无机材料学报 ›› 2024, Vol. 39 ›› Issue (1): 51-60.DOI: 10.15541/jim20230302 CSTR: 32189.14.10.15541/jim20230302

所属专题: 【结构材料】陶瓷基复合材料(202506)

吴军1,2( ), 徐培飞1,2, 荆瑞1,2, 张大海1,2(

), 徐培飞1,2, 荆瑞1,2, 张大海1,2( ), 费庆国1,2

), 费庆国1,2

收稿日期:2023-06-29

修回日期:2023-08-30

出版日期:2024-01-20

网络出版日期:2023-09-12

通讯作者:

张大海, 副教授. E-mail: dzhang@seu.edu.cn作者简介:吴 军(1999-), 男, 博士研究生. E-mail: 220200292@seu.edu.cn

基金资助:

WU Jun1,2( ), XU Peifei1,2, JING Rui1,2, ZHANG Dahai1,2(

), XU Peifei1,2, JING Rui1,2, ZHANG Dahai1,2( ), FEI Qingguo1,2

), FEI Qingguo1,2

Received:2023-06-29

Revised:2023-08-30

Published:2024-01-20

Online:2023-09-12

Contact:

ZHANG Dahai, associate professor. E-mail: dzhang@seu.edu.cnAbout author:WU Jun (1999-), male, PhD candidate. E-mail: 220200292@seu.edu.cn

Supported by:摘要:

高速飞行器中的陶瓷基复合材料结构在服役过程中不可避免地会遇到低速冲击问题, 低速冲击后的损伤形式以及剩余承载能力是影响飞行器结构安全的关键问题。本研究以二维编织SiC/SiC复合材料板件为研究对象, 在不同能量下开展了低速冲击试验, 分析了低速冲击载荷下试验件的表面损伤状态, 通过计算机断层扫描技术观察了试验件内部的损伤形貌, 结合冲击过程中的冲击响应曲线以及应变历史曲线, 分析了SiC/SiC复合材料低速冲击过程的损伤机理。针对含勉强目视可见损伤的试验件开展了冲击后剩余强度试验, 研究了勉强目视可见损伤对SiC/SiC复合材料剩余承载性能的影响。结果表明, 在低速冲击载荷的作用下, 试验件的表面损伤主要包括无表面损伤、勉强目视可见损伤、半穿透损伤以及穿透损伤, 试验件的内部损伤主要有锥形体裂纹、纱线断裂以及分层损伤。低速冲击损伤会严重影响SiC/SiC复合材料的剩余性能, 虽然试验件损伤勉强目视可见,但其剩余压缩强度为无损件81%, 剩余拉伸强度仅为无损件的68%。

中图分类号:

吴军, 徐培飞, 荆瑞, 张大海, 费庆国. SiC/SiC复合材料层板低速冲击及其剩余强度试验研究[J]. 无机材料学报, 2024, 39(1): 51-60.

WU Jun, XU Peifei, JING Rui, ZHANG Dahai, FEI Qingguo. Experimental Study on Low-velocity Impact and Residual Strength of SiC/SiC Composite Laminates[J]. Journal of Inorganic Materials, 2024, 39(1): 51-60.

