无机材料学报 ›› 2021, Vol. 36 ›› Issue (7): 685-694.DOI: 10.15541/jim20200440 CSTR: 32189.14.10.15541/jim20200440

收稿日期:2020-08-10

修回日期:2020-10-10

出版日期:2021-07-20

网络出版日期:2020-10-30

通讯作者:

王松, 研究员. E-mail:wangs_0731@163.com

作者简介:肖鹏(1991-), 男, 博士研究生. E-mail:xspi3@126.com

XIAO Peng1( ), ZHU Yulin2, WANG Song1(

), ZHU Yulin2, WANG Song1( ), YU Yiping1, LI Hao1

), YU Yiping1, LI Hao1

Received:2020-08-10

Revised:2020-10-10

Published:2021-07-20

Online:2020-10-30

Contact:

WANG Song, professor. E-mail:wangs_0731@163.com

About author:XIAO Peng(1991-)male, PhD candidate. E-mail:xspi3@126.com

摘要:

TaxHf1-xC固溶陶瓷是碳化钽(TaC)和碳化铪(HfC)在一定条件下以任意比例形成的系列固溶体, 其熔点普遍在4000 K以上, 最高可达4300 K, 且硬度高、模量高、热导率低、抗高温氧化和抗烧蚀性能优异, 具备在极端热环境(>3000 K)下服役的潜力, 成为耐超高温材料领域的研究热点和前沿。本文综述了近年来TaxHf1-xC固溶陶瓷在粉体合成技术、致密化工艺和机理、室温力学性能、热物理性能、抗氧化性能、抗烧蚀性能等方面所取得的研究进展, 分析了TaxHf1-xC固溶陶瓷粉体不同合成技术的优劣及致密化的难点, 讨论了TaxHf1-xC固溶陶瓷组成、结构和性能之间的相互关系。此外, 本文还指出了TaxHf1-xC固溶陶瓷目前存在的挑战, 并对未来潜在的发展方向作了展望。

中图分类号:

肖鹏, 祝玉林, 王松, 余艺平, 李浩. 超高熔点TaxHf1-xC固溶陶瓷的制备工艺与性能研究进展[J]. 无机材料学报, 2021, 36(7): 685-694.

XIAO Peng, ZHU Yulin, WANG Song, YU Yiping, LI Hao. Research Progress on the Preparation and Characterization of Ultra Refractory TaxHf1-xC Solid Solution Ceramics[J]. Journal of Inorganic Materials, 2021, 36(7): 685-694.

| Solid solution between metal carbides | Carbonization reaction of metals | Carbothermal reduction of metal oxides | |

|---|---|---|---|

| Advantages | Easy to operate; products have high purity and could achieve densification simultaneously | High temperature is not necessary; the whole process lasts only several seconds, not time consuming | Easy to operate; raw materials are cheap; have potential to synthesize single-phase products with fine grain size at relatively low temperature |

| Disadvantages | Needs high temperature and long time; products are not single-phase solid solution with elements uneven distribution | The reaction process are unable to control; products are usually not pure | The phase and microstructure of products are closely related to the distribution and binding state of oxides and carbon |

表1 TaxHf1-xC固溶陶瓷粉体不同合成技术的优缺点

Table 1 Advantages and disadvantages of different techniques for preparation of TaxHf1-xC powder

| Solid solution between metal carbides | Carbonization reaction of metals | Carbothermal reduction of metal oxides | |

|---|---|---|---|

| Advantages | Easy to operate; products have high purity and could achieve densification simultaneously | High temperature is not necessary; the whole process lasts only several seconds, not time consuming | Easy to operate; raw materials are cheap; have potential to synthesize single-phase products with fine grain size at relatively low temperature |

| Disadvantages | Needs high temperature and long time; products are not single-phase solid solution with elements uneven distribution | The reaction process are unable to control; products are usually not pure | The phase and microstructure of products are closely related to the distribution and binding state of oxides and carbon |

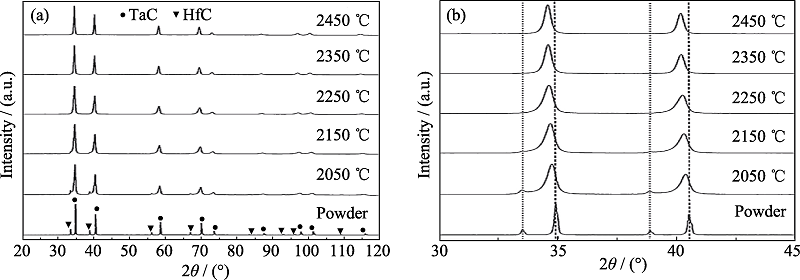

图1 (a)不同合成温度制得Ta0.8Hf0.2C固溶陶瓷的XRD图谱; (b) 2θ为30°~45°区间的XRD图谱[32]

Fig. 1 (a) XRD patterns of Ta0.8Hf0.2C solid solution ceramic before and after SPS at different temperatures and (b) more detailed diffraction patterns between 30° and 45°[32]

