无机材料学报 ›› 2024, Vol. 39 ›› Issue (4): 399-408.DOI: 10.15541/jim20230512 CSTR: 32189.14.10.15541/jim20230512

薛轶凡1( ), 李玮洁2(

), 李玮洁2( ), 张中伟1(

), 张中伟1( ), 庞旭1, 刘愚3

), 庞旭1, 刘愚3

收稿日期:2023-11-03

修回日期:2024-01-01

出版日期:2024-04-20

网络出版日期:2024-01-08

通讯作者:

李玮洁, 副教授, E-mail: wj.li@bjtu.edu.cn;作者简介:薛轶凡(1999-), 男, 硕士研究生. E-mail: 3120211981@bit.edu.cn

基金资助:

XUE Yifan1( ), LI Weijie2(

), LI Weijie2( ), ZHANG Zhongwei1(

), ZHANG Zhongwei1( ), PANG Xu1, LIU Yu3

), PANG Xu1, LIU Yu3

Received:2023-11-03

Revised:2024-01-01

Published:2024-04-20

Online:2024-01-08

Contact:

LI Weijie, associate professor. E-mail: wj.li@bjtu.edu.cn;About author:XUE Yifan (1999-), male, Master candidate. E-mail: 3120211981@bit.edu.cn

Supported by:摘要:

陶瓷基复合材料力学性能与界面相的微观结构和均匀性有密切关系。本研究在碳纤维布表面沉积PyC界面相, 探究沉积温度、丙烯分压、滞留时间和氢气分压等工艺参数对PyC界面相微观结构及均匀性的影响规律。使用多种手段对PyC界面相微观形貌、织构进行表征, 并分析了微观结构、均匀性与工艺参数之间的内在关联。结果表明: 界面相织构的规整度随沉积温度和丙烯分压的提高而提高, 随氢气分压的提高而降低, 而受滞留时间影响较小; 沉积温度和丙烯分压升高均导致界面相厚度分布更加不均匀, 且丙烯分压过高会直接产生炭黑, 延长滞留时间有利于提高界面相的均匀性; 对于中织构和高织构, 随着氢气分压提高, 界面相均匀性先降低后增加, 而低织构的界面相均匀性受其影响较小。最后, 阐明了PyC界面相生长模式, 揭示了工艺参数对PyC界面相织构形态及均匀性的影响规律, 为PyC界面相的精细调控提供了基础。

中图分类号:

薛轶凡, 李玮洁, 张中伟, 庞旭, 刘愚. 碳纤维布表面PyC界面相微观结构及均匀性的工艺调控[J]. 无机材料学报, 2024, 39(4): 399-408.

XUE Yifan, LI Weijie, ZHANG Zhongwei, PANG Xu, LIU Yu. Process Control of PyC Interphases Microstructure and Uniformity in Carbon Fiber Cloth[J]. Journal of Inorganic Materials, 2024, 39(4): 399-408.

