无机材料学报 ›› 2024, Vol. 39 ›› Issue (6): 623-633.DOI: 10.15541/jim20230608 CSTR: 32189.14.10.15541/jim20230608

所属专题: 【结构材料】超高温结构陶瓷(202506); 【结构材料】陶瓷基复合材料(202506)

收稿日期:2023-12-31

修回日期:2024-02-27

出版日期:2024-06-20

网络出版日期:2024-02-26

通讯作者:

汤素芳, 研究员. E-mail: sftang@imr.ac.cn作者简介:赵日达(1995-), 男, 博士, 助理研究员. E-mail: rdzhao16s@imr.ac.cn

基金资助:Received:2023-12-31

Revised:2024-02-27

Published:2024-06-20

Online:2024-02-26

Contact:

TANG Sufang, professor. E-mail: sftang@imr.ac.cnAbout author:ZHAO Rida (1995-), male, PhD, assistant professor. E-mail: rdzhao16s@imr.ac.cn

Supported by:摘要:

连续纤维增强陶瓷基复合材料具有高强韧、耐氧化的特性, 现已成为航空航天领域重要的高温结构候选材料。反应熔渗法可实现陶瓷基复合材料的大规模、短周期和低成本制备, 是目前最具有商业化前景的技术之一。然而, 传统反应熔渗法制得陶瓷基复合材料存在着基体碳残留、纤维刻蚀等问题, 导致材料力学与氧化-烧蚀性能不佳。为突破传统碳基体陶瓷化程度低的局限性, 相关研究人员采用碳基体孔结构构筑方法, 通过多孔碳基体取代传统熔渗预制体中致密碳基体, 以促进碳基体的陶瓷化转变及反应熔体的消耗, 进而实现陶瓷基复合材料的性能优化。本综述介绍了采用多孔碳陶瓷化策略制备SiC陶瓷、SiC/SiC复合材料、C/SiC复合材料及超高温陶瓷基复合材料的相关研究进展, 并且通过与传统反应熔渗法对比, 验证了多孔碳陶瓷化策略的优势, 同时总结了相关多孔碳基体制备方法的发展演变过程, 最后针对先进陶瓷基复合材料的基础理论与工艺技术需求, 对多孔碳陶瓷化改进反应熔渗法的未来发展方向进行了展望。

中图分类号:

赵日达, 汤素芳. 多孔碳陶瓷化改进反应熔渗法制备陶瓷基复合材料研究进展[J]. 无机材料学报, 2024, 39(6): 623-633.

ZHAO Rida, TANG Sufang. Research Progress of Ceramic Matrix Composites Prepared by Improved Reactive Melt Infiltration through Ceramization of Porous Carbon Matrix[J]. Journal of Inorganic Materials, 2024, 39(6): 623-633.

图1 用于制备(a-d) SiC[24⇓⇓-27], (e) SiC/SiC[33], (f, g) C/SiC[31,39]及(h) C/SiC-ZrC[18]的多孔碳典型形貌

Fig. 1 Typical morphologies of porous carbon for preparation of (a-d) SiC[24⇓⇓-27], (e) SiC/SiC[33], (f, g) C/SiC[31,39] and (h) C/SiC-ZrC[18]

| Carbon source | Density of porous carbon/(g·cm-3) | Median pore diameter of porous carbon/nm | Density of ceramic/ (g·cm-3) | Si content/% (in mass) | Ref. |

|---|---|---|---|---|---|

| Furfuryl alcohol | / | 1000 | / | / | [ |

| Furfuryl alcohol | 0.86 | 1300 | / | / | [ |

| Furfuryl | 0.74 | 2580 | 3.04 | 17.6 | [ |

| 0.65 | 1940 | 2.81 | 34.7 | ||

| 0.58 | 670 | 3.01 | / | ||

| 0.90 | 40 | 3.07 | / | ||

| Phenol formaldehyde | 0.79 | 2363 | 2.10 | 13.0 | [ |

| 0.79 | 1552 | 2.81 | 12.0 | ||

| 0.74 | 1226 | 2.88 | 16.0 | ||

| 0.74 | 642 | 2.91 | 14.0 | ||

| 0.73 | 190 | 2.93 | 16.0 | ||

| Phenol formaldehyde | 0.72 | 39.9 | 2.92 | 20.0 | [ |

| 0.72 | 39.9 | 3.07 | 15.4 | ||

| 0.79 | 28.8 | 3.08 | 12.2 | ||

| 0.78 | 38.7 | 2.95 | 3.1 | ||

| Phenol formaldehyde | 0.90 | 20.1 | 2.90 | 3.6 | [ |

表1 多孔碳的碳源、密度、中位孔径及生成陶瓷的密度与硅含量

Table 1 Carbon sources, densities and median pore diameters of porous carbon, densities and Si content of obtained ceramics

| Carbon source | Density of porous carbon/(g·cm-3) | Median pore diameter of porous carbon/nm | Density of ceramic/ (g·cm-3) | Si content/% (in mass) | Ref. |

