无机材料学报 ›› 2020, Vol. 35 ›› Issue (7): 759-768.DOI: 10.15541/jim20190401 CSTR: 32189.14.10.15541/jim20190401

所属专题: 生物材料论文精选(2020)

收稿日期:2019-08-09

修回日期:2019-10-02

出版日期:2020-07-20

网络出版日期:2020-01-20

作者简介:张晓旭(1991-), 男, 博士研究生. E-mail: 15202203589@163.com基金资助:

ZHANG Xiaoxu1,2,ZHU Dongbin1,2,3( ),LIANG Jinsheng1,2

),LIANG Jinsheng1,2

Received:2019-08-09

Revised:2019-10-02

Published:2020-07-20

Online:2020-01-20

Supported by:摘要:

近年来, 齿科氧化锆陶瓷凭借高强韧性、良好生物相容性和美观自然色泽而成为牙齿临床修复的首选对象, 可用于修复、固定局部义齿和种植牙。然而, 在低温潮湿环境中氧化锆陶瓷易发生t-m相变老化, 服役寿命显著缩短, 严重影响其临床稳定性。本文综述了氧化锆陶瓷低温老化的特点、机制及其老化动力学规律, 并介绍了表征氧化锆低温老化现象的常规技术手段以及光学相干断层扫描、聚焦离子束等新方法; 总结了低温老化行为的主要影响因素以及抗老化措施, 具体可通过调整材料体系、改进加工方式等来增强氧化锆的韧性, 解决其存在的低温老化问题。随着齿科氧化锆陶瓷抗老化性能的提高以及健康功能化的未来需求, 其在齿科修复领域的应用将会越来越广泛。

中图分类号:

张晓旭,朱东彬,梁金生. 齿科氧化锆陶瓷水热稳定性研究进展[J]. 无机材料学报, 2020, 35(7): 759-768.

ZHANG Xiaoxu,ZHU Dongbin,LIANG Jinsheng. Progress on Hydrothermal Stability of Dental Zirconia Ceramics[J]. Journal of Inorganic Materials, 2020, 35(7): 759-768.

图1 氧化锆老化前后的形貌对比[17]

Fig. 1 SEM images of zirconia microstructure (a) without and (b) with LTD, and AFM images of zirconia (c) without and (d) with LTD[17]

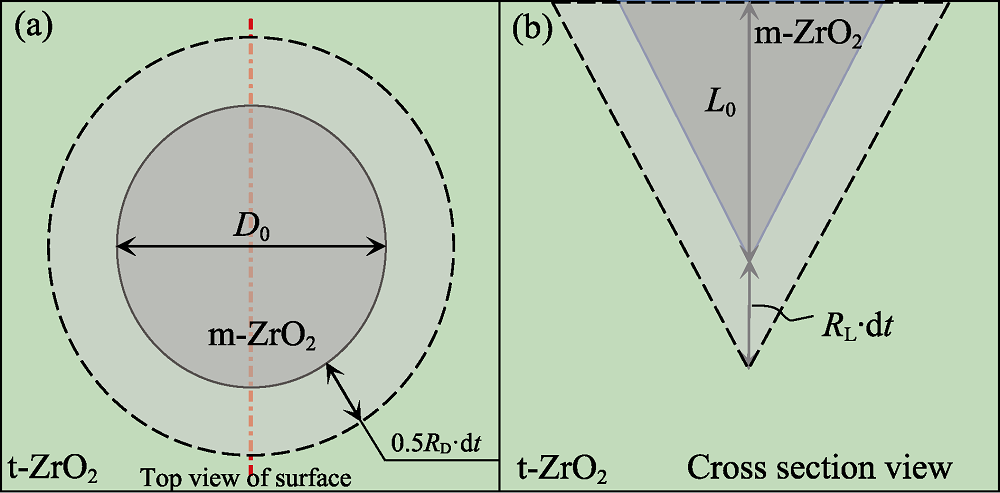

图3 m-ZrO2晶核的初始尺寸和生长速率理论模型[32]

Fig. 3 Theoretical model of initial dimensions and growth rate of m-ZrO2 nuclei[32] (a) Top view of surface; (b) Cross section view

