无机材料学报 ›› 2025, Vol. 40 ›› Issue (2): 205-214.DOI: 10.15541/jim20240269 CSTR: 32189.14.10.15541/jim20240269

所属专题: 【结构材料】陶瓷基复合材料(202506)

收稿日期:2024-06-03

修回日期:2024-09-03

出版日期:2025-02-20

网络出版日期:2024-09-23

通讯作者:

栾新刚, 教授. E-mail: xgluan@nwpu.edu.cn;作者简介:栾新刚(1976-), 男, 博士. E-mail: xgluan@nwpu.edu.cn

LUAN Xingang1( ), HE Dianwei1, TU Jianyong2(

), HE Dianwei1, TU Jianyong2( ), CHENG Laifei1

), CHENG Laifei1

Received:2024-06-03

Revised:2024-09-03

Published:2025-02-20

Online:2024-09-23

Contact:

LUAN Xingang, professor. E-mail: xgluan@nwpu.edu.cn;Supported by:摘要:

连续碳纤维增强碳化硅(C/SiC)复合材料用作热防护结构材料时, 可能遭受低速冲击损伤。然而, 目前对于C/SiC复合材料面内冲击损伤和多次冲击损伤的研究尚不充分。本研究通过落锤冲击试验, 测试了C/SiC条状试样的面内冲击破坏行为, 并与C/SiC复合板的落锤冲击试验进行了比较。结果表明, C/SiC条状试样的面内冲击行为与C/SiC复合板相似, 冲击载荷随位移的变化可分为三个阶段: 近似线性阶段、载荷骤降阶段、冲击能量超过峰值后试样位移发生反弹阶段。对二维(2D)平纹C/SiC复合材料和三维(3D)针刺C/SiC复合材料在不同冲击能量和时间下的单次和多次冲击破坏行为进行了研究。借助计算机断层扫描(CT)技术研究了C/SiC复合材料的裂纹扩展。对于2D平纹C/SiC复合材料, 冲击过程中载荷难以在预制体的层间传播, 导致分层和90°纤维脆性断裂。随着冲击能量增大, 垂直于冲击方向的裂纹长度增加, 0°纤维断裂加剧, 纤维损失面积增大。对于3D针刺C/SiC复合材料, 冲击过程中载荷通过针刺纤维的连接在层间传播, 纤维依然起到良好的支撑作用, 出现纤维拉断和脱黏现象, 其抗冲击性能优于2D平纹C/SiC复合材料。对于受到两次1.5 J冲击的3D针刺C/SiC复合材料, 第二次冲击的能量吸收率明显降低, 冲击位移减小, 两次1.5 J冲击的总能量吸收效率低于单次3.0 J冲击。

中图分类号:

栾新刚, 何典蔚, 涂建勇, 成来飞. 2D平纹和3D针刺C/SiC复合材料的低速冲击破坏行为和失效机理[J]. 无机材料学报, 2025, 40(2): 205-214.

LUAN Xingang, HE Dianwei, TU Jianyong, CHENG Laifei. 2D Plain and 3D Needle-punched C/SiC Composites: Low-velocity Impact Damage Behavior and Failure Mechanism[J]. Journal of Inorganic Materials, 2025, 40(2): 205-214.

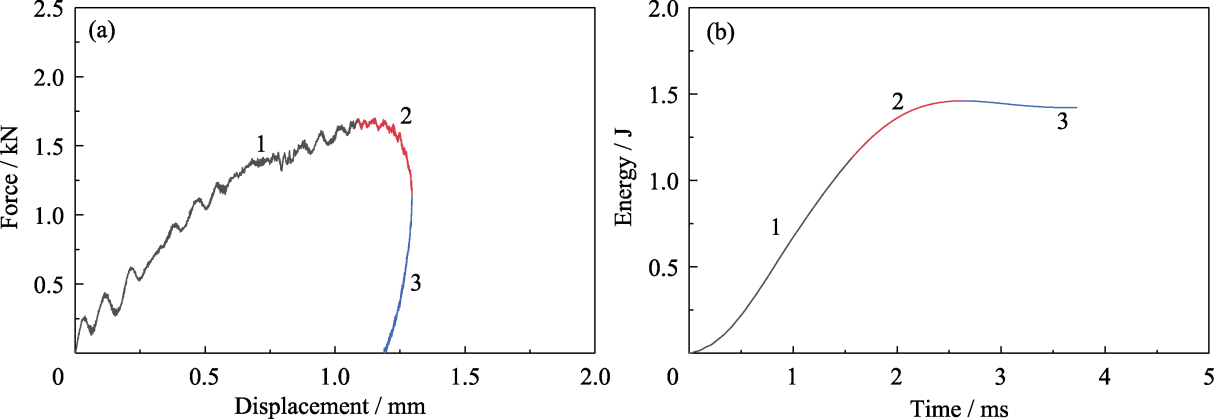

Fig. 2 Impact response of a 3D sample subjected to 1.5 J impact (a) Displacement-load curve; (b) Energy-time curve. Colorful figures are available on website

