无机材料学报 ›› 2018, Vol. 33 ›› Issue (5): 475-482.DOI: 10.15541/jim20170330 CSTR: 32189.14.10.15541/jim20170330

所属专题: 离子电池材料

• 综述 • 下一篇

谭毅1,2, 薛冰1,2

收稿日期:2017-07-06

修回日期:2017-08-22

出版日期:2018-05-20

网络出版日期:2018-04-26

TAN Yi1,2, XUE Bing1,2

Received:2017-07-06

Revised:2017-08-22

Published:2018-05-20

Online:2018-04-26

摘要:

锂离子电池作为一种动力能源, 在电动汽车和各种储能系统中有着良好的应用前景。尖晶石结构的钛酸锂(Li4Ti5O12)负极材料具有较高的脱嵌锂电位平台、优异的循环稳定性、以及突出的安全性能, 被认为是一种非常有潜力的锂离子电池负极材料, 在锂离子动力电池中具有巨大的发展潜力。然而, 尖晶石型Li4Ti5O12存在着本征导电率低, 理论容量小等缺陷, 极大地限制了其规模化应用, 需要进一步改善和提高。本文总结了尖晶石型Li4Ti5O12材料在结构形貌、制备方法和性能方面的研究进展, 深入分析和讨论了离子掺杂、碳表面改性和纳米化等改性方法对尖晶石型Li4Ti5O12综合电化学性能的改善效果, 并展望了尖晶石型Li4Ti5O12作为锂离子电池负极材料未来的发展方向。

中图分类号:

谭毅, 薛冰. 锂离子电池负极材料钛酸锂的研究进展[J]. 无机材料学报, 2018, 33(5): 475-482.

TAN Yi, XUE Bing. Research Progress on Lithium Titanate as Anode Material in Lithium-ion Battery[J]. Journal of Inorganic Materials, 2018, 33(5): 475-482.

| Ion | Radius /nm | Doping content molar ratio | Size/nm | Initial discharge capacity/(mAh.g-1) | Cycle performance/ (mAh.g-1) | Method | Ref. |

|---|---|---|---|---|---|---|---|

| Cation doping in the Li sites(radius 0.076 nm) | |||||||

| Mg2+ | 0.0720 | 0.20 | 100-200 | 190.0(1C)a | 179.0(1C, 100)b; 150.0(5C, 100) | Solid state reaction | [30] |

| Ca2+ | 0.1000 | 0.10 | 1000-2000 | 169.7(0.5C) | 162.4(1C, 100); 148.8(5C, 100) | Solid state reaction | [31] |

| Sc3+ | 0.0745 | 0.05 | 200 | 174.0(1C); 94.0(40C) | 94.0(40C, 50) | Sol-Gel | [32] |

| Cu2+ | 0.0730 | 0.05 | 200-600 | 158.0(0.1C) | 143.8(0.1C, 150) | Sol-Gel | [33] |

| La3+ | 0.1032 | 0.06 | 24.5 | 169.0(0.1C) | 153.4(1C, 10); 146.9(5C, 10) | Liquid method | [34] |

| Cation doping in the Ti sites (radiusTi3+0.067 nm, Ti4+0.0605 nm) | |||||||

| Al3+ | 0.0535 | 0.15 | 50-200 | 216.0(1C); 163.0(10C) | 180.0(5C, 50); 160.0(10C, 50) | Cellulose-assisted glycine-nitratecombustion | [35] |

| Zr4+ | 0.0720 | 0.03 | 200 | 165.0(5C); 152.0(10C) | 142.0(5C, 200); 127.0(10C, 200) | Liquid method | [36] |

| Ce4+ | 0.0870 | 0.10 | <1000 | 190.0(0.2C); 40.0(2C) | 140.0(2C, 100) | Solid state reaction | [37] |

| Ta5+ | 0.0640 | 0.05 | 500-1000 | 193.0(0.2C) | 132.0(5C, 100) | Solid state reaction | [38] |

| Anions doping in the O site (radius 0.14 nm) | |||||||

| Cl- | 0.181 | 0.2 | 3-8 μm | 148.7(0.5C) | 133.8(0.5C, 50) | Solid state reaction | [39] |

| 120.7(2C) | |||||||

| Br- | 0.196 | 0.3 | 1-2 μm | 174.0(0.2C) | 138.0(10C, 100); 104.0(210C,100) | Solid state reaction | [40] |

