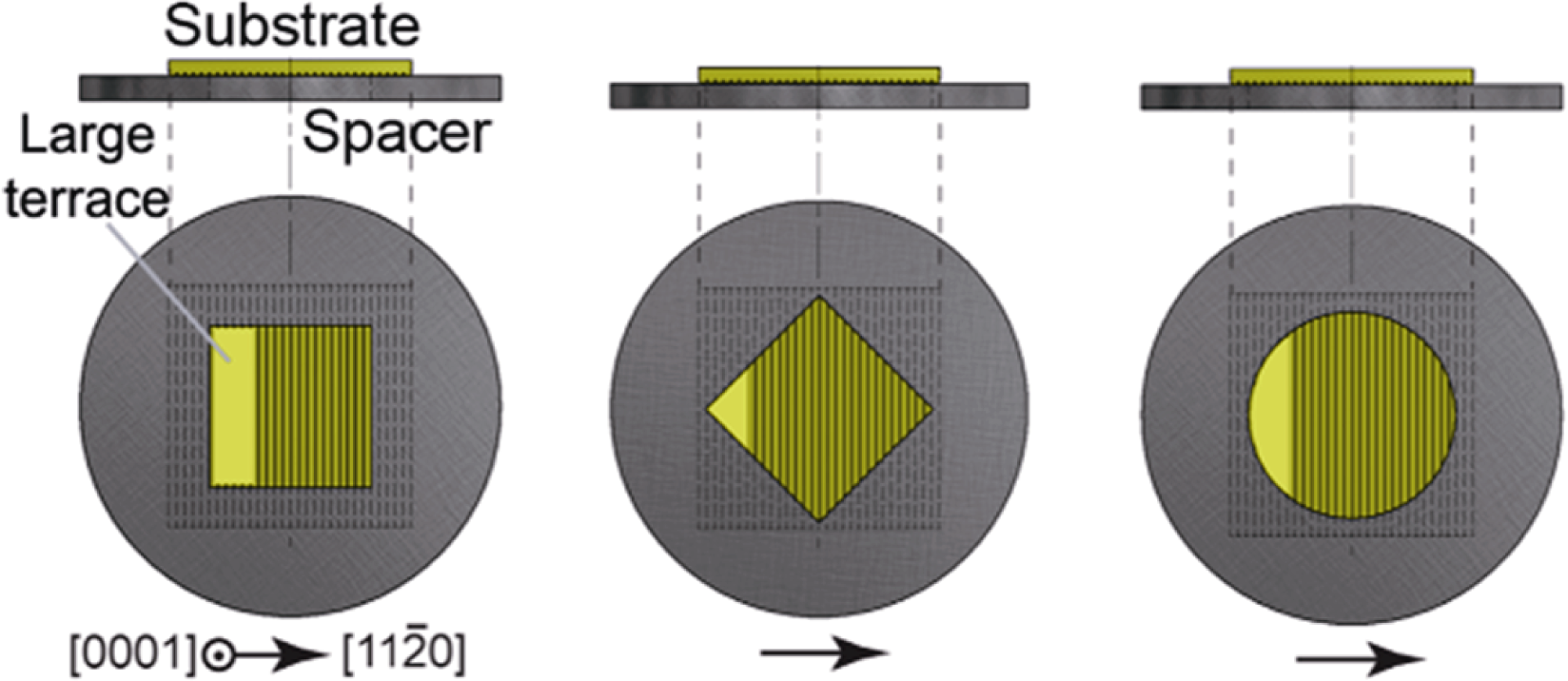

Fig. 9 Process improvement of SE method by a research team of Linköping University, including original (left), 45° rotated (middle) and circular (right) spacer openings[67]

