无机材料学报 ›› 2024, Vol. 39 ›› Issue (3): 267-273.DOI: 10.15541/jim20230259 CSTR: 32189.14.10.15541/jim20230259

所属专题: 【结构材料】陶瓷基复合材料(202506); 【信息功能】MAX、MXene及其他二维材料(202506)

孙川1( ), 何鹏飞1, 胡振峰1, 王荣1, 邢悦1, 张志彬1, 李竞龙1, 万春磊2, 梁秀兵1(

), 何鹏飞1, 胡振峰1, 王荣1, 邢悦1, 张志彬1, 李竞龙1, 万春磊2, 梁秀兵1( )

)

收稿日期:2023-06-02

修回日期:2023-07-28

出版日期:2024-03-20

网络出版日期:2023-08-31

通讯作者:

梁秀兵, 研究员. E-mail: liangxb_d@163.com作者简介:孙川(1986-), 男, 博士. E-mail: sunchuanyeah@163.com

基金资助:

SUN Chuan1( ), HE Pengfei1, HU Zhenfeng1, WANG Rong1, XING Yue1, ZHANG Zhibin1, LI Jinglong1, WAN Chunlei2, LIANG Xiubing1(

), HE Pengfei1, HU Zhenfeng1, WANG Rong1, XING Yue1, ZHANG Zhibin1, LI Jinglong1, WAN Chunlei2, LIANG Xiubing1( )

)

Received:2023-06-02

Revised:2023-07-28

Published:2024-03-20

Online:2023-08-31

Contact:

LIANG Xiubing, professor. E-mail: liangxb_d@163.comAbout author:SUN Chuan (1986-), male, PhD. E-mail: sunchuanyeah@163.com

Supported by:摘要:

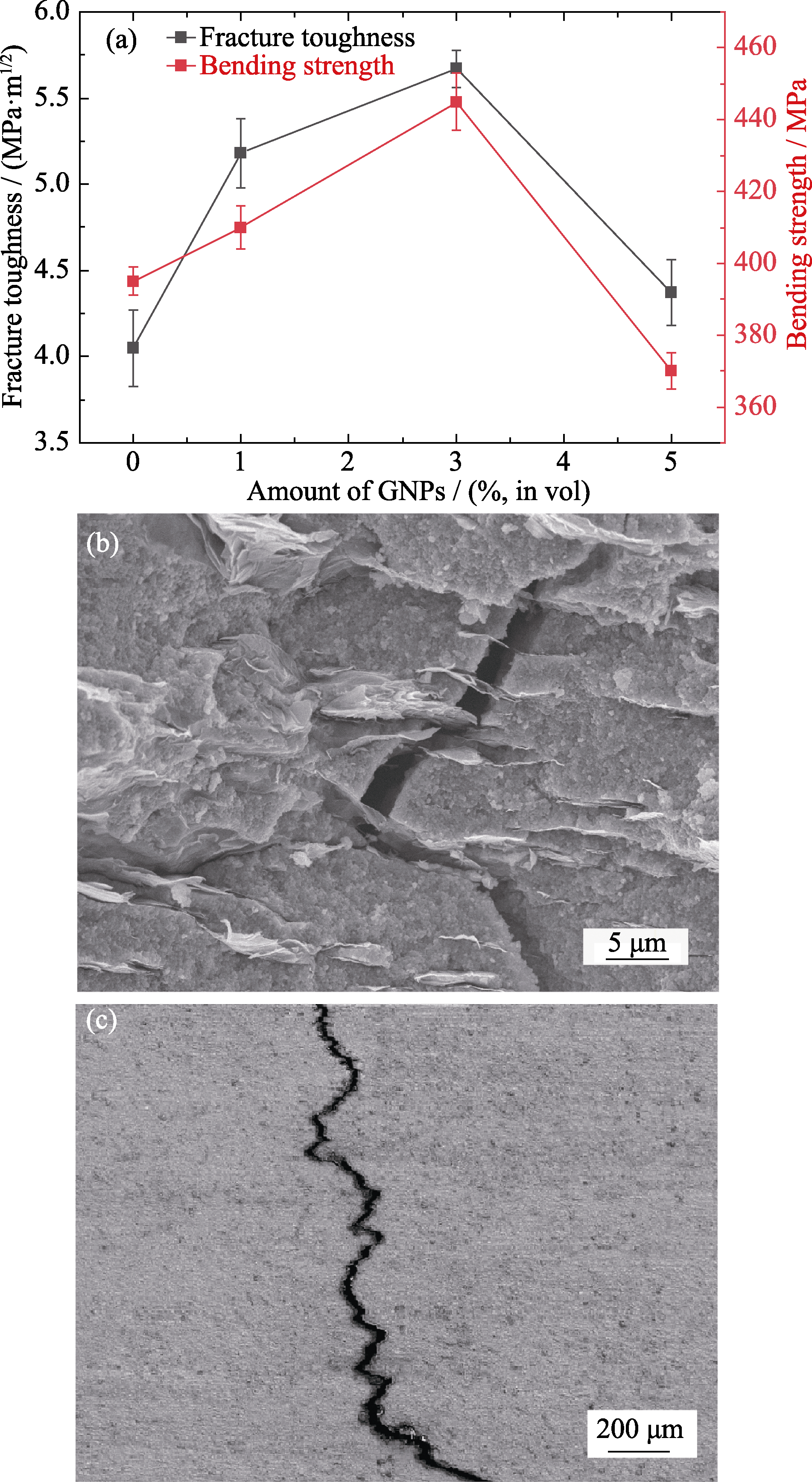

碳化硅陶瓷是一种重要工程材料, 但具有一定的脆性, 这限制了其进一步应用。二维石墨烯具有诸多优良特性, 可以作为第二相对碳化硅陶瓷材料进行性能改善。然而石墨烯在陶瓷基体中存在分散性较差等问题, 难以发挥其对陶瓷基体的改性作用。为解决以上问题, 本工作以陶瓷有机前驱体聚碳硅烷和工业可膨胀石墨为原料, 通过前驱体-纳米插层技术制备了少层石墨烯纳米片(GNPs)的体积分数分别为1%、3%和5%的SiC/GNPs陶瓷基复合材料。GNPs在SiC陶瓷基体中呈阵列态平行排布, 显示出极高的取向性; 随着GNPs含量增加, 阵列中GNPs的间距依次递减, 表现出一定的微观组织拓扑可调节性; 加入GNPs显著提高了SiC陶瓷的断裂韧性, 当GNPs含量为3%时, 样品的相对密度为98.5%, 抗弯强度为445 MPa, 断裂韧性达到最高值5.67 MPa·m1/2, 相比纯SiC陶瓷提高了40%, 由GNPs引发的裂纹偏转与桥连是主要的增韧机制。而进一步提高GNPs含量, 断裂韧性下降至4.37 MPa·m1/2。这种含有石墨烯阵列的复合材料可以用于新型“结构-功能一体化”SiC基陶瓷器件的设计与开发。

中图分类号:

孙川, 何鹏飞, 胡振峰, 王荣, 邢悦, 张志彬, 李竞龙, 万春磊, 梁秀兵. 含有石墨烯阵列的SiC基陶瓷材料的制备与力学性能[J]. 无机材料学报, 2024, 39(3): 267-273.