表1 代表性阴阳离子掺杂Li4Ti5O12的Li, Ti, O各位点对性能的影响

Table 1 Summary of representative LTO doped with various cations/anions in the Li, Ti and O sites

| Ion | Radius /nm | Doping content molar ratio | Size/nm | Initial discharge capacity/(mAh.g-1) | Cycle performance/ (mAh.g-1) | Method | Ref. |

|---|---|---|---|---|---|---|---|

| Cation doping in the Li sites(radius 0.076 nm) | |||||||

| Mg2+ | 0.0720 | 0.20 | 100-200 | 190.0(1C)a | 179.0(1C, 100)b; 150.0(5C, 100) | Solid state reaction | [30] |

| Ca2+ | 0.1000 | 0.10 | 1000-2000 | 169.7(0.5C) | 162.4(1C, 100); 148.8(5C, 100) | Solid state reaction | [31] |

| Sc3+ | 0.0745 | 0.05 | 200 | 174.0(1C); 94.0(40C) | 94.0(40C, 50) | Sol-Gel | [32] |

| Cu2+ | 0.0730 | 0.05 | 200-600 | 158.0(0.1C) | 143.8(0.1C, 150) | Sol-Gel | [33] |

| La3+ | 0.1032 | 0.06 | 24.5 | 169.0(0.1C) | 153.4(1C, 10); 146.9(5C, 10) | Liquid method | [34] |

| Cation doping in the Ti sites (radiusTi3+0.067 nm, Ti4+0.0605 nm) | |||||||

| Al3+ | 0.0535 | 0.15 | 50-200 | 216.0(1C); 163.0(10C) | 180.0(5C, 50); 160.0(10C, 50) | Cellulose-assisted glycine-nitratecombustion | [35] |

| Zr4+ | 0.0720 | 0.03 | 200 | 165.0(5C); 152.0(10C) | 142.0(5C, 200); 127.0(10C, 200) | Liquid method | [36] |

| Ce4+ | 0.0870 | 0.10 | <1000 | 190.0(0.2C); 40.0(2C) | 140.0(2C, 100) | Solid state reaction | [37] |

| Ta5+ | 0.0640 | 0.05 | 500-1000 | 193.0(0.2C) | 132.0(5C, 100) | Solid state reaction | [38] |

| Anions doping in the O site (radius 0.14 nm) | |||||||

| Cl- | 0.181 | 0.2 | 3-8 μm | 148.7(0.5C) | 133.8(0.5C, 50) | Solid state reaction | [39] |

| 120.7(2C) | |||||||

| Br- | 0.196 | 0.3 | 1-2 μm | 174.0(0.2C) | 138.0(10C, 100); 104.0(210C,100) | Solid state reaction | [40] |

| Ion | Radius/nm | Doping content molar ratio | Size/ nm | Initial discharge capacity/(mAh.g-1) | Cycle performance/ (mAh.g-1) | Method | Ref. |

|---|---|---|---|---|---|---|---|

| Zn2+ | 0.074 | 0.20 | 1000-2000 | (0-2.5 V) | 216.4(0.5C, 30) | Solid state reaction | [6] |

| 271.6(0.5C)a; 223.0(3C); | 198.0(3C, 100) | ||||||

| 186.0(5C, 200) | |||||||

| 206.0(5C) | |||||||

| Nb5+ | 0.064 | 0.05 | (0-2.5 V) | 231.0(0.12C, 100) | Sol-Gel | [46] | |

| 351.0(0.12C) | |||||||

| Ru4+ | 0.062 | 0.05 | 100-200 | (0.01-2.5 V) | 259.0(3C, 100); 131.0(60C, 100) | Reverse microemulsion method | [47] |

| 274.0(3C) | |||||||

| Bi+3+ | 0.103 | 0.10 | 500-1000 | (0.01-2.5 V) | 203.0(1C, 50) | Solid state reaction | [48] |

| 214.0(1C) |

表2 低电位下代表性阳离子掺杂Li4Ti5O12的Li, Ti, O各位点对性能的影响

Table 2 Summary of representative LTO doped with various cations in the Li, Ti and O sites at low potential

| Ion | Radius/nm | Doping content molar ratio | Size/ nm | Initial discharge capacity/(mAh.g-1) | Cycle performance/ (mAh.g-1) | Method | Ref. |

|---|---|---|---|---|---|---|---|

| Zn2+ | 0.074 | 0.20 | 1000-2000 | (0-2.5 V) | 216.4(0.5C, 30) | Solid state reaction | [6] |

| 271.6(0.5C)a; 223.0(3C); | 198.0(3C, 100) | ||||||

| 186.0(5C, 200) | |||||||

| 206.0(5C) | |||||||

| Nb5+ | 0.064 | 0.05 | (0-2.5 V) | 231.0(0.12C, 100) | Sol-Gel | [46] | |

| 351.0(0.12C) | |||||||

| Ru4+ | 0.062 | 0.05 | 100-200 | (0.01-2.5 V) | 259.0(3C, 100); 131.0(60C, 100) | Reverse microemulsion method | [47] |

| 274.0(3C) | |||||||

| Bi+3+ | 0.103 | 0.10 | 500-1000 | (0.01-2.5 V) | 203.0(1C, 50) | Solid state reaction | [48] |