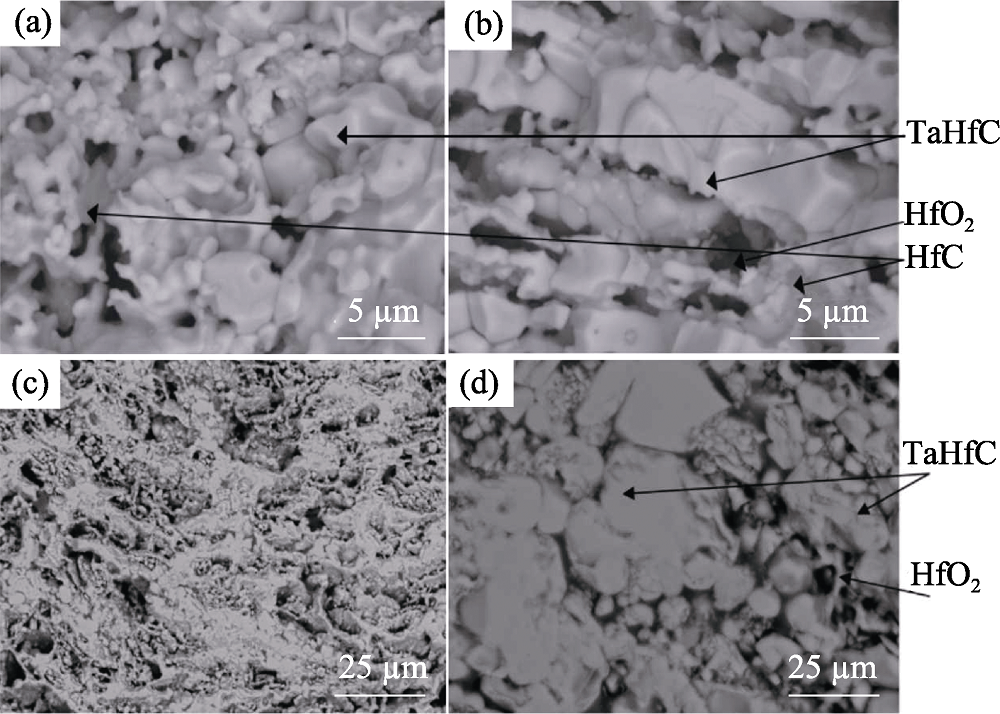

图2 不同SHS工艺合成的Ta0.8Hf0.2C固溶陶瓷粉体微观形貌[43]

Fig. 2 Morphology of Ta0.8Hf0.2C solid solution ceramics synthesised by different SHS methods[43] (a,b) Mixed Ta, Hf and carbon black simultaneously; (c,d) Mixed Hf and carbon black first

图3 采用溶剂热合成Ta0.5Hf0.5C固溶陶瓷粉体的微观形貌[21]

Fig. 3 Morphologies of Ta0.5Hf0.5C powders synthesized via solvothermal method[21] (a) SEM image; (b) TEM image; (c) HRTEM image; (d) EDS mapping

| Raw powder | Sintering method | Relative density/% | Hardness/GPa | Elastic modulus/GPa | KIC/(MPa·m1/2) | Ref. | |

|---|---|---|---|---|---|---|---|

| Ta0.9Hf0.1C-12vol% MoSi2 | TaC, HfC, MoSi2 | SPS | 100.0 | (15.0±0.2) | — | (3.2±0.3) | [26] |

| Ta0.9Hf0.1C-12vol% TaSi2 | TaC, HfC, TaSi2 | SPS | 100.0 | (15.9±0.3) | — | (3.3±0.2) | [26] |

| Ta0.87Hf0.13C | TaC, HfC | HIP | >98.0 | 24.1 | 575.4 | — | [3] |

| Ta0.8Hf0.2C | Ta0.8Hf0.2C | HP | 99.6 | (30.3±1.6) | (462.5±3.1) | (2.2±0.4) | [30] |

| Ta0.8Hf0.2C | TaxHf1-xC | HP | 94.4 | 27.2 | 491.7 | 3.0 | [21] |

| Ta0.8Hf0.2C | TaC, HfC | SPS | 97.8 | (16.7±0.9) | (443.2±23.7) | (4.6±1.1) | [40] |

| Ta0.8Hf0.2C | TaC, HfC | SPS | (97.7±0.1) | (19.3±1.3) | (459.0±5.8) | (2.9±0.9) | [32] |

| Ta0.8Hf0.2C-10vol% MoSi2 | TaC, HfC, MoSi2 | SPS | 99.8 | (18.5±0.5) | (482.0±2.0) | (4.2±0.2) | [29] |

| Ta0.8Hf0.2C-12vol% MoSi2 | TaC, HfC, MoSi2 | SPS | 100.0 | (15.2±0.5) | — | (3.9±0.2) | [26] |

| Ta0.8Hf0.2C-12vol% TaSi2 | TaC, HfC, TaSi2 | SPS | 100.0 | (17.7±0.4) | — | (3.2±0.1) | [26] |