| Sample | Impact energy/J | Er/% | Etr/% | Δh/mm | Case of sample fracture |

|---|---|---|---|---|---|

| 2D | 1.0 | 96.93 | 1.123 | Broken | |

| 1.5 | 96.01 | 1.379 | Broken | ||

| 2.0 | 89.08 | 2.458 | Broken | ||

| 3D | 1.5 | 96.98 | 1.155 | Unbroken | |

| 1.5(1)* | 96.98 | 88.11 | 1.155 | Unbroken | |

| 1.5(2)* | 80.55 | 0.724 | Broken | ||

| 3.0 | 87.15 | 1.997 | Unbroken | ||

| 3.0 | 91.54 | 1.873 | Broken |

Table 1 Energy absorption of sample

| Sample | Impact energy/J | Er/% | Etr/% | Δh/mm | Case of sample fracture |

|---|---|---|---|---|---|

| 2D | 1.0 | 96.93 | 1.123 | Broken | |

| 1.5 | 96.01 | 1.379 | Broken | ||

| 2.0 | 89.08 | 2.458 | Broken | ||

| 3D | 1.5 | 96.98 | 1.155 | Unbroken | |

| 1.5(1)* | 96.98 | 88.11 | 1.155 | Unbroken | |

| 1.5(2)* | 80.55 | 0.724 | Broken | ||

| 3.0 | 87.15 | 1.997 | Unbroken | ||

| 3.0 | 91.54 | 1.873 | Broken |

Fig. 3 Macroscopic morphology of samples From left to right, 2D-1.0J, 2D-1.5J, 2D-2.0J, 3D-1.5J, 3D-2×1.5J (broken), 3D-2×1.5J (unbroken), 3D-3.0J (broken), and 3D-3.0J (unbroken)

