无机材料学报 ›› 2021, Vol. 36 ›› Issue (7): 673-684.DOI: 10.15541/jim20200404 CSTR: 32189.14.10.15541/jim20200404

所属专题: 【虚拟专辑】气凝胶,玻璃(2020~2021)

• 综述 • 下一篇

彭飞( ), 姜勇刚(

), 姜勇刚( ), 冯坚(

), 冯坚( ), 蔡华飞, 冯军宗, 李良军

), 蔡华飞, 冯军宗, 李良军

收稿日期:2020-07-20

修回日期:2020-09-17

出版日期:2021-07-20

网络出版日期:2020-10-30

通讯作者:

姜勇刚, 副研究员. E-mail: jygemail@nudt.edu.cn;冯坚, 研究员. E-mail:fengj@nudt.edu.cn

作者简介:彭飞(1985-), 男, 博士研究生. E-mail: feijigong@126.com

基金资助:

PENG Fei( ), JIANG Yonggang(

), JIANG Yonggang( ), FENG Jian(

), FENG Jian( ), CAI Huafei, FENG Junzong, LI Liangjun

), CAI Huafei, FENG Junzong, LI Liangjun

Received:2020-07-20

Revised:2020-09-17

Published:2021-07-20

Online:2020-10-30

Contact:

JIANG Yonggang, associate professor. E-mail:jygemail@nudt.edu.cn;FENG Jian, professor. E-mail:fengj@nudt.edu.cn

About author:PENG Fei (1985-), male, PhD candidate. E-mail: feijigong@126.com

Supported by:摘要:

氧化铝气凝胶是一种高孔隙率、低密度、高比表面积、耐高温和低热导的纳米多孔材料, 在高温隔热领域(如航天飞行器热防护系统、工业窑炉保温材料等)具有广阔的应用前景。但是, 纯氧化铝气凝胶因耐温性(1000 ℃以上)、力学性能和高温隔热性能相对较差难以直接应用, 需要引入增强相和遮光组分制备成气凝胶复合材料以进行改善。本文对耐高温氧化铝气凝胶的制备、氧化铝气凝胶隔热复合材料的制备及性能等方面的最新研究进展进行了综述。研究人员通过原位掺杂改性、沉积改性、有机链和炭涂层改性等方法提高了氧化铝气凝胶的热稳定性。在氧化铝气凝胶中引入晶须、颗粒、多孔骨架和纤维等增强相, 能够大幅提高其力学性能; 纤维和遮光剂的协同作用, 能够提高氧化铝气凝胶抑制红外辐射的能力, 显著降低高温热导率。本文还提出了后续的研究方向:对氧化铝气凝胶的密度、微观结构进行精细调控, 再引入合适的异质元素和遮光剂,以进一步提高气凝胶的热稳定性和复合材料的隔热性能;深入研究复合材料在高温下结构和性能的演化, 以及氧化铝气凝胶和增强相之间的相互作用。作为一种新型的隔热材料, 氧化铝气凝胶复合材料将在高温隔热领域发挥其优势并逐步实现广泛应用。

中图分类号:

彭飞, 姜勇刚, 冯坚, 蔡华飞, 冯军宗, 李良军. 耐高温氧化铝气凝胶隔热复合材料研究进展[J]. 无机材料学报, 2021, 36(7): 673-684.

PENG Fei, JIANG Yonggang, FENG Jian, CAI Huafei, FENG Junzong, LI Liangjun. Research Progress on Alumina Aerogel Composites for High-temperature Thermal Insulation[J]. Journal of Inorganic Materials, 2021, 36(7): 673-684.

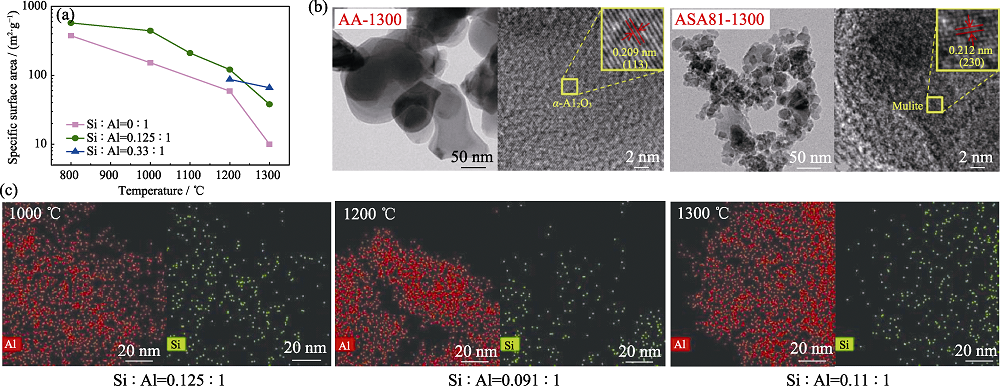

图2 高温热处理后的氧化铝-氧化硅气凝胶[39]

Fig. 2 Alumina-silica aerogels after heat-treatment[39] (a) Specific surface areas of aerogels with different molar ratios of Si; (b) TEM photos of the pristine alumina aerogel (AA-1300) and alumina-silica aerogel calcined at 1300 ℃(ASA81-1300); (c) Distribution and atomic ratio of Si and Al in the aerogel with a theoretical Si/Al molar ratio of 0.125:1 (Bars representing 20 nm; the red and green color representing Si and Al, respectively)