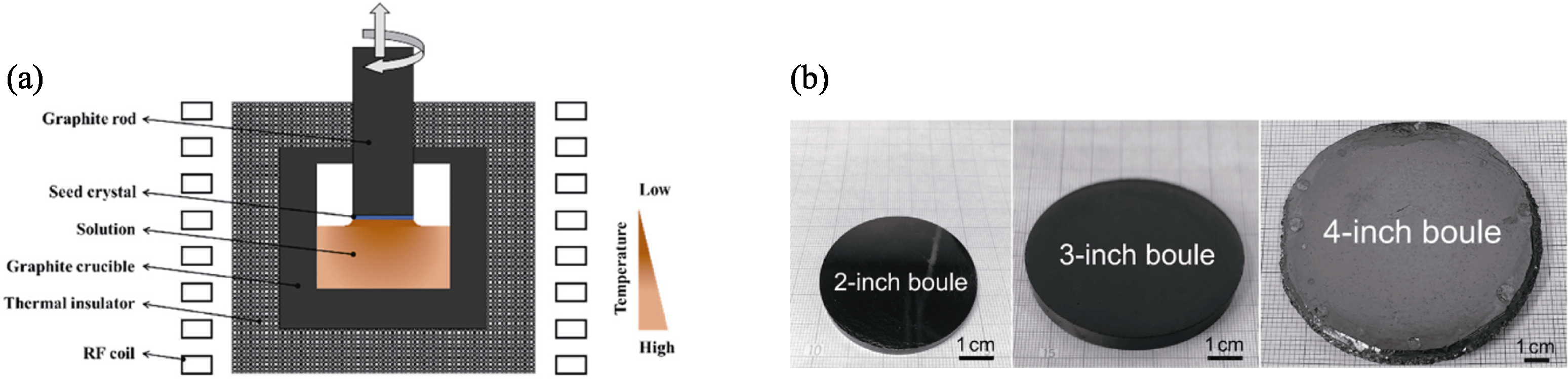

Fig. 10 SiC single crystal grown by the TSSG method[73,81] (a) Two-dimensional growth diagram[73]; (b) Photographs of 2-4 inch 3C-SiC boule at Institute of Physics, Chinese Academy of Sciences in 2024[81]

| Method | Year | Institution | Size | Thickness | Growth rate/ (μm·h-1) | Innovation point | Quality | Ref. |

|---|---|---|---|---|---|---|---|---|

| CVD | 1983 | Kyoto University | ~5 cm2 | 34 μm | 2.5 | Two-step growing process | No other crystal type | [ |

| 2002-2004 | HOYA Company | 10 cm2 | 200 μm | 40 | Wavy Si substrate | Eliminate planar defects APBs | [ | |

| 2009-2010 | CNR-IMM | φ6 inch | 7 μm | 6.5 | Si(111) surfaces are used | Surface and interface are flat with SF as low as 104 cm-1 | [ | |

| 2017-2023 | Wuhan University | 1.5 cm2 | 10 μm | 30 | LCVD | The twin defect density is low and the crystal quality is excellent | [ | |

| CF-PVT | 2005-2006 | Ecole Polytechnique de Grebnol | φ3 cm | 400 μm | 68 | 3C-SiC crystal without BPD | A lot of twins, layer fault | [ |

| SE | 2013-2015 | Linköping University | 0.49 cm2 | 1 mm | 600 | Grow on 4H-SiC | FWHM ranges from 26 to 56 arcsec | [ |

| 2019 | FAU University of Erlangen-Nuremberg | φ2 inch | 320-520 μm | 190-320 | Grow directly on the 3C-SiC seed | FWHM ranges from 138 to 140 arcsec | [ | |

| TSSG | 2010 | French National Institute of Scientific Research | — | 500 μm | 23 | Grow directly on the 3C-SiC seed | SFs and dislocation densities up to 108 cm-2 | [ |

| 2024 | Institute of Physics, Chinese Academy of Sciences | φ2-4 inch | 4-10 mm | 50-113 | Using 4H-SiC as the seed, N2 is blown in | FWHM is 30 arcsec and surface defect density is 92.2 cm-1 | [ |