SUN Chuan, HE Pengfei, HU Zhenfeng, WANG Rong, XING Yue, ZHANG Zhibin, LI Jinglong, WAN Chunlei, LIANG Xiubing. SiC-based Ceramic Materials Incorporating GNPs Array: Preparation and Mechanical Characterization[J]. Journal of Inorganic Materials, 2024, 39(3): 267-273.

| No. | GNPs content/(%, in vol) | Relative density/% | GNPs average layer spacing/μm | KIC/(MPa·m1/2) | Bending strength/MPa |

|---|---|---|---|---|---|

| G0 | 0 | 99.2 | - | 4.05 | 395 |

| G1 | ~1 | 99.0 | 7.5 | 5.18 | 410 |

| G3 | ~3 | 98.5 | 5.2 | 5.67 | 445 |

| G5 | ~5 | 97.4 | 3.4 | 4.37 | 370 |

表1 SiC/GNPs复合材料的基本物性

Table 1 Basic physical properties of SiC/GNPs composites

| No. | GNPs content/(%, in vol) | Relative density/% | GNPs average layer spacing/μm | KIC/(MPa·m1/2) | Bending strength/MPa |

|---|---|---|---|---|---|

| G0 | 0 | 99.2 | - | 4.05 | 395 |

| G1 | ~1 | 99.0 | 7.5 | 5.18 | 410 |

| G3 | ~3 | 98.5 | 5.2 | 5.67 | 445 |

| G5 | ~5 | 97.4 | 3.4 | 4.37 | 370 |

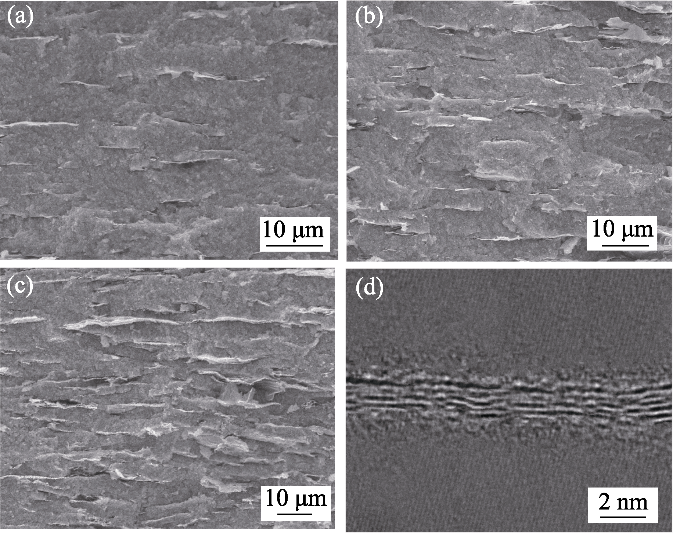

图4 SiC/GNPs复合材料的显微组织形貌

Fig. 4 SEM and TEM images of the fractured surface of SiC/GNPs bulks (a) SEM image of sample G1; (b) SEM image of sample G3; (c) SEM image of sample G5; (d) TEM image of GNP in SiC matrix

图7 SiC/GNPs复合材料的断裂性能

Fig. 7 Fracture properties of SiC/GNPs sample (a) Changing curves of fracture toughness and bending strength of SiC/GNPs with GNPs content; (b) SEM image of sample showing crack bridging; (c) SEM image of sample showing crack deflection

| [1] |

ZABELINA A A, SHCHERBAKOVA G I, FAIKOV P P, et al. SiC composites containing carbon nanotubes and oxide additives based on organoelementoxanes. Preparation by spark plasma sintering. Ceramics International, 2020, 46(3): 2786.

DOI URL |

| [2] |

OUYANG Q, WANG Y F, XU J, et al. Research progress of SiC fiber reinforced SiC composites for nuclear application. Journal of Inorganic Materials, 2022, 37(8): 821.

DOI |

| [3] |

KOYANAGI T, KATOH Y, NOZAWA T, et al. Recent progress in the development of SiC composites for nuclear fusion applications. Journal of Nuclear Materials, 2018, 511(1): 544.

DOI URL |

| [4] |

YAO X Y, LI K Z, REN J J, et al. Microstructure and fatigue behavior of high texture three-dimensional C/C composites prepared by mixed precursors. Journal of Inorganic Materials, 2020, 35(5): 589.

