无机材料学报 ›› 2025, Vol. 40 ›› Issue (2): 215-224.DOI: 10.15541/jim20240322 CSTR: 32189.14.10.15541/jim20240322

所属专题: 【信息功能】透明与闪烁陶瓷(202506)

• 研究快报 • 上一篇

叶君豪1,2( ), 周真真1,2, 胡辰1,2, 王雁斌1,2, 荆延秋1,2, 李廷松1,2, 程梓秋1,2, 吴俊林1,2, IVANOV Maxim3,4, HRENIAK Dariusz5, 李江1,2(

), 周真真1,2, 胡辰1,2, 王雁斌1,2, 荆延秋1,2, 李廷松1,2, 程梓秋1,2, 吴俊林1,2, IVANOV Maxim3,4, HRENIAK Dariusz5, 李江1,2( )

)

收稿日期:2024-07-08

修回日期:2024-09-07

出版日期:2025-02-20

网络出版日期:2024-09-23

通讯作者:

李 江, 研究员. E-mail: lijiang@mail.sic.ac.cn作者简介:叶君豪(2000-), 男, 硕士研究生. E-mail: yejunhao22@mails.ucas.ac.cn

YE Junhao1,2( ), ZHOU Zhenzhen1,2, HU Chen1,2, WANG Yanbin1,2, JING Yanqiu1,2, LI Tingsong1,2, CHENG Ziqiu1,2, WU Junlin1,2, IVANOV Maxim3,4, HRENIAK Dariusz5, LI Jiang1,2(

), ZHOU Zhenzhen1,2, HU Chen1,2, WANG Yanbin1,2, JING Yanqiu1,2, LI Tingsong1,2, CHENG Ziqiu1,2, WU Junlin1,2, IVANOV Maxim3,4, HRENIAK Dariusz5, LI Jiang1,2( )

)

Received:2024-07-08

Revised:2024-09-07

Published:2025-02-20

Online:2024-09-23

Contact:

LI Jiang, professor. E-mail: lijiang@mail.sic.ac.cnAbout author:YE Junhao (2000-), male, Master candidate. E-mail: yejunhao22@mails.ucas.ac.cn

Supported by:摘要:

Sc2O3作为固体激光增益材料的基质, 具有热导率高、与激活离子匹配性好等优点, 在高功率固体激光应用中有着广阔的应用前景。目前, Yb掺杂的Sc2O3陶瓷可以在很高的烧结温度下合成, 但陶瓷的光学质量和烧结温度还有待进一步优化。本研究采用碳酸氢铵共沉淀法制备了分散性好、平均晶粒尺寸29 nm的立方相5%Yb:Sc2O3(掺杂量为质量分数)纳米粉体, 并采用真空预烧结和热等静压(Hot Isostatic Pressing, HIP)后处理制备了5%Yb:Sc2O3透明陶瓷, 详细研究了真空预烧结温度(1500~1700 ℃)对Yb:Sc2O3陶瓷的致密化过程、微观结构变化及光学透过率的影响。结果表明, 所有样品均具有均匀的微观结构, 且随着烧结温度的升高, 样品的平均晶粒尺寸增大。值得注意的是, 1550 ℃预烧的Yb:Sc2O3陶瓷经HIP后处理后, 在1100 nm处的最佳直线透过率达到78.1%(理论值为80%)。同时, 还评估了Yb:Sc2O3陶瓷的光谱性能。5%Yb:Sc2O3陶瓷的最小粒子数反转参数β2和发光衰减时间分别为0.041和0.49 ms。综上所述, 采用共沉淀法成功制备了Yb:Sc2O3纳米粉体, 通过1550 ℃真空预烧结和HIP后处理得到光学质量良好的Yb:Sc2O3透明陶瓷。

中图分类号:

叶君豪, 周真真, 胡辰, 王雁斌, 荆延秋, 李廷松, 程梓秋, 吴俊林, IVANOV Maxim, HRENIAK Dariusz, 李江. 共沉淀纳米粉体制备Yb:Sc2O3透明陶瓷的微结构与光学性能[J]. 无机材料学报, 2025, 40(2): 215-224.