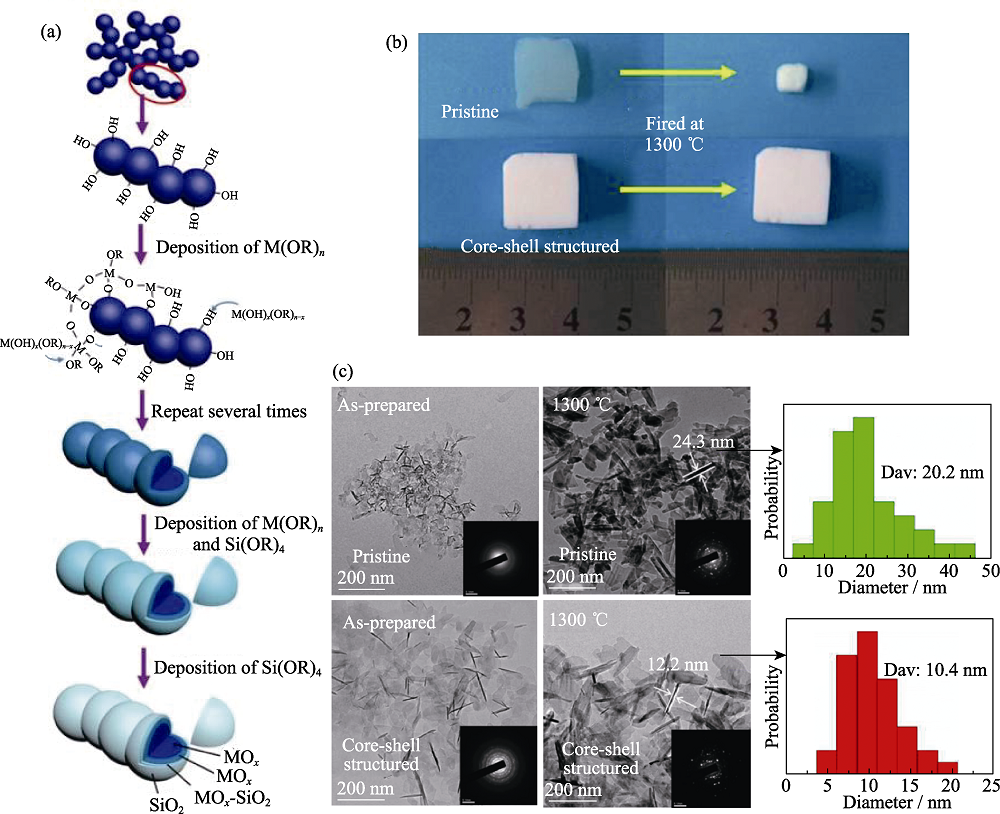

图3 硅改性氧化铝气凝胶[47]

Fig. 3 Si-modified alumina aerogels[47] (a) Deposition modification of the gels; (b) Macro and (c) Micro changing of pristine and Si-modified alumina aerogels after heat-treatment at 1300 ℃

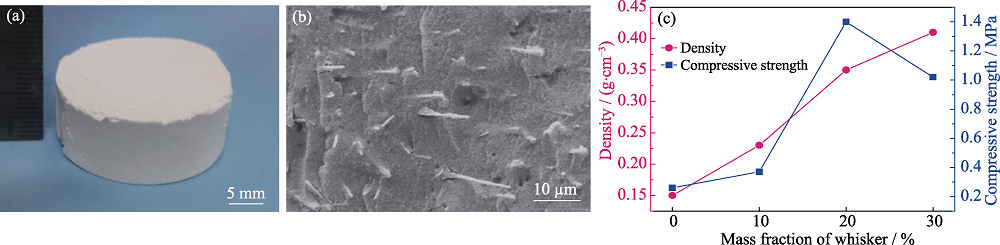

图6 硼酸铝晶须增强氧化铝-氧化硅气凝胶复合材料[27]

Fig. 6 The aluminum borate whisker reinforced alumina-silica aerogel composite[27] (a) Macro and (b) micro morphology; (c) Mechanical properties

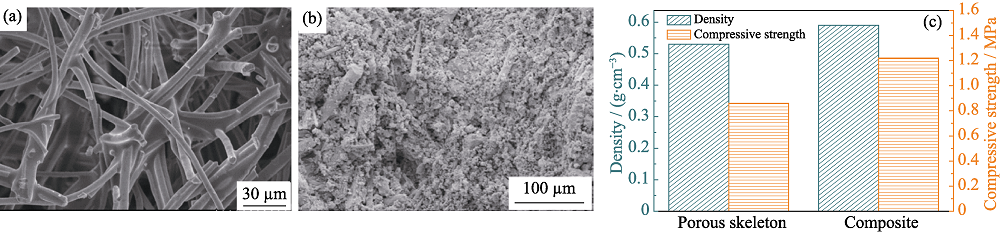

图7 氧化锆纤维多孔骨架及其增强的氧化铝-氧化硅气凝胶复合材料[37]

Fig. 7 Zirconia fiber-based porous skeleton and the alumina-silica aerogel composite reinforced by the skeleton[37] Micro morphology of (a) skeleton and (b) composite, and (c) their mechanical properties