DOI |

| [5] | 李辰冉, 谢志鹏, 赵林. 碳化硅陶瓷材料烧结技术的研究与应用进展. 陶瓷学报, 2020, 41(2): 13. |

| [6] |

LIAO L, CHEN Z, XU X H, et al. Effects of oxidation curing and sintering temperature on the microstructure formation and heat transfer performance of freestanding polymer-derived SiC films for high-power LEDs. Ceramics International, 2018, 44(6): 6072.

DOI URL |

| [7] | 乔玉林, 薛胤昌, 刘军, 等. 聚合物先驱体材料体系的陶瓷化研究进展与展望. 材料导报, 2016, 30(11): 6. |

| [8] |

BALANDIN A A, GHOSH S, BAO W, et al. Superior thermal conductivity of single-layer graphene. Nano Letters, 2008, 8(3): 902.

DOI PMID |

| [9] |

BOLOTIN K I, SIKES K J, JIANG Z, et al. Ultrahigh electron mobility in suspended graphene. Solid State Communications, 2008, 146(9/10): 351.

DOI URL |

| [10] |

CHAE H K, SIBERIO-PÉREZ D Y, KIM J, et al. A route to high surface area, porosity and inclusion of large molecules in crystals. Nature, 2004, 427(6974): 523.

DOI |

| [11] |

MULLER S E, SANTHAPURAM R R, NAIR A K. Failure mechanisms in pre-cracked Ni-graphene nanocomposites. Computational Materials Science, 2018, 152: 341.

DOI URL |

| [12] |

LEE C, WEI X, KYSAR J W, et al. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science, 2008, 321(5887): 385.

DOI PMID |

| [13] |

WANG Y, HUANG Y, SONG Y, et al. Room-temperature ferromagnetism of graphene. Nano Letters, 2009, 9(1): 220.

DOI PMID |

| [14] | HAN T, HE P, WANG J, et al. The effect of vacancy defects on the tensile mechanical properties of single graphene sheets. Journal of Tongji University (Natural Science), 2010, 38(8): 1210. |

| [15] |

ZHANG B, HOU C Y, WANG H P, et al. Preparation and performance of reduced graphene oxide functionalized flexible and multicolor electrothermal chromatic films. Journal of Inorganic Materials, 2018, 33(11): 1232.

DOI |

| [16] |

YU Y, XIA F, HUANG Q, et al. Electrical conductivity of silicon carbonitride-reduced graphene oxide composites. Journal of the American Ceramic Society, 2017, 100(11): 5113.

DOI URL |

| [17] |

LEE B, KOO M Y, JIN S H, et al. Simultaneous strengthening and toughening of reduced graphene oxide/alumina composites fabricated by molecular-level mixing process. Carbon, 2014, 78: 212.

DOI URL |

| [18] |

SUN C, HUANG Y, SHEN Q, et al. Embedding two-dimensional graphene array in ceramic matrix. Science Advances, 2020, 6(39): eabb1338.

DOI URL |

| [19] | FAN Y, WANG L, LI J, et al. Preparation and electrical properties of graphene nanosheet/Al2O3 composites. Materials Science, 2010, 48(6): 1743. |

| [20] |

FAN Y, SONG Y, TUFAIL, et al. Liquid-phase assisted engineering of highly strong SiC composite reinforced by multiwalled carbon nanotubes. Advanced Science, 2020, 7(21): 2002225

DOI URL |

| [21] |

GAO J, DING Q, YAN P, et al. Highly improved microwave absorbing and mechanical properties in cold sintered ZnO by incorporating graphene oxide. Journal of the European Ceramic Society, 2022, 42(3): 993.

DOI URL |

| [22] |

YANG Y F, ZHU T B, DAN J N, et al. Mechanical and tribological properties of SiC-GNPs composites prepared by oscillatory pressure sintering. Ceramics International, 2022, 48(23): 34769.

DOI URL |

| [23] |

HANZEL O, TATARKO P. Preparation and properties of layered SiC-graphene composites for EDM. Materials, 2021, 14(11): 2916.