YE Junhao, ZHOU Zhenzhen, HU Chen, WANG Yanbin, JING Yanqiu, LI Tingsong, CHENG Ziqiu, WU Junlin, IVANOV Maxim, HRENIAK Dariusz, LI Jiang. Yb:Sc2O3 Transparent Ceramics Fabricated from Co-precipitated Nano-powders: Microstructure and Optical Property[J]. Journal of Inorganic Materials, 2025, 40(2): 215-224.

| Sample | SBET/(m2·g-1) | DBET/nm | DSEM/nm | DXRD/nm | N1 |

|---|---|---|---|---|---|

| 5%Yb:Sc2O3 nano-powders | 25 | 58 | 43 | 29 | 6 |

Table 1 Analysis of particle size and agglomeration degree of 5%Yb:Sc2O3 nano-powders

| Sample | SBET/(m2·g-1) | DBET/nm | DSEM/nm | DXRD/nm | N1 |

|---|---|---|---|---|---|

| 5%Yb:Sc2O3 nano-powders | 25 | 58 | 43 | 29 | 6 |

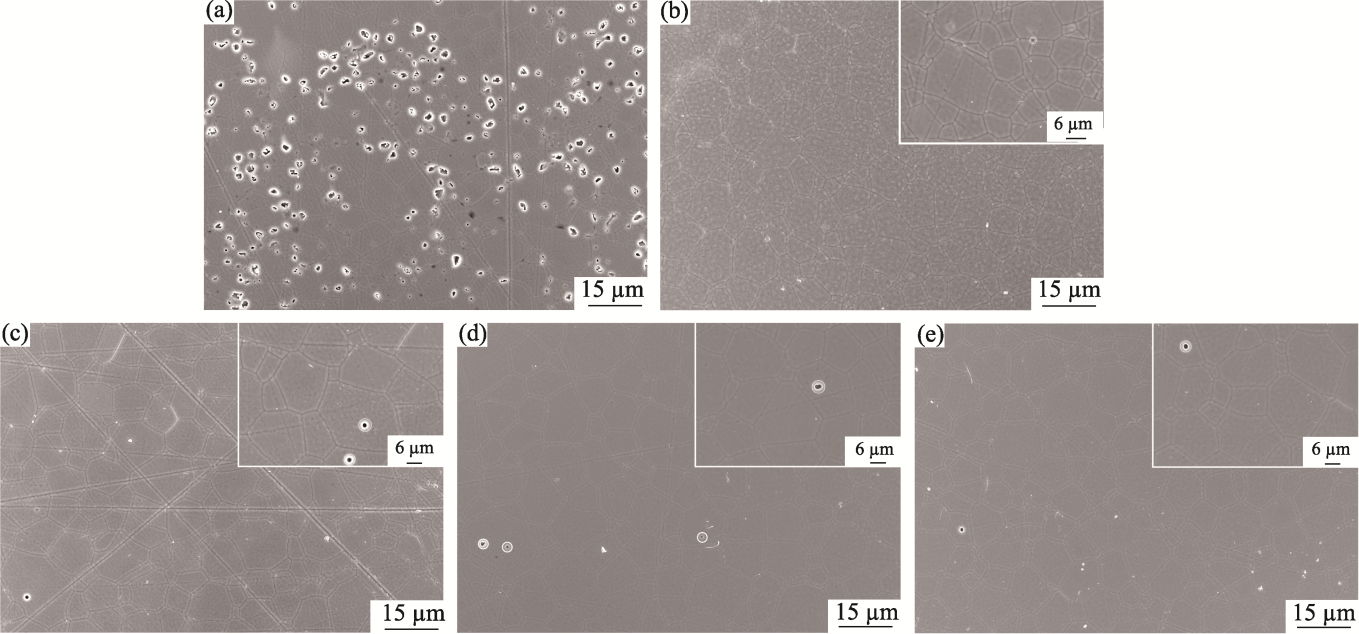

Fig. 4 FESEM micrographs of thermally etched surfaces of the 5%Yb:Sc2O3 ceramics pre-sintered at different temperatures (a) 1500 ℃; (b) 1550 ℃; (c) 1600 ℃; (d) 1650 ℃; (e) 1700 ℃