|---|---|---|---|---|---|

| Furfuryl alcohol | / | 1000 | / | / | [ |

| Furfuryl alcohol | 0.86 | 1300 | / | / | [ |

| Furfuryl | 0.74 | 2580 | 3.04 | 17.6 | [ |

| 0.65 | 1940 | 2.81 | 34.7 | ||

| 0.58 | 670 | 3.01 | / | ||

| 0.90 | 40 | 3.07 | / | ||

| Phenol formaldehyde | 0.79 | 2363 | 2.10 | 13.0 | [ |

| 0.79 | 1552 | 2.81 | 12.0 | ||

| 0.74 | 1226 | 2.88 | 16.0 | ||

| 0.74 | 642 | 2.91 | 14.0 | ||

| 0.73 | 190 | 2.93 | 16.0 | ||

| Phenol formaldehyde | 0.72 | 39.9 | 2.92 | 20.0 | [ |

| 0.72 | 39.9 | 3.07 | 15.4 | ||

| 0.79 | 28.8 | 3.08 | 12.2 | ||

| 0.78 | 38.7 | 2.95 | 3.1 | ||

| Phenol formaldehyde | 0.90 | 20.1 | 2.90 | 3.6 | [ |

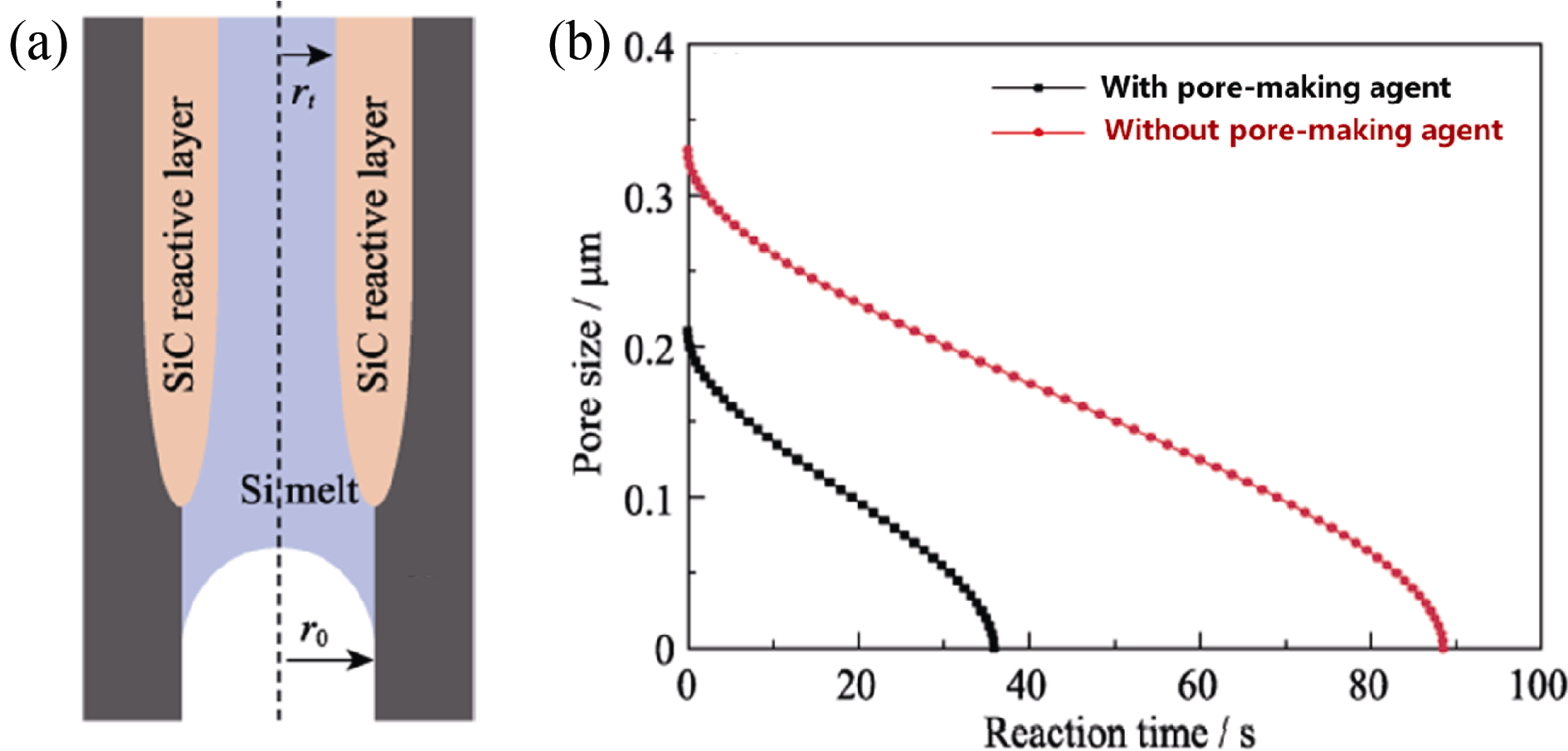

图3 (a) RMI过程中生成的陶瓷层示意图和(b)预制体孔径随渗透时间的变化曲线[33]

Fig. 3 (a) Schematic illustration of ceramic layer generated during the RMI and (b) curves of preforms pore radius vs infiltration time[33]