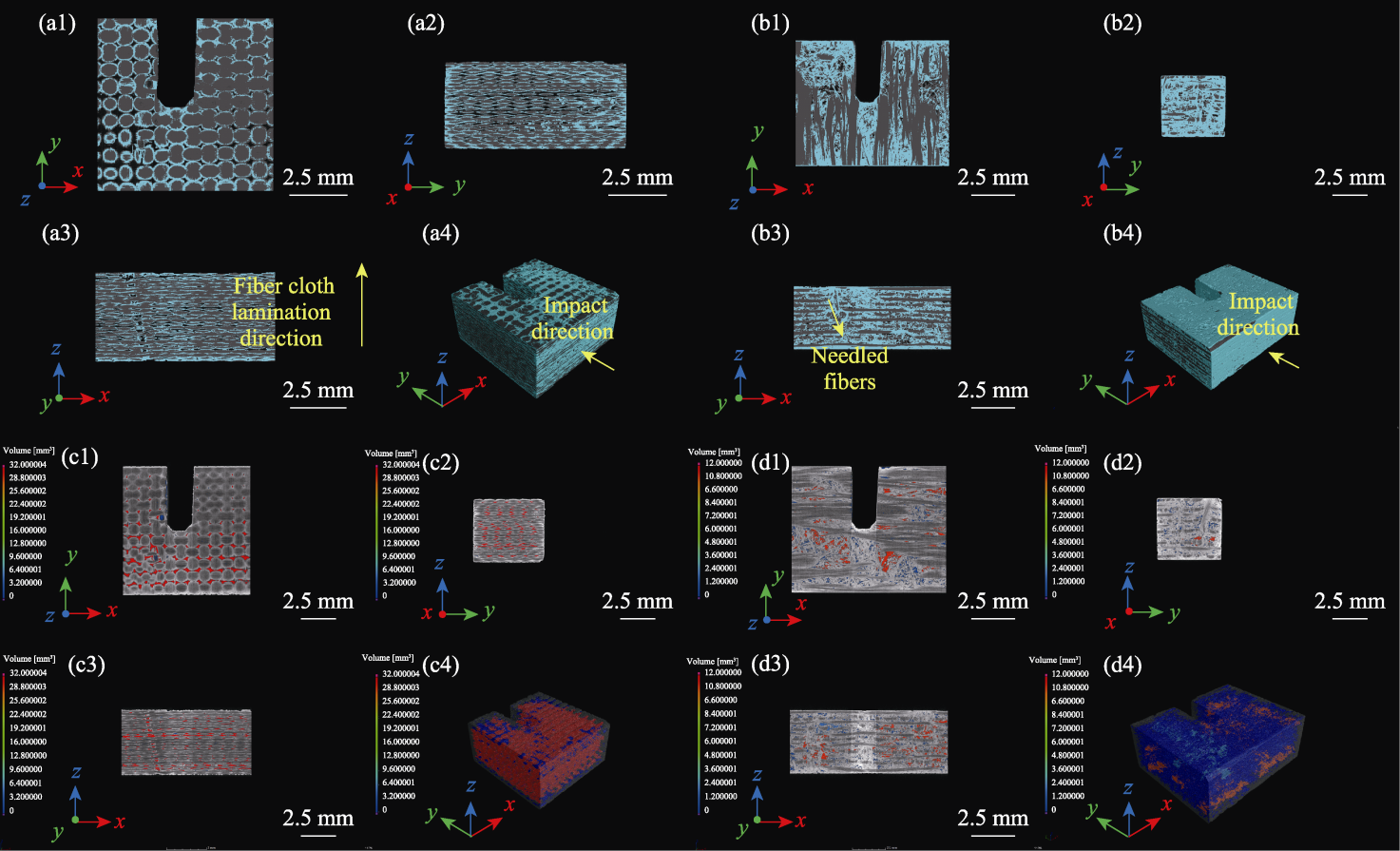

Fig. 4 Phase and pore analyses of samples using CT technique before impact (Grey for C-fiber bundles, light blue for SiC matrix, red for large pores, dark blue for small pores) Phase (a) and pore (c) analyses of the 2D C/SiC composite: (a1, c1) XY plane, (a2, c2) YZ plane, (a3, c3) XZ plane, and (a4, c4) stereogram; Phase (b) and pore (d) analyses of the 3D C/SiC composite: (b1, d1) XY plane, (b2, d2) YZ plane, (b3, d3) XZ plane, and (b4, d4) stereogram. Colorful figures are available on website

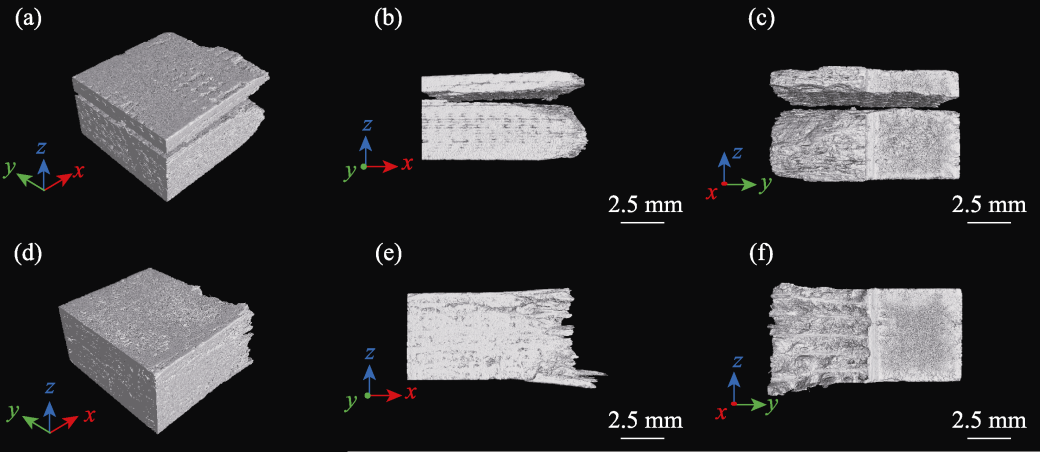

Fig. 6 CT photographs of the appearance of fractured C/SiC samples after impact 2 D C/SiC composite: (a) stereoscopic view, (b) YZ plane, and (c) XZ plane;3D C/SiC composite: (d) stereoscopic view, (e) YZ plane, and (f) XZ plane

