无机材料学报 ›› 2024, Vol. 39 ›› Issue (10): 1077-1083.DOI: 10.15541/jim20230565 CSTR: 32189.14.10.15541/jim20230565

所属专题: 【结构材料】热障与环境障涂层(202506)

• 专题评述 • 下一篇

陶顺衍1( ), 杨加胜1, 邵芳1, 吴应辰1,2, 赵华玉1, 董绍明3, 张翔宇3, 熊瑛4

), 杨加胜1, 邵芳1, 吴应辰1,2, 赵华玉1, 董绍明3, 张翔宇3, 熊瑛4

收稿日期:2024-03-25

修回日期:2024-05-27

出版日期:2024-10-20

网络出版日期:2024-10-09

作者简介:陶顺衍(1969-), 男, 研究员. E-mail: sytao@mail.sic.ac.cn

基金资助:

TAO Shunyan1( ), YANG Jiasheng1, SHAO Fang1, WU Yingchen1,2, ZHAO Huayu1, DONG Shaoming3, ZHANG Xiangyu3, XIONG Ying4

), YANG Jiasheng1, SHAO Fang1, WU Yingchen1,2, ZHAO Huayu1, DONG Shaoming3, ZHANG Xiangyu3, XIONG Ying4

Received:2024-03-25

Revised:2024-05-27

Published:2024-10-20

Online:2024-10-09

About author:TAO Shunyan (1969-), male, professor. E-mail: sytao@mail.sic.ac.cn

Supported by:摘要:

随着航空发动机涡轮前燃气入口温度的不断攀升, 陶瓷基复合材料(Ceramic Matrix Composite, CMC)以其轻质、高强、抗氧化、对裂纹不敏感、耐温性能优异等特点, 成为新一代航空发动机高温部件的首选基体材料。但CMC存在抗高温水氧侵蚀性能不足等问题, 发动机CMC热端部件用热喷涂涂层成为亟待解决的技术瓶颈。本文结合国外航空发动机热端部件选材方案的更迭及工程应用实例, 分析了发动机热端部件采用高温合金+气膜冷却+热障涂层方案的技术局限性, 明确了CMC+适量气膜冷却+环境障碍涂层方案的技术优势; 综述了CMC用热与环境障碍涂层(Thermal and Environmental Barrier Coatings, TEBCs)和环境障碍可磨耗封严涂层(Environmental Barrier Coatings-Abradable Sealing Coatings, EBCs-ASCs)的研究进展、应用情况以及近些年国内外学者的研究成果; 辨析了面向更高温燃气来流时热喷涂环境障碍涂层面临的机遇与挑战, 为后续TEBCs的组分和结构设计以及制备明确了方向, 并对今后研究工作的重点进行了展望。

中图分类号:

陶顺衍, 杨加胜, 邵芳, 吴应辰, 赵华玉, 董绍明, 张翔宇, 熊瑛. 航机CMC热端部件用热喷涂涂层的机遇与挑战[J]. 无机材料学报, 2024, 39(10): 1077-1083.

TAO Shunyan, YANG Jiasheng, SHAO Fang, WU Yingchen, ZHAO Huayu, DONG Shaoming, ZHANG Xiangyu, XIONG Ying. Thermal Spray Coatings for Aircraft CMC Hot-end Components: Opportunities and Challenges[J]. Journal of Inorganic Materials, 2024, 39(10): 1077-1083.