| Impact energy/J | Number of specimen | Residual strength |

|---|---|---|

| 0 | 3 | TAI |

| 3 | CAI | |

| 3 | 5 | TAI |

| 5 | CAI | |

| 1, 2, 4, 5, 10, 20 | 2 | TAI |

| 2 | CAI |

表1 冲击试验件安排以及冲击后剩余强度试验规划

Table 1 Impact test arrangement and residual strength test after impact

| Impact energy/J | Number of specimen | Residual strength |

|---|---|---|

| 0 | 3 | TAI |

| 3 | CAI | |

| 3 | 5 | TAI |

| 5 | CAI | |

| 1, 2, 4, 5, 10, 20 | 2 | TAI |

| 2 | CAI |

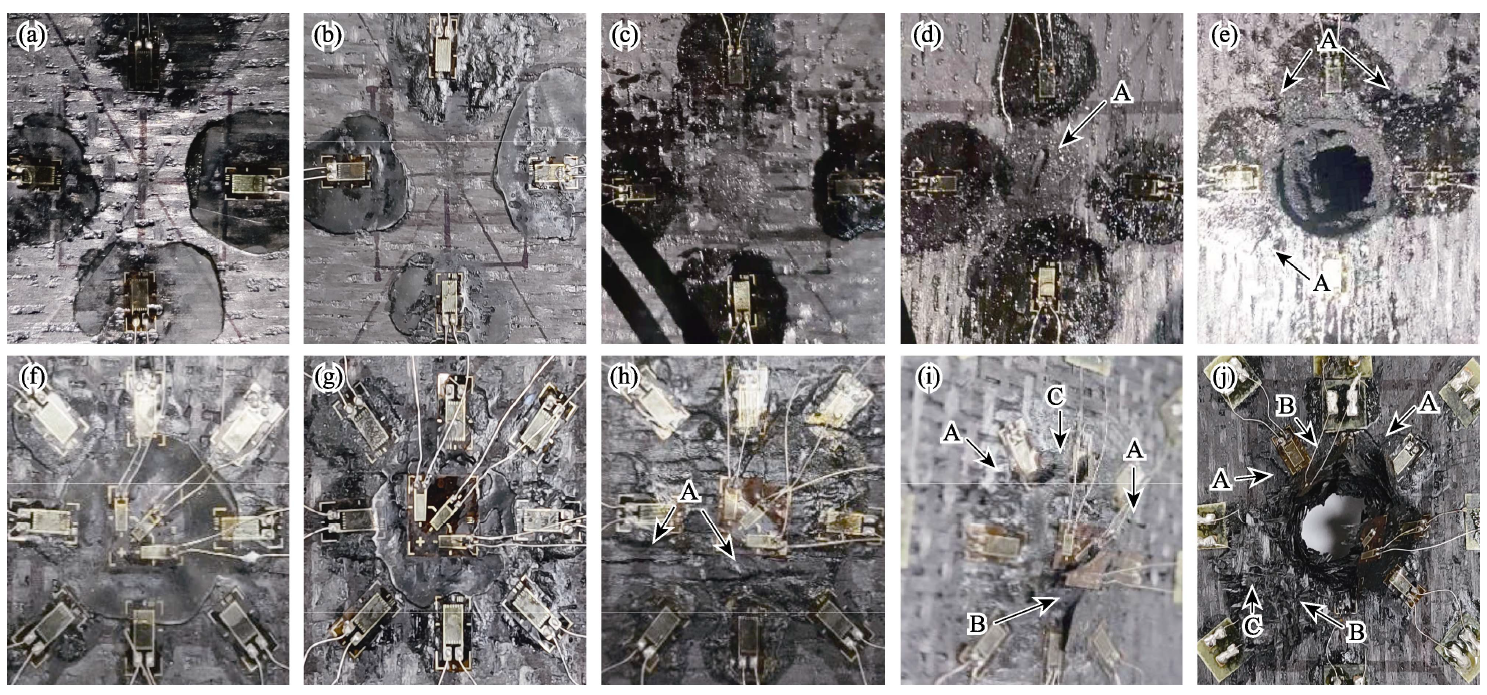

图5 冲击试验后试验件正面(a~e)和背面(f~j)表面损伤形貌

Fig. 5 Front (a-e) and back (f-j) damage morphologies of the specimens after being impacted with different energies (a, f) 1 J; (b, g) 3 J; (c, h) 5 J; (d, i) 10 J; (e, j) 20 J