DOI URL |

| [24] |

HUANG Y H, JIANG D L, CHEN Z M, et al. Fabrication and property of rGO/SiC composite. Journal of Inorganic Materials, 2018, 33(11): 1147.

DOI URL |

| [25] |

RAZMJOO A, BAHARVANDI H R, EHSANI N. αSiC-βSiC- graphene composites. Scientific Reports, 2023, 13: 4306.

DOI |

| [26] |

FAN Y C, WANG L J, JIANG W. Graphene based oxide ceramic composites with high mechanical and functional performance: from preparation to property. Journal of Inorganic Materials, 2018, 33(2): 138.

DOI URL |

| [27] |

TANG J, LIU M, WEI Y, et al. An efficient and low-cost liquid silicon infiltration method to prepare SiC-coated carbon short fiber for fiber protection of Cf/SiC ceramic matrix composites. Ceramics International, 2021, 47(9): 13235.

DOI URL |

| [28] |

LIN B, WEI J, SUI T, et al. Effects of the surface processing on the tribological performance of C/SiCs under dry friction. Scientific Reports, 2020, 10: 5990.

DOI PMID |

| [29] |

HU X, HUANG M, KONG N, et al. Enhancing the electrical insulation of highly thermally conductive carbon fiber powders by SiC ceramic coating for efficient thermal interface materials. Composites Part B Engineering, 2021, 227(2): 109398.

DOI URL |

| [30] |

WANG X, SONG Z, CHENG Z, et al. Tensile creep properties and damage mechanisms of 2D-SiCf/SiC composites reinforced with low-oxygen high-carbon type SiC fiber. Journal of the European Ceramic Society, 2020, 40(14): 4872.

DOI URL |

| [31] | 邓卫斌, 李铁虎, 李昊, 等. 石墨烯/陶瓷复合材料的研究进展. 固体火箭技术, 2022, 45(1): 13. |

| [32] | 侯保江, 水涌涛, 孙向春, 等. 碳化硅陶瓷超声波辅助磨削表面完整性研究. 兵器装备工程学报, 2019(7): 3. |

| [33] | 徐广平, 何江荣, 刘鹏程, 等. 振荡压力烧结技术制备高性能碳化硅陶瓷. 中国陶瓷, 2022(3): 58. |

| [34] |

YIN Z, ZHANG X, HUANG Z, et al. Paraffin/expanded graphite phase change composites with enhanced thermal conductivity prepared by implanted β-SiC nanowires with chemical vapor deposition method. Materials Research Express, 2018, 5(2): 25503.

DOI URL |

| [35] | 贺国旭, 曹测祥, 韩永军, 等. 反应烧结制备碳化硅陶瓷及其性能研究. 耐火材料, 2022(2): 056. |

| [36] | 李红伟, 王瑶琪, 高莹, 等. 工业级石墨烯纳米片对碳化硅陶瓷摩擦磨损性能影响的研究. 中国陶瓷, 2021, 57(5): 7. |

| [37] |

PAPAGEORGIOU D G, KINLOCH I A, YOUNG R J. Mechanical properties of graphene and graphene-based nanocomposites. Progress in Materials science. 2017, 90(10): 75.

DOI URL |

| [38] |

RAMIRE Z, VEGA-DIAZ S M, MORELOS-GÓMEZ A, et al. Synthesis of conducting graphene/Si3N4 composites by spark plasma sintering. Carbon, 2013, 57: 425.

DOI URL |

| [39] |

COLEMAN J N, LOTYA M, O'NEILL A, et al. Two-dimensional nanosheets produced by liquid exfoliation of layered materials. Science, 2011, 331(6017): 568.

DOI PMID |

| [40] |

TAN Y, LUO H, ZHANG H, et al. Lightweight graphene nanoplatelet/boron carbide composite with high EMI shielding effectiveness. AIP Advances, 2016, 6(3): 35208.

