无机材料学报 ›› 2024, Vol. 39 ›› Issue (6): 647-661.DOI: 10.15541/jim20240004 CSTR: 32189.14.10.15541/jim20240004

所属专题: 【结构材料】热障与环境障涂层(202506); 【材料计算】材料模拟计算(202506)

方光武1,2( ), 谢浩元2, 张华军3, 高希光2, 宋迎东2

), 谢浩元2, 张华军3, 高希光2, 宋迎东2

收稿日期:2024-01-03

修回日期:2024-03-11

出版日期:2024-06-20

网络出版日期:2024-03-22

作者简介:方光武(1989-), 男, 博士. E-mail: fgwu89424@nuaa.edu.cn

基金资助:

FANG Guangwu1,2( ), XIE Haoyuan2, ZHANG Huajun3, GAO Xiguang2, SONG Yingdong2

), XIE Haoyuan2, ZHANG Huajun3, GAO Xiguang2, SONG Yingdong2

Received:2024-01-03

Revised:2024-03-11

Published:2024-06-20

Online:2024-03-22

About author:FANG Guangwu (1989-), male, PhD. E-mail: fgwu89424@nuaa.edu.cn

Supported by:摘要:

陶瓷基复合材料与环境障碍涂层组合(CMC-EBC)是目前航空航天领域最具应用前景的热结构材料体系。本文对CMC-EBC失效机理与分析模型的研究进展进行综述。首先, 简要回顾了CMC-EBC材料体系的发展及主要制备工艺。然后, 综述了CMC-EBC在服役环境下的主要损伤模式与失效机理, 总结发现CMC预制体结构、孔洞缺陷和EBC内裂纹等损伤演化相互影响, 这种细观损伤模式的耦合是决定其寿命的关键因素之一, 但目前的机理研究主要集中于涂层本身性能及其受环境因素的影响, 缺乏对涂层和复合材料编制结构在损伤演化过程中协同效应的考虑。接下来, 详细分析了CMC-EBC的失效模拟与预测模型研究的历史与现状, 指出其中存在的问题, 包括环境因素建模方法和损伤耦合演化模拟技术。目前大部分工作致力于分别开发CMC和EBC的失效模型, 而对于CMC-EBC构件的失效预测应考虑其损伤演化与微观结构之间的相互耦合影响。最后, 对CMC-EBC材料体系研发与服役性能预测方法进行了展望, 认为CMC本体和EBC失效模式相互耦合, 开展结构功能一体化设计和分析是CMC-EBC构件研究的趋势。

中图分类号:

方光武, 谢浩元, 张华军, 高希光, 宋迎东. CMC-EBC损伤耦合机理及一体化设计研究进展[J]. 无机材料学报, 2024, 39(6): 647-661.

FANG Guangwu, XIE Haoyuan, ZHANG Huajun, GAO Xiguang, SONG Yingdong. Progress of Damage Coupling Mechanism and Integrated Design Method for CMC-EBC[J]. Journal of Inorganic Materials, 2024, 39(6): 647-661.

| Aero-engine | Material | Component |

|---|---|---|

| M88-2 | C/SiC | Nozzle |

| F119 | SiC/SiC | Nozzle |

| F100 | SiC/SiC | Seal |

| XTC97 | SiC/SiC | Combustion chamber |

| F136 | SiC/SiC | Turbine vane |

| EJ200 | SiC/SiC | Combustion nozzle |

| Leap-1 | SiC/SiC | Turbine vane |

表1 CMC主要应用部件[4]

Table 1 Typical application components of CMC[4]