图10 试验件冲击过程中的应变-时间曲线

Fig. 10 Strain-time curves of specimen during the impact process (a) 1 J; (b) 3 J; (c) 4 J; (d) 10 J. Colorful figures are available on website

| Specimen | Impact energy/J | Fmax/kN | CAI strength/MPa |

|---|---|---|---|

| C-0J-1 | 0 | 42.18 | 210.9 |

| C-0J-2 | 0 | 37.38 | 186.9 |

| C-0J-3 | 0 | 40.66 | 203.3 |

| C-3J-1 | 3 | 35.13 | 175.7 |

| C-3J-2 | 3 | 34.88 | 174.4 |

| C-3J-3 | 3 | 32.28 | 166.6 |

| C-3J-4 | 3 | 28.34 | 141.7 |

| C-3J-5 | 3 | 31.22 | 156.1 |

表2 无损和BVID试验件的CAI强度

Table 2 CAI strength of undamaged and BVID specimens

| Specimen | Impact energy/J | Fmax/kN | CAI strength/MPa |

|---|---|---|---|

| C-0J-1 | 0 | 42.18 | 210.9 |

| C-0J-2 | 0 | 37.38 | 186.9 |

| C-0J-3 | 0 | 40.66 | 203.3 |

| C-3J-1 | 3 | 35.13 | 175.7 |

| C-3J-2 | 3 | 34.88 | 174.4 |

| C-3J-3 | 3 | 32.28 | 166.6 |

| C-3J-4 | 3 | 28.34 | 141.7 |

| C-3J-5 | 3 | 31.22 | 156.1 |

| Specimen | Impact energy/J | Fmax/kN | TAI strength/MPa |

|---|---|---|---|

| T-0J-1 | 0 | 58.77 | 146.9 |

| T-0J-2 | 0 | 65.94 | 164.5 |

| T-0J-3 | 0 | 71.79 | 179.5 |

| T-3J-1 | 3 | 43.62 | 109.1 |

| T-3J-2 | 3 | 45.16 | 112.9 |

| T-3J-3 | 3 | 43.72 | 109.3 |

| T-3J-4 | 3 | 45.48 | 113.7 |

| T-3J-5 | 3 | 45.01 | 112.5 |

表3 无损和BVID试验件的TAI强度

Table 3 TAI strength of undamaged and BVID specimens

| Specimen | Impact energy/J | Fmax/kN | TAI strength/MPa |

|---|---|---|---|

| T-0J-1 | 0 | 58.77 | 146.9 |

| T-0J-2 | 0 | 65.94 | 164.5 |

| T-0J-3 | 0 | 71.79 | 179.5 |

| T-3J-1 | 3 | 43.62 | 109.1 |

| T-3J-2 | 3 | 45.16 | 112.9 |

| T-3J-3 | 3 | 43.72 | 109.3 |

| T-3J-4 | 3 | 45.48 | 113.7 |

| T-3J-5 | 3 | 45.01 | 112.5 |

| [1] | HAN D, GAO X G, ZHANG H J, et al. Dynamic and fluid- structure interaction simulations of a ceramic matrix composite plate. Composite Structures, 2020, 243: 112177. |

| [2] | MEYER P, WAAS A M. Experimental results on the elevated temperature tensile response of SiC/SiC ceramic matrix notched composites. Composites Part B: Engineering, 2018, 143: 269. |

| [3] | WANG L Y, LUO R Y, CUI G Y, et al. Oxidation resistance of SiCf/SiC composites with a PyC/SiC multilayer interface at 500 °C to 1100 ℃. Corrosion Science, 2020, 167: 108522. |

| [4] | DU C L, XIA R Z, LIU P, et al. On the impact damage characteristics of spread-tow woven composites: from high velocity to hyper velocity. Engineering Failure Analysis, 2023, 146: 107109. |

| [5] | JIANG D, QIAN H, XU Y, et al. Residual strength of C/SiC composite after low-velocity impact. Materials Today Communications, 2022, 30: 103140. |

| [6] | ZHOU J W, LIAO B B, SHI Y Y, et al. Low-velocity impact behavior and residual tensile strength of CFRP laminates. Composites Part B: Engineering, 2019, 161: 300. |

| [7] |

HU W, GUAN T H, GAO M T, et al. High-velocity impact behaviors and post-impact tension performance of 2D-C/SiC composite beams. Ceramics International, 2020, 46(9):13282.