| 214.0(1C) |

| Carbon source | Carbon content/wt% | Thickness/ nm | Initial discharge capacity/(mAh.g-1) | Cycle performance/ (mAh.g-1) | Method | Ref. |

|---|---|---|---|---|---|---|

| LPAN+CB | 3.64 | 3-5 | 166.2(10C) | 141.9(10C, 200) | Solid state reaction | [49] |

| PEDOT | 10.00 | 10 | 168.7(1C) | 167.9(1C, 100) | Hydrothermal reaction | [50] |

| Sucrose | 8.60 | 2-4 | 156.7(40C); 142.1(60C); 132.8(80C) | 114.2(40C, 200); 98.1(60C, 200) 82.7(80C, 200) | One-step liquid process | [51] |

| Citric acid | 1.32 | 2-3 | 165.7(1C); 161.7(5C); 153.9(10C); 147.9(20C) | 144.9(20C, 50) | Sol-Gel | [52] |

| Glucose | 8.96 | 8 | 170.9(0.5C) | 155.6(1C, 100) | Hydrothermal-solid state reaction | [53] |

表3 不同碳源、含量、厚度对碳包覆Li4Ti5O12的性能影响

Table 3 The effects of the carbon source, carbon content, thickness, and graphitization on the electrochemical performance of the carbon coated Li4Ti5O12

| Carbon source | Carbon content/wt% | Thickness/ nm | Initial discharge capacity/(mAh.g-1) | Cycle performance/ (mAh.g-1) | Method | Ref. |

|---|---|---|---|---|---|---|

| LPAN+CB | 3.64 | 3-5 | 166.2(10C) | 141.9(10C, 200) | Solid state reaction | [49] |

| PEDOT | 10.00 | 10 | 168.7(1C) | 167.9(1C, 100) | Hydrothermal reaction | [50] |

| Sucrose | 8.60 | 2-4 | 156.7(40C); 142.1(60C); 132.8(80C) | 114.2(40C, 200); 98.1(60C, 200) 82.7(80C, 200) | One-step liquid process | [51] |

| Citric acid | 1.32 | 2-3 | 165.7(1C); 161.7(5C); 153.9(10C); 147.9(20C) | 144.9(20C, 50) | Sol-Gel | [52] |

| Glucose | 8.96 | 8 | 170.9(0.5C) | 155.6(1C, 100) | Hydrothermal-solid state reaction | [53] |