| Ta0.75Hf0.25C | TaC, HfC | HIP | >98.0 | 28.6 | 567.7 | — | [3] |

| Ta0.7Hf0.3C-12vol% MoSi2 | TaC, HfC, MoSi2 | SPS | 97.8 | (15.9±0.6) | — | (3.9±0.1) | [26] |

| Ta0.7Hf0.3C-12vol% TaSi2 | TaC, HfC, TaSi2 | SPS | 98.9 | (18.2±0.7) | — | (2.8±0.1) | [26] |

| Ta0.67Hf0.33C | Ta0.67Hf0.33C | HP | 95.3 | 29.7 | 483.0 | 2.5 | [21] |

| Ta0.5Hf0.5C | Ta0.5Hf0.5C | HP | 99.2 | (36.7±1.2) | (559.3±6.5) | (2.9±0.4) | [30] |

| Ta0.5Hf0.5C | Ta0.5Hf0.5C | HP | 97.9 | 37.9 | 591.0 | 2.5 | [21] |

| Ta0.5Hf0.5C | TaC, HfC | SPS | 98.2 | (17.1±1.1) | (523.8±7.0) | (6.0±0.7) | [40] |

| Ta0.5Hf0.5C | TaC, HfC | SPS | (95.7±0.3) | (22.1±1.8) | (549.0±11.2) | (2.9±0.7) | [32] |

| Ta0.5Hf0.5C | TaC, HfC | HIP | >97.0 | 23.5 | 469.9 | — | [3] |

| Ta0.3Hf0.7C | HfO2, Ta2O5, graphite | SPS | 98.7 | (20.0±0.9) | — | (5.2±0.2) | [48] |

| Ta0.25Hf0.75C | Ta0.25Hf0.75C | HP | 96.5 | (29.9±2.2) | (436.4±13.8) | (2.2±0.2) | [30] |

| Ta0.25Hf0.75C | TaC, HfC | HIP | >98.0 | 29.1 | 593.5 | — | [3] |

| Ta0.2Hf0.8C | Ta0.2Hf0.8C | HP | 95.9 | (35.1±1.1) | (554.7±8.8) | (2.3±0.5) | [21] |

| Ta0.2Hf0.8C | TaC, HfC | SPS | (87.0±0.2) | (16.7±3.0) | (438.0±17.8) | (3.4±0.6) | [32] |

| Ta0.2Hf0.8C | TaC, HfC | SPS | 98.8 | (19.1±0.3) | (577.3±6.0) | (5.5±0.6) | [40] |

| Ta0.2Hf0.8C | HfO2, Ta2O5, graphite | SPS | 100.0 | (19.7±0.7) | — | 5.1 | [48] |

| Ta0.17Hf0.83C | TaC, HfC | HIP | >98.0 | 26.6 | 534.2 | — | [3] |

| Ta0.1Hf0.9C | HfO2, Ta2O5, graphite | SPS | 99.3 | (19.7±0.8) | — | — | [48] |

表2 TaxHf1-xC固溶陶瓷的室温力学性能

Table 2 Mechanical properties of TaxHf1-xC solid solution ceramics at room temperature

| Raw powder | Sintering method | Relative density/% | Hardness/GPa | Elastic modulus/GPa | KIC/(MPa·m1/2) | Ref. | |

|---|---|---|---|---|---|---|---|

| Ta0.9Hf0.1C-12vol% MoSi2 | TaC, HfC, MoSi2 | SPS | 100.0 | (15.0±0.2) | — | (3.2±0.3) | [26] |

| Ta0.9Hf0.1C-12vol% TaSi2 | TaC, HfC, TaSi2 | SPS | 100.0 | (15.9±0.3) | — | (3.3±0.2) | [26] |

| Ta0.87Hf0.13C | TaC, HfC | HIP | >98.0 | 24.1 | 575.4 | — | [3] |

| Ta0.8Hf0.2C | Ta0.8Hf0.2C | HP | 99.6 | (30.3±1.6) | (462.5±3.1) | (2.2±0.4) | [30] |

| Ta0.8Hf0.2C | TaxHf1-xC | HP | 94.4 | 27.2 | 491.7 | 3.0 | [21] |

| Ta0.8Hf0.2C | TaC, HfC | SPS | 97.8 | (16.7±0.9) | (443.2±23.7) | (4.6±1.1) | [40] |

| Ta0.8Hf0.2C | TaC, HfC | SPS | (97.7±0.1) | (19.3±1.3) | (459.0±5.8) | (2.9±0.9) | [32] |

| Ta0.8Hf0.2C-10vol% MoSi2 | TaC, HfC, MoSi2 | SPS | 99.8 | (18.5±0.5) | (482.0±2.0) | (4.2±0.2) | [29] |

| Ta0.8Hf0.2C-12vol% MoSi2 | TaC, HfC, MoSi2 | SPS | 100.0 | (15.2±0.5) | — | (3.9±0.2) | [26] |

| Ta0.8Hf0.2C-12vol% TaSi2 | TaC, HfC, TaSi2 | SPS | 100.0 | (17.7±0.4) | — | (3.2±0.1) | [26] |