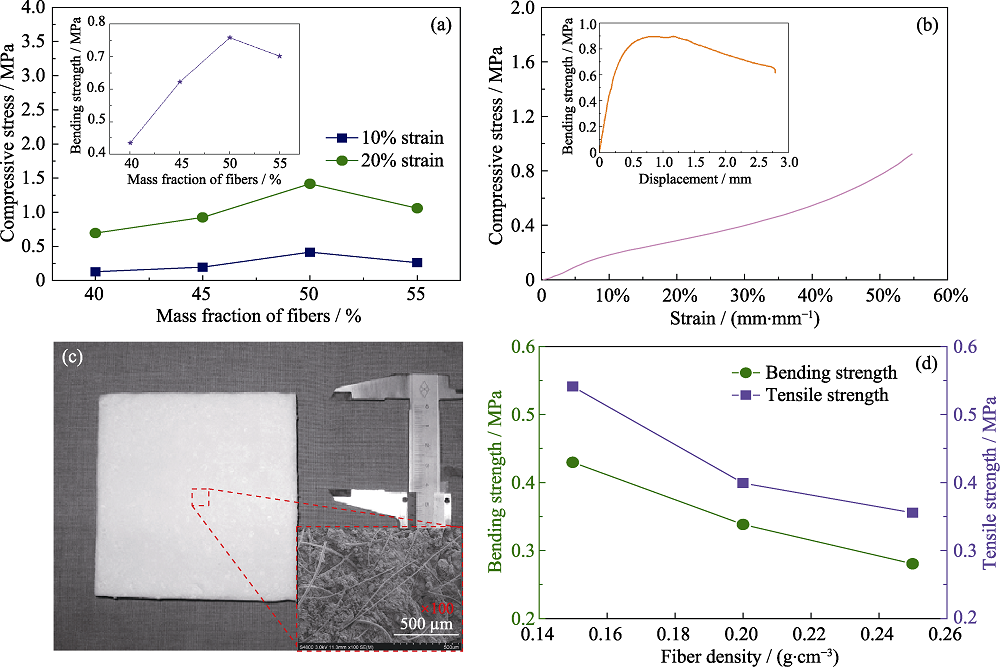

图9 纤维增强氧化铝(氧化铝-氧化硅)气凝胶复合材料[55,56,57]

Fig. 9 Fiber reinforced alumina (alumina-silica) aerogel composites[55,56,57] (a) Influence of mass fraction of fibers on mechanical properties[55]; (b) Behavior of composites under compressive and bending loadings[56]; (c) Morphology and (d) bending/tensile strengths of composites with different fiber densities[57]