Fig. 6 FESEM micrographs of thermally etched surfaces of the synthesized 5%Yb:Sc2O3 ceramics Ceramics pre-sintered at (a) 1500, (b) 1550, (c) 1600, (d) 1650, and (e) 1700 ℃ before HIP post-treatment at 1700 ℃

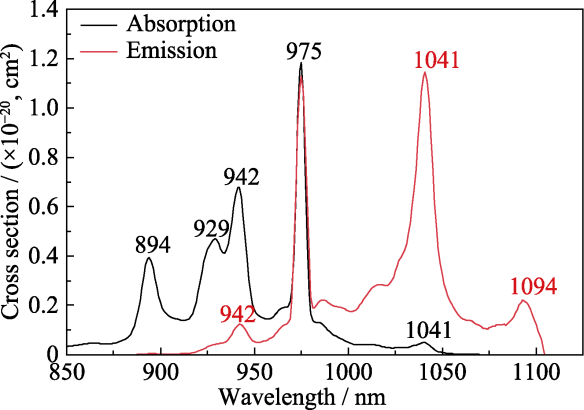

Fig. 9 Absorption and emission cross-sections of the 5%Yb:Sc2O3 transparent ceramics pre-sintered at 1550 ℃ with HIP post-treatment Colorful figure is available on website

| [1] | ZUO J, LIN X. High-power laser systems. Laser & Photonics Reviews, 2022, 16(5): 2100741. |

| [2] | LIU Z Y, IKESUE A, LI J. Research progress and prospects of rare-earth doped sesquioxide laser ceramics. Journal of the European Ceramic Society, 2021, 41(7): 3895. |

| [3] | DANSON C N, HAEFNER C, BROMAGE J, et al. Petawatt and exawatt class lasers worldwide. High Power Laser Science and Engineering, 2019, 7: e54. |

| [4] | SÄNGER J C, PAUW B R, RIECHERS B, et al. Entering a new dimension in powder processing for advanced ceramics shaping. Advanced Materials, 2023, 35(8): 2208653. |

| [5] | WANG X, YU H, LI P, et al. Femtosecond laser-based processing methods and their applications in optical device manufacturing: a review. Optics & Laser Technology, 2021, 135: 106687. |

| [6] | ORAZI L, ROMOLI L, SCHMIDT M, et al. Ultrafast laser manufacturing: from physics to industrial applications. CIRP Annals, 2021, 70(2): 543. |

| [7] | GODARD A. Infrared (2-12 μm) solid-state laser sources: a review. Comptes Rendus. Physique, 2007, 8(10): 1100. |

| [8] | BRENIER A, BOULON G. Overview of the best Yb3+-doped laser crystals. Journal of Alloys and Compounds, 2001, 323/324: 210. |

| [9] | BOULON G. Why so deep research on Yb3+-doped optical inorganic materials? Journal of Alloys and Compounds, 2008, 451(1/2): 1. |

| [10] | RADMARD S, MOSHAII A, PASANDIDEH K. 400 W average power Q-switched Yb:YAG thin-disk-laser. Scientific Reports, 2022, 12(1): 16918. |

| [11] | PERMIN D A, KURASHKIN S V, NOVIKOVA A V, et al. Synthesis and luminescence properties of Yb-doped Y2O3, Sc2O3 and Lu2O3 solid solutions nanopowders. Optical Materials, 2018, 77: 240. |

| [12] | LI W W, HUANG H J, MEI B C, et al. Effect of Yb concentration on the microstructures, spectra, and laser performance of Yb:CaF2 transparent ceramics. Journal of the American Ceramic Society, 2020, 103(10): 5787. |

| [13] | SHANG P, BAI L, WANG S, et al. Research progress on thermal effect of LD pumped solid state laser. Optics & Laser Technology, 2023, 157: 108640. |

| [14] | TOCI G, HOSTAŠA J, PATRIZI B, et al. Fabrication and laser performances of Yb:Sc2O3 transparent ceramics from different combination of vacuum sintering and hot isostatic pressing conditions. Journal of the European Ceramic Society, 2020, 40(3): 881. |

| [15] | PERMIN D A, BALABANOV S S, SNETKOV I L, et al. Hot pressing of Yb:Sc2O3 laser ceramics with LiF sintering aid. Optical Materials, 2020, 100: 109701. |