| Aero-engine | Material | Component |

|---|---|---|

| M88-2 | C/SiC | Nozzle |

| F119 | SiC/SiC | Nozzle |

| F100 | SiC/SiC | Seal |

| XTC97 | SiC/SiC | Combustion chamber |

| F136 | SiC/SiC | Turbine vane |

| EJ200 | SiC/SiC | Combustion nozzle |

| Leap-1 | SiC/SiC | Turbine vane |

| Material | Average CTE/ (×10-6, K-1) | Elastic modulus/GPa | Melting point/℃ |

|---|---|---|---|

| SiC/SiC CMC | 4.75[ | 220[ | 2827[ |

| Si | 3.5-4.5[ | 97[ | 1416[ |

| Mullite | 5-6[ | 150[ | 1800[ |

| BSAS | 4-5[ | 32[ | 1300[ |

| Lu2SiO5 | 6.7[ | 169[ | - |

| Yb2O3 | 6.8-8.4[ | - | 2415[ |

| Yb2SiO5 | 7.1-7.4[ | 158[ | 1950[ |

| Yb2Si2O7 | 3.6-4.5[ | 168[ | 1850[ |

| Y2SiO5 | 6.9[ | 124[ | 1980[ |

| Y2Si2O7 | 3.9[ | 155[ | 1775[ |

| Er2SiO5 | 5-7[ | 159[ | 1980[ |

| Er2SiO5 | 5-7[ | 159[ | 1980[ |

| Gd2SiO5 | 10.3[ | - | 1900[ |

| Sc2Si2O7 | 5.4[ | - | 1850[ |

| La2Zr2O7 | 9.1[ | 63[ | 2250[ |

表2 EBC典型组分热力学性能

Table 2 Basic thermal-mechanical properties of EBC constituents

| Material | Average CTE/ (×10-6, K-1) | Elastic modulus/GPa | Melting point/℃ |

|---|---|---|---|

| SiC/SiC CMC | 4.75[ | 220[ | 2827[ |

| Si | 3.5-4.5[ | 97[ | 1416[ |

| Mullite | 5-6[ | 150[ | 1800[ |

| BSAS | 4-5[ | 32[ | 1300[ |

| Lu2SiO5 | 6.7[ | 169[ | - |

| Yb2O3 | 6.8-8.4[ | - | 2415[ |

| Yb2SiO5 | 7.1-7.4[ | 158[ | 1950[ |

| Yb2Si2O7 | 3.6-4.5[ | 168[ | 1850[ |

| Y2SiO5 | 6.9[ | 124[ | 1980[ |

| Y2Si2O7 | 3.9[ | 155[ | 1775[ |

| Er2SiO5 | 5-7[ | 159[ | 1980[ |

| Er2SiO5 | 5-7[ | 159[ | 1980[ |

| Gd2SiO5 | 10.3[ | - | 1900[ |

| Sc2Si2O7 | 5.4[ | - | 1850[ |

| La2Zr2O7 | 9.1[ | 63[ | 2250[ |

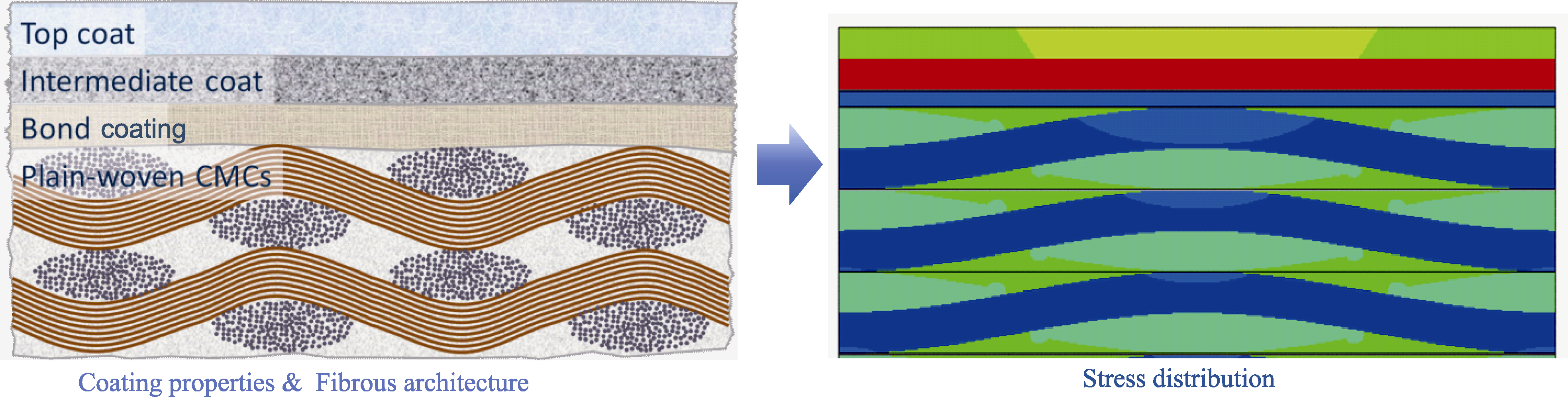

图4 考虑涂层特性和复合材料纤维编织结构的协同效应的CMC-EBC失效分析模型[91]