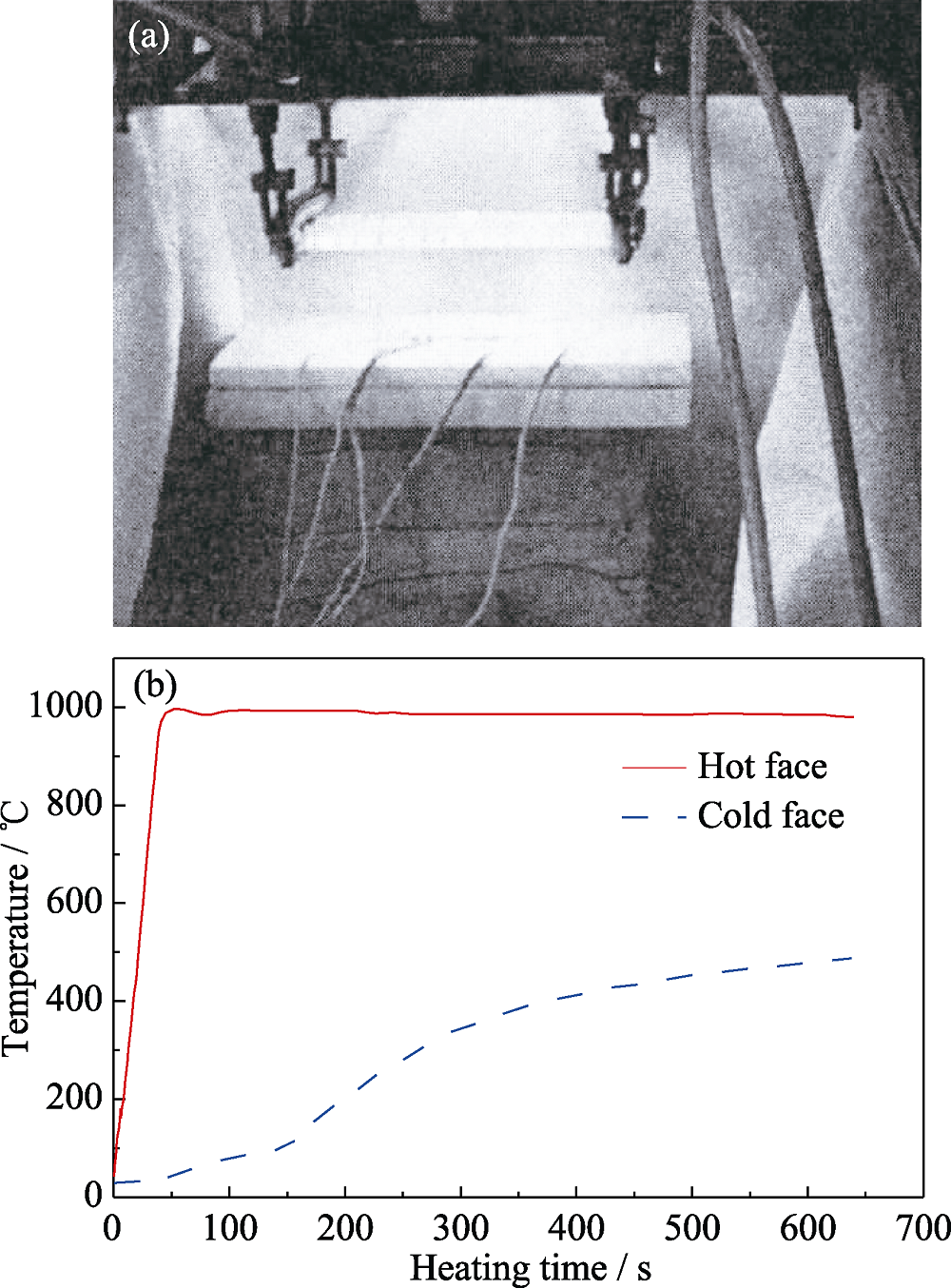

图10 陶瓷纤维增强氧化铝气凝胶复合材料(厚度15 mm)的石英灯单面加热试验现场(a)和温度曲线(b)[56]

Fig. 10 Test site (a) and temperature curves (b) of the ceramic fiber reinforced alumina aerogel composite (15 mm in thickness) heated by a quartz lamp apparatus[56]

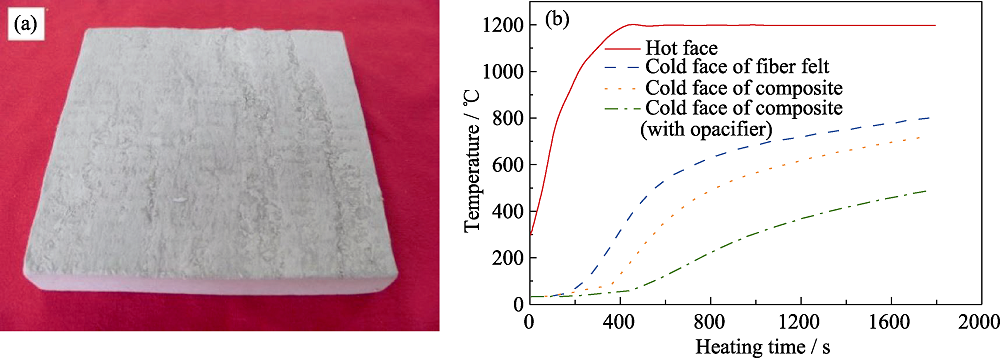

图12 加入遮光剂的莫来石纤维毡增强氧化铝-氧化硅气凝胶复合材料[68]

Fig. 12 Opacifier embedded mullite fiber felt reinforced alumina-silica aerogel composite[68] (a) Macro morphology; (b) Temperature curves of the composite (20 mm in thickness) during one-face heating test

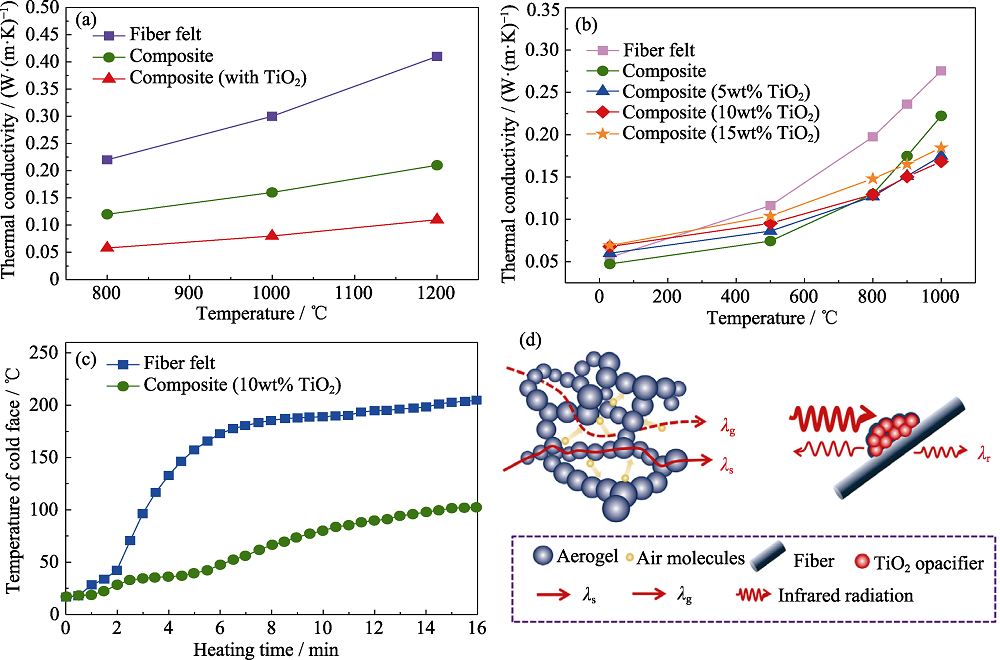

图13 引入氧化钛的莫来石纤维增强氧化铝气凝胶复合材料的高温热导率(a)[47], 不同氧化钛含量复合材料的高温热导率(b)[54], 含氧化钛的复合材料(厚度为20 mm)在丁烷火焰加热(1300 ℃, 15 min)下的冷面温度(c)[54], 复合材料的传热机制(λs、λg分别为固态、气态热导率)(d)[54]

Fig. 13 The mullite fiber felt reinforced alumina-silica aerogel composite doped with TiO2 (a) High-temperature thermal conductivity[47]; (b) High-temperature thermal conductivity of composites with different content of TiO2[54]; (c) Temperature (cold-face) of the composite (doped with 10wt% TiO2) fired by the flame of butane spray gun at 1300 ℃ for 15 min[54]; (d) Heat transfer mechanism of the composite (λs and λg refering to solid and gaseous thermal conductivity, respectively)[54]