Table 2 Progress of growth of 3C-SiC crystals by different growth methods[19,37,41,43 -51,60 -61,65 -67,69,78 -79,81]

| Method | Year | Institution | Size | Thickness | Growth rate/ (μm·h-1) | Innovation point | Quality | Ref. |

|---|---|---|---|---|---|---|---|---|

| CVD | 1983 | Kyoto University | ~5 cm2 | 34 μm | 2.5 | Two-step growing process | No other crystal type | [ |

| 2002-2004 | HOYA Company | 10 cm2 | 200 μm | 40 | Wavy Si substrate | Eliminate planar defects APBs | [ | |

| 2009-2010 | CNR-IMM | φ6 inch | 7 μm | 6.5 | Si(111) surfaces are used | Surface and interface are flat with SF as low as 104 cm-1 | [ | |

| 2017-2023 | Wuhan University | 1.5 cm2 | 10 μm | 30 | LCVD | The twin defect density is low and the crystal quality is excellent | [ | |

| CF-PVT | 2005-2006 | Ecole Polytechnique de Grebnol | φ3 cm | 400 μm | 68 | 3C-SiC crystal without BPD | A lot of twins, layer fault | [ |

| SE | 2013-2015 | Linköping University | 0.49 cm2 | 1 mm | 600 | Grow on 4H-SiC | FWHM ranges from 26 to 56 arcsec | [ |

| 2019 | FAU University of Erlangen-Nuremberg | φ2 inch | 320-520 μm | 190-320 | Grow directly on the 3C-SiC seed | FWHM ranges from 138 to 140 arcsec | [ | |

| TSSG | 2010 | French National Institute of Scientific Research | — | 500 μm | 23 | Grow directly on the 3C-SiC seed | SFs and dislocation densities up to 108 cm-2 | [ |

| 2024 | Institute of Physics, Chinese Academy of Sciences | φ2-4 inch | 4-10 mm | 50-113 | Using 4H-SiC as the seed, N2 is blown in | FWHM is 30 arcsec and surface defect density is 92.2 cm-1 | [ |

| [1] |

KIMOTO T. Material science and device physics in SiC technology for high-voltage power devices. Japanese Journal of Applied Physics, 2015, 54(4): 040103.

DOI URL |

| [2] | MATSUNAMI H. Fundamental research on semiconductor SiC and its applications to power electronics. Proceedings of the Japan Academy,Series B, 2020, 96(7): 235. |

| [3] |

HAMADA K, NAGAO M, AJIOKA M, et al. SiC-emerging power device technology for next-generation electrically powered environmentally friendly vehicles. IEEE Transactions on Electron Devices, 2015, 62(2): 278.

DOI URL |

| [4] | CHIU P, DOGMUS E. Power SiC 2022 market and technology report product brochure. Yole Développement,2022, 1: 1. |

| [5] |

LIMPIJUMNONG S, LAMBRECHT W. Total energy differences between SiC polytypes revisited. Physical Review B, 1998, 57: 12017.

DOI URL |

| [6] |

WELLMANN P J. Review of SiC crystal growth technology. Semiconductor Science and Technology, 2018, 33(10): 103001.

DOI URL |

| [7] | SCHUH P. Sublimation epitaxy of bulk-like cubic silicon carbide. Erlangen: Friedrich-Alexander-Universität Erlangen-Nürnberg PhD Thesis, 2019. |

| [8] | 施尔畏. 碳化硅晶体生长与缺陷. 北京: 科学出版社, 2012: 79-84. |

| [9] | Ltd. Product Center. (2025-02-01) [2025-03-07]. https://www.tankeblue.com/product12/info.html?id=18. |

| [10] | Ltd. Product Center. (2025-02-01)[2025-03-07]. https://www.jinggelingyu.com/product/61.html. |

| [11] |

CHENG Z, LIANG J, KAWAMURA K, et al. High thermal conductivity in wafer-scale cubic silicon carbide crystals. Nature Communications, 2022, 13: 7201.

DOI PMID |

| [12] | SYVÄJÄRVI M, MA Q B, JOKUBAVICIUS V, et al. Cubic silicon carbide as a potential photovoltaic material. Solar Energy Materials and Solar Cells, 2016, 145: 104. |

| [13] |

SCHÖNER A, KRIEGER M, PENSL G, et al. Fabrication and characterization of 3C-SiC-based MOSFETs. Chemical Vapor Deposition, 2006, 12: 523.