图4 μ-Raman分析3Y-TZP陶瓷老化动力学[33]

Fig. 4 Ageing kinetics analysis with 3Y-TZP by μ-Raman spectroscopy[33] (a) m-ZrO2 content depth and corresponding optical images; (b)Transformed depth varies with ageing time

| Equation | |

|---|---|

| Linear | ${{V}_{\text{m}}}=\frac{I_{\text{m}}^{181}+I_{\text{m}}^{190}}{k(I_{\text{t}}^{147}+\delta I_{\text{t}}^{265})+I_{\text{m}}^{181}+I_{\text{m}}^{190}}$ Clarke and Adar[ Katagiri, et al.[ Lim, et al.[ |

| Power law[ | ${{V}_{\text{m}}}=\sqrt{0.19-\frac{0.13}{\frac{I_{\text{m}}^{181}+I_{\text{m}}^{190}}{I_{\text{t}}^{147}+I_{\text{m}}^{181}+I_{\text{m}}^{190}}-1.01}}-0.56$ |

| Logarithmic[ | ${{V}_{\text{m}}}=0.65+0.39\lg \left( \frac{I_{\text{m}}^{181}+I_{\text{m}}^{190}}{I_{\text{t}}^{147}+I_{\text{t}}^{265}+I_{\text{m}}^{181}+I_{\text{m}}^{190}} \right)$ |

表1 基于拉曼光谱的单斜相定量分析模型

Table 1 Proposed models for monoclinic phase quantification by Raman spectroscopy

| Equation | |

|---|---|

| Linear | ${{V}_{\text{m}}}=\frac{I_{\text{m}}^{181}+I_{\text{m}}^{190}}{k(I_{\text{t}}^{147}+\delta I_{\text{t}}^{265})+I_{\text{m}}^{181}+I_{\text{m}}^{190}}$ Clarke and Adar[ Katagiri, et al.[ Lim, et al.[ |

| Power law[ | ${{V}_{\text{m}}}=\sqrt{0.19-\frac{0.13}{\frac{I_{\text{m}}^{181}+I_{\text{m}}^{190}}{I_{\text{t}}^{147}+I_{\text{m}}^{181}+I_{\text{m}}^{190}}-1.01}}-0.56$ |

| Logarithmic[ | ${{V}_{\text{m}}}=0.65+0.39\lg \left( \frac{I_{\text{m}}^{181}+I_{\text{m}}^{190}}{I_{\text{t}}^{147}+I_{\text{t}}^{265}+I_{\text{m}}^{181}+I_{\text{m}}^{190}} \right)$ |

图7 2Y-TZP陶瓷晶粒尺寸[50]

Fig. 7 2Y-TZP ceramic[50] (a) SEM images together with the corresponding grain size distribution, and (b) semi-quantitative Y2O3 distribution

图8 表面氮处理的样品老化后形貌[60]

Fig. 8 Morphologies of samples treated with surface nitrogen after aging[60] (a) LSCM image of N-1600; (b) SEM image of N-1400; AFM images of N-1400 (c) surface and (d) bulk

| [1] |

TURON-VINAS M, ANGLADA M. Strength and fracture toughness of zirconia dental ceramics. Dental Materials, 2018,34(3):365-375.

DOI URL PMID |

| [2] | FERRARI M, VICHI A, ZARONE F. Zirconia abutments and restorations: from laboratory to clinical investigations. Dental Materials, 2015,31(3):63-76. |

| [3] |

GAUTAM C, JOYNER J, GAUTAM A, et al. Zirconia based dental ceramics: structure, mechanical properties, biocompatibility and applications. Dalton Transactions, 2016,45(48):19194-19215.

DOI URL PMID |

| [4] |

GARVIE R C, HANNINK R H, PASCOE R T. Ceramic steel? Nature, 1975,258(5537):703-704.

DOI URL |

| [5] |

DENRY I, KELLY J R. State of the art of zirconia for dental applications. Dental Materials, 2008,24(3):299-307.

DOI URL |

| [6] |

TURON-VINAS M, ANGLADA M. Strength and fracture toughness of zirconia dental ceramics. Dental Materials, 2018,34(3):365-375.