| [16] | DAI Z F, LIU Q, TOCI G, et al. Fabrication and laser oscillation of Yb:Sc2O3 transparent ceramics from co-precipitated nano-powders. Journal of the European Ceramic Society, 2018, 38(4): 1632. |

| [17] | MCMILLEN C D, KOLIS J W. Hydrothermal single crystal growth of Sc2O3 and lanthanide-doped Sc2O3. Journal of Crystal Growth, 2008, 310(7/8/9): 1939. |

| [18] | FORNASIERO L, MIX E, PETERS V, et al. Czochralski growth and laser parameters of RE3+-doped Y2O3 and Sc2O3. Ceramics International, 2000, 26(6): 589. |

| [19] | LU J, BISSON J F, TAKAICHI K, et al. Yb3+:Sc2O3 ceramic laser. Applied Physics Letters, 2003, 83(6): 1101. |

| [20] | MERKLE L D, NEWBURGH G A, TER-GABRIELYAN N, et al. Temperature-dependent lasing and spectroscopy of Yb:Y2O3 and Yb:Sc2O3. Optics Communications, 2008, 281(23): 5855. |

| [21] | LIU Q, DAI Z F, HRENIAK D, et al. Fabrication of Yb:Sc2O3 laser ceramics by vacuum sintering co-precipitated nano-powders. Optical Materials, 2017, 72: 482. |

| [22] | MA M Z, DONG L L, JING W, et al. Fabrication of transparent Yb:Sc2O3 ceramics by hot isostatic pressing without sintering additive. IOP Conference Series: Materials Science and Engineering, 2019, 678(1): 12080. |

| [23] | JIANG B X, HU C, LI J, et al. Synthesis and properties of Yb:Sc2O3 transparent ceramics. Journal of Rare Earths, 2011, 29(10): 951. |

| [24] | GHEORGHE C, LUPEI A, LUPEI V, et al. Intensity parameters of Tm3+ doped Sc2O3 transparent ceramic laser material. Optical Materials, 2011, 33(3): 501. |

| [25] | PERMIN D A, GAVRISHCHUK E M, KLYUSIK O N, et al. Self-propagating high-temperature synthesis of Sc2O3 nanopowders using different precursors. Advanced Powder Technology, 2016, 27(6): 2457. |

| [26] | BRAVO A C, LONGUET L, AUTISSIER D, et al. Influence of the powder preparation on the sintering of Yb-doped Sc2O3 transparent ceramics. Optical Materials, 2009, 31(5): 734. |

| [27] | POIROT N, BREGIROUX D, BOY P, et al. Sintering of nanostructured Sc2O3 ceramics from Sol-Gel-derived nanoparticles. Ceramics International, 2015, 41(3): 3879. |

| [28] | DONG L L, MA M Z, JING W, et al. Synthesis of highly sinterable Yb:Lu2O3 nanopowders via spray co-precipitation for transparent ceramics. Ceramics International, 2019, 45(15): 19554. |

| [29] | LI J S, SUN X D, LIU S H, et al. A homogeneous co-precipitation method to synthesize highly sinterability YAG powders for transparent ceramics. Ceramics International, 2015, 41(2): 3283. |

| [30] | DAI Z, LIU Q, HRENIAK D, et al. Fabrication of Yb:Sc2O3 transparent ceramics from co-precipitated nanopowders: The effect of ammonium hydrogen carbonate to metal ions molar ratio. Optical Materials, 2018, 75: 673. |

| [31] | WANG Y, LU B, SUN X, et al. Synthesis of nanocrystalline Sc2O3 powder and fabrication of transparent Sc2O3 ceramics. Advances in Applied Ceramics, 2013, 110(2): 95. |

| [32] | SERIVALSATIT K, BALLATO J. Submicrometer grain-sized transparent erbium-doped scandia ceramics. Journal of the American Ceramic Society, 2010, 93(11): 3657. |

| [33] | MAYO M J, HAGUE D C, CHEN D J. Processing nanocrystalline ceramics for applications in superplasticity. Materials Science and Engineering: A, 1993, 166(1): 145. |

| [34] | KIM W, BAKER C, VILLALOBOS G, et al. Synthesis of high purity Yb3+-doped Lu2O3 powder for high power solid-state lasers. Journal of the American Ceramic Society, 2011, 94(9): 3001. |