| Group | T/℃ | pC3H6/kPa | τ/s | pH2/kPa |

|---|---|---|---|---|

| 1 | 950 | 5 | 3 | 0 |

| 2 | 950 | 3 | 3 | 0 |

| 3 | 950 | 3 | 1 | 0 |

| 4 | 950 | 1 | 1 | 0 |

| 5 | 950 | 0.5 | 1 | 0 |

| 6 | 950 | 1 | 3 | 0 |

| 7 | 950 | 1 | 0.5 | 0 |

| 8 | 900 | 3 | 1 | 0 |

| 9 | 900 | 1 | 0.5 | 0 |

| 10 | 900 | 1 | 3 | 0 |

| 11 | 900 | 1 | 1 | 0 |

| 12 | 850 | 1 | 0.5 | 0 |

| 13 | 850 | 1 | 1 | 0 |

| 14 | 850 | 1 | 3 | 0 |

| 15 | 950 | 3 | 3 | 1.5 |

| 16 | 950 | 3 | 3 | 3 |

| 17 | 950 | 1 | 3 | 0.5 |

| 18 | 950 | 1 | 3 | 1 |

| 19 | 900 | 3 | 1 | 1.5 |

| 20 | 900 | 3 | 1 | 3 |

表1 实验设计参数

Table 1 Design parameters for experiment

| Group | T/℃ | pC3H6/kPa | τ/s | pH2/kPa |

|---|---|---|---|---|

| 1 | 950 | 5 | 3 | 0 |

| 2 | 950 | 3 | 3 | 0 |

| 3 | 950 | 3 | 1 | 0 |

| 4 | 950 | 1 | 1 | 0 |

| 5 | 950 | 0.5 | 1 | 0 |

| 6 | 950 | 1 | 3 | 0 |

| 7 | 950 | 1 | 0.5 | 0 |

| 8 | 900 | 3 | 1 | 0 |

| 9 | 900 | 1 | 0.5 | 0 |

| 10 | 900 | 1 | 3 | 0 |

| 11 | 900 | 1 | 1 | 0 |

| 12 | 850 | 1 | 0.5 | 0 |

| 13 | 850 | 1 | 1 | 0 |

| 14 | 850 | 1 | 3 | 0 |

| 15 | 950 | 3 | 3 | 1.5 |

| 16 | 950 | 3 | 3 | 3 |

| 17 | 950 | 1 | 3 | 0.5 |

| 18 | 950 | 1 | 3 | 1 |

| 19 | 900 | 3 | 1 | 1.5 |

| 20 | 900 | 3 | 1 | 3 |

图2 三个典型代表样品的TEM表征结果

Fig. 2 TEM charaterizations of three typical samples (a) SEM image of interphase, (b) HRTEM image of interphase and (c) Fourier transform of HT (Group 2); (d) SEM image of interphase, (e) HRTEM image of interphase and (f) Fourier transform of MT (Group 4); (g) SEM image of interphase, (h) HRTEM image of interphase and (i) Fourier transform of LT (Group 8)

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | |

|---|---|---|---|---|---|---|---|---|---|---|

| XRD FWHM/(°) | 5.522 | 5.495 | 5.217 | 5.664 | 5.809 | 5.579 | 5.469 | 5.805 | 5.883 | 5.942 |

| ID/IG | 0.995 | 0.979 | 0.991 | 0.988 | 0.998 | 1.021 | 0.991 | 0.994 | 1.001 | 1.050 |

| Texture | HT | MT | LT | |||||||

| 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | |

| XRD FWHM/(°) | 5.926 | 6.056 | 5.873 | 5.940 | 5.518 | 5.597 | 5.623 | 5.961 | 5.773 | 5.914 |

| ID/IG | 1.028 | 1.031 | 1.037 | 1.033 | 0.978 | 0.974 | 1.011 | 0.992 | 1.012 | 1.003 |

| Texture | LT | HT | MT | LT | ||||||

表2 PyC界面相XRD半峰全宽、拉曼光谱R(R=ID/IG)汇总及织构分类

Table 2 Summary of XRD FWHM and R (R=ID/IG) for Raman spectra of PyC interphases, and texture classifications