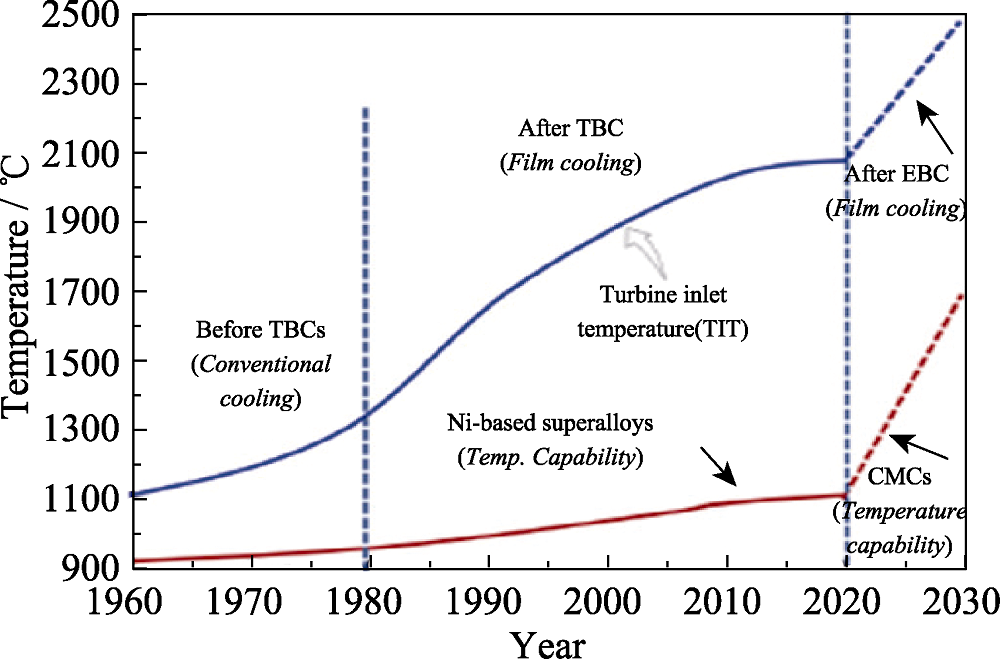

图4 发动机热端部件选材方案及其承温特性[5-6]

Fig. 4 Material selection scheme and its corresponding temperature bearing characteristics of engine hot-end components[5-6]

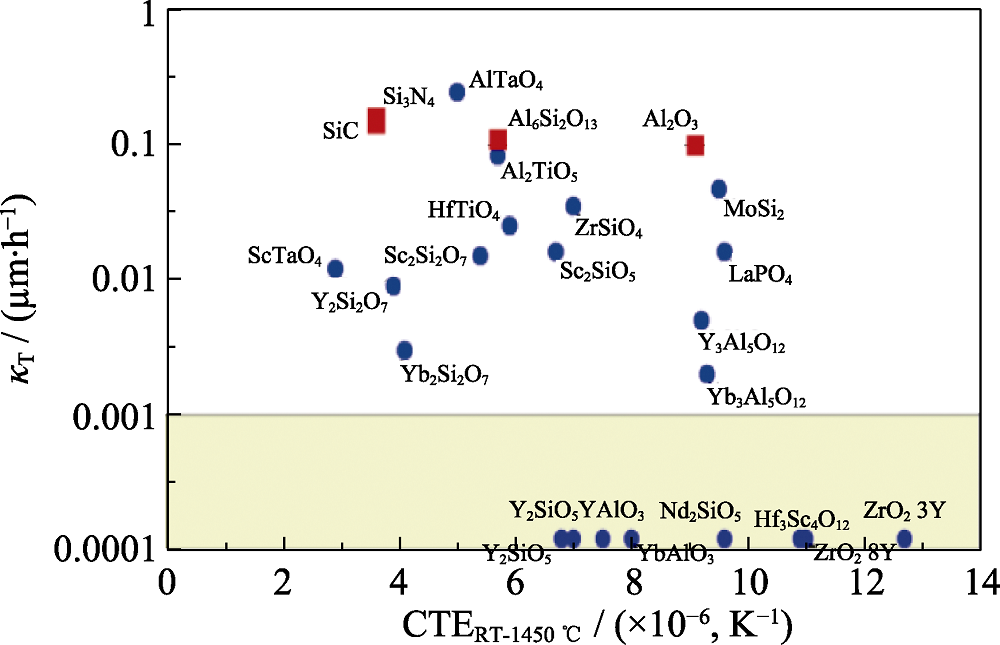

图8 典型陶瓷材料的水氧腐蚀速率与热膨胀系数的关系[24]