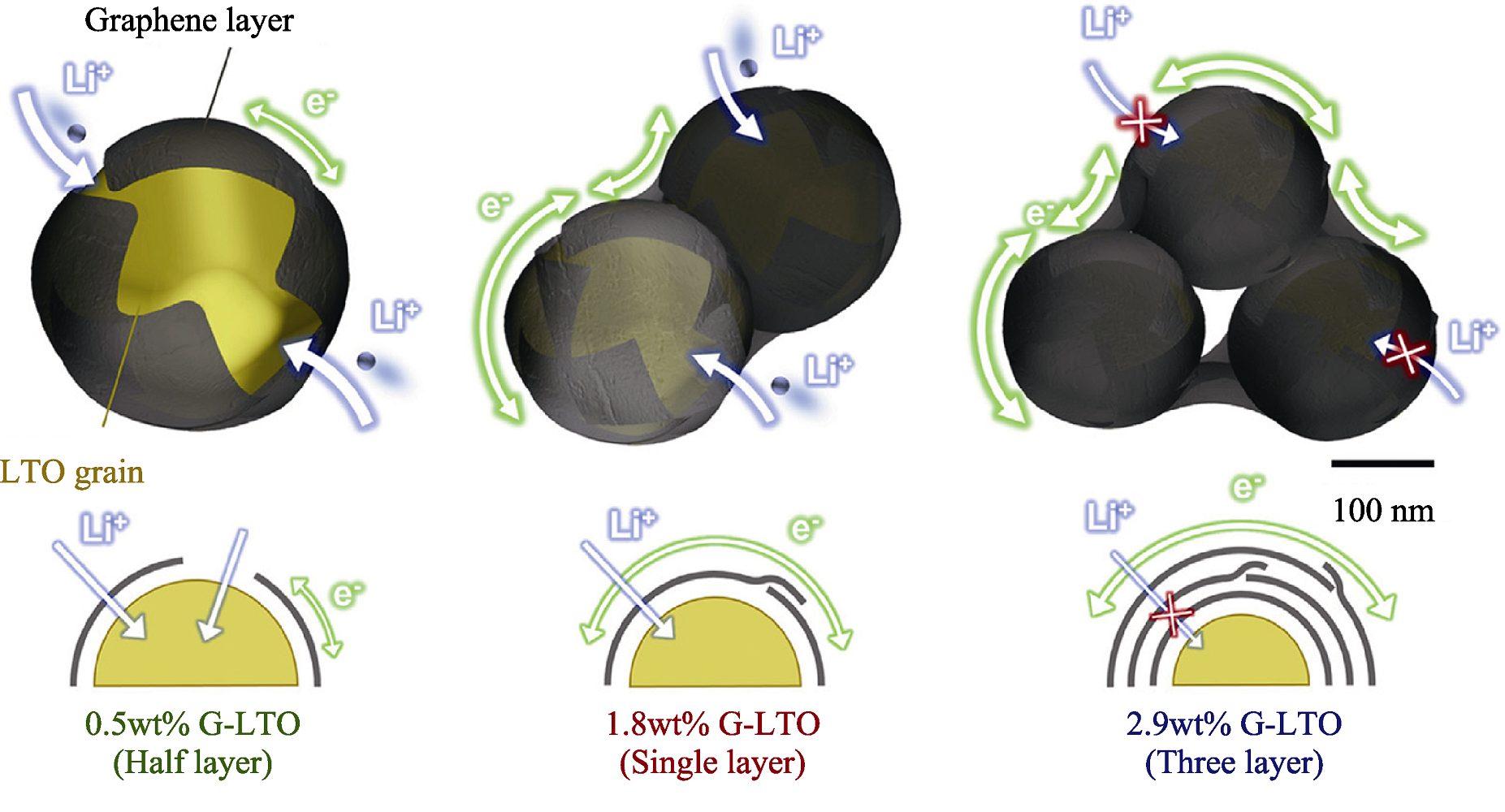

图5 Li4Ti5O12表面石墨烯层数的电子传导和锂离子传输过程示意图[57]

Fig. 5 Schematic illustration representing the electron conduction Li+ and Li+ transport according to the number of graphene layers on the LTO surface[57]

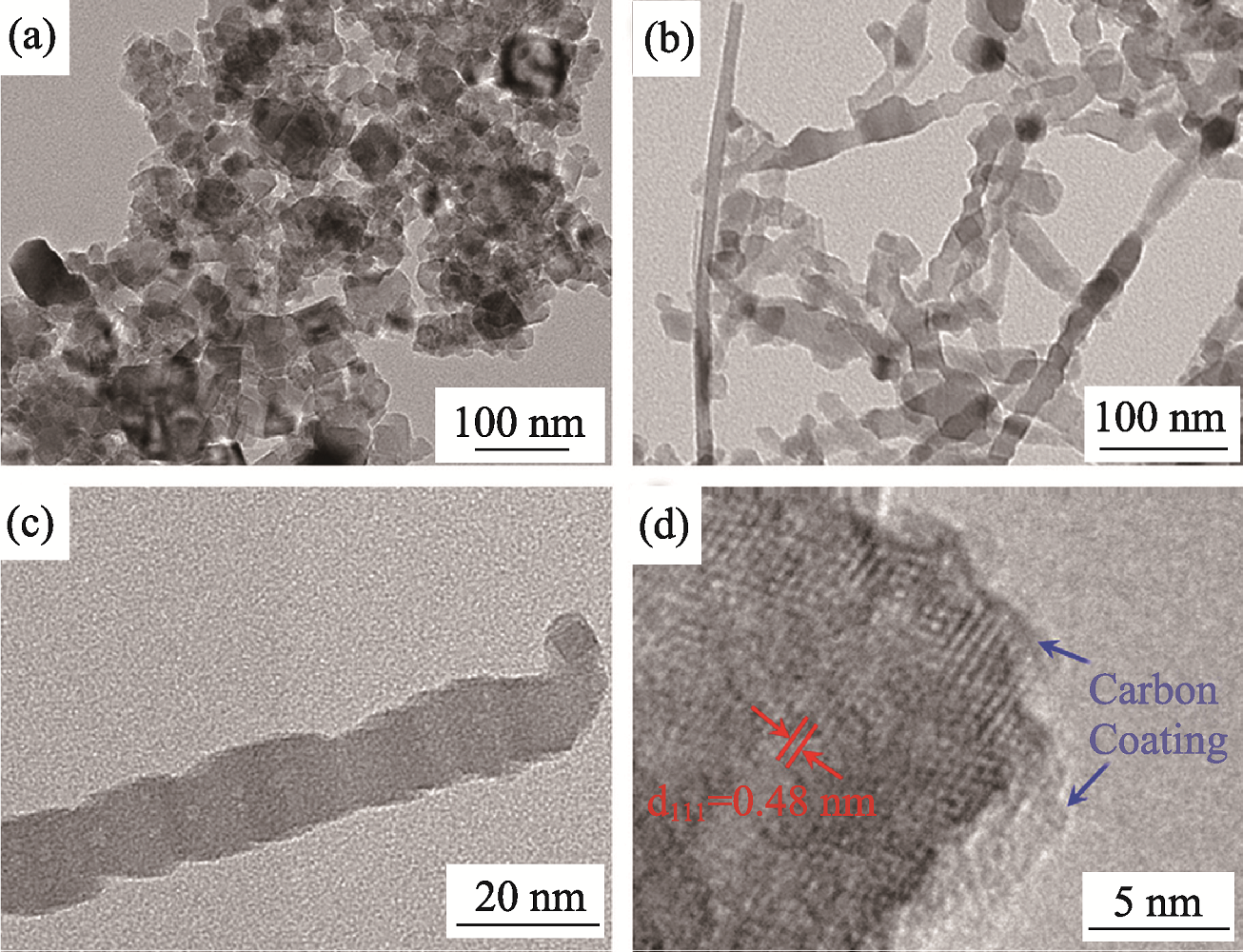

图6 Li4Ti5O12的TEM照片(a), Li4Ti5O12/C纳米棒的TEM照片(b, c)和HRTEM照片(d)[59]