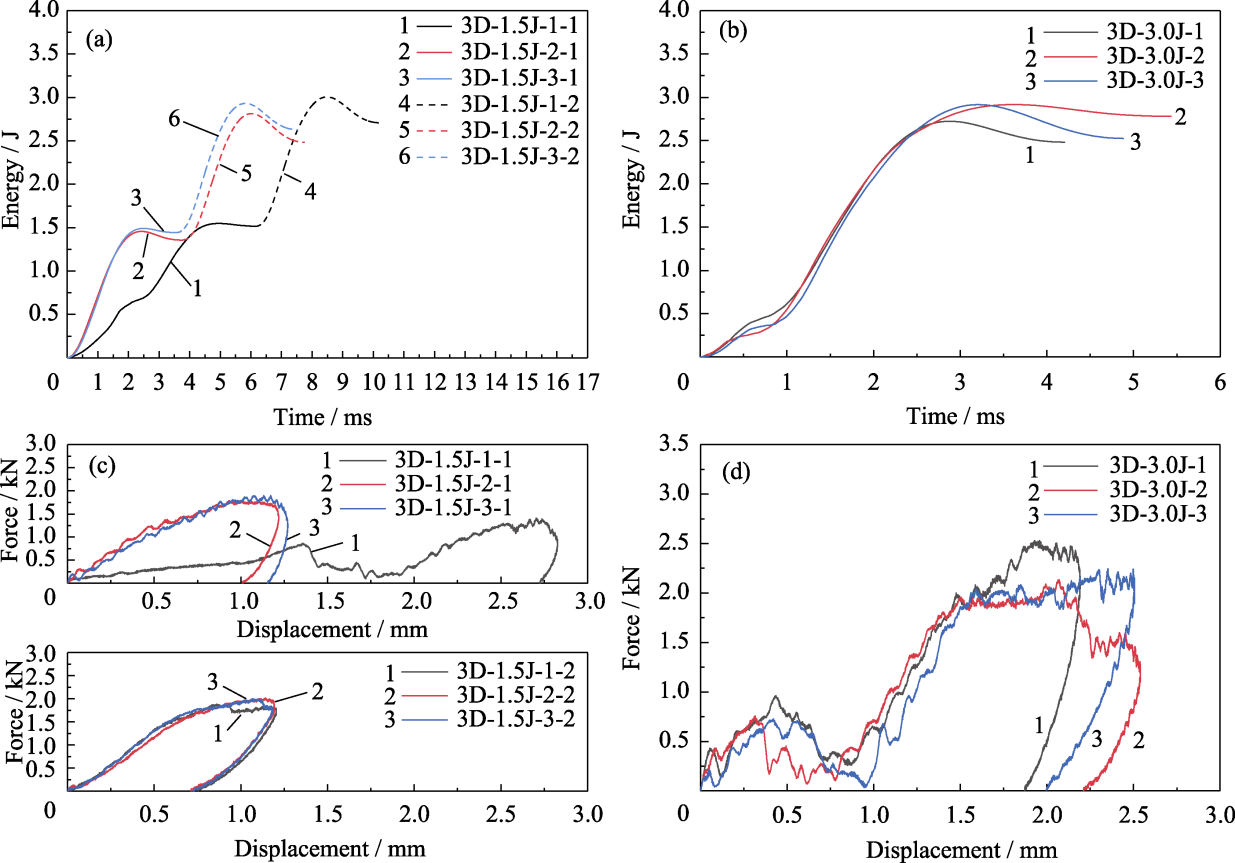

Fig. 8 Energy-time curves and displacement-load curves of 3D C/SiC composite with different impact energies Energy-time: (a) 2×1.5 J and (b) 3.0 J; Displacement-load: (c) 2×1.5 J and (d) 3.0 J