Fig. 4 Failure model of CMC-EBC system considering the synergetic effect of coating properties and fibrous architecture of composite[91]

| [1] |

PADTURE N P. Advanced structural ceramics in aerospace propulsion. Nature Materials, 2016, 15(8):804.

DOI PMID |

| [2] |

高希光, 韩栋, 宋迎东, 等. 陶瓷基复合材料结构的动力学强度设计方法: 研究现状及展望. 机械工程学报, 2021, 57(16):235.

DOI |

| [3] | WANG P, LIU F, WANG H, et al. A review of third generation SiC fibers and SiCf/SiC composites. Journal of Materials Science and Technology, 2019, 35(12):2743. |

| [4] | 江舟, 倪建洋, 张小锋, 等. 陶瓷基复合材料及其环境障涂层发展现状研究. 航空制造技术, 2020, 63(14):48. |

| [5] | HONG Z, CHENG L, ZHANG L, et al. Water vapor corrosion behavior of scandium silicates at 1400 ℃. Journal of the American Ceramic Society, 2009, 92(1):193. |

| [6] | ZHOU Y C, ZHAO C, WANG F, et al. Theoretical prediction and experimental investigation on the thermal and mechanical properties of bulk β-Yb2Si2O7. Journal of the American Ceramic Society, 2013, 96(12):3891. |

| [7] | LEE K N, FOX D S, BANSAL N P. Rare earth silicate environmental barrier coatings for SiC/SiC composites and Si3N4 ceramics. Journal of the European Ceramic Society, 2005, 25(10):1705. |

| [8] | XU J, SARIN V K, DIXIT S, et al. Stability of interfaces in hybrid EBC/TBC coatings for Si-based ceramics in corrosive environments. International Journal of Refractory Metals and Hard Materials, 2015, 49: 339. |

| [9] | 庄铭翔, 都业源, 袁建辉, 等. 等离子体喷涂环境障涂层高温失效研究进展. 中国表面工程, 2020, 33(3):33. |

| [10] | 马壮, 张学勤, 刘玲. 环境障涂层的发展瓶颈及应对措施. 中国表面工程, 2020, 33(5):99. |

| [11] | LEE K N, ZHU D, LIMA R S. Perspectives on environmental barrier coatings (EBCs) manufactured via air plasma spray (APS) on ceramic matrix composites (CMCs): a tutorial paper. Journal of Thermal Spray Technology, 2021, 30(1):40. |

| [12] | TEJERO-MARTIN D, BENNETT C, HUSSAIN T. A review on environmental barrier coatings: history, current state of the art and future developments. Journal of the European Ceramic Society, 2021, 41(3):1747. |

| [13] |

王京阳, 孙鲁超, 罗颐秀, 等. 以抗CMAS腐蚀为目标的稀土硅酸盐环境障涂层高熵化设计与性能提升. 金属学报, 2023, 59(4):523.

DOI |

| [14] |

周邦阳, 崔永静, 王长亮, 等. 稀土硅酸盐环境障涂层研究进展. 材料工程, 2023, 51(12):12.

DOI |

| [15] | 昝文宇, 马北越, 刘涛. 高熵稀土盐类热障/环境障陶瓷涂层体系研究进展. 稀有金属与硬质合金, 2023, 51(4):65. |

| [16] |

赵婷婷, 范立坤, 黎阳. 陶瓷材料抗热震性的研究进展. 机械工程材料, 2022, 46(12):1.