Fig. 6 (a) TEM image of the Li4Ti5O12 nanoparticles and (b, c) TEM and (d) HRTEM images of Li4Ti5O12/C nanorods[59]

| [1] | LI Z Y, DING F X, ZHAO Y G,et al. Synthesis and electrochemical performance of Li4Ti5O12 submicrospheres coated with TiN as anode materials for lithium-ion battery. Ceram. Int., 2016, 42(14): 15464-15470. |

| [2] | HUI Y N, CAO L Y, XU Z W,et al. In situ synthesis of core-shell Li4Ti5O12@polyaniline composites with enhanced rate performance for lithium-ion battery anodes. J. Mater. Sci. Techno., 2016, 33(3): 231-238. |

| [3] | CHEN S, XIN Y L, ZHOU Y Y,et al. Self-supported Li4Ti5O12 nanosheet arrays for lithium ion batteries with excellent rate capability and ultralong cycle life. Energy Environ. Sci., 2014, 7(6): 1924-1930. |

| [4] | YI T F, YANG S Y, XIE Y.Recent advances of Li4Ti5O12 as a promising next generation anode material for high power lithium- ion batteries.J. Mater. Chem. A, 2015, 3(11): 5750-5777. |

| [5] | BORGHOLS W J H, WAGEMAKER M, LAFONT U,et al. Size effects in the Li4+xTi5O12 spinel. J. Am. Chem. Soc., 2009, 131(49): 17786-17792. |

| [6] | YI T F, LIU H P, ZHU Y R,et al. Improving the high rate performance of Li4Ti5O12 through divalent zinc substitution. J. Power Sources, 2012, 215: 258-265. |

| [7] | WIKENING M, IWANIAK W, HEINE J,et al. Microscopic Li self-diffusion parameters in the lithiated anode material Li4+xTi5O12(0 < or = x < or = 3) measured by 7Li solid state NMR. Phys. Chem. Chem. Phys., 2007, 9(47): 6199-6202. |

| [8] | YANG S, WANG Q F, LU M W, et al. Synthesis of graphitized carbon, nanodiamond and graphene supported Li4Ti5O12 and comparison of their electrochemical performance as anodes for lithium ion batteries. Appl. Surf. Sci., 2016, 389: 428-437. |

| [9] | ZHU G N, WANG Y G, XIA Y Y.Ti-based compounds as anode materials for Li-ion batteries.Energy Environ. Sci., 2012, 5(5): 6652-6667. |

| [10] | Yang L Y, LI H Z, LIU J,et al. Effects of TiO2 phase on the performance of Li4Ti5O12 anode for lithium-ion batteries. J. Alloys Compd., 2016, 689: 812-819. |

| [11] | MA J, WANG C, WROBLEWSKI S.Kinetic characteristics of mixed conductive electrodes for lithium ion batteries.J. Power Sources, 2007, 164(2): 849-856. |

| [12] | TAKAMI N, HOSHINA K, INAGAKI H.Lithium diffusion in Li4/3Ti5/3O4 particles during insertion and extraction.J. Electrochem. Soc., 2011, 158(6): A725-A730. |

| [13] | LIU W, ZHANG J, WANG Q,et al. The effects of Li2CO3 particle size on the properties of lithium titanate as anode material for lithium-ion batteries. Ionics, 2014, 20(11): 1553-1560. |

| [14] | CHEN C, SPEARS M, WONDRE F, et al. Crystal growth and superconductivity of LiTi2O4 and Li1+1/3Ti2-1/3O4.J. Cryst. Growth, 2003, 250(1/2): 139-145. |

| [15] | GUERFI A, SEVIGNY S, LAGACE M,et al. Nano-particle Li4Ti5O12 spinel as electrode for electrochemical generators. J. Power Sources, 2003, 119(121): 88-94. |

| [16] | MICHALSKA M, KRAJEWSKI M, ZIOLKOWSKA D,et al. Influence of milling time in solid-state synthesis on structure, morphology and electrochemical properties of Li4Ti5O12 of spinel structure. Powder Technol., 2014, 266(6): 372-377. |