Fig. 8 Relationship between the water-oxygen corrosion rate and the thermal expansion coefficient of ceramic materials[24]

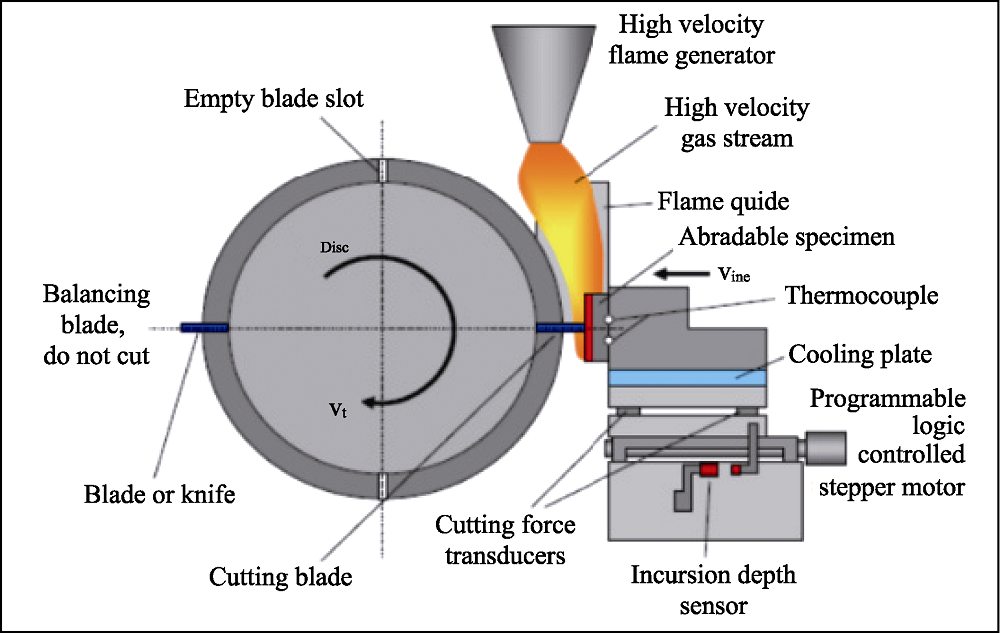

图10 Sulzer Innotec刮磨试验台示意图[44]

Fig. 10 Schematic drawing of the Sulzer Innotec abradability test rig [44] The oxygen / propane high temperature gas is used to heat the test piece, which can be heated to 1200 ℃; Scratch speed: 50-450 m/s; Feed rate: 1.5-3000 μm/s

| [1] | CORMAN G S, LUTHRA K L. Development history of GE's prepreg melt infiltrated ceramic matrix composite material and applications. Comprehensive Composite Materials II, 2018, 5: 325. |

| [2] | LEONARD G, STEGMAIER J. Development of an aeroderivative gas turbine dry low emissions combustion system. Journal of Engineering for Gas Turbines and Power, 1994, 116(3): 542. |

| [3] | ZHU D M, HARDER B. The development of HfO2-rare earth based oxide materials and barrier coatings for thermal protection systems. Materials Science & Technology 2014 Conference & Exhibition, Pittsburgh, 2014. |

| [4] | 刘巧沐, 黄顺洲, 何爱杰. 碳化硅陶瓷基复合材料在航空发动机上的应用需求及挑战. 材料工程, 2019, 47(2): 1. |

| [5] |

PADTURE N P. Advanced structural ceramics in aerospace propulsion. Nature Materials, 2016, 15: 804.