DOI |

| [17] | 董琳, 杨冠军, 张小锋, 等. 抗水氧腐蚀致密环境障涂层研究进展. 中国机械工程, 2022, 33(12):1459. |

| [18] | FITZGERALD K, SHEPHERD D. Review of SiCf/SiCm corrosion, erosion and erosion-corrosion in high temperature helium relevant to GFR conditions. Journal of Nuclear Materials, 2018, 498: 476. |

| [19] | 宋迎东, 高希光, 孙志刚. 航空发动机陶瓷基复合材料疲劳迟滞机理与模型研究进展. 南京航空航天大学学报, 2019, 51(4):417. |

| [20] | 陈明伟, 谢巍杰, 邱海鹏. 连续碳化硅纤维增强碳化硅陶瓷基复合材料研究进展. 现代技术陶瓷, 2016, 37(6):393. |

| [21] |

刘巧沐, 黄顺洲, 何爱杰. 碳化硅陶瓷基复合材料环境障涂层研究进展. 材料工程, 2018, 46(10):1.

DOI |

| [22] | AOKI Y, INOUE J, KAGAWA Y, et al. A simple method for measurement of shear delamination toughness in environmental barrier coatings. Surface and Coatings Technology, 2017, 321: 213. |

| [23] |

刘巧沐, 黄顺洲, 何爱杰. 碳化硅陶瓷基复合材料在航空发动机上的应用需求及挑战. 材料工程, 2019, 47(2):1.

DOI |

| [24] | YANG H, YANG Y, CAO X, et al. Thermal shock resistance and bonding strength of tri-layer Yb2SiO5/mullite/Si coating on SiCf/SiC composites. Ceramics International, 2020, 46(17):27292. |

| [25] | JANG B K, NAGASHIMA N, KIM S, et al. Mechanical properties and microstructure of Yb2SiO5 environmental barrier coatings under isothermal heat treatment. Journal of the European Ceramic Society, 2020, 40(7):2667. |

| [26] | ZHANG X F, ZHOU K S, LIU M, et al. Preparation of Si/Mullite/Yb2SiO5 environment barrier coating (EBC) by plasma spray-physical vapor deposition (PS-PVD). Journal of Inorganic Materials, 2018, 33(3):325. |

| [27] | 王瀚艺, 卢嘉铮, 贺强. 航空发动机SiCf/SiC复合材料与环境障涂层系统及制备技术研究进展. 复合材料科学与工程, 2022, 16(9):109. |

| [28] | UENO S, OHJI T. Development of environmental barrier coatings for non-oxide ceramics. Advances in Applied Ceramics, 2023, 122(3/4):101. |

| [29] | 谭僖, 陈孝业, 张小锋, 等. 硅基非氧化物陶瓷复合材料的环境障涂层系统的研究进展. 材料研究与应用, 2019, 13(2):152. |

| [30] | XIAO S K, LI J Z, HUANG P X, et al. Evaluation of environmental barrier coatings: a review. International Journal of Applied Ceramic Technology, 2023, 20(4): 2055. |

| [31] | PAKSOY A H, XIAO P. Review of processing and design methodologies of environmental barrier coatings for next generation gas turbine applications. Advances in Applied Ceramics, 2023. |

| [32] | TOHER C, RIDLEY M J, TOMKO K Q, et al. Design rules for the thermal and elastic properties of rare-earth disilicates. Materialia, 2023, 28: 101729. |

| [33] | LV X R, LEI Y M, ZHANG Z, et al. Accelerating the design of multicomponent rare earth silicates for SiCf/SiC CMC by combinatorial material chip design and high throughput screening. Journal of Materials Science and Technology, 2023, 150: 96. |

| [34] | ZHENG T, WANG S, XU B S, et al. A study of fracture toughness and thermal property of nanostructured Yb2SiO5 environmental barrier coatings. Journal of Materials Research and Technology, 2023, 26: 4436. |

| [35] | RIDLEY M, GARCIA E, KANE K, et al. Environmental barrier coatings on enhanced roughness SiC: effect of plasma spraying conditions on properties and performance. Journal of the European Ceramic Society, 2023, 43(14):6473. |

| [36] | ZHANG M, LIU R X, MIAO Q, et al. Microstructure and mechanical properties evolution in tri-layer Si-HfO2/ Yb2Si2O7/Yb2SiO5 environmental barrier coating by PS-PVD during post-annealing. Ceramics International, 2023, 49(24):40435. |