| [17] | SENNA M, FAVIAN M, KAVAN L,et al. Electrochemical properties of spinel Li4Ti5O12 nanoparticles prepared via a low-temperature solid route. J. Solid State Electrochem., 2016, 20(10): 2673-2683. |

| [18] | HAN S W, JEONG J, YOON D H.Effects of high-energy milling on the solid-state synthesis of pure nano-sized Li4Ti5O12 for high power lithium battery applications.Appl. Phys. A, 2014, 114(3): 925-930. |

| [19] | WANG Y Q, ZHAO J, QU J,et al. Investigation into the surface chemistry of Li4Ti5O12 nanoparticles for lithium ion batteries. Appl. Mater. Interfaces, 2016, 8(39): 26008-26012. |

| [20] | QIU C X, YUAN Z Z, LIU L,et al. Sol-Gel preparation and electrochemical properties of La-doped Li4Ti5O12 anode material for lithium-ion battery. J. Solid State Electrochem., 2013, 17(3): 841-847. |

| [21] | MOHAMMADI M R, FRAY D J.Low temperature nanostructured lithium titanates: controlling the phase composition, crystal structure and surface area.J. Sol-Gel Sci. Techn., 2010, 55(1): 19-35. |

| [22] | LIU G Y, ZHANG R X, BAO K Y,et al. Synthesis of nano- Li4Ti5O12 anode material for lithium ion batteries by a biphasic interfacial reaction route. Ceram. Int., 2016, 42(9): 11468-11472. |

| [23] | ZHU K X, GAO H Y, HU G X,et al. Scalable synthesis of hierarchical hollow Li4Ti5O12 microspheres assembled by zigzag-like nanosheets for high rate lithium-ion batteries. J. Power Sources, 2017, 340: 263-272. |

| [24] | GUO Q J, LI S Y, WANG H,et al. Molten salt synthesis of nano-sized Li4Ti5O12 doped with Fe2O3 for use as anode material in the lithium ion battery. RSC Adv., 2014. 4(104): 60327-60333. |

| [25] | ZHAO Y G, LI J L, LI Z Y,et al. Pr-modified Li4Ti5O12 nanofibers as an anode material for lithium-ion batteries with outstanding cycling performance and rate performance. Ionics, 2017. 23(3): 597-605. |

| [26] | YANG L H, DONG C D, GUO J.Hybrid microwave synthesis and characterization of the compounds in the Li-Ti-O system.J. Power Sources, 2008, 175(1): 575-580. |

| [27] | LI J, JIN Y L, ZHANG X G,et al. Microwave solid-state synthesis of spinel Li4Ti5O12 nanocrystallites as anode material for lithium- ion batteries. Solid State Ionics, 2007, 178(29/30): 1590-1594. |

| [28] | JIA X L, KAN Y F, ZHU X,et al. Building flexible Li4Ti5O12/CNT lithium-ion battery anodes with superior rate performance and ultralong cycling stability. Nano Energy, 2014, 10: 344-352. |

| [29] | WOLFENSTINE J, ALLEN J L.Electrical conductivity and charge compensation in Ta doped Li4Ti5O12.J. Power Sources, 2008, 180(1): 582-585. |

| [30] | LI F Y, ZHENG M, LI J,et al. Preparation and electrochemical performance of Mg-doped Li4Ti5O12 nanoparticles as anode materials for lithium-ion batteries. Int. J. Electrochem. Sci., 2015, 10(12): 10445-10453. |

| [31] | ZHANG Q Y, ZHANG C L, LI B,et al. Preparation and electrochemical properties of Ca-doped Li4Ti5O12 as anode materials in lithium-ion battery materials for flexible Li-ion batteries. Electrochim. Acta, 2013, 98(16): 146-152. |

| [32] | ZHANG Y Y, ZHANG C M, LIN Y,et al. Influence of Sc3+ doping in B-site on electrochemical performance of Li4Ti5O12 anode materials for lithium-ion battery. J. Power Sources, 2014, 250(3): 50-57. |

| [33] | GE Y Q, JIANG H, FU K,et al. Copper-doped Li4Ti5O12/carbon nanofiber composites as anode for high-performance sodium-ion batteries. J. Power Sources, 2014, 272: 860-865. |

| [34] | BAI Y J, GONG C, QI Y X,et al. Excellent long-term cycling stability of La-doped Li4Ti5O12 anode material at high current rates. J. Mater. Chem., 2012, 22(36): 19054-19060. |

| [35] | CAI R, JIANG S M, YU X,et al. A novel method to enhance rate performance of an Al-doped Li4Ti5O12 electrode by post-synthesis treatment in liquid formaldehyde at room temperature. J. Mater. Chem., 2012, 22(16): 8013-8021. |

| [36] | CHEN Y J, MU D B, HANG R,et al. The Improvement of Discharge Capacity of Zr-doped Lithium Titanate for Lithium Ion Batteries. Matec Web Conf., 2016, 67: 06028. |