DOI URL |

| [14] | UCHIDA H, MINAMI A, SAKATA T, et al. High temperature performance of 3C-SiC MOSFETs with high channel mobility. Materials Science Forum, 2012, 717-720: 1109. |

| [15] |

VIA F L, ZIMBONE M, BONGIORNO C, et al. New approaches and understandings in the growth of cubic silicon carbide. Materials, 2021, 14(18): 5348.

DOI URL |

| [16] |

PÜSCHE R, HUNDHAUSEN M, LEY L, et al. Temperature induced polytype conversion in cubic silicon carbide studied by Raman spectroscopy. Journal of Applied Physics, 2004, 96(10): 5569.

DOI URL |

| [17] |

SCHÖLER M, VIA F L, MAUCERI M, et al. Overgrowth of protrusion defects during sublimation growth of cubic silicon carbide using free-standing cubic silicon carbide substrates. Crystal Growth & Design, 2021, 21(7): 4046.

DOI URL |

| [18] |

KOLLMUSS M, VIA F L, WELLMANN P J. Effect of growth conditions on the surface morphology and defect density of CS-PVT-grown 3C-SiC. Crystal Research and Technology, 2023, 58(7): 2300034.

DOI URL |

| [19] |

SCHUH P, STEINER J, VIA F L, et al. Limitations during vapor phase growth of bulk (100) 3C-SiC using 3C-SiC-on-SiC seeding stacks. Materials, 2019, 12(15): 2353.

DOI URL |

| [20] | LEE K K, PENSL G, SOUEIDAN M, et al. Very low interface state density from thermally oxidized single-domain 3C-SiC/6H- SiC grown by vapour-liquid-solid mechanism. Japanese Journal of Applied Physics, 2006, 45(9R): 6823. |

| [21] |

CAETANO E W S, BEZERRA E F, FREIRE V N, et al. Ultrafast electron drift velocity overshoot in 3C-SiC. Solid State Communications, 2000, 113(9): 539.

DOI URL |

| [22] |

ANZALONE R, PRIVITERA S, CAMARDA M, et al. Interface state density evaluation of high quality hetero-epitaxial 3C-SiC (001) for high-power MOSFET applications. Materials Science and Engineering: B, 2015, 198: 14.

DOI URL |

| [23] |

BEAUCARNE G, BROWN A S, KEEVERS M J, et al. The impurity photovoltaic (IPV) effect in wide-bandgap semiconductors: an opportunity for very-high-efficiency solar cells. Progress in Photovoltaics: Research and Applications, 2002, 10(5): 345.

DOI URL |

| [24] |

ROCCAFORTE F, GRECO G, FIORENZA P, et al. Towards vertical Schottky diodes on bulk cubic silicon carbide (3C-SiC). Applied Surface Science, 2022, 606:154896.

DOI URL |

| [25] |

ICHIKAWA N, KATO M, ICHIMURA M. Photocathode for hydrogen generation using 3C-SiC epilayer grown on vicinal off- angle 4H-SiC substrate. Applied Physics Express, 2015, 8(9): 091301.

DOI URL |

| [26] |

SUN J, JOKUBAVICIUS V, GAO L, et al. Solar driven energy conversion applications based on 3C-SiC. Materials Science Forum, 2016, 858: 1028.

DOI URL |

| [27] |

CHRISTLE D J, KLIMOV P V, CASAS C F D L, et al. Isolated spin qubits in SiC with a high-fidelity infrared spin-to-photon interface. Physical Review X, 2017, 7(2): 021046.

DOI URL |

| [28] |

SCHÖLER M, LEDERER M W, SCHUH P, et al. Intentional incorporation and tailoring of point defects during sublimation growth of cubic silicon carbide by variation of process parameters. Physica Status Solidi B, 2020, 257(1): 1900286.

DOI URL |

| [29] |

SCHÖLER M, BRECHT C, WELLMANN P J. Annealing-induced changes in the nature of point defects in sublimation-grown cubic silicon carbide. Materials, 2019, 12(15): 2487.

DOI URL |

| [30] |

SAMEERA J N, ISLAM M A, ISLAM S, et al. Cubic silicon carbide (3C-SiC) as a buffer layer for high efficiency and highly stable CdTe solar cell. Optical Materials, 2022, 123: 111911.