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | |

|---|---|---|---|---|---|---|---|---|---|---|

| XRD FWHM/(°) | 5.522 | 5.495 | 5.217 | 5.664 | 5.809 | 5.579 | 5.469 | 5.805 | 5.883 | 5.942 |

| ID/IG | 0.995 | 0.979 | 0.991 | 0.988 | 0.998 | 1.021 | 0.991 | 0.994 | 1.001 | 1.050 |

| Texture | HT | MT | LT | |||||||

| 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | |

| XRD FWHM/(°) | 5.926 | 6.056 | 5.873 | 5.940 | 5.518 | 5.597 | 5.623 | 5.961 | 5.773 | 5.914 |

| ID/IG | 1.028 | 1.031 | 1.037 | 1.033 | 0.978 | 0.974 | 1.011 | 0.992 | 1.012 | 1.003 |

| Texture | LT | HT | MT | LT | ||||||

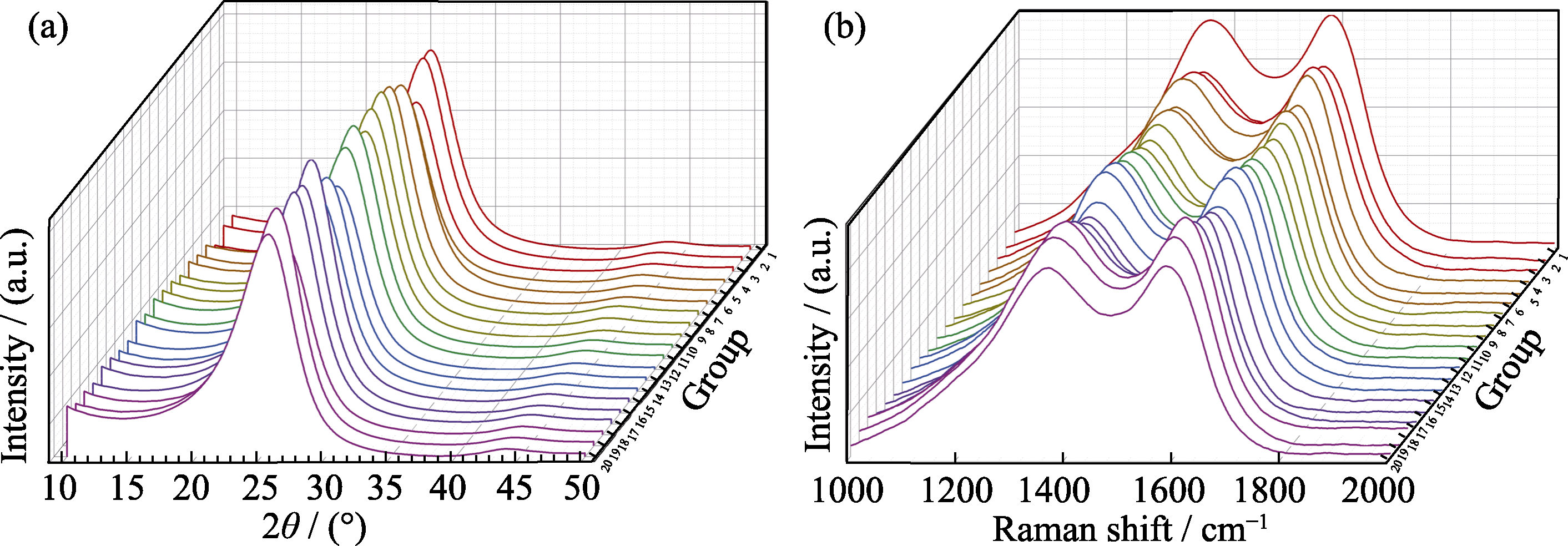

图3 不同工艺制备的碳纤维表面PyC界面相的(a)XRD图谱和(b)Raman图谱

Fig. 3 (a) XRD patterns and (b) Raman spectra of PyC interphase on carbon fiber prepared by different fabrication processes

图6 不同温度下PyC界面相的沉积速率, 均匀性及其典型横截面SEM照片

Fig. 6 Deposition rate, uniformity and typical SEM images of cross-section of PyC interphases at various temperatures