| [37] | ZHOU T P, FENG X Y, GUO X,et al. Solid-state synthesis and electrochemical performance of Ce-doped Li4Ti5O12 anode materials for lithium-ion batteries. Electrochim. Acta, 2015, 174: 369-375. |

| [38] | GUO M, WANG S Q, DING L X,et al. Tantalum-doped lithium titanate with enhanced performance for lithium-ion batteries. J. Power Sources, 2015, 283(25): 372-380. |

| [39] | HUANG Y D, QI Y L, JIA D Z,et al. Synthesis and electrochemical properties of spinel Li4Ti5O12-xClx anode materials for lithium- ion batteries. J. Solid State Electrochem., 2012, 16(5): 2011-2016. |

| [40] | WANG J Q, YANG Z Z, LI W H,et al. Nitridation Br-doped Li4Ti5O12 anode for high rate lithium ion batteries. J. Power Sources, 2014, 266(1): 323-331. |

| [41] | DING K Q, ZHAO J, SUN Y Z,et al. Using potassium ferricyanide as a dopant to prepare K and Fe co-doped Li4Ti5O12. Ceram. Int., 2016, 42(16): 19187-19194. |

| [42] | BAI X, LI W, WEI A J,et al. Preparation and electrochemical properties of Mg2+ and F- co-doped Li4Ti5O12 anode material for use in the lithium-ion batteries materials for flexible Li-ion batteries. Electrochim. Acta, 2016, 222: 1045-1055. |

| [43] | XU P, HUANG X B, REN Y R,et al. Na+ and Zr4+ co-doped Li4Ti5O12 as anode materials with superior electrochemical performance for lithium ion batteries. RSC Adv., 2016, 6(93): 90455-90461. |

| [44] | LONG W M, WANG X Y, YANG S Y,et al. Electrochemical properties of Li4Ti5-2xNixMnxO12 compounds synthesized by Sol-Gel process. Mater. Chem. Phys., 2011, 131(1): 431-435. |

| [45] | SHKROB I A, ZHU Y, MARIN T W,et al. Reduction of carbonate electrolytes and the formation of solid-electrolyte interface (SEI) in lithium-ion batteries. 1. spectroscopic observations of radical intermediates generated in one-electron reduction of carbonates. J. Phys. Chem. C, 2013, 117(38): 19255-19269. |

| [46] | TIAN B B, XIANG H F, ZHANG L,et al. Effect of Nb-doping on electrochemical stability of Li4Ti5O12 discharged to 0 V. J. Solid State Electrochem., 2012, 16(1): 205-211. |

| [47] | WANG W, WANG H L, WANG S B,et al. Ru-doped Li4Ti5O12 anode materials for high rate lithium-ion batteries. J. Power Sources, 2013, 228(11): 244-249. |

| [48] | SUBBURAJ T, PRASANNA K, KIM K J,et al. Structural and electrochemical evaluation of bismuth doped lithium titanium oxides for lithium ion batteries. J. Power Sources, 2015, 280: 23-29. |

| [49] | HUANG P X, TANG S H, PENG H,et al. In-situ synthesis of graphitized-carbon coated Li4Ti5O12/C anode for high-rate lithium ion batteries. Mater. Sci. Forum, 2015, 814: 358-364. |

| [50] | WANG X Y, SHEN L F, LI H S,et al. PEDOT coated Li4Ti5O12 nanorods: soft chemistry approach synthesis and their lithium storage properties. Electrochim. Acta, 2014, 129(16): 283-289. |

| [51] | MU D B, CHEN Y J, WU B R,et al. Nano-sized Li4Ti5O12/C anode material with ultrafast charge/discharge capability for lithium ion batteries. J. Alloys Compd., 2016, 671: 157-163. |

| [52] | KUO Y C, LIN J Y.One-pot Sol-Gel synthesis of Li4Ti5O12/C anode materials for high-performance Li-ion batteries.Electrochim. Acta, 2014, 142: 43-50. |

| [53] | GAO L, LIU R J, HU H,et al. Carbon-decorated Li4Ti5O12/rutile TiO2 mesoporous microspheres with nanostructures as high-performance anode materials in lithium-ion batteries. Nanotechnology, 2014, 25(17): 175402-175410. |

| [54] | XUE R, YAN J W, JIANG L,et al. Fabrication of lithium titanate/ graphene composites with high rate capability as electrode materials for hybrid electrochemical super capacitors. Mater. Chem. Phys., 2015, 160: 375-382. |

| [55] | LI R Y, CHEN T Y, SUN B B,et al. Novel lithium titanate-graphene hybrid containing two graphene conductive frameworks for lithium- ion battery with excellent electrochemical performance. Mater. Res. Bull., 2015, 70: 965-975. |

| [56] | YANG X J, ZHENG A B, WANG X L,et al. Graphene nanosheet and carbon layer co-decorated Li4Ti5O12 as high performance anode material for rechargeable lithium-ion batteries. Ceram. Int., 2017, 43(3): 3252-3258. |