| Ta0.75Hf0.25C | TaC, HfC | HIP | >98.0 | 28.6 | 567.7 | — | [3] |

| Ta0.7Hf0.3C-12vol% MoSi2 | TaC, HfC, MoSi2 | SPS | 97.8 | (15.9±0.6) | — | (3.9±0.1) | [26] |

| Ta0.7Hf0.3C-12vol% TaSi2 | TaC, HfC, TaSi2 | SPS | 98.9 | (18.2±0.7) | — | (2.8±0.1) | [26] |

| Ta0.67Hf0.33C | Ta0.67Hf0.33C | HP | 95.3 | 29.7 | 483.0 | 2.5 | [21] |

| Ta0.5Hf0.5C | Ta0.5Hf0.5C | HP | 99.2 | (36.7±1.2) | (559.3±6.5) | (2.9±0.4) | [30] |

| Ta0.5Hf0.5C | Ta0.5Hf0.5C | HP | 97.9 | 37.9 | 591.0 | 2.5 | [21] |

| Ta0.5Hf0.5C | TaC, HfC | SPS | 98.2 | (17.1±1.1) | (523.8±7.0) | (6.0±0.7) | [40] |

| Ta0.5Hf0.5C | TaC, HfC | SPS | (95.7±0.3) | (22.1±1.8) | (549.0±11.2) | (2.9±0.7) | [32] |

| Ta0.5Hf0.5C | TaC, HfC | HIP | >97.0 | 23.5 | 469.9 | — | [3] |

| Ta0.3Hf0.7C | HfO2, Ta2O5, graphite | SPS | 98.7 | (20.0±0.9) | — | (5.2±0.2) | [48] |

| Ta0.25Hf0.75C | Ta0.25Hf0.75C | HP | 96.5 | (29.9±2.2) | (436.4±13.8) | (2.2±0.2) | [30] |

| Ta0.25Hf0.75C | TaC, HfC | HIP | >98.0 | 29.1 | 593.5 | — | [3] |

| Ta0.2Hf0.8C | Ta0.2Hf0.8C | HP | 95.9 | (35.1±1.1) | (554.7±8.8) | (2.3±0.5) | [21] |

| Ta0.2Hf0.8C | TaC, HfC | SPS | (87.0±0.2) | (16.7±3.0) | (438.0±17.8) | (3.4±0.6) | [32] |

| Ta0.2Hf0.8C | TaC, HfC | SPS | 98.8 | (19.1±0.3) | (577.3±6.0) | (5.5±0.6) | [40] |

| Ta0.2Hf0.8C | HfO2, Ta2O5, graphite | SPS | 100.0 | (19.7±0.7) | — | 5.1 | [48] |

| Ta0.17Hf0.83C | TaC, HfC | HIP | >98.0 | 26.6 | 534.2 | — | [3] |

| Ta0.1Hf0.9C | HfO2, Ta2O5, graphite | SPS | 99.3 | (19.7±0.8) | — | — | [48] |

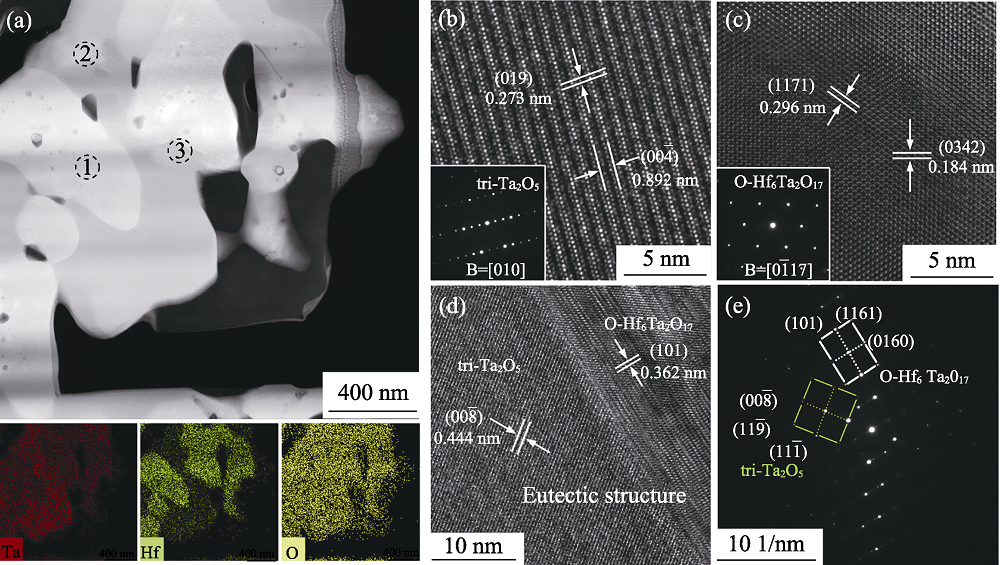

图6 Hf6Ta2O17-Ta2O5共晶结构的形貌[6]

Fig. 6 Morphologies of Hf6Ta2O17-Ta2O5 eutectic structure[6] (a) STEM imagies and associated EDS element mapping; (b) HRTEM image and corresponding SAED pattern of area 2; (c) HRTEM image and corresponding SAED pattern of area 1; (d) HRTEM image of area 3; (e) SAED pattern of area 3