DOI URL PMID |

| [7] |

DENRY I, HOLLOWAY J. Ceramics for dental applications: a review. Materials, 2010,3(1):351-368.

DOI URL |

| [8] |

NAKONIECZNY D S, ZIĘBOWICZ A, PASZENDA Z K, et al. Trends and perspectives in modification of zirconium oxide for a dental prosthetic applications: a review. Biocybernetics and Biomedical Engineering, 2017,37(1):229-245.

DOI URL |

| [9] |

LI R W K, CHOW T W, MATINLINNA J P. Ceramic dental biomaterials and CAD/CAM technology: state of the art. Journal of Prosthodontic Research, 2014,58(4):208-216.

DOI URL |

| [10] | ZHU DONG-BIN, CHU RUI-QING, ZHANG XIAO-XU, et al. Progress in mechanism of ceramics inkjet printing. Journal of Mechanical Engineering, 2017,53(13):108-117. |

| [11] |

SIVARAMAN K, CHOPRA A, NARAYAN A I, et al. Is zirconia a viable alternative to titanium for oral implant? a critical review. Journal of Prosthodontic Research, 2018,62(2):121-133.

DOI URL PMID |

| [12] |

DURACCIO D, MUSSANO F, FAGA M G. Biomaterials for dental implants: current and future trends. Journal of Materials Science, 2015,50(14):4779-4812.

DOI URL |

| [13] |

KOBAYASHI K, KUWAJIMA H, MASAKI T. Phase change and mechanical properties of ZrO2-Y2O3 solid electrolyte after ageing. Solid State Ionics, 1981 3-4:489-493.

DOI URL |

| [14] |

KOSMAČ T, KOCJAN A. Ageing of dental zirconia ceramics. Journal of the European Ceramic Society, 2012,32(11):2613-2622.

DOI URL |

| [15] |

PEREIRA G K R, VENTURINI A B, SILVESTRI T, et al. Low-temperature degradation of Y-TZP ceramics: a systematic review and meta-analysis. Journal of the Mechanical Behavior of Biomedical Materials, 2016,55:151-163.

DOI URL PMID |

| [16] |

ÖZCAN M, VOLPATO C Â M, FREDEL M C. Artificial aging of zirconium dioxide: an evaluation of current knowledge and clinical relevance. Current Oral Health Reports, 2016,3(3):193-197.

DOI URL |

| [17] |

WU Z K, LI N, YAN J Z, et al. Effect of hydrothermal aging on the phase mtability, microstructure and mechanical properties of dental 3Y-TZP ceramics. Applied Mechanics and Materials, 2014,529:251-255.

DOI URL |

| [18] | LUGHI V, SERGO V. Low temperature degradation aging of zirconia: a critical review of the relevant aspects in dentistry. Denal Materials, 2010,26(8):807-820. |

| [19] |

LANGE F F, DUNLOP G L, DAVIS B I. Degradation during aging of transformationt toughened ZrO2-Y2O3 materials at 250 ℃. Journal of the American Ceramic Society, 1986,69(3):237-240.

DOI URL |

| [20] |

SATO T, SHIMADA M. Transformation of yttria-doped tetragonal ZrO2 polycrystals by annealing in water. Journal of the American Ceramic Society, 1985,68(6):356-356.

DOI URL |

| [21] |

YOSHIMURA M, NOMA T, KAWABATA K, et al. Role of H2O on the degradation process of Y-TZP. Journal of Materials Science Letters, 1987,6(4):465-467.

DOI URL |

| [22] |

GUO X. Hydrothermal degradation mechanism of tetragonal zirconia. Journal of Materials Science, 2001,36(15):3737-3744.

DOI URL |

| [23] |

GUO X, SCHOBER T. Water incorporation in tetragonal zirconia. Journal of the American Ceramic Society, 2004,87(4):746-748.

DOI URL |

| [24] |

LANCE M J, VOGEL E M, REITH L A, et al. Low-temperature aging of zirconia ferrules for optical connectors. Journal of the American Ceramic Society, 2001,84(11):2731-2733.