DOI URL |

| [8] | HH W, HUANG J Z, LI Y H, et al. High-temperature compressive performance of the pre-impacted 2D-C/SiC composites: coupling effect of pre-impact energy, temperature, temperature-keeping duration, and strain rate. Carbon, 2021, 184: 728. |

| [9] | ICTEN B M, KIRAL B G, DENIZ M E. Impactor diameter effect on low velocity impact response of woven glass epoxy composite plates. Composites Part B: Engineering, 2013, 50: 325. |

| [10] | KAZEMIANFAR B, ESMAEELI M, NAMI M R. Response of 3D woven composites under low velocity impact with different impactor geometries. Aerospace Science and Technology, 2020, 102: 105849. |

| [11] |

PRESBY M J, MANSOUR R, MANIGANDAN K, et al. Characterization and simulation of foreign object damage in curved and flat SiC/SiC ceramic matrix composites. Ceramics International, 2019, 45(2):2635.

DOI URL |

| [12] | YANG Y, XU F, GAO X Y, et al. Impact resistance of 2D plain-woven C/SiC composites at high temperature. Materials & Design, 2016, 90: 635. |

| [13] |

YAO L J, LYU P, BAI G D, et al. Influence of low velocity impact on oxidation performance of SiC coated C/SiC composites. Ceramics International, 2019, 45(16):20470.

DOI URL |

| [14] |

HERB V, MARTIN E, COUEGNAT G. Damage analysis of thin 3D-woven SiC/SiC composite under low velocity impact loading. Composites Part A: Applied Science and Manufacturing, 2012, 43(2):247.

DOI URL |

| [15] | MEI H, YU C K, XU Y W, et al. Effect of impact energy on damage resistance and mechanical property of C/SiC composites under low velocity impact. Materials Science and Engineering: A, 2017, 687: 141. |

| [16] | HAN D, JIA X, ZHANG H J, et al. Foreign object damage and post-impact tensile behavior of plain-woven SiC/SiC composites. Composite Structures, 2022, 295: 115767. |

| [17] | NARESH K, SHANKAR K, VELMURUGAN R, et al. Statistical analysis of the tensile strength of GFRP, CFRP and hybrid composites. Thin-Walled Structures, 2018, 126: 150. |

| [18] | RUIVOFUGA F, DONADON M V. Low velocity impact on pre-loaded composite plates: a novel standard-based experimental apparatus. Composite Structures, 2021, 261: 113315. |

| [19] | LI B, HOO FATT M S. Impact damage and residual strength predictions of 2D woven SiC/SiC composites. Finite Elements in Analysis and Design, 2016, 113: 30. |

| [20] | ZHAO Q L, WANG W H, LIU Y T, et al. Multiscale modeling framework to predict the low-velocity impact and compression after impact behaviors of plain woven CFRP composites. Composite Structures, 2022, 299: 116090. |

| [21] | LI T, YANG Y, YU X, et al. Micro-structure response and fracture mechanisms of C/SiC composites subjected to low-velocity ballistic penetration. Ceramics International, 2017, 43(9): 6910. |

| [22] | KIM E H, RIM M S, LEE I, et al. Composite damage model based on continuum damage mechanics and low velocity impact analysis of composite plates. Composite Structures, 2013, 95: 123. |

| [23] |

SINGH A K, KAHLE K, JAMES H, et al. Environmental effects on the strength and impact damage resistance of alumina based oxide/oxide ceramic matrix composites. Ceramics International, 2021, 47(12):17268.

DOI URL |

| [24] | HAN Y F, YUAN M E, TANG E L, et al. Experimental study on flash radiation and damage characteristics of C/SiC composites induced by hypervelocity impact. International Journal of Impact Engineering, 2021, 155: 103902. |

| [25] |

YASHIRO S, OGI K, OSHITA M. High-velocity impact damage behavior of plain-woven SiC/SiC composites after thermal loading. Composites Part B: Engineering, 2012, 43(3):1353.

DOI URL |

| [26] |

CHOI S R. Foreign Object damage phenomenon by steel ball projectiles in a SiC/SiC ceramic matrix composite at ambient and elevated temperatures. Journal of the American Ceramic Society, 2008, 91(9):2963.