DOI PMID |

| [6] | CLARKE D R, OECHSNER M, PADTURE N P. Thermal-barrier coatings for more efficient gas-turbine engines. MRS Bulletin, 2012, 37(10): 891. |

| [7] | LEE K N, ZHU D M, LIMA R S. Perspectives on environmental barrier coatings (EBCs) manufactured via air plasma spray (APS) on ceramic matrix composites (CMCs): a tutorial paper. Journal of Thermal Spray Technology, 2021, 30: 40. |

| [8] | TEJERO-MARTIN D, BENNETT C, HUSSAIN T. A review on environmental barrier coatings: history, current state of the art and future developments. Journal of the European Ceramic Society, 2021, 41: 1747. |

| [9] | 江舟, 倪建洋, 张小锋, 等. 陶瓷基复合材料及其环境障涂层发展现状研究. 航空制造技术, 2020, 63(14): 48. |

| [10] | 郑伟, 张佳平, 杨翠波. 陶瓷基复合材料环境障涂层研究进展. 纤维复合材料, 2021, 2: 65. |

| [11] | 刘巧沐, 黄顺洲, 何爱杰. 碳化硅陶瓷基复合材料环境障涂层研究进展. 材料工程, 2018, 46(10): 1. |

| [12] | 赵春玲, 杨博, 李阔, 等. 陶瓷基复合材料表面环境障涂层材料研究进展. 中国材料进展, 2021, 40(4): 257. |

| [13] | 白博添, 章德铭, 冀晓鹃, 等. 环境障涂层选材研究进展. 热喷涂技术, 2022, 14(3): 1. |

| [14] | HERMAN H, SAMPATH S, MCCUNE R. Thermal spray: current status and future trends. MRS Bulletin, 2000, 25(7): 17. |

| [15] | LEE K N. Yb2Si2O7 environmental barrier coatings with reduced bond coat oxidation rates via chemical modifications for long life. Journal of the American Ceramic Society, 2019, 102(3): 1507. |

| [16] | RICHARDS B T, YOUNG K A, DE FRANQUEVILLE F, et al. Response of ytterbium disilicate-silicon environmental barrier coatings to thermal cycling in water vapor. Acta Materials, 2016, 106: 1. |

| [17] | ZHU D M. Advanced environmental barrier coatings for SiC/SiC ceramic matrix composite turbine components//Engineered ceramics: current status and future prospects. Hoboken: John Wiley & Sons, 2015. |

| [18] | BAKAN E, SOHN Y J, VASSEN R. Microstructure and phase composition evolution of silicon-hafnia feedstock during plasma spraying and following cyclic oxidation. Acta Materialia, 2021, 214: 117007. |

| [19] | LI C, HE J, MA Y, et al. Evolution mechanism of the microstructure and mechanical properties of plasma-sprayed yttria-stabilized hafnia thermal barrier coating at 1400 ℃. Ceramics International, 2020, 46: 23417. |

| [20] | LI G, LU X R, HUANG J Q, et al. Thermal cycling behavior and failure mechanism of the Si-HfO2 environmental barrier coating bond coats prepared by atmospheric plasma spraying. Journal of Alloys and Compounds, 2022, 913: 165319. |

| [21] | ZHANG Z Y, PARK Y J, KIM D H, et al. High-temperature oxidation performance of novel environmental barrier coating 50HfO2-50SiO2/YxYb(2-x)Si2O7 at 1475 ℃. Journal of the European Ceramic Society, 2023, 43: 1127. |

| [22] | JACOBSON N S. Corrosion of silicon-based ceramics in combustion environments. Journal of the American Ceramic Society, 1993, 76(1): 3. |

| [23] | OPILA E J. Variation of the oxidation rate of silicon carbide with water-vapor pressure. Journal of the American Ceramic Society, 1999, 82(3): 625. |

| [24] | KLEMM H. Silicon nitride for high-temperature applications. Journal of the American Ceramic Society, 2010, 93(6): 1501. |

| [25] | BAKAN E, MARCANO D, ZHOU D P, et al. Yb2Si2O7environmental barrier coatings deposited by various thermal spray techniques: a preliminary comparative study. Jouranl of Thermal Spray Technology, 2017, 26: 1011. |