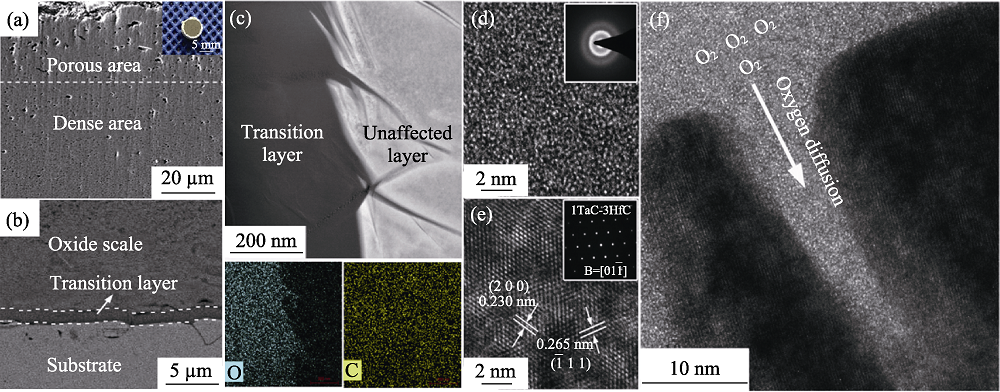

图7 Ta0.25Hf0.75C固溶陶瓷的氧化层微观形貌[6]

Fig. 7 Morphologies of Ta0.25Hf0.75C ceramic after oxidation[6] (a,b) SEM image of oxide scale; (c) STEM image of transition layer; (d) STEM and SAED results for transition layer; (e) STEM and SAED results for unaffected layer; (f) STEM result for border area of transition layer and unaffected layer

| [1] | BARRAZA O C. Process development and characterisation of (Ta, Hf)C ultra-high temperature ceramics. London: Imperial College London, PhD Thesis, 2015. |

| [2] |

SAVVATIMSKIY A I, ONUFRIEV S V, MUBOYADZHYAN S A. Thermophysical properties of the most refractory carbide Ta0.8Hf0.2C under high temperatures (2000-5000 K). Journal of the European Ceramic Society, 2019,39:907-914.

DOI URL |

| [3] |

SMITH C J, YU X X, GUO Q Y, et al. Phase, hardness, and deformation slip behavior in mixed HfxTa1-xC. Acta Materialia, 2018,145:142-153.

DOI URL |

| [4] |

IVASHCHENKO V I, TURCHI P E A, MEDUKH N R, et al. A first-principles study of the stability and mechanical properties of ternary transition metal carbide alloys. Journal of Applied Physics, 2019,125:235101.

DOI URL |

| [5] |

KIM J, KWON H, KIM B, et al. Finite temperature thermal expansion and elastic properties of (Hf1-xTax)C ultrahigh temperature ceramics. Ceramics International, 2019,45(8):10805-10809.

DOI URL |

| [6] |

ZHANG J, WANG S, LI W, et al. Understanding the oxidation behavior of Ta-Hf-C ternary ceramics at high temperature. Corrosion Science, 2020,164:108348.

DOI URL |

| [7] |

ZHANG C, BOESL B, AGARWAL A. Oxidation resistance of tantalum carbide-hafnium carbide solid solutions under the extreme conditions of a plasma jet. Ceramics International, 2017,43(17):14798-14806.

DOI URL |

| [8] |

PATTERSON M C L, HE S, FEHRENBACHER L L, et al. Advanced HfC-TaC oxidation resistant composite rocket thruster. Materials and Manufacturing Processes, 1996,11(3):367-379.

DOI URL |

| [9] | PATTERSON M C L, FULCHER M, HILMAS G, et al. Advanced tactical and boost nozzle materials. 41st AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Tucson, 2005: 4497-4509. |

| [10] | DEADMORE D L. Vaporization of tantalum carbide-hafnium carbide solid solutions at 2500 to 3000 K, NASA TECHNICAL NOTE, TN D-2512, Washington, D. C, 1964: 1-17. |

| [11] |

DEADMORE D L. Normal spectral emittance (0.65) of TaC-HfC solid solutions and tungsten above 1600 ℃. Journal of the American Ceramic Society, 1964,47(12):649-650.

DOI URL |

| [12] |

DEADMORE D L. Vaporization of tantalum carbide-hafnium carbide solid solutions. Journal of the American Ceramic Society, 1965,48(7):357-359.

DOI URL |

| [13] | RUDY E. Ternary phase equilibria in transition metal-boron-carbon- silicon systems. Part II. Ternary systems. Vol. I. Ta-Hf-C system. Air Force Materials Laboratory Technical Report, AD-470827/7/XAB, United States, 1965. |

| [14] | RUDY E. Ternary phase equilibra in transition metal-boron-carbon- silicon systems. Part V. Compendium of phase diagram data. Air Force Materials Laboratory Technical Report, AFML-TR-65-2, United States, 1969. |

| [15] |

ANDRIEVSKII R A, STRELNIKOVA N S, POLTORATSKII N I, et al. Melting point in systems ZrC-HfC, TaC-ZrC, TaC-HfC. Soviet Powder Metallurgy and Metal Ceramics, 1967,6(1):65-67.