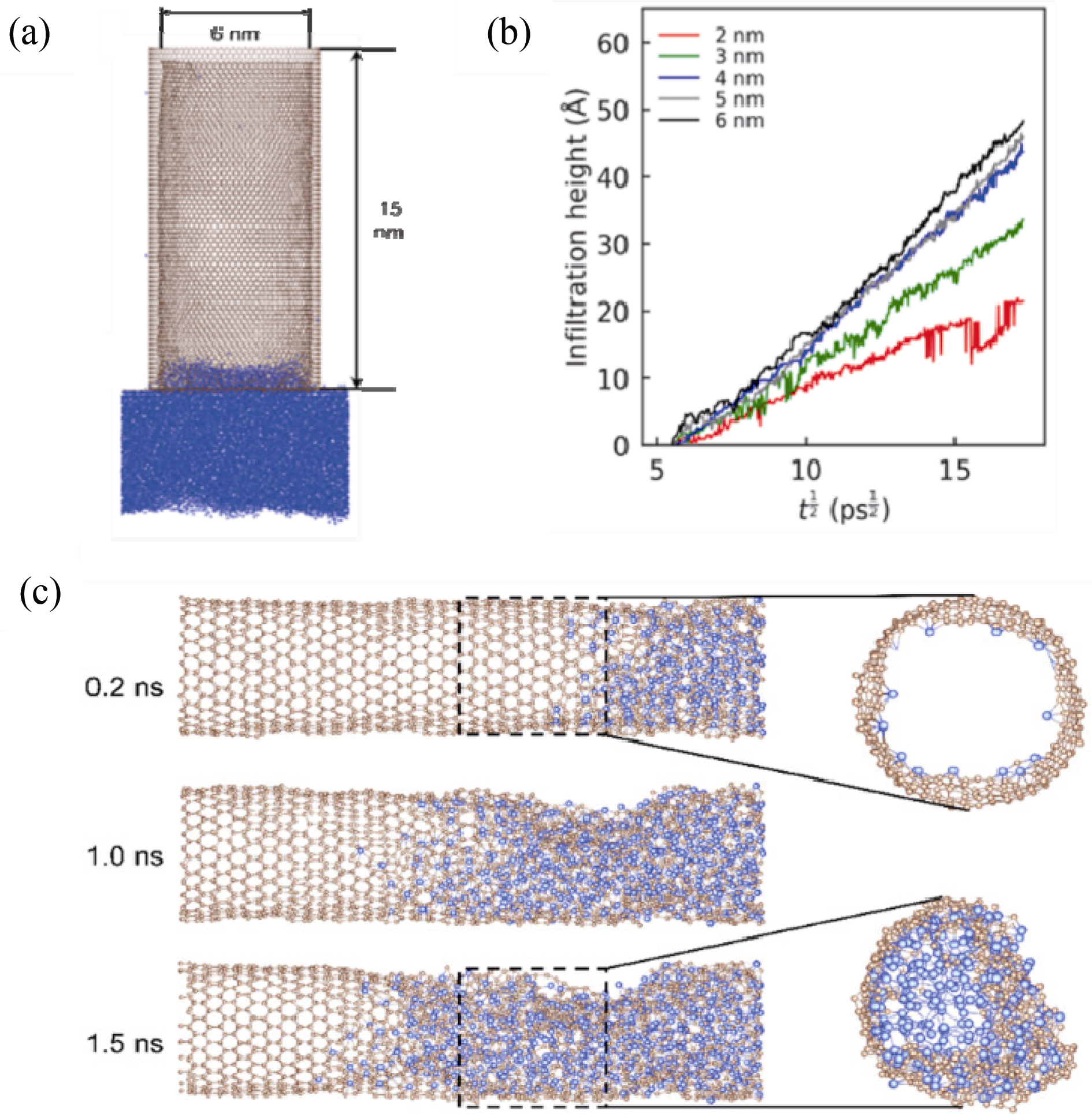

图6 (a)双壁碳纳米管液硅熔渗模型示意图, (b)液硅熔渗高度(H)与融渗时间(t)之间的对应关系和(c)液硅在内径2 nm双壁碳纳米管模型中的毛细熔渗行为[51]

Fig. 6 (a) Schematic illustration of liquid Si infiltration in double-walled carbon nanotubes, (b) relationship between infiltration height (H) and infiltration time (t) for liquid Si infiltration, and (c) capillary infiltration behavior of liquid Si into a double-walled carbon nanotubes with an inner tube diameter of 2 nm[51]

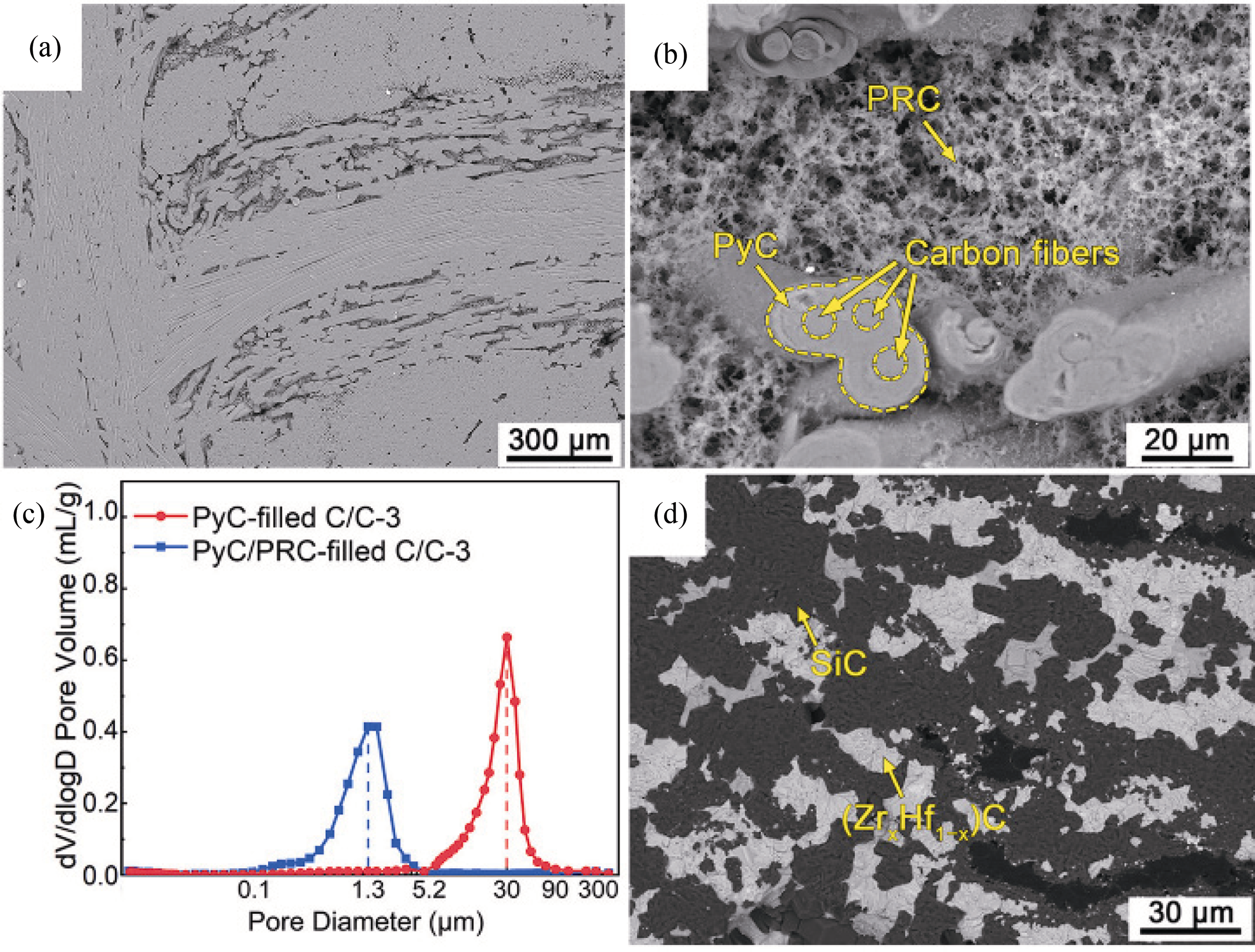

图8 多孔C/C的(a, b)微观结构与(c)孔径分布曲线, (d) C/C- SiC-(ZrxHf1-x)C的截面形貌[35]