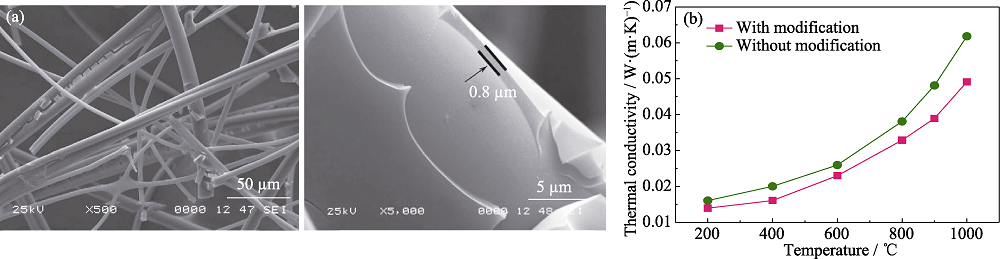

图14 碳化硅改性莫来石纤维的微观形貌(a)和以改性莫来石纤维作为增强相的氧化铝-氧化硅气凝胶复合材料的热导率(b)[69]

Fig. 14 (a) Micro morphology of SiC modified mullite fibers; (b) Thermal conductivity of the alumina-silica aerogel composite reinforced by SiC modified mullite fibers[69]

| [1] |

UYANNA O, NAJAFI H. Thermal protection systems for space vehicles: a review on technology development, current challenges and future prospects. Acta Astronautica, 2020,176:341-356.

DOI URL |

| [2] | KOEBEL M M, RIGACCI A, ACHARD P. Aerogels Handbook, 2010: 607-632. |

| [3] | CAI H, JIANG Y, FENG J, et al. Preparation of silica aerogels with high temperature resistance and low thermal conductivity by monodispersed silica sol. Materials & Design, 2020,191:108640. |

| [4] |

WANG F, DOU L, DAI J, et al. In situ synjournal of biomimetic silica nanofibrous aerogels with temperature-invariant superelasticity over one million compressions. Angewandte Chemie International Edition, 2020,59(21):8285-8292.

DOI URL |

| [5] |

POCO J F, JR J H S, HRUBESH L W. Synthesis of high porosity, monolithic alumina aerogels. Journal of Non-Crystalline Solids, 2001,285:57-63.

DOI URL |

| [6] | 高庆福, 张长瑞, 冯坚, 等. 低密度、块状氧化铝气凝胶制备. 无机化学学报, 2008,24(9):1456-1460. |

| [7] |

ZU G, SHEN J, ZOU L, et al. Nanoengineering super heat-resistant, strong alumina aeroegels. Chemistry of Materials, 2013,25:4757-4764.

DOI URL |

| [8] | ZU G, SHEN J, ZOU L, et al. Highly thermally stable zirconia/ silica composite aerogels prepared by supercritical deposition. Microporous and Mesoporous Materials, 2017,238:90-96. |

| [9] |

SU L, WANG H, NIU M, et al. Ultralight, recoverable, and high temperature-resistant SiC nanowire aerogel. ACS Nano, 2018,12(4):3103-3111.

DOI URL |

| [10] |

XU X, ZHANG Q, HAO M, et al. Double-negative-index ceramic aerogels for thermal superinsulation. Science, 2019,363:723-727.

DOI URL |

| [11] | 艾素芬, 孙言, 雷尧飞, 等. 低密度气凝胶的高温结构变化及其耐温性研究. 北京化工大学学报, 2019,46(1):63-68. |

| [12] |

CAI H, JIANG Y, FENG J, et al. Nanostructure evolution of silica aerogels under rapid heating from 600 ℃ to 1300 ℃ via in-situ TEM observation. Ceramics International, 2020,46(8):12489-12498.

DOI URL |

| [13] |

BAUMANN T F, GASH A E, CHINN S C, et al. Synthesis of high-surface-area alumina aerogels without the use of alkoxide precursors. Chemistry of Materials, 2005,17:395-401.

DOI URL |

| [14] |

ZU G, SHEN J, WEI X, et al. Preparation and characterization of monolithic alumina aerogels. Journal of Non-Crystalline Solids, 2011,357:2903-2906.

DOI URL |

| [15] |

WANG W, ZHANG Z, ZU G, et al. Trimethylethoxysilane- modified super heat-resistant alumina aerogels for high-temperature thermal insulation and adsorption applications. RSC Advances, 2014,4:54864-54871.

DOI URL |

| [16] | 温培刚, 巢雄宇, 袁武华, 等. 耐高温氧化铝气凝胶研究进展. 材料导报, 2016,30(8):51-56. |

| [17] | 李华鑫, 赵春林, 陈俊勇, 等. 氧化铝气凝胶研究进展. 金属世界, 2018(4):27-33. |

| [18] |

PAKHARUKOVA V P, SHALYGIN A S, GERASIMOV E Y, et al. Structure and morphology evolution of silica-modified pseudoboehmite aerogels during heat treatment. Journal of Solid State Chemistry, 2016,233:294-302.

DOI URL |

| [19] |

BARARPOUR S T, KARAMI D, MAHINPEY N. Investigation of the effect of alumina-aerogel support on the CO2 capture performance of K2CO3. Fuel, 2019,242:124-132.