DOI URL |

| [16] |

BARANTSEVA I G, PADERNO V N, PADERNO Y B. Some physical properties of alloys of the systems ZrC-NbC and TaC-HfC. Soviet Powder Metallurgy and Metal Ceramics, 1967,6:139-141.

DOI URL |

| [17] | BARANTSEVA I G, PADERNO V N. Thermal expansion of solid solutions in the systems ZrC-NbC and HfC-TaC. Refractory Carbides. New York: Springer, 1974: 283-285. |

| [18] |

KIM J, KIM M, ROH K, et al. Bond characteristics, mechanical properties, and high-temperature thermal conductivity of (Hf1-xTax)C composites. Journal of the American Ceramic Society, 2019,102(10):6298-6308.

DOI URL |

| [19] |

PAN Y F, ZHOU P, PENG Y B, et al. A thermodynamic description of the C-Hf-Ta system over the whole composition and temperature ranges. CALPHAD: Computer Coupling of Phase Diagrams and Thermochemistry, 2016,53:1-9.

DOI URL |

| [20] |

JIANG J M, WANG S, LI W. Preparation and characterization of ultrahigh-temperature ternary ceramics Ta4HfC5. Journal of the American Ceramic Society, 2016,99(10):3198-3201.

DOI URL |

| [21] | 蒋进明. Ta-Hf(Zr)-C三元陶瓷的制备及性能研究. 长沙: 国防科技大学博士学位论文, 2017. |

| [22] |

FOROUGHI P, ZHANG CHENG, AGARWAL A, et al. Controlling phase separation of TaxHf1-xC solid solution nanopowders during carbothermal reduction synthesis. Journal of the American Ceramic Society, 2017,100(11):5056-5065.

DOI URL |

| [23] |

SIMONENKO E P, IGNATOV N A, SIMONENKO N P, et al. Synthesis of highly dispersed super-refractory tantalum-zirconium carbide Ta4ZrC5 and tantalum-hafnium carbide Ta4HfC5 via Sol- Gel technology. Russian Journal of Inorganic Chemistry, 2011,56(11):1681-1687.

DOI URL |

| [24] |

ZHANG Z, FU S, AVERSANO F, et al. Arc melting: a novel method to prepare homogeneous solid solutions of transition metal carbides (Zr, Ta, Hf). Ceramics International, 2019,45:9316-9319.

DOI URL |

| [25] |

GABALLA O, COOK B A, RUSSELL A M. Reduced-temperature processing and consolidation of ultra-refractory Ta4HfC5. International Journal of Refractory Metals and Hard Materials, 2013,41:293-299.

DOI URL |

| [26] |

GHAFFARI S A, FAGHIHI-SANI M A, GOLESTANI-FARD F, et al. Spark plasma sintering of TaC-HfC UHTC via disilicides sintering aids. Journal of the European Ceramic Society, 2013,33:1479-1484.

DOI URL |

| [27] |

GHAFFARI S A, FAGHIHI-SANI M A, GOLESTANI-FARD F. Pressureless sintering of Ta0.8Hf0.2C UHTC in the presence of MoSi2. Ceramics International, 2013,39:1985-1989.

DOI URL |

| [28] |

ARIANPOUR F, REZAIE H, GOLESTANI-FARD F, et al. Processing and consolidation of TaC/HfC based composites using MoSi2 and carbon nanotubes. Journal of Nano Research, 2013,21:145-150.

DOI URL |

| [29] |

ARIANPOUR F, GOLESTANI-FARD F, REZAIE H, et al. Processing, phase evaluation and mechanical properties of MoSi2 doped 4TaC-HfC based UHTCs consolidated by spark plasma sintering. International Journal of Refractory Metals and Hard Materials, 2016,56:1-7.

DOI URL |

| [30] |

ZHANG J, WANG S, LI W. Consolidation and characterization of highly dense single phase Ta-Hf-C solid solution ceramics. Journal of the American Ceramic Society, 2019,102(1):58-62.

DOI URL |

| [31] | BARRAZA O C, MANARA D, BOBORIDIS K. Investigating the highest melting temperature materials: a laser melting study of the TaC-HfC system. Scientific Reports, 2016,6:37962. |

| [32] |

BARRAZA O C, GRASSO S, NASIRI N A, et al. Sintering behaviour, solid solution formation and characterisation of TaC, HfC and TaC-HfC fabricated by spark plasma sintering. Journal of the European Ceramic Society, 2016,36:1539-1548.

DOI URL |

| [33] | GUZMÁN P, APERADOR W, YATE L. Enhancement of the pitting corrosion resistance of AISI 316LVM steel with Ta-Hf-C/Au bilayers for biomedical applications. Journal of Nanomaterials, 2017,2017:1-10. |

| [34] |

GUZMÁN P, YATE L, SANDOVAL M, et al. Characterization of the micro-abrasive wear in coatings of TaC-HfC/Au for biomedical implants. Materials, 2017,10(8):842.