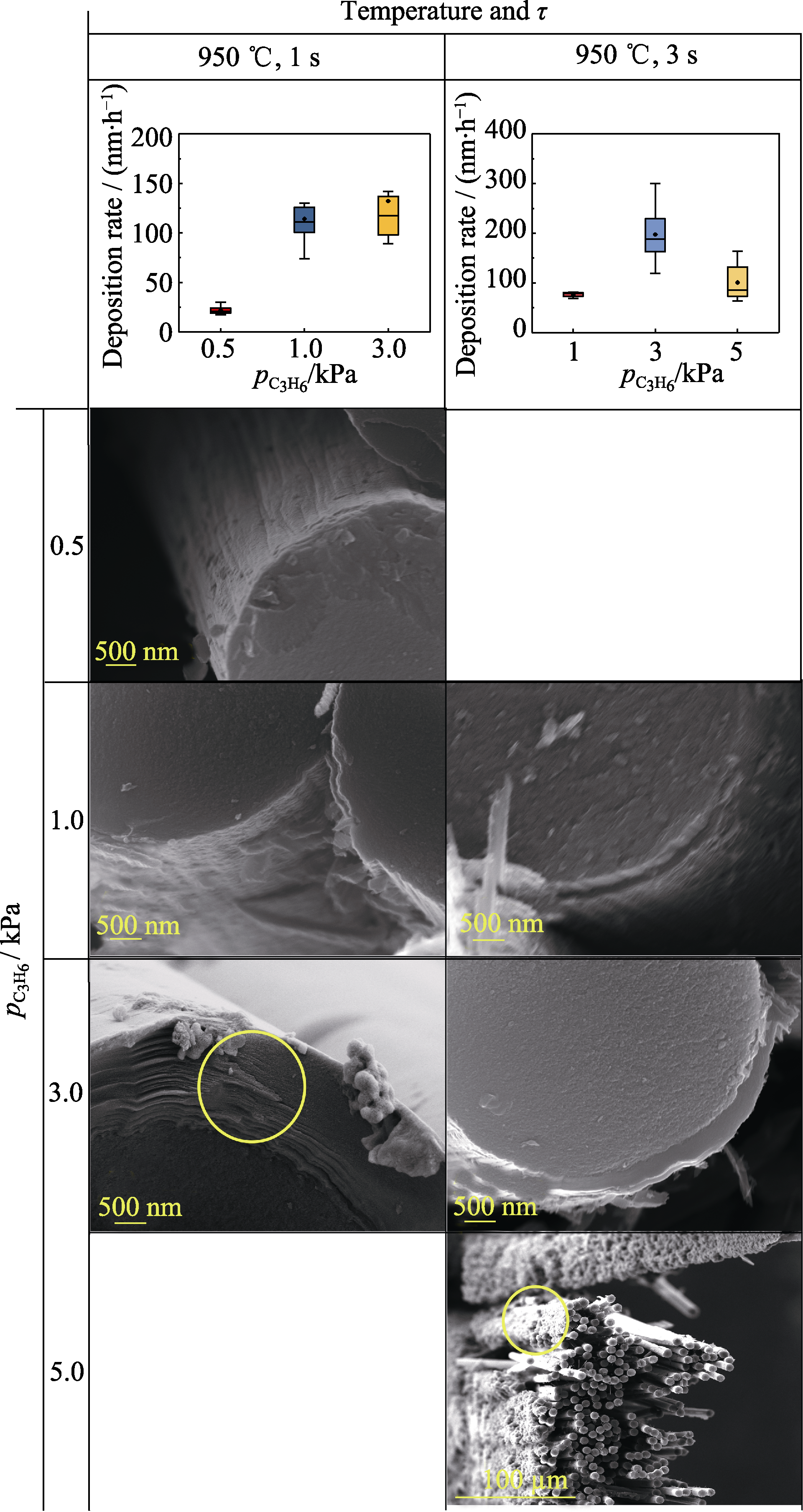

图7 不同丙烯分压下PyC界面相的沉积速率, 均匀性及其典型横截面的SEM照片

Fig. 7 Deposition rate, uniformity and typical SEM images of cross-section of PyC interphases at various pC3H6

图8 不同滞留时间下PyC界面相的沉积速率, 均匀性及其典型横截面SEM照片

Fig. 8 Deposition rate, uniformity and typical SEM images of cross-section of PyC interphases at various residence time