| [26] | CHEN D Y, PEGLER A, DWIVEDI G, et al. Thermal cycling behavior of air plasma-sprayed and low-pressure plasma-sprayed environmental barrier coatings. Coatings, 2021, 11: 868. |

| [27] | DONG Y, REN K, LU Y, et al. High-entropy environmental barrier coating for the ceramic matrix composites. Journal of the European Ceramic Society, 2019, 39(7): 2574. |

| [28] | SUN L, LUO Y, TIAN Z, et al. High temperature corrosion of (Er0.25Tm0.25Yb0.25Lu0.25)2Si2O7 environmental barrier coating material subjected to water vapor and molten calcium- magnesium-aluminosilicate (CMAS). Corrosion Science, 2020, 175: 108881. |

| [29] | RIDLEY M, OPILA E. Thermochemical stability and microstructural evolution of Yb2Si2O7in high-velocity high-temperature water vapor. Journal of the European Ceramic Society, 2020, 41(5): 3141. |

| [30] | TURCER L R, PADTURE N P. Towards multifunctional thermal environmental barrier coatings (TEBCs) based on rare-earth pyrosilicate solid-solution ceramics. Scripta Materialia, 2018, 154: 111. |

| [31] | TIAN Z, ZHENG L, LI Z, et al. Exploration of the low thermal conductivities of γ-Y2Si2O7, β-Y2Si2O7, β-Yb2Si2O7, and β-Lu2Si2O7 as novel environmental barrier coating candidates. Journal of the European Ceramic Society, 2016, 36(11): 2813. |

| [32] | TIAN Z, ZHENG L, WANG J, et al. Theoretical and experimental determination of the major thermo-mechanical properties of RE2SiO5 (RE=Tb, Dy, Ho, Er, Tm, Yb, Lu, and Y) for environmental and thermal barrier coating applications. Journal of the European Ceramic Society, 2016, 36(1): 189. |

| [33] | VISWANATHAN V, DWIVEDI G, SAMPATH S. Multilayer, multimaterial thermal barrier coating systems: design, synthesis, and performance assessment. Journal of the American Ceramic Society, 2015, 98(6): 1769. |

| [34] | GLEDHILL A D, REDDY K M, DREXLER J M, et al. Mitigation of damage from molten fly ash to air-plasma-sprayed thermal barrier coatings. Materials Science and Engineering: A, 2011, 528(24): 7214. |

| [35] | KRAMER S, YANG J, LEVI C G. Infiltration-inhibiting reaction of gadolinium zirconate thermal barrier coatings with CMAS melts. Journal of the American Ceramic Society, 2008, 91(2): 576. |

| [36] | VARDELLE A, MOREAU C, AKEDO J, et al. The 2016 thermal spray roadmap. Journal of Thermal Spray Technology, 2016, 25(8): 1376. |

| [37] | LI W, ZHAO H Y, ZHONG X H, et al. Air plasma-sprayed yttria and yttria-stabilized zirconia thermal barrier coatings subjected to calcium-magnesium-alumino-silicate (CMAS). Journal of Thermal Spray Technology, 2014, 23(6): 975. |

| [38] | MECHNICH P, BRAUE W. Air plasma-sprayed Y2O3 coatings for Al2O3/Al2O3 ceramic matrix composites. Journal of the European Ceramic Society, 2013, 33: 2645. |

| [39] | AUSSAVY D, BOLOT R, MONTAVON G, et al. YSZ-polyester abradable coatings manufactured by APS. Journal of Thermal Spray Technology, 2016, 25(1/2): 252. |

| [40] | SPORER D, REFKE A, DRATWINSKI M, et al. New high-temperature seal system for increased efficiency of gas turbines. Sealing Technology, 2008, 10: 9. |

| [41] | HUANG J Q, LIU R Y, HU Q, et al. High temperature abradable sealing coating for SiCf/SiC ceramic matrix composites. Ceramics International, 2023, 49: 1779. |