DOI URL |

| [25] |

HARAGUCHI K, SUGANO N, NISHII T, et al. Phase transformation of a zirconia ceramic head after total hip arthroplasty. The Journal of Bone and Joint Surgery British volume, 2001,83(7):996-1000.

DOI URL PMID |

| [26] |

CHEVALIER J, GREMILLARD L, VIRKAR A V, et al. The tetragonal-monoclinic transformation in zirconia: Lessons learned and future trends. Journal of the American Ceramic Society, 2009,92(9):1901-1920.

DOI URL |

| [27] |

CHEVALIER J, CALES B, DROUIN J M. Low-temperature aging of Y-TZP ceramics. Journal of the American Ceramic Society, 2004,82(8):2150-2154.

DOI URL |

| [28] |

FABBRI P, PICONI C, BURRESI E, et al. Lifetime estimation of a zirconia-alumina composite for biomedical applications. Dental Materials, 2014,30(2):138-142.

DOI URL |

| [29] |

CHEVALIER J. What future for zirconia as a biomaterial? Biomaterials, 2006,27(4):535-543.

DOI URL |

| [30] |

CATTANI-LORENTE M, DURUAL S, AMEZ-DROZ M, et al. Hydrothermal degradation of a 3Y-TZP translucent dental ceramic: a comparison of numerical predictions with experimental data after 2 years of aging. Dental Materials, 2016,32(3):394-402.

DOI URL PMID |

| [31] |

WEI C, GREMILLARD L. Towards the prediction of hydrothermal ageing of 3Y-TZP bioceramics from processing parameters. Acta Materialia, 2018,144:245-256.

DOI URL |

| [32] |

ZHIGACHEV A O, UMRIKHIN A V, RODAEV V V. Theoretical description of zirconia ceramics aging kinetics. Journal of the Australian Ceramic Society, 2018,55(1):65-70.

DOI URL |

| [33] |

ZHANG F, INOKOSHI M, VANMEENSEL K, et al. Lifetime estimation of zirconia ceramics by linear ageing kinetics. Acta Materialia, 2015,92:290-298.

DOI URL |

| [34] |

GARVIE R C, NICHOLSON P S. Phase analysis in zirconia systems. Journal of the American Ceramic Society, 1972,55(6):303-305.

DOI URL |

| [35] | TORAYA H, YOSHIMURA M, SOMIYA S. Calibration curve for quantitative analysis of the monoclinic-tetragonal ZrO2 system by X-ray diffraction. Journal of the American Ceramic Society, 1984,67(6):119-121. |

| [36] |

KOYAMA T, KUMAMOTO A, MATSUI K, et al. Revealing tetragonal-to-monoclinic phase transformation in Y-TZP at an initial stage of low temperature degradation using grazing incident-angle X-ray diffraction measurement. Journal of the Ceramic Society of Japan, 2018,126(9):728-731.

DOI URL |

| [37] |

GREMILLARD L, GRANDJEAN S, CHEVALIER J. A new method to measure monoclinic depth profile in zirconia-based ceramics from X-ray diffraction data. International Journal of Materials Research, 2010,101(1):88-94.

DOI URL |

| [38] |

CLARKE D R, ADAR F. Measurement of the crystallographically transformed zone produced by fracture in ceramics containing tetragonal zirconia. Journal of the American Ceramic Society, 1982,65(6):284-288.

DOI URL |

| [39] | KATAGIRI G, ISHIDA H, ISHITANI A, et al. Direct determination by Raman microprobe of the transformation zone size in Y2O3 containing tetragonal ZrO2 polycrystals. Advances in Ceramics, 1986,24A:537-544. |

| [40] |

LIM C S, FINLAYSON T R, NINIO F, et al. In-situ measurement of the stress-induced phase transformations in magnesia-partially-stabilized zirconia using Raman spectroscopy. Journal of the American Ceramic Society, 1992,75(6):1570-1573.

DOI URL |

| [41] |

KIM B K, HAHN J W, HAN K R. Quantitative phase analysis in tetragonal-rich tetragonal/monoclinic two phase zirconia by Raman spectroscopy. Journal of Materials Science Letters, 1997,16(8):669-671.