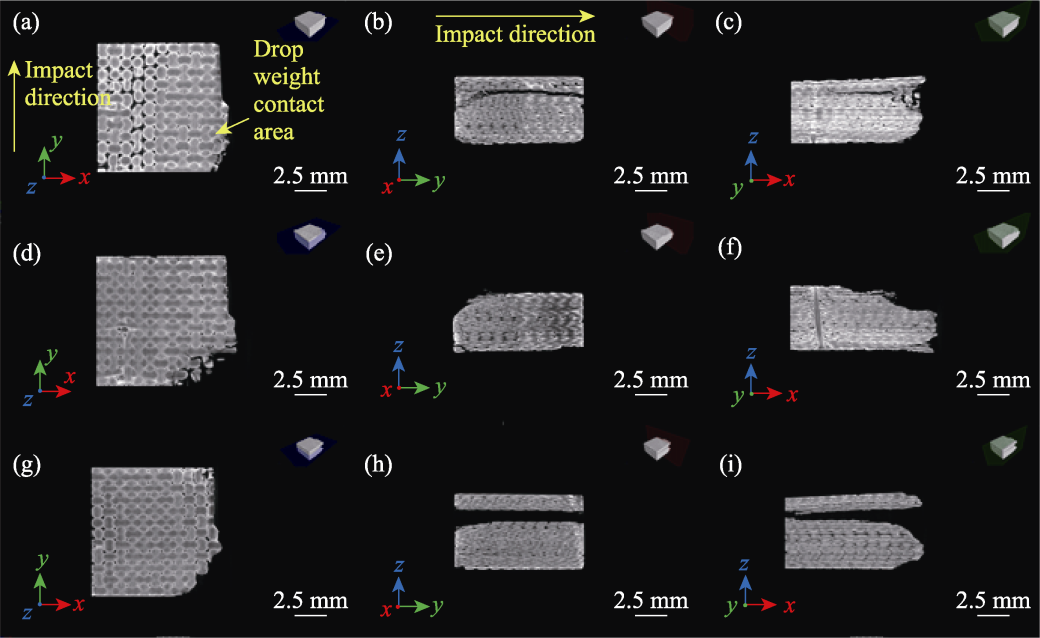

Fig. 9 CT scan results of 3D C/SiC composite after impact XY plane: (a) 1.5 J, (d) 3.0 J, and (g) 2×1.5 J; YZ plane: (b) 1.5 J, (e) 3.0 J, and (h) 2×1.5 J; XZ plane: (c) 1.5 J, (f) 3.0 J, and (i) 2×1.5 J

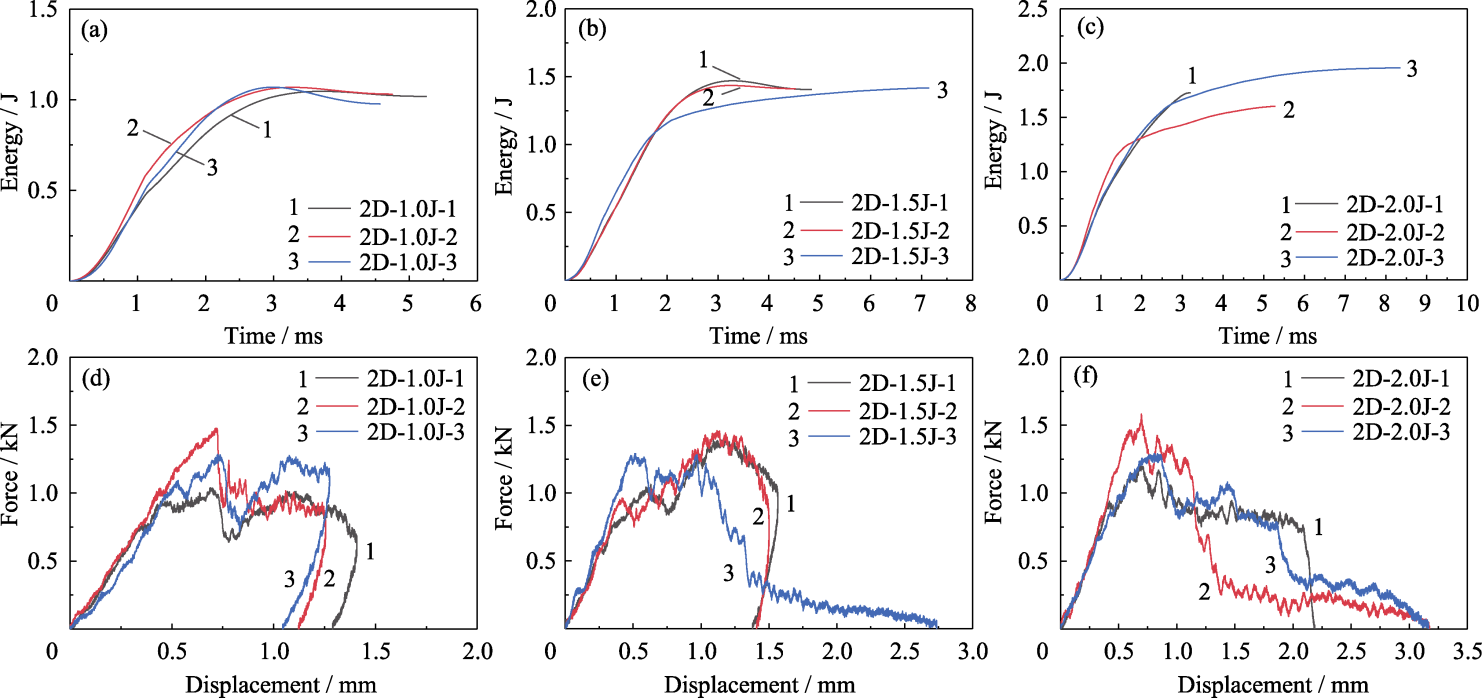

Fig. 10 Energy-time curves (a-c) and displacement-load (d-f) curves of 2D C/SiC composite with different impact energies of 1.0 J (a, d), 1.5 J (b, e), and 2.0 J (c, f)