DOI URL |

| [1] | 王鲁杰, 张玉新, 李彤阳, 于源, 任鹏伟, 王建章, 汤华国, 姚秀敏, 黄毅华, 刘学建, 乔竹辉. 深海服役环境下碳化硅陶瓷材料的腐蚀及磨损行为[J]. 无机材料学报, 2025, 40(7): 799-807. |

| [2] | 杨茗凯, 黄泽皑, 周芸霄, 刘彤, 张魁魁, 谭浩, 刘梦颖, 詹俊杰, 陈国星, 周莹. 基于Cu与金属氧化物-KCl熔融介质的甲烷热解制备少层石墨烯与氢气联产研究[J]. 无机材料学报, 2025, 40(5): 473-480. |

| [3] | 李紫薇, 弓伟露, 崔海峰, 叶丽, 韩伟健, 赵彤. 前驱体法制备(Zr, Hf, Nb, Ta, W)C-SiC复相陶瓷及性能研究[J]. 无机材料学报, 2025, 40(3): 271-280. |

| [4] | 高晨光, 孙晓亮, 陈君, 李达鑫, 陈庆庆, 贾德昌, 周玉. 基于湿法纺丝技术的SiBCN-rGO陶瓷纤维的组织结构、力学和吸波性能[J]. 无机材料学报, 2025, 40(3): 290-296. |

| [5] | 王悦, 王欣, 于显利. 室温铁磁性还原氧化石墨烯基全碳膜[J]. 无机材料学报, 2025, 40(3): 305-313. |

| [6] | 王浩, 刘学超, 郑重, 潘秀红, 徐锦涛, 朱新锋, 陈锟, 邓伟杰, 汤美波, 郭辉, 高攀. 非本征背照触发平面型4H-SiC光导开关性能研究[J]. 无机材料学报, 2024, 39(9): 1070-1076. |

| [7] | 王康龙, 殷杰, 陈晓, 王力, 刘学建, 黄政仁. 颗粒级配对选区激光烧结打印结合常压固相烧结制备碳化硅陶瓷性能的影响[J]. 无机材料学报, 2024, 39(7): 754-760. |

| [8] | 李红兰, 张俊苗, 宋二红, 杨兴林. Mo/S共掺杂的石墨烯用于合成氨: 密度泛函理论研究[J]. 无机材料学报, 2024, 39(5): 561-568. |

| [9] | 王艳莉, 钱心怡, 沈春银, 詹亮. 石墨烯基介孔锰铈氧化物催化剂: 制备和低温催化还原NO[J]. 无机材料学报, 2024, 39(1): 81-89. |

| [10] | 杨平军, 李铁虎, 李昊, 党阿磊. 石墨烯对环氧树脂泡沫炭石墨化、电导率和力学性能的影响[J]. 无机材料学报, 2024, 39(1): 107-112. |

| [11] | 董怡曼, 谭占鳌. 宽带隙钙钛矿基二端叠层太阳电池复合层的研究进展[J]. 无机材料学报, 2023, 38(9): 1031-1043. |

| [12] | 徐昊, 钱伟, 花银群, 叶云霞, 戴峰泽, 蔡杰. 皮秒激光加工的微织构对碳化硅润湿性的影响[J]. 无机材料学报, 2023, 38(8): 923-930. |

| [13] | 王雪瑶, 王武港, 李应卫, 彭奇, 梁瑞虹. PZT陶瓷本构行为与断裂性能的相关性研究[J]. 无机材料学报, 2023, 38(7): 839-844. |

| [14] | 陈强, 白书欣, 叶益聪. 热管理用高导热碳化硅陶瓷基复合材料研究进展[J]. 无机材料学报, 2023, 38(6): 634-646. |

| [15] | 顾薛苏, 殷杰, 王康龙, 崔崇, 梅辉, 陈忠明, 刘学建, 黄政仁. 颗粒级配对黏结剂喷射打印碳化硅陶瓷性能的影响[J]. 无机材料学报, 2023, 38(12): 1373-1378. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||