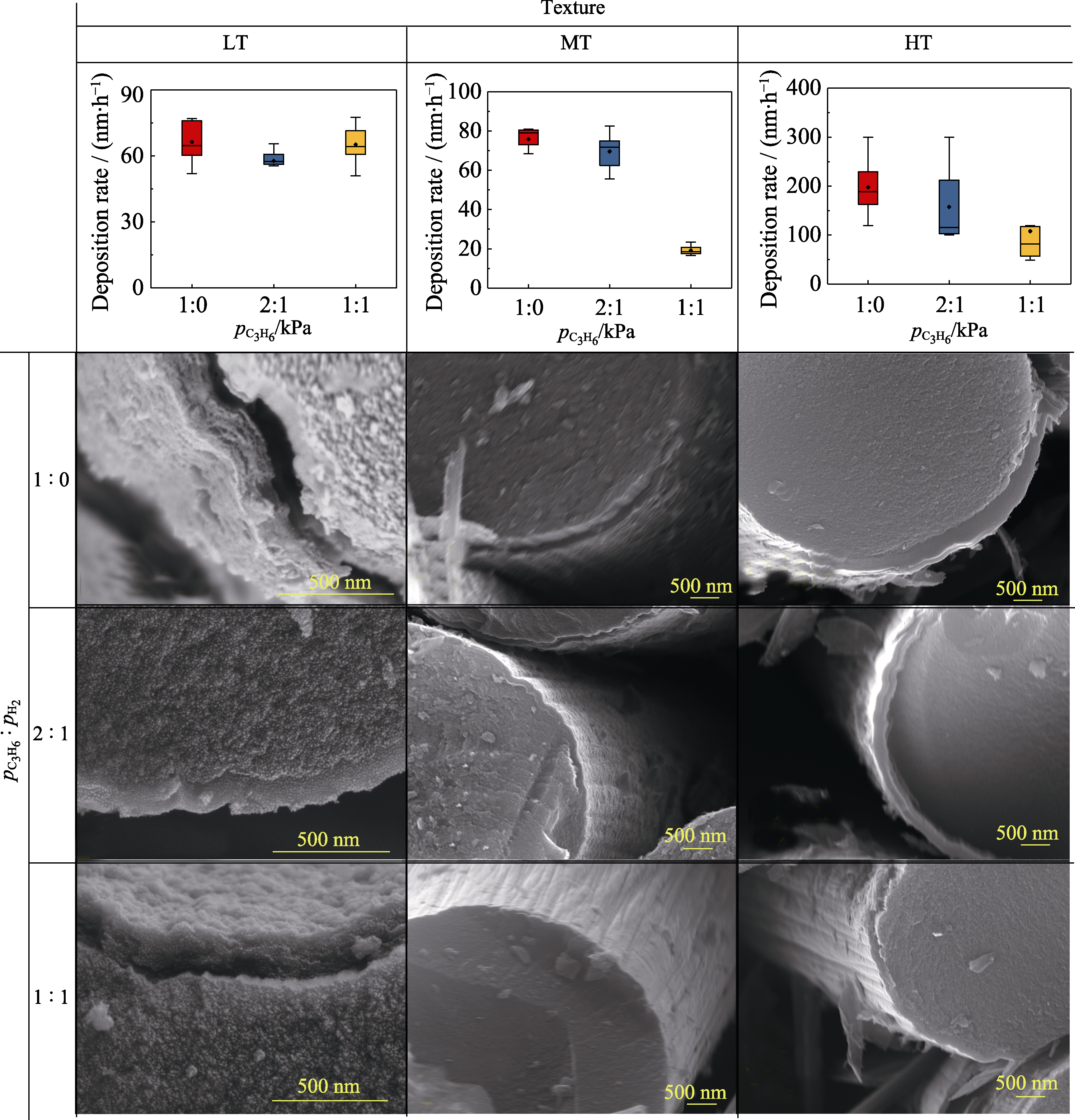

图9 不同丙烯分压和氢气分压比例下PyC界面相的沉积速率, 均匀性及其典型横截面SEM照片

Fig. 9 Deposition rate, uniformity and typical SEM images of cross-section of PyC interphases at various pC3H6 : pH2

| [1] | TANG S F, HU C L. Design, preparation and properties of carbon fiber reinforced ultra-high temperature ceramic composites for aerospace applications: a review. Journal of Materials Science & Technology, 2017, 33(2): 117. |

| [2] |

SCHMIDT S, BEYER S, KNABE H, et al. Advanced ceramic matrix composite materials for current and future propulsion technology applications. Acta Astronautica, 2004, 55(3-9): 409.

DOI URL |

| [3] |

ZHAO D L, GUO T, FAN X M, et al. Effect of pyrolytic carbon interphase on mechanical properties of mini T800-C/SiC composites. Journal of Advanced Ceramics, 2021, 10(2): 219.