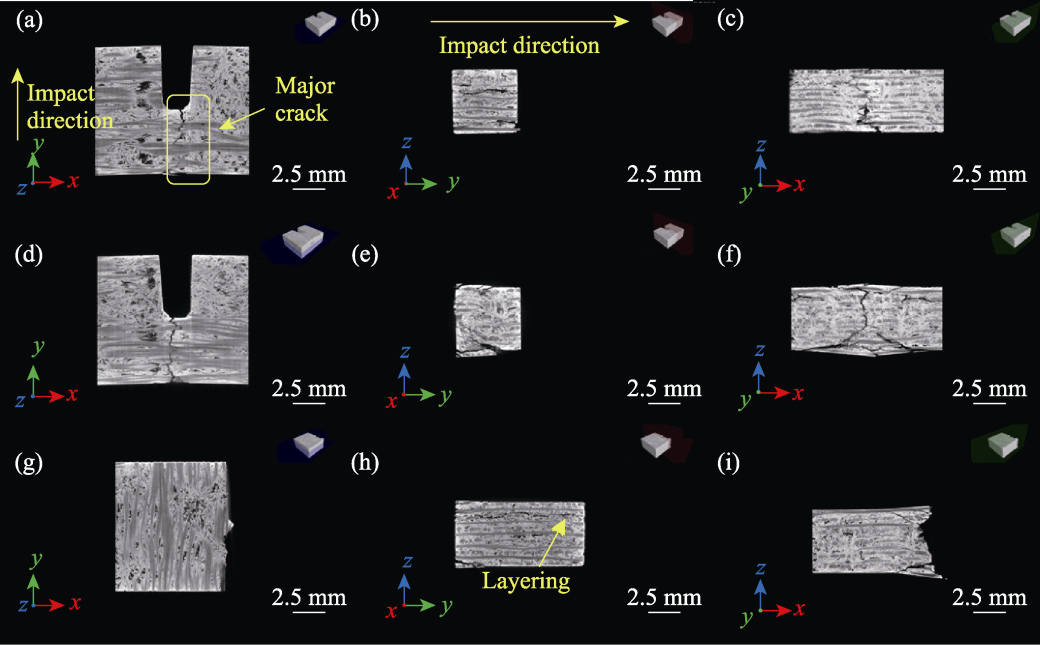

Fig. 11 CT scan results of 2D C/SiC composite after impact XY plane: (a) 1.0, (d) 1.5, and (g) 2.0 J; YZ plane: (b) 1.0, (e) 1.5, and (h) 2.0 J; XZ plane: (c) 1.0, (f) 1.5, and (i) 2.0 J

| Sample | Number | Impact energy/J | Er/% | Etr/% | Δh/mm | Case of sample fracture |

|---|---|---|---|---|---|---|

| 2D | 1 | 1.0 | 97.69 | 1.289 | Broken | |

| 2 | 1.0 | 96.93 | 1.123 | Broken | ||

| 3 | 1.0 | 92.13 | 1.045 | Broken | ||

| 1 | 1.5 | 96.01 | 1.379 | Broken | ||

| 2 | 1.5 | 98.58 | 1.410 | Broken | ||

| 3 | 1.5 | 93.67 | 2.737* | Broken | ||

| 1 | 2.0 | 80.79 | 3.175 | Broken | ||

| 2 | 2.0 | 98.69 | 3.166 | Broken | ||

| 3 | 2.0 | 89.08 | 2.458 | Broken | ||

| 3D | 1 | 1.5 | 91.35 | 2.277 | Unbroken | |

| 2 | 1.5 | 97.58 | 1.188 | Unbroken | ||

| 3 | 1.5 | 96.98 | 1.155 | Unbroken | ||

| 1 | 1.5 | 98.15 | 89.72 | 2.725* | Unbroken | |

| 1.5 | 80.88 | 0.754 | Broken | |||

| 2 | 1.5 | 93.60 | 86.01 | 1.008 | Unbroken | |

| 1.5 | 78.36 | 0.712 | Unbroken | |||

| 3 | 1.5 | 96.98 | 88.11 | 1.155 | Unbroken | |

| 1.5 | 80.55 | 0.724 | Broken | |||

| 1 | 3.0 | 95.73 | 2.212 | Unbroken | ||

| 2 | 3.0 | 87.15 | 1.997 | Unbroken | ||

| 3 | 3.0 | 91.54 | 1.873 | Broken |

Table S1 Impact energy absorption for all samples

| Sample | Number | Impact energy/J | Er/% | Etr/% | Δh/mm | Case of sample fracture |