DOI URL |

| [20] |

HURWITZ F I, GALLAGHER M, OLIN T C, et al. Optimization of alumina and aluminosilicate aerogel structure for high-temperature performance. International Journal of Applied Glass Science, 2014,5(3):276-286.

DOI URL |

| [21] |

YOROV K E, YAPRYNTSEV A D, BARANCHIKOV A E, et al. Luminescent alumina-based aerogels modified with tris(8-hydroxyquinolinato)aluminum. Journal of Sol-Gel Science and Technology, 2018,86:400-409.

DOI URL |

| [22] |

WEN S, REN H, ZHU J, et al. Fabrication of Al2O3 aerogel-SiO2 fiber composite with enhanced thermal insulation and high heat resistance. Journal of Porous Materials, 2018,26:1027-1034.

DOI URL |

| [23] |

ARAVIND P R, MUKUNDAN P, PILLAI P K, et al. Mesoporous silica-alumina aerogels with high thermal pore stability through hybrid Sol-Gel route followed by subcritical drying. Microporous and Mesoporous Materials, 2006,96(1):14-20.

DOI URL |

| [24] |

HAYASE G, NONOMURA K, HASEGAWA G, et al. Ultralow- density, transparent, superamphiphobic boehmite nanofiber aerogels and their alumina derivatives. Chemistry of Materials, 2015,27(1):3-5.

DOI URL |

| [25] | 冯坚, 高庆福, 武纬, 等. 硅含量对Al2O3-SiO2气凝胶结构和性能的影响. 无机化学学报, 2009,25(10):1758-1763. |

| [26] |

WU X, SHAO G, SHEN X, et al. Novel Al2O3-SiO2 composite aerogels with high specific surface area at elevated temperatures with different alumina/silica molar ratios prepared by a non- alkoxide Sol-Gel method. RSC Advances, 2016,6:5611-5620.

DOI URL |

| [27] |

HOU X, ZHANG R, FANG D. Novel whisker-reinforced Al2O3- SiO2 aerogel composites with ultra-low thermal conductivity. Ceramics International, 2017,43:9547-9551.

DOI URL |

| [28] |

YANG J, WANG Q, WANG T, et al. Facile one-step precursor- to-aerogel synthesis of silica-doped alumina aerogels with high specific surface area at elevated temperatures. Journal of Porous Materials, 2017,24:889-897.

DOI URL |

| [29] |

KARAMI D, MAHINPEY N. Utilization of alumina aerogel as high surface area support for the fabrication of oxygen carriers in the chemical looping combustion process. Energy & Fuels, 2019,33:5408-5414.

DOI URL |

| [30] |

MIZUSHIMA Y, HORI M. Preparation of heat-resistant alumina aerogels. Journal of Materials Research, 1993,8(11):2993-2999.

DOI URL |

| [31] |

OSAKI T, NAGASHIMA K, WATARI K, et al. Silica-doped alumina cryogels with high thermal stability. Journal of Non- Crystalline Solids, 2007,353:2436-2442.

DOI URL |

| [32] |

JI X, ZHOU Q, QIU G, et al. Synthesis of an alumina enriched Al2O3-SiO2 aerogel: reinforcement and ambient pressure drying. Journal of Non-Crystalline Solids, 2017,471:160-168.

DOI URL |

| [33] |

YU H, JIANG Y, LU Y, et al. Quartz fiber reinforced Al2O3-SiO2 aerogel composite with highly thermal stability by ambient pressure drying. Journal of Non-Crystalline Solids, 2019,505:79-86.

DOI URL |

| [34] |

HORIUCHI T, OSAKI T, SUGIYAMA T, et al. Maintenance of large surface area of alumina heated at elevated temperatures above 1300 ℃ by preparing silica-containing pseudoboehmite aerogel. Journal of Non-Crystalline Solids, 2001,291:187-198.

DOI URL |

| [35] |

HURWITZ F I, GUO H, ROGERS R B, et al. Influence of Ti addition on boehmite-derived aluminum silicate aerogels: structure and propeties. Journal of Sol-Gel Science and Technology, 2012,64:367-374.

DOI URL |

| [36] |

WU X, SHAO G, CUI S, et al. Synthesis of a novel Al2O3-SiO2 composite aerogel with high specific surface area at elevated temperatures using inexpensive inorganic salt of aluminum. Ceramics International, 2016,42:874-882.

DOI URL |

| [37] | ZHANG R, YE C, WANG B. Novel Al2O3-SiO2 aerogel/porous zirconia composite with ultralow thermal conductivity. Journal of Porous Materials, 2017. |

| [38] | 张恩爽, 黄红岩, 刘韬, 等. 结构强健的 Al2O3-SiO2气凝胶的制备及可重复使用性能. 高等学校化学学报, 2019,40(12):2566-2573. |

| [39] |

PENG F, JIANG Y, FENG J, et al. A facile method to fabricate monolithic alumina-silica aerogels with high surface areas and good mechanical properties. Journal of the European Ceramic Society, 2020,40(6):2480-2488.

DOI URL |

| [40] |

TOKUBOME Y, NAKANISHI K, HANADA T. Effect of La addition on thermal microstructural evolution of macroporous alumina monolith prepared from ionic precursors. Journal of the Ceramic Society of Japan, 2009,117(1363):351-355.

DOI URL |

| [41] |

YANG J, WANG Q, WANG T, et al. Rapid preparation process, structure and thermal stability of lanthanum doped alumina aerogels with a high specific surface area. RSC Advances, 2016,6:26271-26279.