DOI URL |

| [31] |

HEIDARZADEH H. Performance analysis of cubic silicon carbide solar cell as an appropriate candidate for high temperature application. Optical and Quantum Electronics, 2020, 52(4): 192.

DOI |

| [32] |

XING Y M, HU E Y, WANG F Z, et al. Cubic silicon carbide/zinc oxide heterostructure fuel cells. Applied Physics Letters, 2020, 117(16): 162105.

DOI URL |

| [33] |

LI H J, ZHOU Z D, CAO X H, et al. Fabrication and performance of 3C-SiC photocathode materials for water splitting. Progress in Natural Science: Materials International, 2024, 34(1): 12.

DOI URL |

| [34] | BASAK N. Fabrication and characterization of 3C-silicon carbide micro sensor for wireless blood pressure measurements. Washington: Howard University PhD Thesis, 2008. |

| [35] |

LEBEDEV A A, PETROV V N, TITKOV A N, et al. Heteropolytype structures with SiC quantum dots. Technical Physics Letters, 2005, 31: 997.

DOI URL |

| [36] |

NAGASAWA H, YAGI K. 3C-SiC single-crystal films grown on 6 inch Si substrates. Physica Status Solidi B, 1997, 202(1): 335.

DOI URL |

| [37] | 孙清云. 激光CVD法制备3C-SiC薄膜的结构调控及性能研究. 武汉: 武汉理工大学博士学位论文, 2023. |

| [38] | NAGASAWA H, YAGI K, KAWAHARA T. 3C-SiC hetero- epitaxial growth on undulant Si (001) substrate. Journal of Crystal Growth, 2002, 237: 1244. |

| [39] | 梁涛. CVD法制备3C-SiC/Si薄膜研究. 成都: 电子科技大学硕士学位论文, 2006. |

| [40] | 石彪, 朱明星, 陈义, 等. 单晶硅衬底异质外延3C-SiC薄膜研究进展. 硅酸盐通报, 2011, 30(5): 1083. |

| [41] |

NISHINO S, POWELL J A, WILL H A. Production of large area single crystal wafers of cubic SiC for semiconductor devices. Applied Physics Letters, 1983, 42(5): 460.

DOI URL |

| [42] | FLEISCHMAN A J, ZORMAN C A, MEHREGANY M, et al. Epitaxial growth of 3C-SiC films on 4-inch diameter (100) silicon wafers by APCVD. Institute of Physics Conference Series, 1996, 142: 197. |

| [43] | NAGASAWA H, YAGI K, KAWAHARA T, et al. Low-defect 3C-SiC grown on undulant-Si (001) substrates//CHOYKE W J. Silicon carbide:recent major advances. New York: Springer, 2004: 207-228. |

| [44] | NAGASAWA H, YAGI K, KAWAHARA T, et al. 3C-SiC monocrystals grown on undulant Si(001) substrates. MRS Online Proceedings Library, 2002, 742: 16. |

| [45] | NAGASAWA H, KAWAHARA T, YAGI K. Heteroepitaxial growth and characteristics of 3C-SiC on large-diameter Si (001) substrates. Materials Science Forum, 2002, 389-393: 319. |

| [46] |

NISHIGUCHI T, NAKAMURA M, NISHIO K, et al. Heteroepitaxial growth of (111) 3C-SiC on well-lattice-matched (110) Si substrates by chemical vapor deposition. Applied Physics Letters, 2004, 84(16): 3082.

DOI URL |

| [47] | SEVERINO A, BONGIORNO C, PILUSO N, et al. High-quality 6 inch (111) 3C-SiC films grown on off-axis (111) Si substrates. Thin Solid Films, 2010, 518(6): 165. |

| [48] |

SEVERINO A, CAMARDA M, SCALESE S, et al. Preferential oxidation of stacking faults in epitaxial off-axis (111) 3C-SiC films. Applied Physics Letters, 2009, 95(11): 111905.

DOI URL |

| [49] |

ZHU P, XU Q, CHEN R, et al. Structural study of β-SiC (001) films on Si (001) by laser chemical vapor deposition. Journal of the American Ceramic Society, 2017, 100(4): 1634.