Fig. 8 (a, b) Microstructures and (c) pore size distribution curves of the porous C/C, and (d) cross-sectional micrograph of the C/C-SiC-(ZrxHf1-x)C[35]

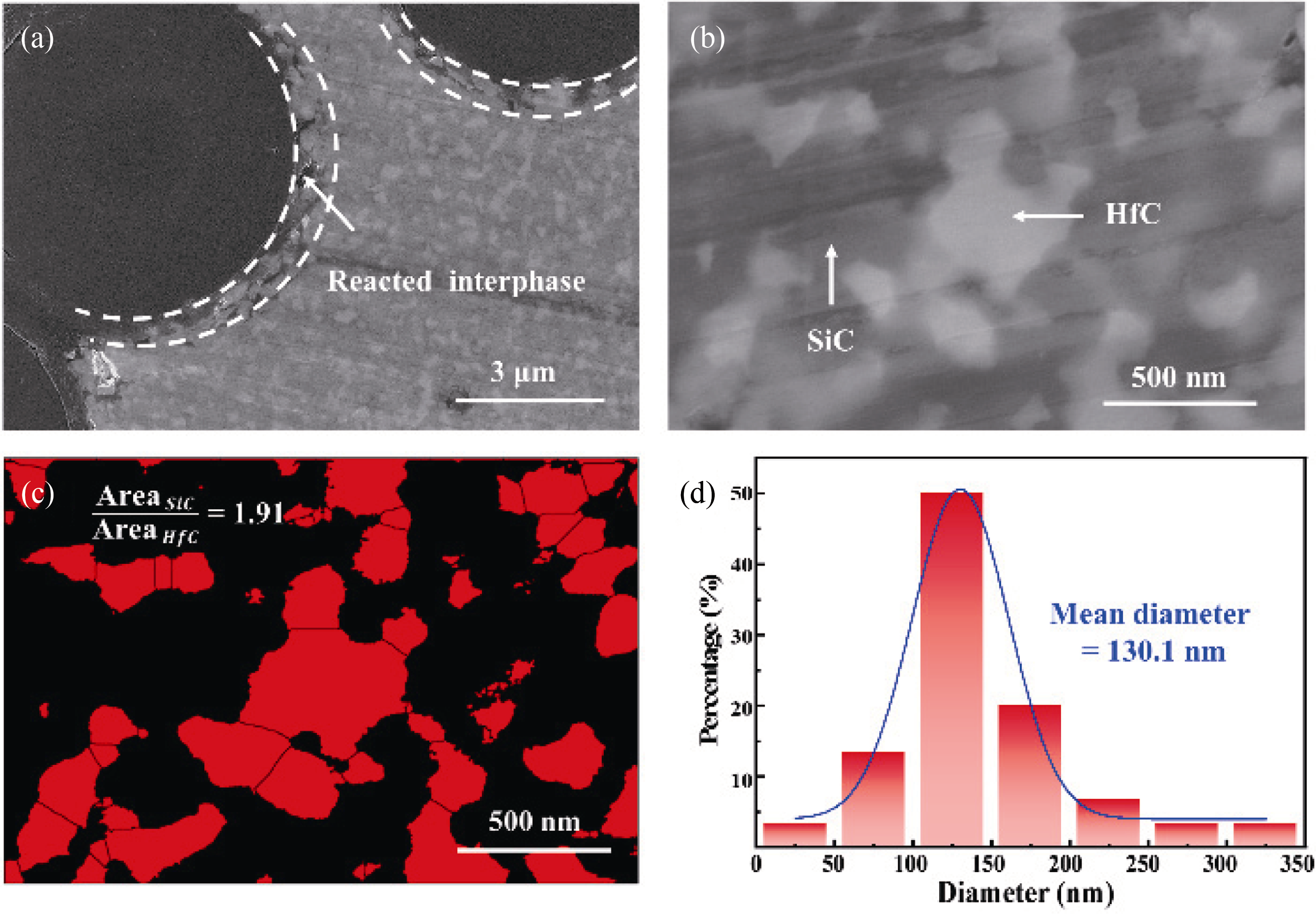

图9 (a) C/SiC-HfC与(b, c) SiC-HfC基体截面形貌, (d) HfC晶粒直径分布及其平均直径[18]

Fig. 9 Cross-sectional morphologies of (a) C/SiC-HfC and (b, c) SiC-HfC matrix, and (d) grain diameter distribution of HfC and its mean diameter[18]