DOI URL |

| [42] |

SUN X, WU Y, WANG Y, et al. Investigation of the effect of lanthanum oxide on the thermal stability of alumina aerogel. Journal of Porous Materials, 2018,26:327-333.

DOI URL |

| [43] | AL-YASSIR N, MAO R L V. Thermal stability of alumina aerogel doped with yttrium oxide, use as a catalyst support for the thermocatalytic cracking (TCC) process: an investigation of its textural and structural properties. Applied Catalysis, 2007,317:275-283. |

| [44] | 周洁洁, 陈晓红, 宋怀河, 等. 氧化钇掺杂对Al2O3块状气凝胶结构与性能的影响. 硅酸盐通报, 2010,29(5):1002-1006. |

| [45] | 孙雪峰, 吴玉胜, 李来时, 等. 锶掺杂对氧化铝气凝胶高温热稳定性的影响. 功能材料, 2018,8(9):09078-09081, 09086. |

| [46] |

SHI Z, GAO H, WANG X, et al. One-step synthesis of monolithic micro-nano yttria stabilized ZrO2-Al2O3 composite aerogel. Microporous and Mesoporous Materials, 2018,259:26-32.

DOI URL |

| [47] |

ZU G, SHEN J, WANG W, et al. Robust, highly thermally stable, core-shell nanostructured metal oxide aerogels as high-temperature thermal superinsulators, adsorbents, and catalyst. Chemistry of Materials, 2014,26:5761-5772.

DOI URL |

| [48] |

MIZUSHIMA Y, HORI M. Preparation and properties of alumina-organic compound aerogels. Journal of Non-Crystalline Solids, 1994,170:215-222.

DOI URL |

| [49] |

YAKOVLEVA I V, VOLODINA A M, ZAIKOVSKIIA V I, et al. Stabilizing effect of the carbon shell on phase transformation of the nanocrystalline alumina particles. Ceramics International, 2018,44:4801-4806.

DOI URL |

| [50] |

MIZUSHIMA Y, HORI M. Preparation of an alumina aerogel with SiC whisker inclusion. Journal of the European Ceramic Society, 1994,14:117-121.

DOI URL |

| [51] | 隋超. 纤维素掺杂 SiO2与 Al2O3柔性气凝胶的制备及性能表征. 哈尔滨: 哈尔滨工业大学博士学位论文, 2015. |

| [52] | 曹凤朝. 高强度氧化铝气凝胶复合材料的制备研究. 南京: 东南大学硕士学位论文, 2015. |

| [53] | 孙晶晶, 胡子君, 吴文军, 等. 氧化铝气凝胶复合高温隔热瓦的制备及性能. 宇航材料工艺, 2017(3):33-36, 41. |

| [54] |

ZOU W, WANG X, WU Y, et al. Opacifier embedded and fiber reinforced alumina-based aerogel composites for ultra-high temperature thermal insulation. Ceramics International, 2019,45(1):644-650.

DOI URL |

| [55] | YU Y, PENG K, FANG J, et al. Mechanical and thermal conductive properties of fiber-reinforced silica-alumina aerogels. Applied Ceramic Technology, 2018,15(5):1138-1145. |

| [56] | 高庆福. 纳米多孔SiO2、Al2O3气凝胶及其高效隔热复合材料的研究. 长沙: 国防科技大学博士学位论文, 2009. |

| [57] | 武纬. Al2O3-SiO2气凝胶及其隔热复合材料的制备与性能研究. 长沙: 国防科技大学硕士学位论文, 2008. |

| [58] | ZHU Z, WANG F, YAO J, et al. High-temperature insulation property of opacifier-doped Al2O3-SiO2 aerogel/mullite fiber composites. Journal of Inorganic Materials, 2018,33(9):970-975. |

| [59] |

TANG G H, BI C, ZHAO Y, et al. Thermal transport in nano-porous insulation of aerogel: factors, models and outlook. Energy, 2015,90:701-721.

DOI URL |

| [60] |

LEE S C, CUNNINGTON G R. Conduction and radiation heat transfer in high-porosity fiber thermal insulation. Journal of Thermophysics and Heat Transfer, 2000,14(2):121-136.

DOI URL |

| [61] |

ZHAO J, DUAN Y, WANG X, et al. Radiative properties and heat transfer characteristics of fiber-loaded silica aerogel composites for thermal insulation. International Journal of Heat and Mass Transfer, 2012,55:5196-5204.

DOI URL |

| [62] |

ZHANG H, FANG W, LI Z, et al. The influence of gaseous heat conduction to the effective thermal conductivity of nano-porous materials. International Communications in Heat and Mass Transfer, 2015,68:158-161.

DOI URL |

| [63] | 高庆福, 张长瑞, 冯坚, 等. 氧化铝气凝胶复合材料的制备与隔热性能. 国防科技大学学报, 2008,30(4):39-42. |

| [64] |

YANG G, JIANG Y, FENG J, et al. Synthesis of fibre reinforced Al2O3-SiO2 aerogel composite with high density uniformity via a facile high-pressure impregnation approach. Processing and Application of Ceramics, 2017,11(3):185-190.

DOI URL |

| [65] | WANG K Y, LIU R X, ZHANG L, et al. Preparation and thermal stability of quartz fiber reinforced silicon doped aluminum aerogel composites. IOP Conf. Series: Materials Science and Engineering, 2019,678:012076. |

| [66] |

ZHONG Y, ZHANG J, WU X, et al. Carbon-fiber felt reinforced carbon/alumina aerogel composite fabricated with high strength and low thermal conductivity. Journal of Sol-Gel Science and Technology, 2017,84:129-134.