DOI URL |

| [50] |

SUN Q, ZHU P, XU Q, et al. High-speed heteroepitaxial growth of 3C-SiC (111) thick films on Si (110) by laser chemical vapor deposition. Journal of the American Ceramic Society, 2018, 101(3): 1048.

DOI URL |

| [51] |

SUN Q, YANG M, LI J, et al. Heteroepitaxial growth of thick 3C-SiC (110) films by laser CVD. Journal of the American Ceramic Society, 2019, 102(8): 4480.

DOI |

| [52] | LELY J A. The preparation of silicon carbide single crystal and the control of the type and amount of internal impurities. Berichte der Deutschen Keramischen Gesellschaft, 1969, 32: 229. |

| [53] | HAMILTON D R. The growth of silicon carbide by sublimation. High Temperature Semiconductor, 1960: 45. |

| [54] |

TAIROV Y M, TSVETKOV V F. Investigation of growth processes of ingots of silicon carbide single crystals. Journal of Crystal Growth, 1978, 43(2): 209.

DOI URL |

| [55] | CHAUSSENDE D, BAILLET F, CHARPENTIER L, et al. Continuous feed physical vapor transport: toward high purity and long boule growth of SiC. Journal of the Electrochemical Society, 2003, 150(10): 653. |

| [56] | MANTZARI A, MERCIER F, SOUEIDAN M, et al. Structural characterization of CF-PVT grown bulk 3C-SiC. Materials Science Forum, 2009, 600: 67. |

| [57] | SUN G L, GALBEN-SANDULACHE I G, OUISSE T, et al. Improvements of the continuous feed-physical vapor transport technique (CF-PVT) for the seeded growth of 3C-SiC crystals. Silicon Carbide and Related Materials, 2010, 645: 63. |

| [58] | SEMMELROTH K, SCHULZE N, PENSL G. Growth of SiC polytypes by the physical vapour transport technique. Journal of Physics: Condensed Matter, 2004, 16(17): 1597. |

| [59] |

SEMMELROTH K, KRIEGER M, PENSL G, et al. Growth of cubic SiC single crystals by the physical vapor transport technique. Journal of Crystal Growth, 2007, 308(2): 241.

DOI URL |

| [60] | LATU-ROMAIN L, CHAUSSENDE D, BALLOUD C, et al. Characterization of bulk <111> 3C-SiC single crystals grown on 4H-SiC by the CF-PVT method. Materials Science Forum, 2006, 527/528/529: 99. |

| [61] |

LATU-ROMAIN L, CHAUSSENDE D, CHAUDOUËT P, et al. Study of 3C-SiC nucleation on (0001) 6H-SiC nominal surfaces by the CF-PVT method. Journal of Crystal Growth, 2005, 275(1/2): e609.

DOI URL |

| [62] |

TAIROV Y M, TSVETKOV V F, LILOV S K, et al. Studies of growth kinetics and polytypism of silicon carbide epitaxial layers grown from the vapour phase. Journal of Crystal Growth, 1976, 36(1): 147.

DOI URL |

| [63] |

VODAKOV Y A, ROENKOV A D, RAMM M G, et al. Use of Ta-container for sublimation growth and doping of SiC bulk crystals and epitaxial layers. Physica Status Solidi B, 1997, 202(1): 177.

DOI URL |

| [64] |

MOKHOV E N, RAMM M G, ROENKOV A D, et al. Growth of silicon carbide bulk crystals by the sublimation sandwich method. Materials Science and Engineering: B, 1997, 46(1/2/3): 317.

DOI URL |

| [65] | JOKUBAVICIUS V, HUANG H H, SCHIMMEL S, et al. Towards bulk-like 3C-SiC growth using low off-axis substrates. Materials Science Forum, 2013, 740/741/742: 275. |

| [66] |

JOKUBAVICIUS V, YAZDI G R, LILJEDAHL R, et al. Lateral enlargement growth mechanism of 3C-SiC on off-oriented 4H-SiC substrates. Crystal Growth & Design, 2014, 14(12): 6514.