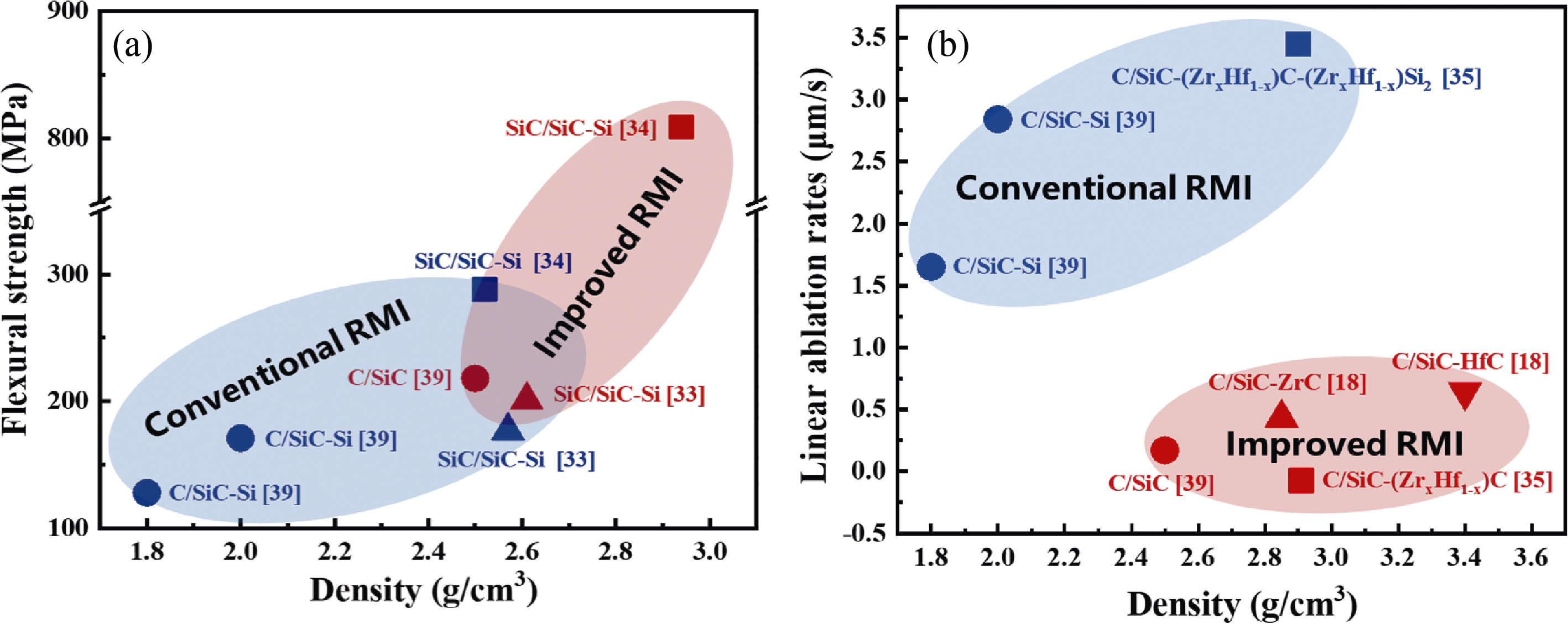

图10 传统RMI与多孔碳陶瓷化改进RMI制得陶瓷基复合材料的(a)弯曲强度与(b)2200 ℃线烧蚀率对比[18,33⇓-35,39]

Fig. 10 Comparison of (a) flexural strength and (b) 2200 ℃ linear ablation rates of ceramic matrix composites obtained by conventional RMI and improved RMI through ceramization of porous carbon matrix[18,33⇓-35,39]

| Preform | Preparation method of porous matrix | Median pore diameter/nm | Predominant pore size range/nm | Ceramic matrix composites | Flexural strength/MPa | Ref. |

|---|---|---|---|---|---|---|

| C/SiC-C | Phase separation | 1800 | 500-10000 | C/SiC-Si | / | [ |

| SiC/BNx/SiNx/C | Phase separation | / | 1000-4500 | SiC/BNx/SiNx/SiC-Si | / | [ |

| C/B4C-C | Sol-Gel | 39800 | 25000-75000 | C/ZrB2-SiC-ZrC | 231 | [ |

| C/B4C-Al2O3-C | Sol-Gel | / | 10-10000 | C/B4C-Al2O3-SiC-Si | 300 | [ |

| C/ZrC-C | Carbothermal reduction | / | 4-130000 | C/ZrC-SiC-ZrSi2 | 380 | [ |

| C/C | Phase separation | 41.6 | 10-80 | C/SiC | 218 | [ |

| SiC/SiC-C | Phase separation | / | 100-5000 | SiC/SiC-Si | 201 | [ |

| C/C | Phase separation | 1300 | 100-5200 | C/C-SiC-(ZrxHf1−x)C | / | [ |

| SiC/SiC-C | Sol-Gel | / | 500-10000 | SiC/SiC-Si | 809 | [ |

| C/C | Phase separation | / | 10-130 | C/SiC-ZrC | 288 | [ |

| C/SiC-HfC | 251 |

表2 多孔预制体的基体制备方法、中位孔径、孔径分布范围及所生成陶瓷基复合材料的弯曲强度

Table 2 Preparation methods of porous matrix in preform, median pore diameters and predominant pore size ranges of preform, and flexural strength of the obtained ceramic matrix composites

| Preform | Preparation method of porous matrix | Median pore diameter/nm | Predominant pore size range/nm | Ceramic matrix composites | Flexural strength/MPa | Ref. |

|---|---|---|---|---|---|---|

| C/SiC-C | Phase separation | 1800 | 500-10000 | C/SiC-Si | / | [ |

| SiC/BNx/SiNx/C | Phase separation | / | 1000-4500 | SiC/BNx/SiNx/SiC-Si | / | [ |

| C/B4C-C | Sol-Gel | 39800 | 25000-75000 | C/ZrB2-SiC-ZrC | 231 | [ |

| C/B4C-Al2O3-C | Sol-Gel | / | 10-10000 | C/B4C-Al2O3-SiC-Si | 300 | [ |

| C/ZrC-C | Carbothermal reduction | / | 4-130000 | C/ZrC-SiC-ZrSi2 | 380 | [ |

| C/C | Phase separation | 41.6 | 10-80 | C/SiC | 218 | [ |

| SiC/SiC-C | Phase separation | / | 100-5000 | SiC/SiC-Si | 201 | [ |

| C/C | Phase separation | 1300 | 100-5200 | C/C-SiC-(ZrxHf1−x)C | / | [ |

| SiC/SiC-C | Sol-Gel | / | 500-10000 | SiC/SiC-Si | 809 | [ |

| C/C | Phase separation | / | 10-130 | C/SiC-ZrC | 288 | [ |

| C/SiC-HfC | 251 |

| [1] | 张俊敏, 蔡飞燕, 靳喜海, 等. 连续纤维增强陶瓷基复合材料研究与应用进展. 陶瓷学报, 2023, 44(2):195. |

| [2] | 赵日达.纳米多孔碳均匀陶瓷化制备超高温陶瓷基复合材料及其性能研究. 沈阳: 中国科学技术大学博士学位论文, 2022. |

| [3] | JIANG Y, HU C L, LIANG B, et al. Cyclic ablation resistance at 2300 ℃ of (Hf0.4Zr0.4Ta0.2)B2-SiC-Si coating for C/SiC composites prepared by SiC-assisted reactive infiltration of silicon. Surface & Coatings Technology, 2022, 451: 129072. |