| [37] | LV K Y, DONG S J, HUANG Y, et al. Influence of post heat treatment on the high-temperature performances of multi-layered thermal/environmental barrier coatings on SiC-based composites. Ceramics International, 2023, 49(17):28130. |

| [38] | OKAWA A, NGUYEN S T, WIFF J P, et al. Self-healing ability, strength enhancement, and high-temperature oxidation behavior of silicon carbide-dispersed ytterbium disilicate composite for environmental barrier coatings under isothermal heat treatment. Journal of the European Ceramic Society, 2022, 42(13):6170. |

| [39] | ABDUL-AZIZ A. Durability modeling review of thermal- and environmental-barrier-coated fiber-reinforced ceramic matrix composites part i. Materials, 2018, 11(7):1251. |

| [40] | DEIJKERS J A, BEGLEY M R, WADLEY H N G. Failure mechanisms in model thermal and environmental barrier coating systems. Journal of the European Ceramic Society, 2022, 42(12):5129. |

| [41] | DU J P, LIU R J, WAN F, et al. Failure mechanism of ytterbium silicate/silicon bi-layer environmental barrier coatings on SiCf/SiC composites upon long-time water vapor and oxygen corrosion test. Surface and Coating Technology, 2022, 447: 128871. |

| [42] | ARCHER T, BERNY M, BEAUCHêNE P, et al. Creep behavior identification of an environmental barrier coating using full-field measurements. Journal of the European Ceramic Society, 2020, 40(15):5704. |

| [43] | BAKAN E, MACK D E, LOBE S, et al. An investigation on burner rig testing of environmental barrier coatings for aerospace applications. Journal of the European Ceramic Society, 2020, 40(15):6236. |

| [44] | TIAN Z, ZHENG L, WANG J, et al. Theoretical and experimental determination of the major thermo-mechanical properties of RE2SiO5(RE = Tb, Dy, Ho, Er, Tm, Yb, Lu, and Y) for environmental and thermal barrier coating applications. Journal of the European Ceramic Society, 2016, 36(1):189. |

| [45] | HAO S, OLEKSAK R P, DOĞAN Ö N, et al. Low-cost thermal/environmental barrier coatings: a first-principles study. Computational Materials Science, 2023, 230: 112541. |

| [46] | HEVERAN C M, XU J, SARIN V K, et al. Simulation of stresses in TBC-EBC coating systems for ceramic components in gas turbines. Surface and Coating Technology, 2013, 235(11):354. |

| [47] | SUZUKI M, SHAHIEN M, SHINODA K, et al. The current status of environmental barrier coatings and future direction of thermal spray process. Materials Transactions, 2022, 63(8):1101. |

| [48] | ABDUL-AZIZ A, WROBLEWSKI A C. Durability analysis and experimental validation of environmental barrier coating (EBC) performance using combined digital image correlation and NDE. Coatings, 2016, 70: 1. |

| [49] | WANG L, WANG Y, ZHANG W Q, et al. Finite element simulation of stress distribution and development in 8YSZ and double-ceramic-layer La2Zr2O7/8YSZ thermal barrier coatings during thermal shock. Applied Surface Science, 2012, 258(8):3540. |

| [50] | ZHANG J, GUO X, JUNG Y G, et al. Lanthanum zirconate based thermal barrier coatings: a review. Surface and Coating Technology, 2017, 323: 18. |

| [51] | NAIR S V, EATON H E, SUN E Y. Measurements of interface strength and toughness in shear of environmental barrier coatings on ceramic substrates at ambient and at elevated temperature. Surface and Coating Technology, 2006, 200(18/19):5175. |

| [52] | ROBERTSON A L, SOLA F, ZHU D M, et al. Microscale fracture mechanisms of HfO-Si environmental barrier coatings. Journal of the European Ceramic Society, 2019, 39(7):2409. |

| [53] | KASSEM R, AL NASIRI N. A comprehensive study on the mechanical properties of Yb2SiO5 as a potential environmental barrier coating. Surface and Coating Technology, 2021, 426: 127783. |