DOI URL |

| [35] |

WANG Y L, XIONG X, LI G D, et al. Preparation and ablation properties of Hf(Ta)C co-deposition coating for carbon/carbon composites. Corrosion Science, 2013,66:177-182.

DOI URL |

| [36] |

MONTEYNARD A D, LUO H, CHEHIMI M, et al. The structure, morphology, and mechanical properties of Ta-Hf-C coatings deposited by pulsed direct current reactive magnetron sputtering. Coatings, 2020,10(3):212.

DOI URL |

| [37] | VALENCIA D P, YATE L, APERADOR W, et al. High electrocatalytic response of ultra-refractory ternary alloys of Ta-Hf-C carbide toward hydrogen evolution reaction in acidic media. The Journal of Physical Chemistry C, 2018,122(44):25433-25440. |

| [38] |

YATE L, COY L E, APERADOR W. Robust tribo-mechanical and hot corrosion resistance of ultra-refractory Ta-Hf-C ternary alloy films. Scientific Reports, 2017,7:3080.

DOI URL |

| [39] | GABALLA O. Processing development of 4TaC-HfC and related carbides and borides for extreme environments. Ames: Iowa State University, PhD Thesis, 2012. |

| [40] |

ZHANG C, GUPTA A, SEAL S, et al. Solid solution synthesis of tantalum carbide-hafnium carbide by spark plasma sintering. Journal of the American Ceramic Society, 2017,100(5):1853-1862.

DOI URL |

| [41] |

GHAFFARI S A, FAGHIHI-SANI M A, GOLESTANI-FARD F, et al. Diffusion and solid solution formation between the binary carbides of TaC, HfC and ZrC. International Journal of Refractory Metals and Hard Materials, 2013,41:180-184.

DOI URL |

| [42] |

CASTLE E, CSANADI T, GRASSO S, et al. Processing and properties of high-entropy ultra-high temperature carbides. Scientific Reports, 2018,8:8609.

DOI URL |

| [43] |

KURBATKINA V V, PATSERA E I, LEVASHOV E A, et al. Self- propagating high-temperature synthesis of single-phase binary tantalum-hafnium carbide (Ta, Hf)C and its consolidation by hot pressing and spark plasma sintering. Ceramics International, 2018,44(4):4320-4329.

DOI URL |

| [44] | KURBATKINA V V, PATSERA E I, LEVASHOV E A, et al. SHS processing and consolidation of Ta-Ti-C, Ta-Zr-C, and Ta-Hf-C carbides for ultra-high-temperatures application. Advanced Engineering Materials, 2018,20(8):1701075. |

| [45] |

PATSERA E I, KURBATKINA V V, LEVASHOV E A, et al. Research into the possibility of producing single-phase tantalum- hafnium carbide by SHS. Russian Journal of Non-Ferrous Metals, 2018,59(5):576-582.

DOI URL |

| [46] |

NAZAROVA S Z, KURMAEV E Z, MEDVEDEVA N I. Physical properties and electronic structure of TaC-HfC solid solutions. Russian Journal of Inorganic Chemistry, 2007,52(2):233-237.

DOI URL |

| [47] |

FENG L, KIM J, LEE S, et al. Synthesis of a fine (Ta0.8, Hf0.2)C powder from carbide or oxide powder mixtures. Journal of the American Ceramic Society, 2016,99(4):1129-1132.

DOI URL |

| [48] |

HA D, KIM J, HAN J, et al. Synthesis and properties of (Hf1-xTax)C solid solution carbides. Ceramics International, 2018,44(16):19247-19253.

DOI URL |

| [49] |

LU Y, SUN Y N, ZHANG T Z, et al. Polymer-derived Ta4HfC5 nanoscale ultrahigh-temperature ceramics: synthesis, microstructure and properties. Journal of the European Ceramic Society, 2019,39:205-211.

DOI URL |

| [50] |

SUN Y N, YANG C M, LU Y, et al. Transformation of metallic polymer precursor into nanosized HfTaC2 ceramics. Ceramics International, 2020,46:6022-6028.

DOI URL |

| [51] |

REZAEI F, KAKROUDI M G, SHAHEDIFAR V, et al. Consolidation and mechanical properties of hot pressed TaC-HfC-VC composites. Ceramics International, 2017,43(17):15537-15543.

DOI URL |

| [52] |

ZHANG B H, YIN J, CHEN J, et al. Pressureless densification, microstructure tailoring and properties of Ta0.8Hf0.2C-based composites. Journal of the European Ceramic Society, 2018,38:1227-1236.

DOI URL |

| [53] |

ZHANG B H, YIN J, ZHENG J Q, et al. High temperature ablation behavior of pressureless sintered Ta0.8Hf0.2C-based ultra-high temperature ceramics. Journal of the European Ceramic Society, 2020,40:1784-1789.

DOI URL |

| [54] |

ZHANG B H, YIN J, HUANG Y H, et al. Harmonized toughening and strengthening in pressurelessly reactive-sintered Ta0.8Hf0.2C-SiC composite. Journal of the European Ceramic Society, 2018,38:5610-5614.