| [4] | TANG P J, HU C L, PANG S Y, et al. Self-densifcation behavior, interfacial bonding and cyclic ablation resistance of HfSi2-ZrSi2 modified SiC/ZrB2-SiC/SiC coating for Cf/SiC composite. Corrosion Science, 2023, 219: 111223. |

| [5] | TANG P J, HU C L, PANG S Y, et al. Interfacial modification and cyclic ablation behaviors of a SiC/ZrB2-SiC/SiC triple-layer coating for C/SiC composites at above 2000 ℃. Corrosion Science, 2020, 169: 108604. |

| [6] |

OUYANG Q, WANG Y F, XU J, et al. Research progre.ss of SiC fiber reinforced SiC composites for nuclear application. Journal of Inorganic Materials, 2022, 37(8):821.

DOI |

| [7] |

CHEN Q, BAI S X, YE Y. Highly thermal conductive silicon carbide ceramics matrix composites for thermal management: a review. Journal of Inorganic Materials, 2023, 38(6):634.

DOI |

| [8] |

ZHANG B Y, WANG L, WANG X M, et al. Effect of precursors on impregnation behaviors of C/SiC composites. Journal of Inorganic Materials, 2020, 35(9):1017.

DOI |

| [9] | SHEN X Y, MA Q, XUE Y D, et al. Effects of multilayered interfaces on mechanical damage of SiCf/SiC composites. Journal of Inorganic Materials, 2023, 38(8):917. |

| [10] | JI S Y, LIANG B, YANG B, et al. Long-term oxidation behaviors and strength retention properties of self-healing SiCf/SiC-SiBCN composites. Journal of the European Ceramic Society, 2023, 43(5): 1843. |

| [11] | YAO J J, PANG S Y, HU C L, et al. Mechanical, oxidation and ablation properties of C/(C-SiC)CVI-(ZrC-SiC)PIP composites. Corrosion Science, 2020, 162: 108200. |

| [12] |

JU Y C, LIU X Y, WANG Q, et al. Ablation behavior of ultra-high temperature composite ceramic matrix composites. Journal of Inorganic Materials, 2022, 37(1):86.

DOI |

| [13] |

LIU Y F, FENG X, WANG J M, et al. Preparation and properties of high-performance needled C/C composites. Journal of Inorganic Materials, 2020, 35(10):1105.

DOI |

| [14] | PANG S Y, WANG P Y, HU C L, et al. Carbon fiber preform's structure on mechanical property of C/C composites and bolts. Journal of Inorganic Materials, 2019, 34(12):1272. |

| [15] |

PAN B C, REN P H, ZHOU T J, et al. Microstructure and property of thermal insulation coating on the carbon fiber reinforced epoxy resin composites. Journal of Inorganic Materials, 2020, 35(8):947.

DOI |

| [16] | 宋若康, 张梦珊, 戴珍, 等. 烧蚀型防热/吸波多功能一体化复合材料的制备及性能. 复合材料学报, 2023, 41(1):252. |

| [17] | SCITI D, ZOLI L, REIMER T, et al. A systematic approach for horizontal and vertical scale up of sintered ultra-high temperature ceramic matrix composites for aerospace-advances and perspectives. Composites Part B: Engineering, 2022, 234: 109709. |

| [18] | ZHAO R D, PANG S Y, LIANG B, et al. Comparative ablation behaviors of C/SiC-ZrC and C/SiC-HfC composites prepared by ceramization of carbon aerogel preforms. Corrosion Science, 2023, 225: 111623. |

| [19] | 孙倩, 张会丰, 黄传兵, 等. 碳纤维增强超高温陶瓷基复合材料的多相反应制备与抗烧蚀性能. 过程工程学报, 2023, 23(2):10. |

| [20] | 姜毅, 李国栋, 于士杰, 等. 浆料注射法制备Cf/SiC-ZrC复合材料的力学和抗氧化性能. 粉末冶金材料科学与工程, 2022, 27(2):151. |

| [21] | YAO J J, LIANG B, HU C L, et al. Pitch resin addition induced evolution of composition, microstructure and mechanical property of C/C-SiC-ZrC composites. Journal of the European Ceramic Society, 2022, 42(14):6412. |

| [22] |

ZHANG S, FU Q Q, ZHANG P, et al. Influence of high temperature treatment of C/C porous preform on friction and wear behavior of C/C-SiC composites. Journal of Inorganic Materials, 2023, 38(5):561.