DOI |

| [4] |

SCHMIDT S, BEYER S, IMMICH H, et al. Ceramic matrix composites: a challenge in space-propulsion technology applications. International Journal of Applied Ceramic Technology, 2005, 2(2): 85.

DOI URL |

| [5] |

NIU C, ZHANG Q, CHENG L, et al. Microstructure and mechanical properties of Cf/SiC composites with dispersed C-SiC interphase prepared by chemical vapor infiltration. Composites Part A: Applied Science and Manufacturing, 2023, 165: 107339.

DOI URL |

| [6] |

NASLAIN R R, PAILLER R J F, LAMON J L. Single- and multilayered interphases in SiC/SiC composites exposed to severe environmental conditions: an overview. International Journal of Applied Ceramic Technology, 2010, 7(3): 263.

DOI URL |

| [7] |

KERANS R J, HAY R S, PARTHASARATHY T A, et al. Interface design for oxidation-resistant ceramic composites. Journal of the American Ceramic Society, 2002, 85(11): 2599

DOI URL |

| [8] |

KABEL J, HOSEMANN P, ZAYACHUK Y, et al. Ceramic composites: a review of toughening mechanisms and demonstration of micropillar compression for interface property extraction. Journal of Materials Research, 2018, 33(4): 424.

DOI URL |

| [9] |

NASLAIN R, DUGNE O, GUETTE A, et al. Boron-nitride interphase in ceramic-matrix composites. Journal of the American Ceramic Society, 1991, 74(10): 2482.

DOI URL |

| [10] |

SU K, CHEN Z K, LI L B, et al. Effects of single-phase and Co-deposited interphases on mechanical hysteresis behavior in T700(TM) mini-Cf/SiC composites. International Journal of Fatigue, 2023, 168: 107473.

DOI URL |

| [11] |

NAGARAJA A M, GURURAJA S, UDAYAKUMAR A. Tensile behavior of ceramic matrix minicomposites with engineered interphases fabricated by chemical vapor infiltration. Journal of the European Ceramic Society, 2022, 42(6): 2659.

DOI URL |

| [12] |

NASLAIN R, LAMON J, PAILLER R, et al. Micro/minicomposites: a useful approach to the design and development of non-oxide CMCs. Composites Part A: Applied Science and Manufacturing, 1999, 30(4): 537.

DOI URL |

| [13] |

CAO X Y, YIN X W, MA X K, et al. Oxidation behavior of SiBC matrix modified C/SiC composites with different PyC interphase thicknesses. Ceramics International, 2015, 41(1): 1695.

DOI URL |

| [14] |

DUAN H Z, ZHANG Z W, LI L B, et al. Effect of pyrocarbon interphase texture and thickness on tensile damage and fracture in T-700 (TM) carbon fiber-reinforced silicon carbide minicomposites. Journal of the American Ceramic Society, 2022, 105(3): 2171.

DOI URL |

| [15] |

MEI H, BAI Q L, SUN Y Y, et al. The effect of heat treatment on the strength and toughness of carbon fiber/silicon carbide composites with different pyrolytic carbon interphase thicknesses. Carbon, 2013, 57: 288.

DOI URL |

| [16] |

REZNIK B, HÜTTINGER K J. On the terminology for pyrolytic carbon. Carbon, 2002, 40(4): 621.

DOI URL |

| [17] |

LI W, LI H J, WANG J, et al. Preparation and mechanical properties of carbon/carbon composites with high textured pyrolytic carbon matrix. Transactions of Nonferrous Metals Society of China, 2013, 23(7): 2129.

DOI URL |

| [18] |

VALLEROT J M, BOURRAT X, MOUCHON A, et al. Quantitative structural and textural assessment of laminar pyrocarbons through Raman spectroscopy, electron diffraction and few other techniques. Carbon, 2006, 44(9): 1833.

DOI URL |

| [19] |

BECKER A, HUTTINGER K J. Chemistry and kinetics of chemical vapor deposition of pyrocarbon-III-pyrocarbon deposition from propylene and benzene in the low temperature regime. Carbon, 1998, 36(3): 201.