DOI URL |

| [27] |

LAWN B R. Indentation of ceramics with spheres: a century after Hertz. Journal of the American Ceramic Society, 1998, 81(8): 1977.

DOI URL |

| [1] | 陈义, 邱海鹏, 陈明伟, 徐昊, 崔恒. SiC/SiC复合材料基体硼改性方法及其力学性能研究[J]. 无机材料学报, 2025, 40(5): 504-510. |

| [2] | 穆爽, 马沁, 张禹, 沈旭, 杨金山, 董绍明. Yb2Si2O7改性SiC/SiC复合材料的氧化行为研究[J]. 无机材料学报, 2025, 40(3): 323-328. |

| [3] | 栾新刚, 何典蔚, 涂建勇, 成来飞. 2D平纹和3D针刺C/SiC复合材料的低速冲击破坏行为和失效机理[J]. 无机材料学报, 2025, 40(2): 205-214. |

| [4] | 王旭, 李翔, 寇华敏, 方伟, 吴庆辉, 苏良碧. 不同浓度Y3+离子掺杂对CaF2晶体性能的影响[J]. 无机材料学报, 2024, 39(9): 1029-1034. |

| [5] | 赵日达, 汤素芳. 多孔碳陶瓷化改进反应熔渗法制备陶瓷基复合材料研究进展[J]. 无机材料学报, 2024, 39(6): 623-633. |

| [6] | 方光武, 谢浩元, 张华军, 高希光, 宋迎东. CMC-EBC损伤耦合机理及一体化设计研究进展[J]. 无机材料学报, 2024, 39(6): 647-661. |

| [7] | 李广宇, 岳一凡, 王波, 张程煜, 索涛, 李玉龙. 2D-SiC/SiC复合材料的弹丸冲击损伤及冲击后拉伸性能[J]. 无机材料学报, 2024, 39(5): 494-500. |

| [8] | 薛轶凡, 李玮洁, 张中伟, 庞旭, 刘愚. 碳纤维布表面PyC界面相微观结构及均匀性的工艺调控[J]. 无机材料学报, 2024, 39(4): 399-408. |

| [9] | 陶顺衍, 杨加胜, 邵芳, 吴应辰, 赵华玉, 董绍明, 张翔宇, 熊瑛. 航机CMC热端部件用热喷涂涂层的机遇与挑战[J]. 无机材料学报, 2024, 39(10): 1077-1083. |

| [10] | 阮景, 杨金山, 闫静怡, 游潇, 王萌萌, 胡建宝, 张翔宇, 丁玉生, 董绍明. 三维碳化硅纳米线增强碳化硅陶瓷基复合材料的电磁屏蔽性能[J]. 无机材料学报, 2022, 37(5): 579-584. |

| [11] | 魏婷婷, 高希光, 宋迎东. 2D SiC/SiC复合材料电阻率对服役环境的响应特性[J]. 无机材料学报, 2022, 37(4): 420-426. |

| [12] | 王洪达, 冯倩, 游潇, 周海军, 胡建宝, 阚艳梅, 陈小武, 董绍明. SiC/SiC-哈氏合金异质连接机制及其氟熔盐腐蚀特性分析[J]. 无机材料学报, 2022, 37(4): 452-458. |

| [13] | 琚印超, 刘小勇, 王琴, 张伟刚, 魏玺. 超高温复相陶瓷基复合材料烧蚀行为研究[J]. 无机材料学报, 2022, 37(1): 86-92. |

| [14] | 马登浩, 侯振华, 李军平, 孙新, 金恩泽, 尹健. 界面相对3D-SiC/SiC复合材料静态力学性能及内耗特征的影响[J]. 无机材料学报, 2021, 36(1): 55-60. |

| [15] | 党潇琳, 范晓孟, 殷小玮, 马昱昭, 马晓康. 多功能一体化MAX相改性连续纤维增韧陶瓷基复合材料的研究进展[J]. 无机材料学报, 2020, 35(1): 29-34. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||