| [54] | KAKISAWA H, NISHIMURA T, YOKOI T, et al. Measurement of the in-plane coefficient of thermal expansion of ceramic protective coatings from room temperature to 1400 °C. Surface and Coating Technology, 2022, 439: 128427. |

| [55] | YE C, JIANG P. Accurate residual stress measurement as a function of depth in environmental barrier coatings via a combination of X-ray diffraction and Raman spectroscopy. Ceramics International, 2020, 46(8):12613. |

| [56] | SLEEPER J, GARG A, WIESNER V L, et al. Thermochemical interactions between CMAS and Ca2Y8(SiO4)6O2 apatite environmental barrier coating material. Journal of the European Ceramic Society, 2019, 39(16):5380. |

| [57] | STOLZENBURG F, KENESEI P, ALMER J, et al. The influence of calcium-magnesium-aluminosilicate deposits on internal stresses in Yb2SiO5 multilayer environmental barrier coatings. Acta Materialia, 2016, 105: 189. |

| [58] | EL SHAFEI K, KASSEM R, AL NASIRI N. Diffusion behaviour and corrosion rate of rare earth monosilicate-based EBCs under CMAS exposure. Ceramics International, 2023, 49(23):38544. |

| [59] | HARDER B J, STOKES J L, KOWALSKI B A, et al. Steam oxidation performance of Yb2Si2O7 environmental barrier coatings exposed to CMAS. Journal of the European Ceramic Society, 2024, 44(4):2486. |

| [60] | KIM S H, OSADA T, MATSUSHITA Y, et al. CMAS corrosion behavior of dual-phase composite Gd2Si2O7/Sc2Si2O7 as a promising EBC material. Journal of the European Ceramic Society, 2023, 43(14):6440. |

| [61] | TEJERO-MARTIN D, ROMERO A R, WELLMAN R G, et al. Interaction of CMAS on thermal sprayed ytterbium disilicate environmental barrier coatings: a story of porosity. Ceramics International, 2022, 48(6):8286. |

| [62] | GODBOLE E P, HEWAGE N, VON DER HANDT A, et al. Quantifying the efficiency of reactions between silicate melts and rare earth aluminate-zirconate T/EBC materials. Journal of the European Ceramic Society, 2023, 43(13):5626. |

| [63] | LEE K N, GARG A, JENNINGS W D. Effects of the chemistry of coating and substrate on the steam oxidation kinetics of environmental barrier coatings for ceramic matrix composites. Journal of the European Ceramic Society, 2021, 41(11):5675. |

| [64] | PRESBY M J, HARDER B J. Solid particle erosion of a plasma spray-physical vapor deposition environmental barrier coating in a combustion environment. Ceramics International, 2021, 47(17):24403. |

| [65] | BHATT R T, CHOI S R, COSGRIFF L M, et al. Impact resistance of environmental barrier coated SiC/SiC composites. Materials Science and Engineering: A, 2008, 476(1/2):8. |

| [66] | KEDIR N, GARCIA E, KIRK C, et al. Impact damage of narrow silicon carbide (SiC) ceramics with and without environmental barrier coatings (EBCs) by various foreign object debris (FOD) simulants. Surface and Coatings Technology, 2021, 407: 126779. |

| [67] | HU Q, WANG Y C, GUO X J, et al. Oxidation resistance of SiC/SiC composites with three-layer environmental barrier coatings up to 1360 °C in air atmosphere. Ceramics International, 2022, 48(7):9610. |

| [68] | HU Q, ZHOU X, TU Y W, et al. High-temperature mechanical properties and oxidation resistance of SiCf/SiC ceramic matrix composites with multi-layer environmental barrier coatings for turbine applications. Ceramics International, 2021, 47(21):30012. |

| [69] | APPLEBY M P, ZHU D M, MORSCHER G N. Mechanical properties and real-time damage evaluations of environmental barrier coated SiC/SiC CMCs subjected to tensile loading under thermal gradients. Surface & Coatings Technology., 2015, 284: 318 |

| [70] | QUAN H F, WANG L Y, HUANG J T, et al. Durable protection and failure mechanism of the multilayer coating system for SiC/SiC composites under high-temperature oxidation. Composites Part B: Engineering, 2022, 244: 110197. |