|---|---|---|---|---|---|---|

| 2D | 1 | 1.0 | 97.69 | 1.289 | Broken | |

| 2 | 1.0 | 96.93 | 1.123 | Broken | ||

| 3 | 1.0 | 92.13 | 1.045 | Broken | ||

| 1 | 1.5 | 96.01 | 1.379 | Broken | ||

| 2 | 1.5 | 98.58 | 1.410 | Broken | ||

| 3 | 1.5 | 93.67 | 2.737* | Broken | ||

| 1 | 2.0 | 80.79 | 3.175 | Broken | ||

| 2 | 2.0 | 98.69 | 3.166 | Broken | ||

| 3 | 2.0 | 89.08 | 2.458 | Broken | ||

| 3D | 1 | 1.5 | 91.35 | 2.277 | Unbroken | |

| 2 | 1.5 | 97.58 | 1.188 | Unbroken | ||

| 3 | 1.5 | 96.98 | 1.155 | Unbroken | ||

| 1 | 1.5 | 98.15 | 89.72 | 2.725* | Unbroken | |

| 1.5 | 80.88 | 0.754 | Broken | |||

| 2 | 1.5 | 93.60 | 86.01 | 1.008 | Unbroken | |

| 1.5 | 78.36 | 0.712 | Unbroken | |||

| 3 | 1.5 | 96.98 | 88.11 | 1.155 | Unbroken | |

| 1.5 | 80.55 | 0.724 | Broken | |||

| 1 | 3.0 | 95.73 | 2.212 | Unbroken | ||

| 2 | 3.0 | 87.15 | 1.997 | Unbroken | ||

| 3 | 3.0 | 91.54 | 1.873 | Broken |

| [1] | ZHAO G C, JIANG Z G, QU Z L, et al. Fracture characteristics and in-situ damage mechanism of PIP-C/SiC composites to various temperatures and loading velocities. Engineering Fracture Mechanics, 2023, 286: 109300. |

| [2] | YAO L J, LI Z S, CHENG Q Y, et al. Damage behavior of 2D C/SiC composites under low velocity impact. Journal of Inorganic Materials, 2010, 25(3): 311. |

| [3] | YIN D Z, DENG Y F, MA Y Z, et al. Effect of SiC content on the mechanical behaviour of a three-dimensional needled C/SiC composite. Ceramics International, 2021, 47(17): 25067. |

| [4] | LI Y, XIAO P, SHI Y, et al. Mechanical behavior of LSI based C/C-SiC composites subjected to flexural loadings. Composites Part A, 2017, 95: 315. |

| [5] | NIU Z B, CHEN S A, LI Y, et al. A damage constitutive model for the nonlinear mechanical behavior of C/SiC composites during mechanical cyclical loading/unloading. Composites Part A: Applied Science and Manufacturing, 2022, 161: 107072. |

| [6] | ALMEIDA R S M, CHEN S A, BESSER B, et al. Fatigue behavior and damage analysis of PIP C/SiC composite. Journal of the European Ceramic Society, 2022, 42(13): 5391. |

| [7] | YAO L J, LYU P, BAI G D, et al. Influence of low velocity impact on oxidation performance of SiC coated C/SiC composites. Ceramics International, 2019, 45(16): 20470. |

| [8] | MEI H, YU C K, XU H R, et al. The effects of stitched density on low-velocity impact damage of cross-woven carbon fiber reinforced silicon carbide composites. Ceramics International, 2016, 42(1): 1762. |

| [9] | FRANKEL P G, WITHERS P J, PREUSS M, et al. Residual stress fields after FOD impact on flat and aerofoil-shaped leading edges. Mechanics of Materials, 2012, 55: 130. |

| [10] | KHARGHANI N, SOARES C G. Behavior of composite laminates with embedded delaminations. Composite Structures, 2016, 150: 226. |

| [11] | SINGH A, MALL S. Tensile and fatigue behavior of oxide/oxide ceramic matrix composite with simulated foreign object damage in combustion environment. International Journal of Applied Ceramic Technology, 2017, 15(1): 16. |

| [12] | ESPINO N V. Prediction of foreign object debris/damage (FOD) type for elimination in the aeronautics manufacturing environment through logistic regression model. Texas: The University of Texas at El Paso, Master's thesis, 2013. |

| [13] | CHEN X. Foreign object damage on the leading edge of a thin blade. Mechanics of Materials, 2005, 37(4): 447. |

| [14] | DING J, HALL R F, BYRNE J, et al. Fatigue crack growth from foreign object damage under combined low and high cycle loading. Part I: experimental studies. International Journal of Fatigue, 2007, 29(7): 1339. |

| [15] | TRABANDT U, ESSER B, KOCH D, et al. Ceramic matrix composites life cycle testing under reusable launcher environmental conditions. International Journal of Applied Ceramic Technology, 2005, 2(2): 150. |

| [16] | MEI H, YU C K, XU Y W, et al. Effect of impact energy on damage resistance and mechanical property of C/SiC composites under low velocity impact. Materials Science and Engineering: A, 2017, 687: 141. |

| [17] | LIU B, AN Q J, ZHONG J G, et al. Study on notch sensitivity and failure of 3D needled C/SiC fracture toughness. Advances in Aeronautical Science and Engineering, 2022, 13(2): 85. |

| [18] |

PI H L, ZHANG B P, YU X M, et al. Damage characteristics of 2D C/SiC-ZrC composites under low velocity impact. Journal of Inorganic Materials, 2020, 35(12): 1327.