DOI |

| [23] | WANG Y X, TAN S H, JIANG D L. Research and development of reaction sintered silicon carbide. Journal of Inorganic Materials, 2004, 19(3):456. |

| [24] | MESSNER R P, CHIANG Y M. Liquid-phase reaction-bonding of silicon carbide using alloyed silicon-molybdenum melts. Journal of the American Ceramic Society, 1990, 73(5):1193. |

| [25] | CHIANG Y M, MESSNER R P, TERWILLIGER C D, et al. Reaction-formed silicon carbide. Materials Science and Engineering: A, 1991, 144(1/2):63. |

| [26] | SINGH M, DICKERSON R M. Microstructure and mechanical properties of reaction-formed silicon carbide (RFSC) ceramics. Materials Science and Engineering: A, 1994, 187(2):183. |

| [27] | XU S J, QIAO G J, LI D C, et al. Reaction forming of silicon carbide ceramic using phenolic resin derived porous carbon preform. Journal of the European Ceramic Society, 2009, 29(11):2395. |

| [28] | SINGH M, DICKERSON R M. Characterization of SiC fiber (SCS-6) reinforced-reaction formed silicon carbide matrix composites. Journal of Materials Research, 1996, 11(3):746. |

| [29] | SINGH M, DICKERSON R M, OLMSTEAD F A, et al. SiC (SCS-6) fiber reinforced-reaction formed SiC matrix composites: microstructure and interfacial properties. Journal of Materials Research, 1997, 12(3):706. |

| [30] | MAINZER B, RODER K, WÖCKEL L, et al. Development of wound SiCBNx/SiNx/SiC with near stoichiometric SiC matrix via LSI process. Journal of the European Ceramic Society, 2016, 36(7):1571. |

| [31] | ZHONG Q, ZHANG X Y, DONG S M, et al. Reactive melt infiltrated Cf/SiC composites with robust matrix derived from novel engineered pyrolytic carbon structure. Ceramics International, 2017, 43(7):5832. |

| [32] | 董绍明, 钟强, 张翔宇, 等.一种高致密的碳化硅陶瓷基复合材料及其制备方法: CN106588060A. 2017-04-26. |

| [33] | ZHANG J M, CHEN XW, LIAO C J, et al. Optimizing microstructure and properties of SiCf/SiC composites prepared by reactive melt infiltration. Journal of Inorganic Materials, 2021, 36(10):1103. |

| [34] | GUO G D, YE F, CHENG L F, et al. A novel porous carbon synthesized to serve in the preparation of highly dense and high-strength SiC/SiC by reactive melt infiltration. Composites Part A: Applied Science and Manufacturing, 2024, 176: 107839. |

| [35] | LIU Z D, WANG Y L, XIONG X, et al. Structural optimization and air-plasma ablation behaviors of C/C-SiC-(ZrxHf1-x)C composites prepared by reactive melt infiltration method. Corrosion Science, 2023, 222: 111408. |

| [36] | 冯志海, 刘宇峰, 张中伟, 等. 一种基于熔融渗硅工艺的复合材料、碳/碳多孔体及其制备方法: CN108794040A. 2018-11-13. |

| [37] | 杨良伟, 王鹏, 宋环君, 等.一种碳/碳化硅-碳化锆陶瓷基复合材料的制备方法: CN112321315A. 2021-02-05. |

| [38] | 汤素芳, 赵日达, 庞生洋, 等.一种多孔碳均匀陶瓷化制备碳化硅基复合材料的方法: CN115557800A. 2023-01-03. |

| [39] | ZHAO R D, PANG S Y, HU C L, et al. Fabrication of C/SiC composites by siliconizing carbon fiber reinforced nanoporous carbon matrix preforms and their properties. Journal of the European Ceramic Society, 2023, 43(2):273. |

| [40] | WU Y, ZHAO R D, LIANG B, et al. Construction of C/SiC-Cu3Si-Cu interpenetrating composites for long-duration thermal protection at 2500 ℃ by cooperative active-passive cooling. Composites Part B: Engineering, 2023, 266: 111015. |

| [41] | SINGH M, DICKERSON R M. Reactive melt infiltration of silicon-molybdenum alloys into microporous carbon preforms. Materials Science and Engineering: A, 1995, 194(2):193. |

| [42] | SINGH M. Joining of sintered silicon carbide ceramics for high-temperature applications. Journal of materials science letters, 1998, 17(6):459. |

| [43] | WANG Y X, TAN S H, JIANG D L. The effect of porous carbon preform and the infiltration process on the properties of reaction-formed SiC. Carbon, 2004, 42(8/9): 1833. |

| [44] | WANG Y X, TAN S H, JIANG D L. The fabrication of reaction- formed silicon carbide with controlled microstructure by infiltrating a pure carbon preform with molten Si. Ceramics International, 2004, 30(3):435. |

| [45] | XU S J, QIAO G J, WANG H J, et al. Preparation of mesoporous carbon by phenol resin polymerization-dependent phase separation and pyrolysis. Journal of Inorganic Materials, 2008, 23(5):971. |

| [46] | 徐顺建, 乔冠军. 复杂形状 SiC 陶瓷的模板法成型研究进展. 材料导报, 2009, 23(21):59. |

| [47] | XU S J, QIAO G J, WANG H J, et al. Microstructure evolution and reaction mechanism of microporous carbon derived SiC ceramic. Journal of Inorganic Materials, 2009, 24(2):291. |

| [48] | 袁志勇.树脂碳源反应烧结碳化硅陶瓷凝胶注模成型机理研究. 哈尔滨: 哈尔滨工业大学博士学位论文, 2014. |

| [49] | 吴西士.Cf/SiC复合材料陶瓷连接层的设计、 制备与连接性能研究. 上海: 中国科学院上海硅酸盐研究所博士学位论文, 2019. |

| [50] | WU X S, ZHU Y Z, HUANG Q, et al. Effect of pore structure of organic resin-based porous carbon on joining properties of Cf/SiC composites. Journal of Inorganic Materials, 2022, 37(12):1275. |

| [51] | ZHANG K Y, ZHAO R D, YANG Y Q, et al. Capillary infiltration of liquid silicon in carbon nanotubes: a molecular dynamics simulation. Journal of Materials Science & Technology, 2023, 144: 219. |

| [52] | ZHAO R D, HU C L, WANG Y H, et al. Construction of sandwich-structured C/C-SiC and C/C-SiC-ZrC composites with good mechanical and anti-ablation properties. Journal of the European Ceramic Society, 2022, 42(4):1219. |

| [53] | WANG D K, DONG S M, ZHOU H J, et al. Fabrication and microstructure of 3D Cf/ZrC-SiC composites: through RMI method with ZrO2 powders as pore-making agent. Ceramics International, 2016, 42(6):6720. |