| [71] | RAMACHANDRAN K, CHAFFEY B, ZUCCARINI C, et al. Experimental and mathematical modelling of corrosion behaviour of CMAS coated oxide/oxide CMCs. Ceramics International, 2023, 49(3):4213. |

| [72] | LI B, FAN X L, ZHOU K, et al. A semi-analytical model for predicting stress evolution in multilayer coating systems during thermal cycling. International Journal of Mechanical Sciences, 2018, 135: 31. |

| [73] | DU J K, YU G Q, JIA Y F, et al. Numerical study of residual stresses in environmental barrier coatings with random rough geometry interfaces. Ceramics International, 2023, 49(4):5748. |

| [74] | DU J K, YU G Q, ZHOU S H, et al. Effect of the thermally grown oxide and interfacial roughness on stress distribution in environmental barrier coatings. Journal of the European Ceramic Society, 2023, 43(15):7118. |

| [75] | HUANG Y P, WEI Z Y, ZHANG Q, et al. Comprehensive understanding of coupled stress characteristics in ytterbium disilicate environmental barrier coatings undergoing corrosion transformation and thermal cycling. Ceramics International, 2022, 48(17):25528. |

| [76] | LV B, ZHUO X S, WANG C, et al. Mechanisms of crack healing in dense Yb-Si-O environmental barrier coatings by plasma spray-physical vapor deposition. Ceramics International, 2022, 48(11):15975. |

| [77] | HUANG Y P, WEI Z Y, SUN J, et al. Undulating and porous structure tuned surface cracking behavior of Yb2Si2O7environmental barrier coatings under steam cycling. Journal of the European Ceramic Society, 2023, 43(16):7644. |

| [78] | SUMMERS W D, BEGLEY M R, ZOK F W. Transition from penetration cracking to spallation in environmental barrier coatings on ceramic composites. Surface and Coatings Technology, 2019, 378: 125083. |

| [79] | LIU R X, LIANG W P, MIAO Q, et al. Micromechanical analysis and theoretical predictions towards thermal shock resistance of HfO2-Si environmental barrier coatings. Composites Part B: Engineering, 2021, 226: 109334. |

| [80] | HATTIANGADI A, SIEGMUND T. An analysis of the delamination of an environmental protection coating under cyclic heat loads. European Journal of Mechanics - A/Solids, 2005, 24(3):361. |

| [81] | BAKAN E, VASSEN R. Oxidation kinetics of atmospheric plasma sprayed environmental barrier coatings. Journal of the European Ceramic Society, 2022, 42(12):5122. |

| [82] | SEHR S, COLLIER V, ZOK F, et al. Oxide growth and stress evolution underneath cracked environmental barrier coatings. Journal of the Mechanics and Physics of Solids, 2023, 175: 105275. |

| [83] | RICHARDS B T, SEHR S, DE FRANQUEVILLE F, et al. Fracture mechanisms of ytterbium monosilicate environmental barrier coatings during cyclic thermal exposure. Acta Materialia, 2016, 103: 448. |

| [84] | GRUJICIC M, SNIPES J, YAVARI R, et al. Computational investigation of foreign object damage sustained by environmental barrier coatings (EBCs) and SiC/SiC ceramic-matrix composites (CMCs). Multidiscipline Modeling in Materials and Structures, 2015, 11(2):238. |

| [85] | LV B, JIN X, CAO J, et al. Advances in numerical modeling of environmental barrier coating systems for gas turbines. Journal of the European Ceramic Society, 2020, 40(9):3363. |

| [86] | MESQUITA-GUIMARãES J, GARCIA E, OSENDI M I, et al. Effect of aging on the onset of cracks due to redistribution of residual stresses in functionally graded environmental barrier coatings of mullite/ZrO2. Composites Part B: Engineering, 2014, 61: 199. |

| [87] | HARDER B J, ALMER J D, WEYANT C M, et al. Residual stress analysis of multilayer environmental barrier coatings. Journal of the American Ceramic Society, 2009, 92(2):452. |

| [88] | YANG Z, LI W, CHEN Y, et al. Life assessment of thermomechanical fatigue in a woven SiC/SiC ceramic matrix composite with an environmental barrier coating at elevated temperature. International Journal of Fatigue, 2023, 172: 107584. |