| [42] | GUO M Q, CUI Y J, WANG C L, et al. Design and characterization of BSAS-polyester abradable environmental barrier coatings (A/EBCs) on SiC/SiC composites. Surface & Coatings Technology, 2023, 465: 129617. |

| [43] | QIN D D, NIU Y R, LI H, et al. Fabrication and characterization of Yb2Si2O7-based composites as novel abradable sealing coatings. Ceramics International, 2021, 47: 23153. |

| [44] | STEINKE T, MAUER G, VAΒEN R, et al. Process design and monitoring for plasma sprayed abradable coatings. Journal of Thermal Spray Technology, 2010, 19: 756. |

| [45] | LIANG J J, MATSUMOTO K, KAWAGISHI K, et al. Morphological evolution of thermal barrier coatings with equilibrium (EQ) and NiCoCrAlY bond coats during thermal cycling. Surface & Coatings Technology, 2012, 207: 413. |

| [1] | 栾新刚, 何典蔚, 涂建勇, 成来飞. 2D平纹和3D针刺C/SiC复合材料的低速冲击破坏行为和失效机理[J]. 无机材料学报, 2025, 40(2): 205-214. |

| [2] | 赵日达, 汤素芳. 多孔碳陶瓷化改进反应熔渗法制备陶瓷基复合材料研究进展[J]. 无机材料学报, 2024, 39(6): 623-633. |

| [3] | 方光武, 谢浩元, 张华军, 高希光, 宋迎东. CMC-EBC损伤耦合机理及一体化设计研究进展[J]. 无机材料学报, 2024, 39(6): 647-661. |

| [4] | 李广宇, 岳一凡, 王波, 张程煜, 索涛, 李玉龙. 2D-SiC/SiC复合材料的弹丸冲击损伤及冲击后拉伸性能[J]. 无机材料学报, 2024, 39(5): 494-500. |

| [5] | 薛轶凡, 李玮洁, 张中伟, 庞旭, 刘愚. 碳纤维布表面PyC界面相微观结构及均匀性的工艺调控[J]. 无机材料学报, 2024, 39(4): 399-408. |

| [6] | 李雷, 程群峰. 高性能MXenes纳米复合材料研究进展[J]. 无机材料学报, 2024, 39(2): 153-161. |

| [7] | 徐向明, Husam N ALSHAREEF. MXetronics—MXene电子学[J]. 无机材料学报, 2024, 39(2): 171-178. |

| [8] | 李腊, 沈国震. 二维MXenes材料在柔性光电探测器中的应用展望[J]. 无机材料学报, 2024, 39(2): 186-194. |

| [9] | 巴坤, 王建禄, 韩美康. MXene的红外特性及其应用研究展望[J]. 无机材料学报, 2024, 39(2): 162-170. |

| [10] | 尹建宇, 刘逆霜, 高义华. MXene在压力传感中的研究进展[J]. 无机材料学报, 2024, 39(2): 179-185. |

| [11] | 刘艳艳, 谢曦, 刘增乾, 张哲峰. MAX相陶瓷增强金属基复合材料: 制备、性能与仿生设计[J]. 无机材料学报, 2024, 39(2): 145-152. |

| [12] | 邓顺桂, 张传芳. 多功能MXene油墨:面向印刷能源及电子器件的新视角[J]. 无机材料学报, 2024, 39(2): 195-203. |

| [13] | 陈泽, 支春义. MXene在锌离子电池中的应用: 研究进展与展望[J]. 无机材料学报, 2024, 39(2): 204-214. |

| [14] | 丁浩明, 陈科, 李勉, 李友兵, 柴之芳, 黄庆. 无机材料的“化学剪刀”结构编辑策略[J]. 无机材料学报, 2024, 39(2): 115-128. |

| [15] | 万胡杰, 肖旭. MXenes及其复合物的太赫兹电磁屏蔽与吸收[J]. 无机材料学报, 2024, 39(2): 129-144. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||