| [54] | NI D W, WANG J X, DONG S M, et al. Fabrication and properties of Cf/ZrC-SiC-based composites by an improved reactive melt infiltration. Journal of the American Ceramic Society, 2018, 101(8):3253. |

| [55] | 陈小武, 董绍明, 倪德伟, 等. 碳纤维增强超高温陶瓷基复合材料研究进展. 中国材料进展, 2019, 38(9):842. |

| [56] | CHEN X W, NI D W, KAN Y M, et al. Reaction mechanism and microstructure development of ZrSi2 melt-infiltrated Cf/SiC-ZrC- ZrB2 composites: the influence of preform pore structures. Journal of Materiomics, 2018, 4(3):266. |

| [57] | MAGNANT J, MAILLÉ L, PAILLER R, et al. Carbon fiber/reaction-bonded carbide matrix for composite materials- manufacture and characterization. Journal of the European Ceramic Society, 2012, 32(16):4497. |

| [58] | GAO Y Q, LIU Y S, WANG J, et al. Formation mechanism of Si-Y-C ceramic matrix by reactive melt infiltration using Si-Y alloy and properties of C/Si-Y-C composites. Ceramics International, 2020, 46(11):18976. |

| [59] | 史扬帆, 潘勇, 高扬, 等. 超高温陶瓷及其复合材料的稀土改性研究进展. 硅酸盐通报, 2023, 42(2):682. |

| [60] | GUO W J, HU J, FANG W, et al. A novel strategy for rapid fabrication of continuous carbon fiber reinforced (TiZrHfNbTa)C high-entropy ceramic composites: high-entropy alloy in-situ reactive melt infiltration. Journal of the European Ceramic Society, 2023, 43(6):2295. |

| [61] | HE H R, TANG J G, GUO W J, et al. Microstructures and formation mechanism of continuous carbon fiber-reinforced (TiZrHfNbTa)C high-entropy ceramic composites fabricated via high-entropy alloy reactive melt infiltration. Ceramics International, 2023, 49(22):36997. |

| [62] | GUO W J, BAI S X, YE Y C. Controllable fabrication and mechanical properties of C/C-SiC composites based on an electromagnetic induction heating reactive melt infiltration. Journal of the European Ceramic Society, 2021, 41(4):2347. |

| [63] | ZOU X G, NI D, CHEN B W, et al. Fabrication and properties of Cf/Ta4HfC5-SiC composite via precursor infiltration and pyrolysis. Journal of the American Ceramic Society, 2021, 104(12):6601. |

| [64] | CAI F Y, NI D W, BAO W C, et al. Ablation behavior and mechanisms of Cf/(Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2) C-SiC high-entropy ceramic matrix composites. Composites Part B: Engineering, 2022, 243: 110177. |

| [1] | 朱文杰, 唐璐, 陆继长, 刘江平, 罗永明. 钙钛矿型氧化物催化氧化挥发性有机化合物的研究进展[J]. 无机材料学报, 2025, 40(7): 735-746. |

| [2] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [3] | 吴琼, 沈炳林, 张茂华, 姚方周, 邢志鹏, 王轲. 铅基织构压电陶瓷研究进展[J]. 无机材料学报, 2025, 40(6): 563-574. |

| [4] | 张碧辉, 刘小强, 陈湘明. Ruddlesden-Popper结构杂化非常规铁电体的研究进展[J]. 无机材料学报, 2025, 40(6): 587-608. |

| [5] | 吴杰, 杨帅, 王明文, 李景雷, 李纯纯, 李飞. 铅基织构压电陶瓷的发展历程、现状与挑战[J]. 无机材料学报, 2025, 40(6): 575-586. |

| [6] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| [7] | 田睿智, 兰正义, 殷杰, 郝南京, 陈航榕, 马明. 基于微流控技术的纳米无机生物材料制备: 原理及其研究进展[J]. 无机材料学报, 2025, 40(4): 337-347. |

| [8] | 张继国, 吴田, 赵旭, 杨钒, 夏天, 孙士恩. 钠离子电池正极材料循环稳定性提升策略及产业化进程[J]. 无机材料学报, 2025, 40(4): 348-362. |

| [9] | 殷杰, 耿佳毅, 王康龙, 陈忠明, 刘学建, 黄政仁. SiC陶瓷的3D打印成形与致密化新进展[J]. 无机材料学报, 2025, 40(3): 245-255. |

| [10] | 谌广昌, 段小明, 朱金荣, 龚情, 蔡德龙, 李宇航, 杨东雷, 陈彪, 李新民, 邓旭东, 余瑾, 刘博雅, 何培刚, 贾德昌, 周玉. 直升机特定结构先进陶瓷材料研究进展与应用展望[J]. 无机材料学报, 2025, 40(3): 225-244. |

| [11] | 范晓波, 祖梅, 杨向飞, 宋策, 陈晨, 王子, 罗文华, 程海峰. 质子调控型电化学离子突触研究进展[J]. 无机材料学报, 2025, 40(3): 256-270. |

| [12] | 栾新刚, 何典蔚, 涂建勇, 成来飞. 2D平纹和3D针刺C/SiC复合材料的低速冲击破坏行为和失效机理[J]. 无机材料学报, 2025, 40(2): 205-214. |

| [13] | 海热古·吐逊, 郭乐, 丁嘉仪, 周嘉琪, 张学良, 努尔尼沙·阿力甫. 上转换荧光探针辅助的光学成像技术在肿瘤显影中的应用研究进展[J]. 无机材料学报, 2025, 40(2): 145-158. |

| [14] | 孙树娟, 郑南南, 潘昊坤, 马猛, 陈俊, 黄秀兵. 单原子催化剂制备方法的研究进展[J]. 无机材料学报, 2025, 40(2): 113-127. |

| [15] | 陶桂龙, 支国伟, 罗添友, 欧阳佩东, 衣新燕, 李国强. 空腔型薄膜体声波滤波器的关键技术进展[J]. 无机材料学报, 2025, 40(2): 128-144. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||