DOI URL |

| [42] |

CASELLAS D, CUMBRERA F L, SáNCHEZ-BAJO F, et al. On the transformation toughening of Y-ZrO2 ceramics with mixed Y-TZP/PSZ microstructures. Journal of the European Ceramic Society, 2001,21(6):765-777.

DOI URL |

| [43] |

LANGE F F. Transformation toughening. Journal of Materials Science, 1982,17(1):225-234.

DOI URL |

| [44] |

CHEN S Y, LU H Y. Low-temperature ageing map for 3mol% Y2O3-ZrO2. Journal of Materials Science, 1989,24(2):453-456.

DOI URL |

| [45] |

HALLMANN L, ULMER P, REUSSER E, et al. Effect of dopants and sintering temperature on microstructure and low temperature degradation of dental Y-TZP-zirconia. Journal of the European Ceramic Society, 2012,32(16):4091-4104.

DOI URL |

| [46] |

PAUL A, VAIDHYANATHAN B, BINNER J G P. Hydrothermal aging behavior of nanocrystalline Y-TZP ceramics. Journal of the American Ceramic Society, 2011,94(7):2146-2152.

DOI URL |

| [47] |

SWAB J J. Low temperature degradation of Y-TZP materials. Journal of Materials Science, 1991,26(24):6706-6714.

DOI URL |

| [48] |

LAWSON S, GILL C, DRANSFIELD G P. Hydrothermal and corrosive degradation of Y-TZP ceramics. Key Engineering Materials, 1995,113:207-214.

DOI URL |

| [49] |

DEVILLE S, CHEVALIER J, FANTOZZI G, et al. Low temperature ageing of zirconia-toughened alumina ceramics and its implication in biomedical implants. Journal of the European Ceramic Society, 2003,23(15):2975-2982.

DOI URL |

| [50] |

SMIRNOV A, KURLAND H D, GRABOW J, et al. Microstructure, mechanical properties and low temperature degradation resistance of 2Y-TZP ceramic materials derived from nanopowders prepared by laser vaporization. Journal of the European Ceramic Society, 2015,35(9):2685-2691.

DOI URL |

| [51] |

SUTHARSINI U, THANIHAICHELVAN M, TING C H, et al. Effect of two-step sintering on the hydrothermal ageing resistance of tetragonal zirconia polycrystals. Ceramics International, 2017,43(10):7594-7599.

DOI URL |

| [52] |

PRESENDA A, SALVADOR M D, MORENO R, et al. Hydrothermal degradation behavior of Y-TZP ceramics sintered by nonconventional microwave technology. Journal of the American Ceramic Society, 2015,98(12):3680-3689.

DOI URL |

| [53] |

CHINTAPALLI R, MESTRA A, MARRO F G, et al. stability of nanocrystalline spark plasma sintered 3Y-TZP. Materials, 2010,3(2):800-814.

DOI URL |

| [54] |

WEI C, GREMILLARD L. Surface treatment methods for mitigation of hydrothermal ageing of zirconia. Journal of the European Ceramic Society, 2019,39(14):4322-4329.

DOI URL |

| [55] |

DEVILLE S, CHEVALIER J, GREMILLARD L. Influence of surface finish and residual stresses on the ageing sensitivity of biomedical grade zirconia. Biomaterials, 2006,27(10):2186-2192.

DOI URL PMID |

| [56] |

INOKOSHI M, VANMEENSEL K, ZHANG F, et al. Aging resistance of surface-treated dental zirconia. Dental Materials, 2015,31(2):182-194.

DOI URL PMID |

| [57] |

WEI C, GREMILLARD L. The influence of stresses on ageing kinetics of 3Y- and 4Y- stabilized zirconia. Journal of the European Ceramic Society, 2018,38(2):753-760.

DOI URL |

| [58] | GILES J C. Préparation par reaction à l’état solide et structure des oxynitrures de zirconium. Bulletin de la Société Chimique de France, 1962,22:2118-2122. |

| [59] |

CHUNG T J, SONG H S, KIM G H, et al. Microstructure and phase stability of yttria-doped tetragonal zirconia polycrystals heat treated in nitrogen atmosphere. Journal of the American Ceramic Society, 1997,80(10):2607-2612.