| [35] | JIANG N, LIN W P, ZHAO Y, et al. Fabrication and kW-level MOPA laser output of planar waveguide YAG/Yb:YAG/YAG ceramic slab. Journal of the American Ceramic Society, 2018, 102(4): 1758. |

| [36] | LI X, ZHANG L, HU D, et al. Fabrication and characterizations of Tb3Al5O12-based magneto-optical ceramics. International Journal of Applied Ceramic Technology, 2022, 20(1): 493. |

| [37] | WANG Y, SUN X D, QIU G M. Synthesis of scandium oxide nano power and fabrication of transparent scandium oxide ceramics. Journal of Rare Earths, 2007, 25: 68. |

| [38] | LU B, WANG Y, SUN X D, et al. Synthesis of Sc2O3 nanopowders and fabrication of transparent, two-step sintered Sc2O3 ceramics. Advances in Applied Ceramics, 2013, 111(7): 389. |

| [39] | LI J G, IKEGAMI T, MORI T. Fabrication of transparent, sintered Sc2O3 ceramics. Journal of the American Ceramic Society, 2005, 88(4): 817. |

| [40] | LU X, JIANG B X, LI J, et al. Synthesis of highly sinterable Yb:Sc2O3 nanopowders for transparent ceramic. Ceramics International, 2013, 39(4): 4695. |

| [41] | FU G Y, WEI J M, CHEN S X, et al. Preparation of spherical scandium oxide powders by ammonium bicarbonate precipitation. Rare Metal Materials and Engineering, 2023, 52(10): 3417. |

| [42] | MONSHI A, FOROUGHI M R, MONSHI M R. Modified Scherrer equation to estimate more accurately nano-crystallite size using XRD. World Journal of Nano Science and Engineering, 2012, 2(3): 154. |

| [43] | CAO W B, MAO X, YUAN Y, et al. Sintering kinetics of disperse ultrafine equiaxed α-Al2O3 nanoparticles. Journal of the European Ceramic Society, 2017, 37(13): 4005. |

| [44] | SEELEY Z M, KUNTZ J D, CHEREPY N J, et al. Transparent Lu2O3:Eu ceramics by sinter and HIP optimization. Optical Materials, 2011, 33(11): 1721. |

| [45] | LIU Q, JING Y Q, SU S, et al. Microstructure and properties of MgAl2O4 transparent ceramics fabricated by hot isostatic pressing. Optical Materials, 2020, 104: 109938. |

| [46] | TAKAICHI K, YAGI H, BECKER P, et al. New data on investigation of novel laser ceramic on the base of cubic scandium sesquioxide: two-band tunable CW generation of Yb3+:Sc2O3 with laser-diode pumping and the dispersion of refractive index in the visible and near-IR of undoped Sc2O3. Laser Physics Letters, 2007, 4(7): 507. |

| [47] | KRELL A, KLIMKE J, HUTZLER T. Transparent compact ceramics: inherent physical issues. Optical Materials, 2009, 31(8): 1144. |

| [48] | DELOACH L D, PAYNE S A, CHASE L L, et al. Evaluation of absorption and emission properties of Yb3+ doped crystals for laser applications. IEEE Journal of Quantum Electronics, 1993, 29(4): 1179. |

| [49] | LU S Z, YANG Q H. Spectroscopic characterization of Yb:Sc2O3 transparent ceramics. Chinese Physics B, 2012, 21(4): 47801. |

| [50] | LIU Z Y, TOCI G, PIRRI A, et al. Fabrication, microstructures, and optical properties of Yb:Lu2O3 laser ceramics from co-precipitated nano-powders. Journal of Advanced Ceramics, 2020, 9(6): 674. |

| [51] | FORNASIERO L, MIX E, PETERS V, et al. New oxide crystals for solid state lasers. Crystal Research and Technology, 1999, 34(2): 255. |

| [52] | GALCERAN M, PUJOL M C, CARVAJAL J J, et al. Structural characterization and ytterbium spectroscopy in Sc2O3 nanocrystals. Journal of Luminescence, 2010, 130(8): 1437. |

| [1] | 吕朝阳, 徐勇, 杨久延, 涂广升, 涂兵田, 王皓. MgF2助剂对MgAl1.9Ga0.1O4透明陶瓷的制备与光学性能的影响[J]. 无机材料学报, 2024, 39(5): 531-538. |