DOI |

| [19] | TITA V, DE CARVALHO J, VANDEPITTE D. Failure analysis of low velocity impact on thin composite laminates: experimental and numerical approaches. Composite Structures, 2008, 83(4): 413. |

| [20] | ZHAO D L, GUO T, FAN X M, et al. Effect of pyrolytic carbon interphase on mechanical properties of mini T800-C/SiC composites. Journal of Advanced Ceramics, 2021, 10(2): 219. |

| [21] |

LIU B, GAO Y D, TAN Z Y, et al. Low energy level impact damage on 2D C/SiC composites: experimental study. Acta Aeronautica et Astronautica Sinica, 2021, 42(2): 224202.

DOI |

| [1] | 赵日达, 汤素芳. 多孔碳陶瓷化改进反应熔渗法制备陶瓷基复合材料研究进展[J]. 无机材料学报, 2024, 39(6): 623-633. |

| [2] | 方光武, 谢浩元, 张华军, 高希光, 宋迎东. CMC-EBC损伤耦合机理及一体化设计研究进展[J]. 无机材料学报, 2024, 39(6): 647-661. |

| [3] | 李广宇, 岳一凡, 王波, 张程煜, 索涛, 李玉龙. 2D-SiC/SiC复合材料的弹丸冲击损伤及冲击后拉伸性能[J]. 无机材料学报, 2024, 39(5): 494-500. |

| [4] | 薛轶凡, 李玮洁, 张中伟, 庞旭, 刘愚. 碳纤维布表面PyC界面相微观结构及均匀性的工艺调控[J]. 无机材料学报, 2024, 39(4): 399-408. |

| [5] | 孙川, 何鹏飞, 胡振峰, 王荣, 邢悦, 张志彬, 李竞龙, 万春磊, 梁秀兵. 含有石墨烯阵列的SiC基陶瓷材料的制备与力学性能[J]. 无机材料学报, 2024, 39(3): 267-273. |

| [6] | 陶顺衍, 杨加胜, 邵芳, 吴应辰, 赵华玉, 董绍明, 张翔宇, 熊瑛. 航机CMC热端部件用热喷涂涂层的机遇与挑战[J]. 无机材料学报, 2024, 39(10): 1077-1083. |

| [7] | 吴军, 徐培飞, 荆瑞, 张大海, 费庆国. SiC/SiC复合材料层板低速冲击及其剩余强度试验研究[J]. 无机材料学报, 2024, 39(1): 51-60. |

| [8] | 师维刚, 张超, 李玫, 王晶, 张程煜. 2D-SiCf/SiC复合材料层间I型断裂试验及表征[J]. 无机材料学报, 2024, 39(1): 45-50. |

| [9] | 王雪瑶, 王武港, 李应卫, 彭奇, 梁瑞虹. PZT陶瓷本构行为与断裂性能的相关性研究[J]. 无机材料学报, 2023, 38(7): 839-844. |

| [10] | 荆开开, 管皞阳, 朱思雨, 张超, 刘永胜, 王波, 王晶, 李玫, 张程煜. Cansas-II SiCf/SiC复合材料的高温拉伸蠕变行为[J]. 无机材料学报, 2023, 38(2): 177-183. |

| [11] | 阮景, 杨金山, 闫静怡, 游潇, 王萌萌, 胡建宝, 张翔宇, 丁玉生, 董绍明. 三维碳化硅纳米线增强碳化硅陶瓷基复合材料的电磁屏蔽性能[J]. 无机材料学报, 2022, 37(5): 579-584. |

| [12] | 魏婷婷, 高希光, 宋迎东. 2D SiC/SiC复合材料电阻率对服役环境的响应特性[J]. 无机材料学报, 2022, 37(4): 420-426. |

| [13] | 琚印超, 刘小勇, 王琴, 张伟刚, 魏玺. 超高温复相陶瓷基复合材料烧蚀行为研究[J]. 无机材料学报, 2022, 37(1): 86-92. |

| [14] | 马德隆, 包亦望, 万德田, 邱岩, 郑德志, 付帅. 陶瓷薄基板材料裂纹预制与断裂韧性评价[J]. 无机材料学报, 2021, 36(7): 733-737. |

| [15] | 梁汉琴, 尹金伟, 左开慧, 夏咏锋, 姚冬旭, 曾宇平. 添加BaTiO3的热压烧结Si3N4陶瓷的力学和介电性能[J]. 无机材料学报, 2021, 36(5): 535-540. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||