DOI URL |

| [60] |

VALLE J, MESTRA A, MARRO F G, et al. Mechanical properties and resistance to low temperature degradation of surface nitrided 3Y-TZP. Journal of the European Ceramic Society, 2013,33(15/16):3145-3155.

DOI URL |

| [61] |

HÜBSCH C, DELLINGER P, MAIER H J, et al. Protection of yttria-stabilized zirconia for dental applications by oxidic PVD coating. Acta Biomaterialia, 2015,11(1):488-493.

DOI URL |

| [62] |

SIVAKUMAR S, TEOW H L, SINGH R, et al. The effect of iron oxide on the mechanical and ageing properties of Y-TZP ceramic. Key Engineering Materials, 2016,701:225-229.

DOI URL |

| [63] |

MAURYA R, GUPTA A, OMAR S, et al. Effect of sintering on mechanical properties of ceria reinforced yttria stabilized zirconia. Ceramics International, 2016,42(9):11393-11403.

DOI URL |

| [64] |

KHAN M M, RAMESH S, BANG L T, et al. Effect of copper oxide and manganese oxide on properties and low temperature degradation of sintered Y-TZP ceramic. Journal of Materials Engineering and Performance, 2014,23(12):4328-4335.

DOI URL |

| [65] |

PIVA D H, PIVA R H, ROCHA M C, et al. Resistance of InO1.5-stabilized tetragonal zirconia polycrystals to low-temperature degradation. Materials Letters, 2016,163:226-230.

DOI URL |

| [66] |

LEE H B, PRINZF B, CAI W. Atomistic simulations of grain boundary segregation in nanocrystalline yttria stabilized zirconia and gadolinia doped ceria solid oxide electrolytes. Acta Materialia, 2013,61(10):3872-3887.

DOI URL |

| [67] |

YOKOI T, YOSHIYA M, YASUDA H. On modeling of grain boundary segregation in aliovalent cation doped ZrO2: critical factors in site-selective point defect occupancy. Scripta Materialia, 2015,102:91-94.

DOI URL |

| [68] |

ZHANG F, BATUK M, HADERMANN J, et al. Effect of cation dopant radius on the hydrothermal stability of tetragonal zirconia: grain boundary segregation and oxygen vacancy annihilation. Acta Materialia, 2016,106:48-58.

DOI URL |

| [69] |

ZHANG F, VANMEENSEL K, INOKOSHI M, et al. Critical influence of alumina content on the low temperature degradation of (2-3)mol% yttria-stabilized TZP for dental restorations. Journal of the European Ceramic Society, 2015,35(2):741-750.

DOI URL |

| [70] |

JING Q, BAO J, RUAN F, et al. High-fracture toughness and aging-resistance of 3Y-TZP ceramics with a low Al2O3 content for dental applications. Ceramics International, 2019,45(5):6066-6073.

DOI URL |

| [71] |

ZHANG F, VANMEENSEL K, BATUK M, et al. Highly-translucent, strong and aging-resistant 3Y-TZP ceramics for dental restoration by grain boundary segregation. Acta Biomaterials, 2015,16:215-222.

DOI URL |

| [72] |

NAKAMURA T, NAKANO Y, USAMI H, et al. Translucency and low-temperature degradation of silica-doped zirconia: a pilot study. Dental Materials Journal, 2016,35(4):571-577.

DOI URL PMID |

| [73] |

GREMILLARD L, EPICIER T, CHEVALIER J, et al. Microstructural study of silica-doped zirconia ceramics. Acta Materialia, 2000,48(18/19):4647-4652.

DOI URL |

| [74] |

SAMODUROVA A, KOCJAN A, SWAIN M V, et al. The combined effect of alumina and silica co-doping on the ageing resistance of 3Y-TZP bioceramics. Acta Biomaterials, 2015,11:477-487.

DOI URL |

| [75] |

MOHAMED E, TAHERI M, MEHRJOO M, et al. In vitro biocompatibility and ageing of 3Y-TZP/CNTs composites. Ceramics International, 2015,41(10):12773-12781.