DOI URL |

| [55] | HONG Q J, WALLE A V D. Prediction of the material with highest known melting point from ab initio molecular dynamics calculations. Physical Review B, 2015,92(2):020104. |

| [56] | ZHANG C, LOGANATHAN A, BOESL B. Thermal analysis of tantalum carbide-hafnium carbide solid solutions from room temperature to 1400 ℃. Coatings, 2017,7(8):111. |

| [57] | COURTRIGHT E L, PRATER J T, HOLCOMB G R, et al. Oxidation of hafnium carbide and hafnium carbide with additions of tantalum and praseodymium. Oxidation of Metals, 1991,36(5/6):423-437. |

| [58] | MCCORMACK S J, TSENG K P, WEBER R J K, et al. In-situ determination of the HfO2-Ta2O5-temperature phase diagram up to 3000 ℃. Journal of the American Ceramic Society, 2019,102(8):4848-4861. |

| [59] | MCCORMACK S J, WEBER R J, KRIVEN W M. In-situ investigation of Hf6Ta2O17 anisotropic thermal expansion and topotactic, peritectic transformation. Acta Materialia, 2018,161:127-137. |

| [60] | FENG G H, LI H J, YAO X Y, et al. Ablation resistance of TaC- modified HfC coating prepared by supersonic plasma spraying for SiC-coated carbon/carbon composites. Ceramics International, 2019,45(14):17936-17945. |

| [61] | FENG G H, LI H J, YANG L, et al. Investigation on the ablation performance and mechanism of HfC coating modified with TaC. Corrosion Science, 2020,170:108649. |

| [62] | REN J C, ZHANG Y L, FU Y Q, et al. Effects of the second phase on the microstructure and ablation resistance of HfC coating on C/C composites. Surface & Coatings Technology, 2018,344:250-258. |

| [1] | 朱文杰, 唐璐, 陆继长, 刘江平, 罗永明. 钙钛矿型氧化物催化氧化挥发性有机化合物的研究进展[J]. 无机材料学报, 2025, 40(7): 735-746. |

| [2] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [3] | 吴琼, 沈炳林, 张茂华, 姚方周, 邢志鹏, 王轲. 铅基织构压电陶瓷研究进展[J]. 无机材料学报, 2025, 40(6): 563-574. |

| [4] | 张碧辉, 刘小强, 陈湘明. Ruddlesden-Popper结构杂化非常规铁电体的研究进展[J]. 无机材料学报, 2025, 40(6): 587-608. |

| [5] | 吴杰, 杨帅, 王明文, 李景雷, 李纯纯, 李飞. 铅基织构压电陶瓷的发展历程、现状与挑战[J]. 无机材料学报, 2025, 40(6): 575-586. |

| [6] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| [7] | 田睿智, 兰正义, 殷杰, 郝南京, 陈航榕, 马明. 基于微流控技术的纳米无机生物材料制备: 原理及其研究进展[J]. 无机材料学报, 2025, 40(4): 337-347. |

| [8] | 张继国, 吴田, 赵旭, 杨钒, 夏天, 孙士恩. 钠离子电池正极材料循环稳定性提升策略及产业化进程[J]. 无机材料学报, 2025, 40(4): 348-362. |

| [9] | 殷杰, 耿佳毅, 王康龙, 陈忠明, 刘学建, 黄政仁. SiC陶瓷的3D打印成形与致密化新进展[J]. 无机材料学报, 2025, 40(3): 245-255. |

| [10] | 谌广昌, 段小明, 朱金荣, 龚情, 蔡德龙, 李宇航, 杨东雷, 陈彪, 李新民, 邓旭东, 余瑾, 刘博雅, 何培刚, 贾德昌, 周玉. 直升机特定结构先进陶瓷材料研究进展与应用展望[J]. 无机材料学报, 2025, 40(3): 225-244. |

| [11] | 范晓波, 祖梅, 杨向飞, 宋策, 陈晨, 王子, 罗文华, 程海峰. 质子调控型电化学离子突触研究进展[J]. 无机材料学报, 2025, 40(3): 256-270. |

| [12] | 海热古·吐逊, 郭乐, 丁嘉仪, 周嘉琪, 张学良, 努尔尼沙·阿力甫. 上转换荧光探针辅助的光学成像技术在肿瘤显影中的应用研究进展[J]. 无机材料学报, 2025, 40(2): 145-158. |

| [13] | 孙树娟, 郑南南, 潘昊坤, 马猛, 陈俊, 黄秀兵. 单原子催化剂制备方法的研究进展[J]. 无机材料学报, 2025, 40(2): 113-127. |

| [14] | 陶桂龙, 支国伟, 罗添友, 欧阳佩东, 衣新燕, 李国强. 空腔型薄膜体声波滤波器的关键技术进展[J]. 无机材料学报, 2025, 40(2): 128-144. |

| [15] | 周帆, 田志林, 李斌. 热防护系统用碳化物超高温陶瓷抗烧蚀涂层研究进展[J]. 无机材料学报, 2025, 40(1): 1-16. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||