DOI URL |

| [67] |

JOKUBAVICIUS V, YAZDI G R, LILJEDAHL R, et al. Single domain 3C-SiC growth on off-oriented 4H-SiC substrates. Crystal Growth & Design, 2015, 15(6): 2940.

DOI URL |

| [68] | VASILIAUSKAS R. Sublimation growth and performance of cubic silicon carbide. Linköping: Linköping University PhD Thesis, 2012. |

| [69] |

SCHUH P, VIA F L, MAUCERI M, et al. Growth of large-area, stress-free, and bulk-like 3C-SiC (100) using 3C-SiC-on-Si in vapor phase growth. Materials, 2019, 12(13): 2179.

DOI URL |

| [70] | HOFMANN D H, MÜLLER M H. Prospects of the use of liquid phase techniques for the growth of bulk silicon carbide crystals. Materials Science and Engineering: B, 1999, 61(62): 29. |

| [71] | WANG G B, LI H, SHENG D, et al. Research progress on growth of SiC single crystal via high temperature solution method. Journal of Synthetic Crystals, 2022, 51(1): 3. |

| [72] | GU P, LEI P, YE S, et al. Research progress on the growth of silicon carbide single crystal via top-seeded solution growth method and its key issues. Journal of Synthetic Crystals, 2024, 53(5): 741. |

| [73] |

WANG G B, SHENG D, LI H, et al. Influence of interfacial energy on the growth of SiC single crystals from high temperature solutions. CrystEngComm, 2023, 25(4): 560.

DOI URL |

| [74] | YOSHIKAWA T, KAWANISHI S, TANAKA T. Solution growth of silicon carbide using Fe-Si solvent. Japanese Journal of Applied Physics, 2010, 49(5R): 051302. |

| [75] |

YAMAMOTO Y, HARADA S, SEKI K, et al. Low-dislocation- density 4H-SiC crystal growth utilizing dislocation conversion during solution method. Applied Physics Express, 2014, 7(6): 065501.

DOI URL |

| [76] |

DAIKOKU H, KADO M, SEKI A, et al. Solution growth on concave surface of 4H-SiC crystal. Crystal Growth & Design, 2016, 16(3): 1256.

DOI URL |

| [77] |

KAWANISHI S, SHIBATA H, YOSHIKAWA T. Contribution of dislocations in SiC seed crystals on the melt-back process in SiC solution growth. Materials, 2022, 15(5): 1796.

DOI URL |

| [78] | MERCIER F, KIM-HAK O, LORENZZI J, et al. Is the liquid phase a viable approach for bulk growth of 3C-SiC? Materials Science Forum, 2010, 645-648: 67. |

| [79] | CHAUSSENDE D. Vapor phase vs. liquid phase: what is the best choice for the growth of bulk 3C-SiC crystals? AIP Conference Proceedings, 2010, 1292(1): 1. |

| [80] | FERRO G. Overview of 3C-SiC crystalline growth. Materials Science Forum, 2010, 645-648: 49. |

| [81] |

WANG G B, SHENG D, YANG Y, et al. High-quality and wafer- scale cubic silicon carbide single crystals. Energy & Environmental Materials, 2024, 7(4): e12678.

DOI URL |

| [82] |

SHENG D, WANG G, YANG Y, et al. Modeling and suppressing interfacial instability in growth of SiC from high-temperature solutions. Crystal Growth & Design, 2025, 25(4): 1211.

DOI URL |

| [83] |

SCACE R I, SLACK G A. Solubility of carbon in silicon and germanium. The Journal of Chemical Physics, 1959, 30(6): 1551.

DOI URL |

| [84] |

LIANG G Q, QIAN H, SU Y L, et al. Review of solution growth techniques for 4H-SiC single crystal. China Foundry, 2023, 20(2): 159.

DOI |

| [85] |

MITANI T, KOMATSU N, TAKAHASHI T, et al. Growth rate and surface morphology of 4H-SiC crystals grown from Si-Cr-C and Si-Cr-Al-C solutions under various temperature gradient conditions. Journal of Crystal Growth, 2014, 401: 681.