DOI URL |

| [76] |

MORALES-RODRIGUEZ A, POYATO R, GUTIERREZ-MORA F, et al. The role of carbon nanotubes on the stability of tetragonal zirconia polycrystals. Ceramics International, 2018,44(15):17716-17723.

DOI URL |

| [77] |

SONG YAN-JUN, ZHU DONG-BIN, LIANG JIN-SHENG, et al. Enhanced mechanical properties of 3mol% Y2O3 stabilized tetragonal ZrO2, incorporating tourmaline particles. Ceramics International, 2018,44(13):15550-15556.

DOI URL |

| [78] |

ZHU DONG-BIN, SONG YAN-JUN, LIANG JIN-SHNEG, et al. Progress of toughness in dental zirconia ceramics. Journal of Inorganic Materials, 2018,33(4):363-372.

DOI URL |

| [1] | 朱文杰, 唐璐, 陆继长, 刘江平, 罗永明. 钙钛矿型氧化物催化氧化挥发性有机化合物的研究进展[J]. 无机材料学报, 2025, 40(7): 735-746. |

| [2] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [3] | 吴琼, 沈炳林, 张茂华, 姚方周, 邢志鹏, 王轲. 铅基织构压电陶瓷研究进展[J]. 无机材料学报, 2025, 40(6): 563-574. |

| [4] | 张碧辉, 刘小强, 陈湘明. Ruddlesden-Popper结构杂化非常规铁电体的研究进展[J]. 无机材料学报, 2025, 40(6): 587-608. |

| [5] | 吴杰, 杨帅, 王明文, 李景雷, 李纯纯, 李飞. 铅基织构压电陶瓷的发展历程、现状与挑战[J]. 无机材料学报, 2025, 40(6): 575-586. |

| [6] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| [7] | 田睿智, 兰正义, 殷杰, 郝南京, 陈航榕, 马明. 基于微流控技术的纳米无机生物材料制备: 原理及其研究进展[J]. 无机材料学报, 2025, 40(4): 337-347. |

| [8] | 张继国, 吴田, 赵旭, 杨钒, 夏天, 孙士恩. 钠离子电池正极材料循环稳定性提升策略及产业化进程[J]. 无机材料学报, 2025, 40(4): 348-362. |

| [9] | 殷杰, 耿佳毅, 王康龙, 陈忠明, 刘学建, 黄政仁. SiC陶瓷的3D打印成形与致密化新进展[J]. 无机材料学报, 2025, 40(3): 245-255. |

| [10] | 谌广昌, 段小明, 朱金荣, 龚情, 蔡德龙, 李宇航, 杨东雷, 陈彪, 李新民, 邓旭东, 余瑾, 刘博雅, 何培刚, 贾德昌, 周玉. 直升机特定结构先进陶瓷材料研究进展与应用展望[J]. 无机材料学报, 2025, 40(3): 225-244. |

| [11] | 范晓波, 祖梅, 杨向飞, 宋策, 陈晨, 王子, 罗文华, 程海峰. 质子调控型电化学离子突触研究进展[J]. 无机材料学报, 2025, 40(3): 256-270. |

| [12] | 海热古·吐逊, 郭乐, 丁嘉仪, 周嘉琪, 张学良, 努尔尼沙·阿力甫. 上转换荧光探针辅助的光学成像技术在肿瘤显影中的应用研究进展[J]. 无机材料学报, 2025, 40(2): 145-158. |

| [13] | 孙树娟, 郑南南, 潘昊坤, 马猛, 陈俊, 黄秀兵. 单原子催化剂制备方法的研究进展[J]. 无机材料学报, 2025, 40(2): 113-127. |

| [14] | 陶桂龙, 支国伟, 罗添友, 欧阳佩东, 衣新燕, 李国强. 空腔型薄膜体声波滤波器的关键技术进展[J]. 无机材料学报, 2025, 40(2): 128-144. |

| [15] | 周帆, 田志林, 李斌. 热防护系统用碳化物超高温陶瓷抗烧蚀涂层研究进展[J]. 无机材料学报, 2025, 40(1): 1-16. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||