DOI URL |

| [67] |

LI H, CHEN Y, WANG P, et al. Porous carbon-bonded carbon fiber composites impregnated with SiO2-Al2O3 aerogel with enhanced thermal insulation and mechanical properties. Ceramics International, 2018,44(3):3484-3487.

DOI URL |

| [68] | 周洁洁, 王钦, 姚先周, 等. 纤维毡增强Al2O3-SiO2气凝胶复合材料的制备与隔热性能研究. 第一届中国国际复合材料科技大会论文集, 北京, 2013, 1090-1093. |

| [69] |

XU L, JIANG Y, FENG J, et al. Infrared-opacified Al2O3-SiO2 aerogel composites reinforced by SiC-coated mullite fibers for thermal insulations. Ceramics International, 2015,41(1):437-442.

DOI URL |

| [70] |

GAO M, LIU B, ZHAO P, et al. Mechanical strengths and thermal properties of titania-doped alumina aerogels and the application as high-temperature thermal insulator. Journal of Sol-Gel Science and Technology, 2019,91:514-522.

DOI URL |

| [71] | 隗小庆, 倪星元, 沈军, 等. 氧化铝气凝胶隔热材料的制备和热学性能. 材料研究学报, 2012,26(3):261-266. |

| [72] | 吴宇, 沈军, 祖国庆, 等. 耐高温Al2O3基气凝胶的制备和特性研究. 南京工业大学学报(自然科学版), 2016,38(2):15-19. |

| [73] |

ZOU W, WANG X, WU Y, et al. Highly thermally stable alumina- based aerogels modified by partially hydrolyzed aluminum tri-sec-butoxide. Journal of Sol-Gel Science and Technology, 2017,84:507-514.

DOI URL |

| [74] | 王虹, 周裴灿, 李荣年, 等. 氧化硅气凝胶与氧化铝气凝胶的性能对比. 中国建材科技, 2019(6):34-35. |

| [75] | 冯坚. 气凝胶高效隔热材料. 北京: 科学出版社, 2016: 1-206. |

| [1] | 朱文杰, 唐璐, 陆继长, 刘江平, 罗永明. 钙钛矿型氧化物催化氧化挥发性有机化合物的研究进展[J]. 无机材料学报, 2025, 40(7): 735-746. |

| [2] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [3] | 吴琼, 沈炳林, 张茂华, 姚方周, 邢志鹏, 王轲. 铅基织构压电陶瓷研究进展[J]. 无机材料学报, 2025, 40(6): 563-574. |

| [4] | 张碧辉, 刘小强, 陈湘明. Ruddlesden-Popper结构杂化非常规铁电体的研究进展[J]. 无机材料学报, 2025, 40(6): 587-608. |

| [5] | 吴杰, 杨帅, 王明文, 李景雷, 李纯纯, 李飞. 铅基织构压电陶瓷的发展历程、现状与挑战[J]. 无机材料学报, 2025, 40(6): 575-586. |

| [6] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| [7] | 陈义, 邱海鹏, 陈明伟, 徐昊, 崔恒. SiC/SiC复合材料基体硼改性方法及其力学性能研究[J]. 无机材料学报, 2025, 40(5): 504-510. |

| [8] | 田睿智, 兰正义, 殷杰, 郝南京, 陈航榕, 马明. 基于微流控技术的纳米无机生物材料制备: 原理及其研究进展[J]. 无机材料学报, 2025, 40(4): 337-347. |

| [9] | 张继国, 吴田, 赵旭, 杨钒, 夏天, 孙士恩. 钠离子电池正极材料循环稳定性提升策略及产业化进程[J]. 无机材料学报, 2025, 40(4): 348-362. |

| [10] | 袁利萍, 吴袁泊, 俞佳静, 张世琰, 孙铱, 胡云楚, 范友华. 磷钼酸插层水滑石复合CNFs气凝胶的制备及其隔热保温性能[J]. 无机材料学报, 2025, 40(4): 415-424. |

| [11] | 穆爽, 马沁, 张禹, 沈旭, 杨金山, 董绍明. Yb2Si2O7改性SiC/SiC复合材料的氧化行为研究[J]. 无机材料学报, 2025, 40(3): 323-328. |

| [12] | 殷杰, 耿佳毅, 王康龙, 陈忠明, 刘学建, 黄政仁. SiC陶瓷的3D打印成形与致密化新进展[J]. 无机材料学报, 2025, 40(3): 245-255. |

| [13] | 杨舒琪, 杨存国, 牛慧祝, 石唯一, 舒珂维. GeP3/科琴黑复合材料作为钠离子电池高性能负极材料[J]. 无机材料学报, 2025, 40(3): 329-336. |

| [14] | 谌广昌, 段小明, 朱金荣, 龚情, 蔡德龙, 李宇航, 杨东雷, 陈彪, 李新民, 邓旭东, 余瑾, 刘博雅, 何培刚, 贾德昌, 周玉. 直升机特定结构先进陶瓷材料研究进展与应用展望[J]. 无机材料学报, 2025, 40(3): 225-244. |

| [15] | 范晓波, 祖梅, 杨向飞, 宋策, 陈晨, 王子, 罗文华, 程海峰. 质子调控型电化学离子突触研究进展[J]. 无机材料学报, 2025, 40(3): 256-270. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||