| [89] | MURTHY P L N, NEMETH N N, BREWER D N, et al. Probabilistic analysis of a SiC/SiC ceramic matrix composite turbine vane. Composites Part B: Engineering, 2008, 39(4):694. |

| [90] | FANG G, GAO X, SONG Y. A review on ceramic matrix composites and environmental barrier coatings for aero-engine: material development and failure analysis. Coatings, 2023, 13(2):357. |

| [91] | FANG G W, ZHONG Y, SUN J, et al. Synergetic effect of coating properties and fibrous architecture on stress evolution in plain-woven ceramic matrix composites. Composite Interfaces, 2022, 29(2):141. |

| [92] | EVANS A G, HUTCHINSON J W. The mechanics of coating delamination in thermal gradients. Surface and Coating Technology, 2007, 201(18):7905. |

| [1] | 朱文杰, 唐璐, 陆继长, 刘江平, 罗永明. 钙钛矿型氧化物催化氧化挥发性有机化合物的研究进展[J]. 无机材料学报, 2025, 40(7): 735-746. |

| [2] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [3] | 吴琼, 沈炳林, 张茂华, 姚方周, 邢志鹏, 王轲. 铅基织构压电陶瓷研究进展[J]. 无机材料学报, 2025, 40(6): 563-574. |

| [4] | 张碧辉, 刘小强, 陈湘明. Ruddlesden-Popper结构杂化非常规铁电体的研究进展[J]. 无机材料学报, 2025, 40(6): 587-608. |

| [5] | 吴杰, 杨帅, 王明文, 李景雷, 李纯纯, 李飞. 铅基织构压电陶瓷的发展历程、现状与挑战[J]. 无机材料学报, 2025, 40(6): 575-586. |

| [6] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| [7] | 田睿智, 兰正义, 殷杰, 郝南京, 陈航榕, 马明. 基于微流控技术的纳米无机生物材料制备: 原理及其研究进展[J]. 无机材料学报, 2025, 40(4): 337-347. |

| [8] | 张继国, 吴田, 赵旭, 杨钒, 夏天, 孙士恩. 钠离子电池正极材料循环稳定性提升策略及产业化进程[J]. 无机材料学报, 2025, 40(4): 348-362. |

| [9] | 殷杰, 耿佳毅, 王康龙, 陈忠明, 刘学建, 黄政仁. SiC陶瓷的3D打印成形与致密化新进展[J]. 无机材料学报, 2025, 40(3): 245-255. |

| [10] | 谌广昌, 段小明, 朱金荣, 龚情, 蔡德龙, 李宇航, 杨东雷, 陈彪, 李新民, 邓旭东, 余瑾, 刘博雅, 何培刚, 贾德昌, 周玉. 直升机特定结构先进陶瓷材料研究进展与应用展望[J]. 无机材料学报, 2025, 40(3): 225-244. |

| [11] | 范晓波, 祖梅, 杨向飞, 宋策, 陈晨, 王子, 罗文华, 程海峰. 质子调控型电化学离子突触研究进展[J]. 无机材料学报, 2025, 40(3): 256-270. |

| [12] | 栾新刚, 何典蔚, 涂建勇, 成来飞. 2D平纹和3D针刺C/SiC复合材料的低速冲击破坏行为和失效机理[J]. 无机材料学报, 2025, 40(2): 205-214. |

| [13] | 海热古·吐逊, 郭乐, 丁嘉仪, 周嘉琪, 张学良, 努尔尼沙·阿力甫. 上转换荧光探针辅助的光学成像技术在肿瘤显影中的应用研究进展[J]. 无机材料学报, 2025, 40(2): 145-158. |

| [14] | 孙树娟, 郑南南, 潘昊坤, 马猛, 陈俊, 黄秀兵. 单原子催化剂制备方法的研究进展[J]. 无机材料学报, 2025, 40(2): 113-127. |

| [15] | 陶桂龙, 支国伟, 罗添友, 欧阳佩东, 衣新燕, 李国强. 空腔型薄膜体声波滤波器的关键技术进展[J]. 无机材料学报, 2025, 40(2): 128-144. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||