DOI URL |

| [1] | 穆浩洁, 张源江, 喻彬, 付秀梅, 周世斌, 李晓东. ZrO2掺杂Y2O3-MgO纳米复相陶瓷的制备及性能研究[J]. 无机材料学报, 2025, 40(3): 281-289. |

| [2] | 栾新刚, 何典蔚, 涂建勇, 成来飞. 2D平纹和3D针刺C/SiC复合材料的低速冲击破坏行为和失效机理[J]. 无机材料学报, 2025, 40(2): 205-214. |

| [3] | 范武刚, 曹雄, 周响, 李玲, 赵冠楠, 张兆泉. 8YSZ陶瓷在模拟压水堆水环境中的耐腐蚀性能[J]. 无机材料学报, 2024, 39(7): 803-809. |

| [4] | 姜灵毅, 庞生洋, 杨超, 张悦, 胡成龙, 汤素芳. C/SiC-BN复合材料的制备及氧化行为[J]. 无机材料学报, 2024, 39(7): 779-786. |

| [5] | 赵日达, 汤素芳. 多孔碳陶瓷化改进反应熔渗法制备陶瓷基复合材料研究进展[J]. 无机材料学报, 2024, 39(6): 623-633. |

| [6] | 方光武, 谢浩元, 张华军, 高希光, 宋迎东. CMC-EBC损伤耦合机理及一体化设计研究进展[J]. 无机材料学报, 2024, 39(6): 647-661. |

| [7] | 李广宇, 岳一凡, 王波, 张程煜, 索涛, 李玉龙. 2D-SiC/SiC复合材料的弹丸冲击损伤及冲击后拉伸性能[J]. 无机材料学报, 2024, 39(5): 494-500. |

| [8] | 陶顺衍, 杨加胜, 邵芳, 吴应辰, 赵华玉, 董绍明, 张翔宇, 熊瑛. 航机CMC热端部件用热喷涂涂层的机遇与挑战[J]. 无机材料学报, 2024, 39(10): 1077-1083. |

| [9] | 吴军, 徐培飞, 荆瑞, 张大海, 费庆国. SiC/SiC复合材料层板低速冲击及其剩余强度试验研究[J]. 无机材料学报, 2024, 39(1): 51-60. |

| [10] | 吴爽, 苟燕子, 王永寿, 宋曲之, 张庆雨, 王应德. 高温热处理对国产KD-SA型SiC纤维组成结构与力学性能的影响[J]. 无机材料学报, 2023, 38(5): 569-576. |

| [11] | 李建波, 田震, 蒋全伟, 于砺锋, 康慧君, 曹志强, 王同敏. 不同元素掺杂对CaTiO3微观结构及热电性能的影响[J]. 无机材料学报, 2023, 38(12): 1396-1404. |

| [12] | 产思义, 屠菊萍, 黄珂, 邵思武, 杨志亮, 刘鹏, 刘金龙, 陈良贤, 魏俊俊, 安康, 郑宇亭, 李成明. 2英寸MPCVD光学级均匀金刚石膜的制备研究[J]. 无机材料学报, 2023, 38(12): 1413-1419. |

| [13] | 吴东江, 赵紫渊, 于学鑫, 马广义, 由竹琳, 任冠辉, 牛方勇. Al2O3-TiCp复相陶瓷激光定向能量沉积直接增材制造[J]. 无机材料学报, 2023, 38(10): 1183-1192. |

| [14] | 邓陶丽, 陈河莘, 黑玲丽, 李淑星, 解荣军. 第二相引入荧光转换材料实现激光驱动高均匀性白光光源[J]. 无机材料学报, 2022, 37(8): 891-896. |

| [15] | 阮景, 杨金山, 闫静怡, 游潇, 王萌萌, 胡建宝, 张翔宇, 丁玉生, 董绍明. 三维碳化硅纳米线增强碳化硅陶瓷基复合材料的电磁屏蔽性能[J]. 无机材料学报, 2022, 37(5): 579-584. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||