DOI URL |

| [86] |

NARUMI T, KAWANISHI S, YOSHIKAWA T, et al. Thermodynamic evaluation of the C-Cr-Si, C-Ti-Si, and C-Fe-Si systems for rapid solution growth of SiC. Journal of Crystal Growth, 2014, 408: 25.

DOI URL |

| [87] |

MITANI T, KOMATSU N, TAKAHASHI T, et al. Effect of aluminum addition on the surface step morphology of 4H-SiC grown from Si-Cr-C solution. Journal of Crystal Growth, 2015, 423: 45.

DOI URL |

| [1] | FAN Yuzhu, WANG Yuan, WANG Linyan, XIANG Meiling, YAN Yuting, LI Benhui, LI Min, WEN Zhidong, WANG Haichao, CHEN Yongfu, QIU Huidong, ZHAO Bo, ZHOU Chengyu. Graphene Oxide-based Adsorbents for Pb(II) Removing in Water: Progresses on Synthesis, Performance and Mechanism [J]. Journal of Inorganic Materials, 2026, 41(1): 12-26. |

| [2] | YU Shengyang, SU Haijun, JIANG Hao, YU Minghui, YAO Jiatong, YANG Peixin. A Review of Pore Defects in Ultra-high Temperature Oxide Ceramics by Laser Additive Manufacturing: Formation and Suppression [J]. Journal of Inorganic Materials, 2025, 40(9): 944-956. |

| [3] | LIU Jiangping, GUAN Xin, TANG Zhenjie, ZHU Wenjie, LUO Yongming. Research Progress on Catalytic Oxidation of Nitrogen-containing Volatile Organic Compounds [J]. Journal of Inorganic Materials, 2025, 40(9): 933-943. |

| [4] | XIAO Xiaolin, WANG Yuxiang, GU Peiyang, ZHU Zhenrong, SUN Yong. Advances in Regulation of Damaged Skin Regeneration by Two-dimensional Inorganic Materials [J]. Journal of Inorganic Materials, 2025, 40(8): 860-870. |

| [5] | MA Jingge, WU Chengtie. Application of Inorganic Bioceramics in Promoting Hair Follicle Regeneration and Hair Growth [J]. Journal of Inorganic Materials, 2025, 40(8): 901-910. |

| [6] | ZHANG Hongjian, ZHAO Ziyi, WU Chengtie. Inorganic Biomaterials on Regulating Neural Cell Function and Innervated Tissue Regeneration: A Review [J]. Journal of Inorganic Materials, 2025, 40(8): 849-859. |

| [7] | AI Minhui, LEI Bo. Micro-nanoscale Bioactive Glass: Functionalized Design and Angiogenic Skin Regeneration [J]. Journal of Inorganic Materials, 2025, 40(8): 921-932. |

| [8] | WANG Yutong, CHANG Jiang, XU He, WU Chengtie. Advances in Silicate Bioceramic/Bioglass for Wound Healing: Effects, Mechanisms and Application Ways [J]. Journal of Inorganic Materials, 2025, 40(8): 911-920. |

| [9] | MA Wenping, HAN Yahui, WU Chengtie, LÜ Hongxu. Application of Inorganic Bioactive Materials in Organoid Research [J]. Journal of Inorganic Materials, 2025, 40(8): 888-900. |

| [10] | LUO Xiaomin, QIAO Zhilong, LIU Ying, YANG Chen, CHANG Jiang. Inorganic Bioactive Materials Regulating Myocardial Regeneration [J]. Journal of Inorganic Materials, 2025, 40(8): 871-887. |

| [11] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [12] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [13] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [14] | ZHANG Bihui, LIU Xiaoqiang, CHEN Xiangming. Recent Progress of Hybrid Improper Ferroelectrics with Ruddlesden-Popper Structure [J]. Journal of Inorganic Materials, 2025, 40(6): 587-608. |

| [15] | WU Jie, YANG Shuai, WANG Mingwen, LI Jinglei, LI Chunchun, LI Fei. Textured PT-based Piezoelectric Ceramics: Development, Status and Challenge [J]. Journal of Inorganic Materials, 2025, 40(6): 575-586. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||