| [57] | KIM J, LEE K E, KIM K H,et al. Single-layer graphene-wrapped Li4Ti5O12 anode with superior lithium storage capability. Carbon, 2017, 114: 275-283. |

| [58] | KIM K T, YU C Y, YOON C S,et al. Carbon-coated Li4Ti5O12 nanowires showing high rate capability as an anode material for rechargeable sodium batteries. Nano Energy, 2015, 12: 725-734. |

| [59] | LUO H J, SHEN L F, RUI K,et al. Carbon coated Li4Ti5O12 nanorods as superior anode material for high rate lithium ion batteries. J. Alloys Compd., 2013, 572: 37-42. |

| [60] | LIU J, SONG K, AKEN P A,et al. Self-supported Li4Ti5O12-C nanotube arrays as high-rate and long-life anode materials for flexible Li-ion batteries. Nano Lett., 2014, 14(5): 2597-2603. |

| [1] | 谭博文, 耿双龙, 张锴, 郑百林. 硅电极组分梯度设计抑制力-化学耦合劣化[J]. 无机材料学报, 2025, 40(7): 772-780. |

| [2] | 刘鹏东, 王桢, 刘永锋, 温广武. 硅泥在锂离子电池中的应用研究进展[J]. 无机材料学报, 2024, 39(9): 992-1004. |

| [3] | 程节, 周月, 罗薪涛, 高美婷, 骆思妃, 蔡丹敏, 吴雪垠, 朱立才, 袁中直. 蛋黄壳结构FeF3·0.33H2O@N掺杂碳纳米笼正极材料的构筑及其电化学性能[J]. 无机材料学报, 2024, 39(3): 299-305. |

| [4] | 胡梦菲, 黄丽萍, 李贺, 张国军, 吴厚政. 锂/钠离子电池硬碳负极材料的研究进展[J]. 无机材料学报, 2024, 39(1): 32-44. |

| [5] | 苏楠, 邱介山, 王治宇. 高容量氟掺杂碳包覆纳米硅负极材料: 气相氟化法制备及其储锂性能[J]. 无机材料学报, 2023, 38(8): 947-953. |

| [6] | 杨卓, 卢勇, 赵庆, 陈军. X射线衍射Rietveld精修及其在锂离子电池正极材料中的应用[J]. 无机材料学报, 2023, 38(6): 589-605. |

| [7] | 宿拿拿, 韩静茹, 郭印毫, 王晨宇, 石文华, 吴亮, 胡执一, 刘婧, 李昱, 苏宝连. 基于ZIF-8的三维网络硅碳复合材料锂离子电池性能研究[J]. 无机材料学报, 2022, 37(9): 1016-1022. |

| [8] | 王洋, 范广新, 刘培, 尹金佩, 刘宝忠, 朱林剑, 罗成果. 钾离子掺杂提高锂离子电池正极锰酸锂性能的微观机制[J]. 无机材料学报, 2022, 37(9): 1023-1029. |

| [9] | 朱河圳, 王选朋, 韩康, 杨晨, 万睿哲, 吴黎明, 麦立强. 超高镍LiNi0.91Co0.06Al0.03O2@Ca3(PO4)2正极材料的储锂稳定性的提升机制[J]. 无机材料学报, 2022, 37(9): 1030-1036. |

| [10] | 冯锟, 朱勇, 张凯强, 陈长, 刘宇, 高彦峰. 勃姆石纳米片增强锂离子电池隔膜性能研究[J]. 无机材料学报, 2022, 37(9): 1009-1015. |

| [11] | 陈莹, 栾伟玲, 陈浩峰, 朱轩辰. 基于应力场的锂离子电池正极多尺度失效研究[J]. 无机材料学报, 2022, 37(8): 918-924. |

| [12] | 江依义, 沈旻, 宋半夏, 李南, 丁祥欢, 郭乐毅, 马国强. 双功能电解液添加剂对锂离子电池高温高电压性能的影响[J]. 无机材料学报, 2022, 37(7): 710-716. |

| [13] | 苏东良, 崔锦, 翟朋博, 郭向欣. 石榴石型Li6.4La3Zr1.4Ta0.6O12对Si/C负极表面固体电解质中间相的调控机制研究[J]. 无机材料学报, 2022, 37(7): 802-808. |

| [14] | 肖美霞, 李苗苗, 宋二红, 宋海洋, 李钊, 毕佳颖. 表面端基卤化Ti3C2 MXene应用于锂离子电池高容量电极材料的研究[J]. 无机材料学报, 2022, 37(6): 660-668. |

| [15] | 王禹桐, 张非凡, 许乃才, 王春霞, 崔立山, 黄国勇. 水系锂离子电池负极材料LiTi2(PO4)3的研究进展[J]. 无机材料学报, 2022, 37(5): 481-492. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||