| [2] | 顾军毅, 范武刚, 张兆泉, 姚琴, 展红全. 还原制备Pr2O3粉体及其结构和光学性能研究[J]. 无机材料学报, 2023, 38(7): 771-777. |

| [3] | 李悦, 张旭良, 景芳丽, 胡章贵, 吴以成. 铈掺杂硼酸钙镧晶体的生长与性能研究[J]. 无机材料学报, 2023, 38(5): 583-588. |

| [4] | 吴俊林, 丁继扬, 黄新友, 朱丹阳, 黄东, 代正发, 杨文钦, 蒋兴奋, 周健荣, 孙志嘉, 李江. Gd2O2S:Tb闪烁陶瓷的制备与结构: 水浴合成中H2SO4/Gd2O3摩尔比的影响[J]. 无机材料学报, 2023, 38(4): 452-460. |

| [5] | 靳喜海, 董满江, 阚艳梅, 梁波, 董绍明. 透明AlON陶瓷凝胶浇注成型及其无压烧结制备[J]. 无机材料学报, 2023, 38(2): 193-198. |

| [6] | 王海东, 王燕, 朱昭捷, 李坚富, LAKSHMINARAYANA Gandham, 涂朝阳. Dy3+掺杂SrGdGa3O7晶体的晶体生长, 结构、光学和可见光荧光特性[J]. 无机材料学报, 2023, 38(12): 1475-1482. |

| [7] | 汪德文, 王俊平, 袁厚呈, 刘章, 周进, 邓佳杰, 王鑫, 吴贲华, 章健, 王士维. 真空反应烧结制备米级尺寸钇铝石榴石(YAG)透明陶瓷[J]. 无机材料学报, 2023, 38(12): 1483-1484. |

| [8] | 李文俊, 王皓, 涂兵田, 谌强国, 郑凯平, 王为民, 傅正义. 宽光谱透过Mg0.9Al2.08O3.97N0.03透明陶瓷的制备与性能研究[J]. 无机材料学报, 2022, 37(9): 969-975. |

| [9] | 母利成, 杨金萍, 王俊平, 赵瑾, 刘梦玮, 汪德文, 章健. 环氧树脂改性自发凝固成型制备YAG透明陶瓷[J]. 无机材料学报, 2022, 37(9): 941-946. |

| [10] | 刘强, 王倩, 陈鹏辉, 李晓英, 章立轩, 谢腾飞, 李江. 两步烧结法制备红色Ce:8YSZ透明陶瓷及其性能研究[J]. 无机材料学报, 2022, 37(8): 911-917. |

| [11] | 肖舒琳, 戴中华, 李定妍, 张凡博, 杨利红, 任晓兵. 氧化镧掺杂铌酸钾钠陶瓷的电、光性能研究[J]. 无机材料学报, 2022, 37(5): 520-526. |

| [12] | 荆延秋, 刘强, 苏莎, 李晓英, 刘子玉, 王静雅, 李江. 1.5 μm被动调Q可饱和吸收体用Co:MgAl 2O4透明陶瓷的制备[J]. 无机材料学报, 2021, 36(8): 877-882. |

| [13] | 曾建军, 张魁宝, 陈代梦, 郭海燕, 邓婷, 刘奎. 真空烧结制备(La0.2Nd0.2Sm0.2Gd0.2Er0.2)2Zr2O7高熵透明陶瓷[J]. 无机材料学报, 2021, 36(4): 418-424. |

| [14] | 孙娅楠, 叶丽, 赵文英, 陈凤华, 邱文丰, 韩伟健, 刘伟, 赵彤. 液相聚合物前驱体法制备高熵碳化物纳米粉体[J]. 无机材料学报, 2021, 36(4): 393-398. |

| [15] | 刘子玉, TOCI Guido, PIRRI Angela, PATRIZI Barbara, 冯亚刚, 陈肖朴, 胡殿君, 田丰, 吴乐翔, VANNINIMatteo, 李江. 固体激光用Nd:Lu2O3透明陶瓷的制备和光学性能研究[J]. 无机材料学报, 2021, 36(2): 210-216. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||